Professional Documents

Culture Documents

Ultrasonic Thickness Gauge Testing Report: Authorized Signatory: Witnessed By: Performed / Evaluated by

Ultrasonic Thickness Gauge Testing Report: Authorized Signatory: Witnessed By: Performed / Evaluated by

Uploaded by

Aileen May Caminero SumampaoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ultrasonic Thickness Gauge Testing Report: Authorized Signatory: Witnessed By: Performed / Evaluated by

Ultrasonic Thickness Gauge Testing Report: Authorized Signatory: Witnessed By: Performed / Evaluated by

Uploaded by

Aileen May Caminero SumampaoCopyright:

Available Formats

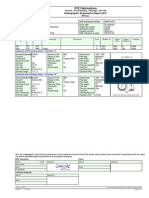

ULTRASONIC THICKNESS GAUGE TESTING REPORT

Client Project Name Date of Inspection Acceptance Criteria Ultrasonic Unit Serial No. Couplant Used Probe Size Frequency Nature of Test Method of Testing Calibration Block Client Verification KRAUTKRAMER USM 35X DAC LEMO 7900 a Oil 6mm 5 Mhz Thickness Gauging Pulse Echo "A" Scan Direct IIW V1 Block / V2 Block / Step Block Sta Clara International Corporation Address Location / Site Sample Card No. Laboratory No. NDT Procedure No. Technique Sensitivity Setting Heat Treatment Material Specification Surface Condition Tested Item Drwng. Ref. No. XWELL-UTG-2009-01 Straight Beam Technique 80% Full Screen Height N/A Carbon Steel Ground Smooth Pipe As per Client Specified Wall Thickness Reduction Min mm % mm Max % Remarks 2nd floor highway 54 Plaza Mandaluyong City

Item Identification No.

Original Thickness mm

Gauge Reading Min (mm) Max (mm)

12 26

7 4

11 9

5 22

41.67 84.62

1 17

8.33 65.38

Performed / Evaluated By:

Witnessed By:

Authorized Signatory:

NDT Technician / QC Engr. NDT Inspector

XWELL Form Rev. 0

SCIC

Page 1 of 2

Laboratory Manager/NDT Level II For and On-Behalf of X'Well Testing Services Inc.

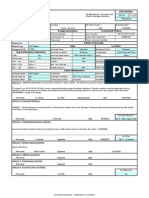

ULTRASONIC THICKNESS GAUGE TESTING REPORT

Sketch Detail / Part / Joint Location

Performed / Evaluated By:

Witnessed By:

Authorized Signatory:

Edison A. Walit

Qc Engr. / NDT Level II

XWELL Form Rev. 0

J. Salomon / A. Pajarillo

ATI / SCIC

Page 2 of 2

Thelma G. Mendoza

Laboratory Manager/NDT Level II For and On-Behalf of X'Well Testing Services Inc.

ONIC THICKNESS GAUGE TESTING REPORT

Sketch Detail / Part / Joint Location

Authorized Signatory:

Thelma G. Mendoza

Laboratory Manager/NDT Level II For and On-Behalf of X'Well Testing Services Inc.

XWELL Form Rev. 0 Page 2 of 2

You might also like

- ISA Format DatasheetDocument110 pagesISA Format Datasheetpankajskec33% (3)

- Test Report For Lab Iso 17025Document6 pagesTest Report For Lab Iso 17025vines7831No ratings yet

- PQR 014 (Qualified Sa 106 GR BDocument5 pagesPQR 014 (Qualified Sa 106 GR Bersenthil100% (1)

- OSI Spec LibraryDocument120 pagesOSI Spec LibraryClaudio Salvador Vera AranedaNo ratings yet

- NCR - SampleDocument7 pagesNCR - SamplecamycaxNo ratings yet

- PQRDocument3 pagesPQRCatalina Sorina ParfeneNo ratings yet

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Ut Format AwsDocument2 pagesUt Format Awsmanjeev111No ratings yet

- Standard Instrument Data Sheet Rotameters (Variable Area Flowmeters)Document1 pageStandard Instrument Data Sheet Rotameters (Variable Area Flowmeters)Faizal YaacobNo ratings yet

- 220 Jad Ja16 43001 PDFDocument1 page220 Jad Ja16 43001 PDFFrancisco Antonio Guerrero MonsalvesNo ratings yet

- 1.5'' Conares 82016Document1 page1.5'' Conares 82016siva8000No ratings yet

- LGDD ZZ ITTDSXS 00 45671233 0 Instrument DatasheetDocument37 pagesLGDD ZZ ITTDSXS 00 45671233 0 Instrument DatasheetuyaiekanemNo ratings yet

