Professional Documents

Culture Documents

Membrane Nitrogen

Membrane Nitrogen

Uploaded by

Alexis DonosoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Membrane Nitrogen

Membrane Nitrogen

Uploaded by

Alexis DonosoCopyright:

Available Formats

Membrane Nitrogen Generation

Membrane nitrogen generating units (MNGU) contain hollow fiber membranes that act as a molecular sieve, separating oxygen from the air. Primary air compressors inject air into the MNGU, where it is filtered, dried and brought to the correct temperature before passing through the membrane. Depending on the application, the resultant Membrane Nitrogen can have purities of between 94% and 99.9% nitrogen, with the balance being mainly oxygen and trace gases such as helium, carbon dioxide, etc.

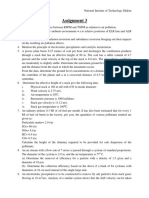

The above graph shows the minimum oxygen concentration required for ignition in a worst-case scenario of methane and oxygen, at different pressures. For a downhole pressure of 1,500 psi for example, 8.5% of oxygen is still required for the mixture to ignite and explode (in presence of an ignition source). For underbalanced drilling and other applications the MNGU is run at about 97% purity, i.e. less than 3% oxygen. The benefits of membrane nitrogen systems are as follows: Guaranteed supply of nitrogen in remote locations Simplified logistics Lower cost than cryogenic nitrogen

Membrane Nitrogen Generating Unit Specifications: Maximum nitrogen output: 2,000 scfm Typical purity range: 94 -99.9% nitrogen

Dimensions: Weight = 26,500 lbs., Width = 8, Length = 20, Height = 8. 20 ISO container

www.oilfieldair.com

You might also like

- Nitrogen Membrane - MEDALDocument7 pagesNitrogen Membrane - MEDALmanzanaNo ratings yet

- N2 Production PresentationDocument2 pagesN2 Production PresentationAnthony Justin EdmaNo ratings yet

- Nitrogen Gas Generation - Integrated Flow Solutions WebsiteDocument3 pagesNitrogen Gas Generation - Integrated Flow Solutions WebsitejohnNo ratings yet

- Nitrogen Gass SystemDocument29 pagesNitrogen Gass SystemshaieraNo ratings yet

- Nitrogen Production SystemsDocument9 pagesNitrogen Production Systemscmar64No ratings yet

- Onsite Nitrogen Generation Via PSA TechnologyDocument4 pagesOnsite Nitrogen Generation Via PSA TechnologyAlexNo ratings yet

- Industrial Oxygen: Its Generation and UseDocument12 pagesIndustrial Oxygen: Its Generation and UseJafar JilaniNo ratings yet

- Producing Nitrogen Via PSADocument5 pagesProducing Nitrogen Via PSAKaten MistryNo ratings yet

- Submitted By:-Sandeep Kumar Mohanta 1301302009Document21 pagesSubmitted By:-Sandeep Kumar Mohanta 1301302009yuvarajanNo ratings yet

- Producing Nitrogen Via Pressure Swing Adsorption ArticleDocument5 pagesProducing Nitrogen Via Pressure Swing Adsorption Articledhlinva100% (1)

- Air Breathing Propulsion Unit-2Document54 pagesAir Breathing Propulsion Unit-2api-271354682No ratings yet

- Membrane Nitrogen GeneratorsDocument2 pagesMembrane Nitrogen GeneratorsRoozbeh PNo ratings yet

- Conclusion: Figure 1 Gas Separation MembraneDocument2 pagesConclusion: Figure 1 Gas Separation MembraneJohny LuisNo ratings yet

- Parker Tank Blanketing White Paper PDFDocument4 pagesParker Tank Blanketing White Paper PDFshashi kant kumarNo ratings yet

- AZEP - Development of An Integrated Air Separation Membrane - Gas TurbineDocument6 pagesAZEP - Development of An Integrated Air Separation Membrane - Gas TurbineeddyNo ratings yet

- CGT PSA Nitrogen Generators Operate On The Pressure Swing AdsorptionDocument3 pagesCGT PSA Nitrogen Generators Operate On The Pressure Swing AdsorptionIgor Yamaha BusljetaNo ratings yet

- Next Generation Dry Low NOx For Gas TurbinesDocument12 pagesNext Generation Dry Low NOx For Gas TurbinesMijail David Felix Narvaez100% (1)

- NOx Control in Power Plants R1Document10 pagesNOx Control in Power Plants R1Vishal JaishankarNo ratings yet

- Module 5 CombustorDocument11 pagesModule 5 CombustorKevin MangroliyaNo ratings yet

- OptimaConcept - Nitrogen Generation Membrane Systems 2009 CATDocument4 pagesOptimaConcept - Nitrogen Generation Membrane Systems 2009 CATpolysourceNo ratings yet

- Exhaust Gas Recirculation in Four Stroke EngineDocument29 pagesExhaust Gas Recirculation in Four Stroke Enginejatin guptaNo ratings yet

- Catalogo Kaeser PDFDocument7 pagesCatalogo Kaeser PDForlando_ubaldoNo ratings yet

- Exhaust Gas Recirculation PresentationDocument18 pagesExhaust Gas Recirculation PresentationMukesh sutharNo ratings yet

- Nitrogen Production From AirDocument9 pagesNitrogen Production From AirOusseini SidibeNo ratings yet

- NOx Reduction TechniquesDocument37 pagesNOx Reduction Techniquesengr kazamNo ratings yet

