Professional Documents

Culture Documents

Activity 6: Click To Edit Master Subtitle Style Roque Santos Sobrevega Solano

Activity 6: Click To Edit Master Subtitle Style Roque Santos Sobrevega Solano

Uploaded by

Angela RoqueCopyright:

Available Formats

You might also like

- Usp 1029 GdocpDocument6 pagesUsp 1029 GdocpYOHANNA50% (2)

- SQ Mark & 100ppm ChecklistDocument14 pagesSQ Mark & 100ppm Checklistkarpags100% (2)

- Appendix 25 VDA 6 3 Process AuditDocument12 pagesAppendix 25 VDA 6 3 Process AuditSeda De Drasnia100% (2)

- Cosmetic GMP Implementation Part 6Document23 pagesCosmetic GMP Implementation Part 6Anonymous yBhOAi5UH100% (1)

- Cosmetic GMP ImplementationDocument23 pagesCosmetic GMP ImplementationAndre Hopfner100% (3)

- GMP of Packaging OperationsDocument19 pagesGMP of Packaging OperationsgeethavinodNo ratings yet

- GMP Audit ChecklistDocument10 pagesGMP Audit Checklistmrshojaee100% (5)

- Process Validation Sample ProtocolDocument5 pagesProcess Validation Sample ProtocolBilal Masood0% (1)

- SOP ReconciliationDocument1 pageSOP ReconciliationFika CuiNo ratings yet

- Aka GMP Audit FormDocument8 pagesAka GMP Audit FormAlpian BosixNo ratings yet

- Bottles, Preforms and Closures: A Design Guide for PET PackagingFrom EverandBottles, Preforms and Closures: A Design Guide for PET PackagingRating: 4.5 out of 5 stars4.5/5 (3)

- GMPDocument5 pagesGMPharwinderpanditNo ratings yet

- Shri Shankaracharya College of Pharmaceutical Sciences: Master Formula RecordDocument14 pagesShri Shankaracharya College of Pharmaceutical Sciences: Master Formula RecordMegha VermaNo ratings yet

- EQPA Tool Box Checklists Batch DispositionDocument13 pagesEQPA Tool Box Checklists Batch DispositionBlueSagaNo ratings yet

- Process Validation Sample ProtocolDocument2 pagesProcess Validation Sample ProtocolAngel Cvetanov100% (2)

- CH 3 CH 4Document53 pagesCH 3 CH 4Vikas JhawatNo ratings yet

- Sourabh Singh: OcumentationDocument50 pagesSourabh Singh: OcumentationSourabh SinghNo ratings yet

- Plant Master FileDocument3 pagesPlant Master Filea4623No ratings yet

- Preparación de La Muestra-Carr - Sensory Evaluation TechniquesDocument3 pagesPreparación de La Muestra-Carr - Sensory Evaluation TechniquesMariagabriela Espinoza MonteroNo ratings yet

- Vendors Cert (Api-Materials) Annexures 1Document6 pagesVendors Cert (Api-Materials) Annexures 1israel afolayan mayomiNo ratings yet

- Supplier Process Survey Check Sheet (Paints) : Results Items Auditor POINTS (%) CommentsDocument13 pagesSupplier Process Survey Check Sheet (Paints) : Results Items Auditor POINTS (%) Commentshamidshah520No ratings yet

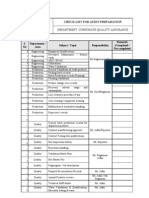

- Laboratories Limited Corporate QA Department: Corporate Quality AssuranceDocument3 pagesLaboratories Limited Corporate QA Department: Corporate Quality AssurancePurushothaman SubramanianNo ratings yet

- VAL MANUAL 018 Potential Critical Packaging Process Parameters and Validation Practices SampleDocument3 pagesVAL MANUAL 018 Potential Critical Packaging Process Parameters and Validation Practices SampleRahul VermaNo ratings yet