- Et 01Document2 pagesEt 01simpangrayaNo ratings yet

- Qcf305 Ut ReportDocument1 pageQcf305 Ut ReportminhnnNo ratings yet

- Isa 20T2201Document4 pagesIsa 20T2201tstepspamNo ratings yet

- UT ReportDocument5 pagesUT ReportMohamed SiddiqueNo ratings yet

- Pressure Gauge: Max Norm Min UnitsDocument1 pagePressure Gauge: Max Norm Min Unitssairam2234No ratings yet

- TG Instrument Data Sheet Ed2Document2 pagesTG Instrument Data Sheet Ed2BraulioOtavaloNo ratings yet

- Factory Test ReportDocument11 pagesFactory Test Reportderabeas100% (1)

- HD Level Gauge Isa TR 20 FormDocument1 pageHD Level Gauge Isa TR 20 FormBraulioOtavaloNo ratings yet

- FRONT PAGE Mockup Report PDFDocument1 pageFRONT PAGE Mockup Report PDFmusaismail8863100% (1)

- Ndtspec Radiographic Nde ReportDocument1 pageNdtspec Radiographic Nde ReportcarlosNo ratings yet

- Annexure-1 Scan PlanDocument6 pagesAnnexure-1 Scan Planநந்த குமார் சம்பத் நாகராஜன்No ratings yet

- Ut Format Report For Ut Libra (Naidu)Document4 pagesUt Format Report For Ut Libra (Naidu)vsnaiduqcNo ratings yet

- F6-F170 Gas SensorDocument1 pageF6-F170 Gas SensorMurugan KarunakaranNo ratings yet

- Quality PlanDocument3 pagesQuality PlanhjgajjarNo ratings yet

- Magnetic Particle Inspection Report: Test Performed by Witnessed/ Reviewed by Aries Client Class/TpiDocument1 pageMagnetic Particle Inspection Report: Test Performed by Witnessed/ Reviewed by Aries Client Class/TpiMurugan Raja100% (1)

- Borealis Kallo Scan Plan - Shear + DMA L On 28.58mmt Austenitic Weld (Rev 0.0)Document7 pagesBorealis Kallo Scan Plan - Shear + DMA L On 28.58mmt Austenitic Weld (Rev 0.0)Massimo FumarolaNo ratings yet

- Beamtool Scan Plan Inspection Layout: 50Mm 289Mm 223Mm 0Mm Steel 1020 3.24Mm/Μs 5.89Mm/ΜsDocument3 pagesBeamtool Scan Plan Inspection Layout: 50Mm 289Mm 223Mm 0Mm Steel 1020 3.24Mm/Μs 5.89Mm/Μsநந்த குமார் சம்பத் நாகராஜன்No ratings yet

- Corrosion Damage Report (CDR)Document4 pagesCorrosion Damage Report (CDR)diaccessltd_17172961No ratings yet

- Magnetic Particle Inspection ReportDocument1 pageMagnetic Particle Inspection ReportHadi BarakNo ratings yet

- ISA - TR20 - 00 - 01 - 2001 - Vortex PDFDocument1 pageISA - TR20 - 00 - 01 - 2001 - Vortex PDFDaniel CadenaNo ratings yet

- WPS - 008Document11 pagesWPS - 008MAT-LIONNo ratings yet

- Guaranteed Technical Particulars (GTP) OPGWDocument2 pagesGuaranteed Technical Particulars (GTP) OPGWAnonymous ufMAGXcskMNo ratings yet

- Beamtool Scan Plan Inspection Layout: 25Mm 200Mm 100Mm 0Mm Steel 1020 3.24Mm/Μs 5.89Mm/ΜsDocument3 pagesBeamtool Scan Plan Inspection Layout: 25Mm 200Mm 100Mm 0Mm Steel 1020 3.24Mm/Μs 5.89Mm/Μsநந்த குமார் சம்பத் நாகராஜன்No ratings yet

- Ultrasonic Testing Report: Main Lab. Address: Governor Drive Cabilang Baybay Carmona, Cavite Telefax No. (046) 889-0818Document2 pagesUltrasonic Testing Report: Main Lab. Address: Governor Drive Cabilang Baybay Carmona, Cavite Telefax No. (046) 889-0818walitedisonNo ratings yet

- Dial Thermometer DatasheetDocument1 pageDial Thermometer DatasheetmikeylesNo ratings yet

- Ultrasonic Testing Report: ResultsDocument1 pageUltrasonic Testing Report: ResultssamehNo ratings yet