- Tank Blanketing Helps Keep Hydrocarbon Processing Facilities SafeDocument4 pagesTank Blanketing Helps Keep Hydrocarbon Processing Facilities SafeKrishnamoorthyNo ratings yet

- VOC, NOx, SOxDocument47 pagesVOC, NOx, SOxDIANA CALLISTA ARTANTINo ratings yet

- Nitric Oxide PFDDocument16 pagesNitric Oxide PFDPrashit JainNo ratings yet

- N2 Generators BulletinDocument8 pagesN2 Generators Bulletinkutts76No ratings yet

- Specify Better Low NOx Burners For FurnacesDocument4 pagesSpecify Better Low NOx Burners For Furnacesyogitadoda100% (1)

- Nitrogen Intro in ReportDocument6 pagesNitrogen Intro in ReportlintasamimNo ratings yet

- 312 12 048 US Producing Nitrogen Via Pressure Swing AdsorptionDocument6 pages312 12 048 US Producing Nitrogen Via Pressure Swing AdsorptionRonak PanchalNo ratings yet

- Sepuran N2 enDocument8 pagesSepuran N2 enAndri SaputraNo ratings yet

- High Vacuum Techniques-1Document15 pagesHigh Vacuum Techniques-1Nicholas MorganNo ratings yet

- Fig 1.1 Typical Particle Size: Bvcoeri Nashik (B.E. Mechanical) 1Document54 pagesFig 1.1 Typical Particle Size: Bvcoeri Nashik (B.E. Mechanical) 1shailesh pansareNo ratings yet

- Air Separation Unit: Membrane Nitrogen GeneratorDocument1 pageAir Separation Unit: Membrane Nitrogen GeneratorYuri YamirnovNo ratings yet

- Exhaust Gas Recirculation PPT FINALDocument20 pagesExhaust Gas Recirculation PPT FINALAniket Khaire100% (1)

- Thermal Effect of Drain Gas Recirculation Arrangement Combined With Intercooler For Two WheelersDocument7 pagesThermal Effect of Drain Gas Recirculation Arrangement Combined With Intercooler For Two WheelersAlbertoNo ratings yet

- 19MAE0010 - AEC Assignment 3Document16 pages19MAE0010 - AEC Assignment 3Prasad JoshiNo ratings yet

- Continual Removal of Non-Condensable Gases For Binary Power Plant CondensersDocument5 pagesContinual Removal of Non-Condensable Gases For Binary Power Plant Condensersart9165No ratings yet

- CO2 Removal Membranes For Gas ProcessingDocument8 pagesCO2 Removal Membranes For Gas Processinggaluh_pramudiptoNo ratings yet

- NOx ControlDocument4 pagesNOx Controlmathur97No ratings yet

- Thin Film Deposition TechniquesDocument13 pagesThin Film Deposition TechniquesGaganpreetSinghNo ratings yet

- IzvadociStandard VDI2053 СО+ventilacijaGARAZIDocument24 pagesIzvadociStandard VDI2053 СО+ventilacijaGARAZIErica MorrisonNo ratings yet

- Assignment 3Document3 pagesAssignment 3HARINo ratings yet

- Nitrogen & Oxygen GeneratorsDocument16 pagesNitrogen & Oxygen GeneratorsRoozbeh PNo ratings yet

- Balston Nitrogen GeneratorDocument10 pagesBalston Nitrogen GeneratorNguyễn NgọcNo ratings yet

- Air Composition DryDocument11 pagesAir Composition DryrahulNo ratings yet

- Chimney 3m TallerDocument1 pageChimney 3m TallerfardinaNo ratings yet

- Selective Catalytic ReductionDocument15 pagesSelective Catalytic ReductionJuan Esteban EnriquezNo ratings yet

- Handbook Nitrogen Oxides Pollution Prevention and ControlDocument5 pagesHandbook Nitrogen Oxides Pollution Prevention and ControlrupigapigaNo ratings yet

- Enhancing Gas Turbine Output Through Inlet Air Cooling: ArticleDocument9 pagesEnhancing Gas Turbine Output Through Inlet Air Cooling: ArticleAhamed Yaseen SalimNo ratings yet

- MESSER Gase For Life On-Site - Gas - Production PDFDocument12 pagesMESSER Gase For Life On-Site - Gas - Production PDFnefoussiNo ratings yet

- C03. FläktWoods - Car Park Ventilation - Ducted or Jet Thrust FanDocument7 pagesC03. FläktWoods - Car Park Ventilation - Ducted or Jet Thrust FanCzarSASNo ratings yet

- Design of Dust Extraction SystemDocument28 pagesDesign of Dust Extraction Systemrajeevup2004100% (2)

- Membrane Nitrogen Gas Generation Systems: Presented By: South-South-tek SystemsDocument17 pagesMembrane Nitrogen Gas Generation Systems: Presented By: South-South-tek SystemsWinda Nur'aini TwelvpatwoNo ratings yet

- Exposure Assessment and Safety Considerations for Working with Engineered NanoparticlesFrom EverandExposure Assessment and Safety Considerations for Working with Engineered NanoparticlesNo ratings yet

- Environmental Scenario in Indian Mining Industry - an OverviewFrom EverandEnvironmental Scenario in Indian Mining Industry - an OverviewNo ratings yet

- Encyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"From EverandEncyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"No ratings yet

- The Handbook of Heating, Ventilation and Air Conditioning (HVAC) for Design and ImplementationFrom EverandThe Handbook of Heating, Ventilation and Air Conditioning (HVAC) for Design and ImplementationRating: 1 out of 5 stars1/5 (1)