- Audit Check ListDocument47 pagesAudit Check Listrsharma2910No ratings yet

- Validate A Packaging ProcessDocument3 pagesValidate A Packaging ProcessIndra D. WinarkoNo ratings yet

- Definition of Pilot PlantDocument10 pagesDefinition of Pilot Plantmonoj5859No ratings yet

- Validation On Packaging: Dr. Muslim Suardi, Msi., AptDocument20 pagesValidation On Packaging: Dr. Muslim Suardi, Msi., AptSisKa L. PutriNo ratings yet

- EU - Quality ControlDocument3 pagesEU - Quality Controlapi-3859063No ratings yet

- Prevalidation Study of A Form-Fill-Seal Packaging Machine - Pharmaceutical & Medical Packaging NewsDocument3 pagesPrevalidation Study of A Form-Fill-Seal Packaging Machine - Pharmaceutical & Medical Packaging NewsJanna Hendrix BabsonNo ratings yet

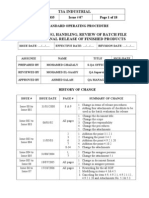

- Issuing, Handling, Revision of Batch File and Final Release of Finished Products For Sale and Distribution 07Document18 pagesIssuing, Handling, Revision of Batch File and Final Release of Finished Products For Sale and Distribution 07ibrahimgomaaNo ratings yet

- Guideline For Sterilization Process ValidationDocument21 pagesGuideline For Sterilization Process Validationboddarambabu100% (1)

- SCA Cool Logistics - An Introduction To Control Temperature PackagingDocument49 pagesSCA Cool Logistics - An Introduction To Control Temperature PackagingIhsan Mhd IlhamNo ratings yet

- Production and In-Process ControlsDocument31 pagesProduction and In-Process ControlsNguyễnHữuĐạtNo ratings yet

- Masterformularecord 180319024817Document20 pagesMasterformularecord 180319024817Mucharla Praveen KumarNo ratings yet

- Standardefficacyreport WithsummaryDocument14 pagesStandardefficacyreport WithsummaryMichelle Morgan LongstrethNo ratings yet

- Pilot PlantDocument5 pagesPilot PlantMahfuzur Rahman100% (1)

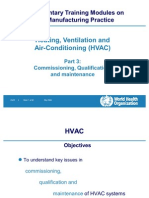

- HVAC Part3Document28 pagesHVAC Part3Noe GeneNo ratings yet

- How To Validate An AutoclaveDocument3 pagesHow To Validate An AutoclaveqhpuongNo ratings yet

- DocumentationDocument46 pagesDocumentationajak16406No ratings yet

- Process Validation For Solid Dosage FormsDocument4 pagesProcess Validation For Solid Dosage Formsnani7862012No ratings yet

- That Part of QA Which Ensures That Products Are Consistently Produced and Controlled To The Quality Standards As Per The SpecificationsDocument44 pagesThat Part of QA Which Ensures That Products Are Consistently Produced and Controlled To The Quality Standards As Per The SpecificationsSai Ram Shyam SundarNo ratings yet

- SOP. Validation. R2Document11 pagesSOP. Validation. R2Zarish IftikharNo ratings yet

- Multi Product Biopharmaceutical Manufacturing FacilitiesDocument18 pagesMulti Product Biopharmaceutical Manufacturing FacilitiesJason WangNo ratings yet

- 11.1.0 Traceability ProcedureDocument5 pages11.1.0 Traceability ProcedureZed100% (1)

- 11.H IdentificationDocument5 pages11.H IdentificationGirgis AiadNo ratings yet

- Pilot Plant Scale Up Techniques SeminarDocument24 pagesPilot Plant Scale Up Techniques Seminarsakumar5678No ratings yet

- ValidationDocument49 pagesValidationAshokPokiriNo ratings yet

- Regulatory Requirements On PV (General)Document52 pagesRegulatory Requirements On PV (General)mokhzanniNo ratings yet

- Pharmaceutical Process Validation - Lecture SlidesDocument19 pagesPharmaceutical Process Validation - Lecture SlidesMD Fahad MiajiNo ratings yet