- Drawing No./Line No.:: DateDocument2 pagesDrawing No./Line No.:: DatesuparnaNo ratings yet

- Beamtool Scan Plan Inspection Layout: 40Mm 250Mm 200Mm 0Mm Steel 1020 3.24Mm/Μs 5.89Mm/ΜsDocument3 pagesBeamtool Scan Plan Inspection Layout: 40Mm 250Mm 200Mm 0Mm Steel 1020 3.24Mm/Μs 5.89Mm/Μsநந்த குமார் சம்பத் நாகராஜன்No ratings yet

- LND712Document5 pagesLND712David KasaiNo ratings yet

- TDC Tech Spec For PlateDocument3 pagesTDC Tech Spec For PlateBantoo RajamandiNo ratings yet

- Rosen Intel PigsDocument1 pageRosen Intel Pigsnrd9771No ratings yet

- Pressure Vessel Inspection ReportDocument34 pagesPressure Vessel Inspection ReportJinlong Su100% (1)

- Specification (WPS) Welding ProcedureDocument1 pageSpecification (WPS) Welding ProcedureBranko FerenčakNo ratings yet

- Ultrasonic Inspection Report A105Document1 pageUltrasonic Inspection Report A105Kumaraswamy ViswanathanNo ratings yet

- Screw ConveyorDocument5 pagesScrew ConveyorEDUARDO100% (3)

- Corrosion Damage Report (CDR)Document4 pagesCorrosion Damage Report (CDR)diaccessltd_17172961100% (1)

- Physical Inspection Report On Hardware - Fittings Components.Document20 pagesPhysical Inspection Report On Hardware - Fittings Components.რაქსშ საჰაNo ratings yet

- NDT Magnetic Particle Inspection ProcedureDocument7 pagesNDT Magnetic Particle Inspection ProcedureCharlesNo ratings yet

- Mpi Report SampleDocument6 pagesMpi Report SampleGowrisanthosh PalikaNo ratings yet

- Corrosion Damage Report (CDR)Document4 pagesCorrosion Damage Report (CDR)diaccessltd_17172961No ratings yet

- LND, Inc.: General SpecificationsDocument5 pagesLND, Inc.: General SpecificationsValentina ManniNo ratings yet

- LND, Inc.: General SpecificationsDocument5 pagesLND, Inc.: General SpecificationsRossana BellaNo ratings yet

- Coriolis Flow MeterDocument6 pagesCoriolis Flow MeterRamadhan AnggoroNo ratings yet

- Data Sheet Insulating JointDocument4 pagesData Sheet Insulating Jointblacx_rzkyNo ratings yet

- Ultrasonic Wall Thickness Report Feb.27-28,20062 - 2Document32 pagesUltrasonic Wall Thickness Report Feb.27-28,20062 - 2Endickk Screamo PoreperrNo ratings yet

- Environmental Monitoring Questionnaire (1/2) : Customer / ProjectDocument2 pagesEnvironmental Monitoring Questionnaire (1/2) : Customer / ProjectalbertbunguriNo ratings yet

- Non-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingFrom EverandNon-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingRaman SinghNo ratings yet

- Types of Welding ElectrodesDocument34 pagesTypes of Welding ElectrodesAileen May Caminero SumampaoNo ratings yet

- Randy Guisihan ResumeDocument2 pagesRandy Guisihan ResumeAileen May Caminero SumampaoNo ratings yet

- DFT FormDocument4 pagesDFT FormAileen May Caminero SumampaoNo ratings yet

- Liquid Penetrant Testing Report: Main Lab. Gov. Drive Brgy.8Carmona, Cavite Telefax (046) 889-0818Document2 pagesLiquid Penetrant Testing Report: Main Lab. Gov. Drive Brgy.8Carmona, Cavite Telefax (046) 889-0818Aileen May Caminero SumampaoNo ratings yet

- Material RequestedDocument1 pageMaterial RequestedAileen May Caminero SumampaoNo ratings yet

- Dry Film Thickness Gauge Report: Main Lab. Gov. Drive Brgy. 8carmona, Cavite Telefax (046) 889-0818Document3 pagesDry Film Thickness Gauge Report: Main Lab. Gov. Drive Brgy. 8carmona, Cavite Telefax (046) 889-0818Aileen May Caminero SumampaoNo ratings yet

- Trial Mix Data Sheet: Sta. Clara Int'l. CorporationDocument49 pagesTrial Mix Data Sheet: Sta. Clara Int'l. CorporationAileen May Caminero SumampaoNo ratings yet