- Technical Study: By: Divina Grace M. Rodriguez Vanessa VasquezDocument40 pagesTechnical Study: By: Divina Grace M. Rodriguez Vanessa VasquezDivina Grace Rodriguez - LibreaNo ratings yet

- Product Development Guideline and Check List For Softgel CapDocument8 pagesProduct Development Guideline and Check List For Softgel CapPranav PatelNo ratings yet

- General SOP Template FinalDocument6 pagesGeneral SOP Template FinallovegamingNo ratings yet

- In Process Checks During ManufacturingDocument2 pagesIn Process Checks During ManufacturingPrince Moni100% (2)

- Line Clearance Procedure at Pharma ManufacturingDocument3 pagesLine Clearance Procedure at Pharma ManufacturingRainMan75No ratings yet

- Good Practices in Quality ControlDocument13 pagesGood Practices in Quality ControlTerrence Terry BhengoeNo ratings yet

- CGMP (Current Good Manufacturing Practices)Document26 pagesCGMP (Current Good Manufacturing Practices)Genalyn LeonardoNo ratings yet

- Salsa, Traceability, Mass Balance, 2015Document4 pagesSalsa, Traceability, Mass Balance, 2015Amine Simo JacksonNo ratings yet

- Audit Checklist SOPDocument43 pagesAudit Checklist SOPthemba100% (4)

- Hold Time Study GuidelineDocument4 pagesHold Time Study GuidelineYousifNo ratings yet

- Practical Design, Construction and Operation of Food FacilitiesFrom EverandPractical Design, Construction and Operation of Food FacilitiesRating: 5 out of 5 stars5/5 (2)

- Drugs, Microbes, Host - The Elements of Chemotherapy: Antibiotics - Still Miracle DrugsDocument54 pagesDrugs, Microbes, Host - The Elements of Chemotherapy: Antibiotics - Still Miracle DrugsAngela RoqueNo ratings yet

- Word 2007 For LegalDocument26 pagesWord 2007 For LegalAngela RoqueNo ratings yet

- Surfactant ClassificationDocument50 pagesSurfactant Classificationrohitpatil3390% (10)

- Proteins Polymers of Amino Acids Linked Head To Tail, From Carboxyl Group To Amino Group, Through Formation of Covalent Peptide BondsDocument59 pagesProteins Polymers of Amino Acids Linked Head To Tail, From Carboxyl Group To Amino Group, Through Formation of Covalent Peptide BondsAngela RoqueNo ratings yet

Activity 6: Click To Edit Master Subtitle Style Roque Santos Sobrevega Solano

Activity 6: Click To Edit Master Subtitle Style Roque Santos Sobrevega Solano

Uploaded by

Angela RoqueOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Activity 6: Click To Edit Master Subtitle Style Roque Santos Sobrevega Solano

Activity 6: Click To Edit Master Subtitle Style Roque Santos Sobrevega Solano

Uploaded by

Angela RoqueCopyright:

Available Formats

Activity 6

Roque Click to edit Master subtitle style Santos Sobrevega Solano

8/3/12

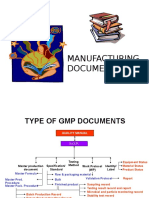

SCHEMATIC DIAGRAM

{

8/3/12

Checks shall be carried to ensure that the work area and equipment are clean and free from any products, product residues or documents not required for the operation

Coding of Components (batch number, lot number, exp date and manuf date) Quarantine (yellow tag)

QC approved (green tag)

QC reject(red tag)

Line Clearance Placement of Materials to packaging lines In Process Quality Control

Product fill At regular intervals

Reworking/Reprinting

Check the last production package to confirm conformance to the master packaging procedure Reconciliation

Destruction or return of the unused materials Documentation

8/3/12

Checks performed during production in order to monitor and, if appropriate, to adjust the process and/or to ensure that the intermediate or API conforms to its specifications.

IPQC

8/3/12

a) Drug contents determination. b) Moisture contents of granules. c) Assay of active ingredients. d) Weight variation of uncoated tablets. e) Hardness test. f) Disintegration test.

IPQC TESTS FOR TABLETS:

8/3/12

a) Drug contents determination. b) Assay of active ingredients. c) pH. d) Weight per ml. e) particle size

FOR SYRUPS AND SUSPENSIONS:

8/3/12

a) Drug contents determination. b) Assay of active ingredients. c) Uniformity and homogeneity test. d) Viscosity and specific gravity test. e) Filling test. f) Leakage test.

FOR SEMI-SOLIDS:

8/3/12

a) Drug contents determination. b) Assay of active ingredients. c) pH. d) Pyrogen test. e) Stability test. f) Leakage test. g) Check up of particulate matters.

FOR INJECTABLES:

8/3/12

Documents

Click to edit Master subtitle style

8/3/12

is a document from which copies are made for use in the packaging of individual batches of product Shall outline a complete and detail procedure and instructions for packaging Shall provide a blank space or form for recording the packaging data. Prepared and signed by production manager and countersigned by quality control manager. .

Master Packaging Procedure

8/3/12

Shall include the following: Product name, dosage form and strength Description of the container, closures and other packaging materials Procedure for reconciliation of the issued quantities in bulk product and packaging materials with the number of units packs. Produced Statement of the theoretical and percentage limit of the actual yield Packaging line and equipment to be used

8/3/12

Record kept for each batch processed Based on the master or specifications (e.g. copied to avoid errors) Check suitability of area and equipment clear of previous products, documents, materials Checks recorded

Batch Processing Record

8/3/12

Name of the product, batch number Dates and times (e.g. start, major steps, completion) Name of person responsible for each stage of production Name of operators carrying out each step (check signatures)

Information recorded during processing includes:

8/3/12

Theoretical quantities for materials in the batch Reference number and quantity of materials used in the batch Main processing steps and key equipment In-process controls carried out, person's initials, and results obtained

8/3/12

Yield at each stage with comments on deviations Expected final yield with acceptable limits Comments on any deviations from process Area clearance check, instructions to operators Record of activities

8/3/12

Thank you for listening!

Click to edit Master subtitle style

8/3/12

You might also like

- Usp 1029 GdocpDocument6 pagesUsp 1029 GdocpYOHANNA50% (2)

- SQ Mark & 100ppm ChecklistDocument14 pagesSQ Mark & 100ppm Checklistkarpags100% (2)

- Appendix 25 VDA 6 3 Process AuditDocument12 pagesAppendix 25 VDA 6 3 Process AuditSeda De Drasnia100% (2)

- Cosmetic GMP Implementation Part 6Document23 pagesCosmetic GMP Implementation Part 6Anonymous yBhOAi5UH100% (1)

- Cosmetic GMP ImplementationDocument23 pagesCosmetic GMP ImplementationAndre Hopfner100% (3)

- GMP of Packaging OperationsDocument19 pagesGMP of Packaging OperationsgeethavinodNo ratings yet

- GMP Audit ChecklistDocument10 pagesGMP Audit Checklistmrshojaee100% (5)

- Process Validation Sample ProtocolDocument5 pagesProcess Validation Sample ProtocolBilal Masood0% (1)

- SOP ReconciliationDocument1 pageSOP ReconciliationFika CuiNo ratings yet

- Aka GMP Audit FormDocument8 pagesAka GMP Audit FormAlpian BosixNo ratings yet

- Bottles, Preforms and Closures: A Design Guide for PET PackagingFrom EverandBottles, Preforms and Closures: A Design Guide for PET PackagingRating: 4.5 out of 5 stars4.5/5 (3)

- GMPDocument5 pagesGMPharwinderpanditNo ratings yet

- Shri Shankaracharya College of Pharmaceutical Sciences: Master Formula RecordDocument14 pagesShri Shankaracharya College of Pharmaceutical Sciences: Master Formula RecordMegha VermaNo ratings yet

- EQPA Tool Box Checklists Batch DispositionDocument13 pagesEQPA Tool Box Checklists Batch DispositionBlueSagaNo ratings yet

- Process Validation Sample ProtocolDocument2 pagesProcess Validation Sample ProtocolAngel Cvetanov100% (2)

- CH 3 CH 4Document53 pagesCH 3 CH 4Vikas JhawatNo ratings yet

- Sourabh Singh: OcumentationDocument50 pagesSourabh Singh: OcumentationSourabh SinghNo ratings yet

- Plant Master FileDocument3 pagesPlant Master Filea4623No ratings yet

- Preparación de La Muestra-Carr - Sensory Evaluation TechniquesDocument3 pagesPreparación de La Muestra-Carr - Sensory Evaluation TechniquesMariagabriela Espinoza MonteroNo ratings yet

- Vendors Cert (Api-Materials) Annexures 1Document6 pagesVendors Cert (Api-Materials) Annexures 1israel afolayan mayomiNo ratings yet

- Supplier Process Survey Check Sheet (Paints) : Results Items Auditor POINTS (%) CommentsDocument13 pagesSupplier Process Survey Check Sheet (Paints) : Results Items Auditor POINTS (%) Commentshamidshah520No ratings yet

- Laboratories Limited Corporate QA Department: Corporate Quality AssuranceDocument3 pagesLaboratories Limited Corporate QA Department: Corporate Quality AssurancePurushothaman SubramanianNo ratings yet

- VAL MANUAL 018 Potential Critical Packaging Process Parameters and Validation Practices SampleDocument3 pagesVAL MANUAL 018 Potential Critical Packaging Process Parameters and Validation Practices SampleRahul VermaNo ratings yet

- Audit Check ListDocument47 pagesAudit Check Listrsharma2910No ratings yet

- Validate A Packaging ProcessDocument3 pagesValidate A Packaging ProcessIndra D. WinarkoNo ratings yet

- Definition of Pilot PlantDocument10 pagesDefinition of Pilot Plantmonoj5859No ratings yet

- Validation On Packaging: Dr. Muslim Suardi, Msi., AptDocument20 pagesValidation On Packaging: Dr. Muslim Suardi, Msi., AptSisKa L. PutriNo ratings yet

- EU - Quality ControlDocument3 pagesEU - Quality Controlapi-3859063No ratings yet

- Prevalidation Study of A Form-Fill-Seal Packaging Machine - Pharmaceutical & Medical Packaging NewsDocument3 pagesPrevalidation Study of A Form-Fill-Seal Packaging Machine - Pharmaceutical & Medical Packaging NewsJanna Hendrix BabsonNo ratings yet

- Issuing, Handling, Revision of Batch File and Final Release of Finished Products For Sale and Distribution 07Document18 pagesIssuing, Handling, Revision of Batch File and Final Release of Finished Products For Sale and Distribution 07ibrahimgomaaNo ratings yet

- Guideline For Sterilization Process ValidationDocument21 pagesGuideline For Sterilization Process Validationboddarambabu100% (1)

- SCA Cool Logistics - An Introduction To Control Temperature PackagingDocument49 pagesSCA Cool Logistics - An Introduction To Control Temperature PackagingIhsan Mhd IlhamNo ratings yet

- Production and In-Process ControlsDocument31 pagesProduction and In-Process ControlsNguyễnHữuĐạtNo ratings yet

- Masterformularecord 180319024817Document20 pagesMasterformularecord 180319024817Mucharla Praveen KumarNo ratings yet

- Standardefficacyreport WithsummaryDocument14 pagesStandardefficacyreport WithsummaryMichelle Morgan LongstrethNo ratings yet

- Pilot PlantDocument5 pagesPilot PlantMahfuzur Rahman100% (1)

- HVAC Part3Document28 pagesHVAC Part3Noe GeneNo ratings yet

- How To Validate An AutoclaveDocument3 pagesHow To Validate An AutoclaveqhpuongNo ratings yet

- DocumentationDocument46 pagesDocumentationajak16406No ratings yet

- Process Validation For Solid Dosage FormsDocument4 pagesProcess Validation For Solid Dosage Formsnani7862012No ratings yet

- That Part of QA Which Ensures That Products Are Consistently Produced and Controlled To The Quality Standards As Per The SpecificationsDocument44 pagesThat Part of QA Which Ensures That Products Are Consistently Produced and Controlled To The Quality Standards As Per The SpecificationsSai Ram Shyam SundarNo ratings yet

- SOP. Validation. R2Document11 pagesSOP. Validation. R2Zarish IftikharNo ratings yet

- Multi Product Biopharmaceutical Manufacturing FacilitiesDocument18 pagesMulti Product Biopharmaceutical Manufacturing FacilitiesJason WangNo ratings yet

- 11.1.0 Traceability ProcedureDocument5 pages11.1.0 Traceability ProcedureZed100% (1)

- 11.H IdentificationDocument5 pages11.H IdentificationGirgis AiadNo ratings yet

- Pilot Plant Scale Up Techniques SeminarDocument24 pagesPilot Plant Scale Up Techniques Seminarsakumar5678No ratings yet

- ValidationDocument49 pagesValidationAshokPokiriNo ratings yet

- Regulatory Requirements On PV (General)Document52 pagesRegulatory Requirements On PV (General)mokhzanniNo ratings yet

- Pharmaceutical Process Validation - Lecture SlidesDocument19 pagesPharmaceutical Process Validation - Lecture SlidesMD Fahad MiajiNo ratings yet

- Technical Study: By: Divina Grace M. Rodriguez Vanessa VasquezDocument40 pagesTechnical Study: By: Divina Grace M. Rodriguez Vanessa VasquezDivina Grace Rodriguez - LibreaNo ratings yet

- Product Development Guideline and Check List For Softgel CapDocument8 pagesProduct Development Guideline and Check List For Softgel CapPranav PatelNo ratings yet

- General SOP Template FinalDocument6 pagesGeneral SOP Template FinallovegamingNo ratings yet

- In Process Checks During ManufacturingDocument2 pagesIn Process Checks During ManufacturingPrince Moni100% (2)

- Line Clearance Procedure at Pharma ManufacturingDocument3 pagesLine Clearance Procedure at Pharma ManufacturingRainMan75No ratings yet

- Good Practices in Quality ControlDocument13 pagesGood Practices in Quality ControlTerrence Terry BhengoeNo ratings yet

- CGMP (Current Good Manufacturing Practices)Document26 pagesCGMP (Current Good Manufacturing Practices)Genalyn LeonardoNo ratings yet

- Salsa, Traceability, Mass Balance, 2015Document4 pagesSalsa, Traceability, Mass Balance, 2015Amine Simo JacksonNo ratings yet

- Audit Checklist SOPDocument43 pagesAudit Checklist SOPthemba100% (4)

- Hold Time Study GuidelineDocument4 pagesHold Time Study GuidelineYousifNo ratings yet

- Practical Design, Construction and Operation of Food FacilitiesFrom EverandPractical Design, Construction and Operation of Food FacilitiesRating: 5 out of 5 stars5/5 (2)

- Drugs, Microbes, Host - The Elements of Chemotherapy: Antibiotics - Still Miracle DrugsDocument54 pagesDrugs, Microbes, Host - The Elements of Chemotherapy: Antibiotics - Still Miracle DrugsAngela RoqueNo ratings yet

- Word 2007 For LegalDocument26 pagesWord 2007 For LegalAngela RoqueNo ratings yet

- Surfactant ClassificationDocument50 pagesSurfactant Classificationrohitpatil3390% (10)

- Proteins Polymers of Amino Acids Linked Head To Tail, From Carboxyl Group To Amino Group, Through Formation of Covalent Peptide BondsDocument59 pagesProteins Polymers of Amino Acids Linked Head To Tail, From Carboxyl Group To Amino Group, Through Formation of Covalent Peptide BondsAngela RoqueNo ratings yet