Professional Documents

Culture Documents

Hints Casting

Hints Casting

Uploaded by

Noir HamannOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hints Casting

Hints Casting

Uploaded by

Noir HamannCopyright:

Available Formats

HELPFUL HINTS:

Casting

1. The casting area and casting equipment should be kept clean and separate crucibles and stirring rods should be used for each metal to prevent contamination. 2. Make sure any scrap being remelted is clean and all investment residue has been removed.

3. Never use 100% scrap metal. It is recommended to use 50% old and 50% new metal. 4. Do not overheat metal. Follow the recommended casting temperatures.

5. Wait 15 to 20 minutes before quenching cans. Quenching before this could lead to cracking. 6. Alter the speed on the casting machine to avoid the problem of non-fill. If the speed is not sufficient then the metal will freeze before it has a chance to fill all the cavities.

Specialist Refractory Services Limited, Amber Business Centre, Riddings, Derbyshire, DE55 4BR, England. Tel: +44 (0)1773 608969 | Fax +44 (0)1773 540105 | www.srs-ltd.co.uk | sales@srs-ltd.co.uk

You might also like

- SCC - Electonics - Q4M3Weeks5-6 - PASSED NO AKDocument18 pagesSCC - Electonics - Q4M3Weeks5-6 - PASSED NO AKLyle Isaac L. IllagaNo ratings yet

- Haresh Steel Centre: Copper-Nickel Pipe, Fittings & FlangesDocument16 pagesHaresh Steel Centre: Copper-Nickel Pipe, Fittings & FlangesHaresh Steel CentreNo ratings yet

- Manufacturing Process Lab R18A0384Document31 pagesManufacturing Process Lab R18A0384muzaffarusNo ratings yet

- Shalimar Aluminium PaintDocument2 pagesShalimar Aluminium PaintDeepak Tantuway100% (1)

- Epas 10 Lecture Maintain and Repair Flat IronDocument2 pagesEpas 10 Lecture Maintain and Repair Flat IronRap PerezNo ratings yet

- Intro OxyacetyleneDocument13 pagesIntro OxyacetylenejapeleNo ratings yet

- Dental Alloys Processing ManualDocument26 pagesDental Alloys Processing ManualIvan LiwuNo ratings yet

- Laboratory Equipment enDocument40 pagesLaboratory Equipment enLUISALBERTO06011985No ratings yet

- Basics of SolderingDocument4 pagesBasics of SolderingNAIR KRISHNA RAVEENDRAN100% (2)

- Gold RecoveryDocument21 pagesGold RecoveryAnoop Chetia100% (2)

- E0900048-V4 LIGO UHV Welding SpecDocument7 pagesE0900048-V4 LIGO UHV Welding SpecBenjamin BrownNo ratings yet

- MuggyWeld 72-InstructionsDocument2 pagesMuggyWeld 72-InstructionsJack NicholsNo ratings yet

- Smelting GoldDocument2 pagesSmelting Gold69afreak69100% (1)

- PEER Seals CatalogDocument64 pagesPEER Seals CatalogRodatecnia Javier100% (1)

- Steel Making ShoukeryDocument95 pagesSteel Making ShoukeryAlaa Hosney100% (1)

- EE603522Document45 pagesEE603522VINITNo ratings yet

- Heareus RTD ApplicationNotesDocument2 pagesHeareus RTD ApplicationNotesAshish GuptaNo ratings yet

- Housing Designs & Seal Options PDFDocument27 pagesHousing Designs & Seal Options PDFmimi_chan_17100% (1)

- Sec11 SilverBrazing WebDocument8 pagesSec11 SilverBrazing Webdm1680No ratings yet

- Welding Gas Report CompressDocument11 pagesWelding Gas Report CompressNIDHI RASUMALLANo ratings yet

- Manual Ferro de Solda Temp RegulDocument1 pageManual Ferro de Solda Temp ReguldgsilvaufgNo ratings yet

- 77 Cast Iron Electrode InstructionsDocument2 pages77 Cast Iron Electrode Instructionsjoaquin r.No ratings yet

- Dewax FiringDocument3 pagesDewax Firingsen.sulekhaNo ratings yet

- Soldering TechniqueDocument23 pagesSoldering TechniquemokongNo ratings yet

- Baking ProcedureDocument2 pagesBaking Proceduregopuvinu4uNo ratings yet

- Die Casting ReportDocument11 pagesDie Casting ReportFaria KhanNo ratings yet

- Customer'S Guide: When Raw Material Is Put Into WarehouseDocument2 pagesCustomer'S Guide: When Raw Material Is Put Into WarehouseRa'oufAli-zadehNo ratings yet

- Metal Ceramic Crown Lab ManualDocument25 pagesMetal Ceramic Crown Lab ManualchusbNo ratings yet

- Troubleshooting GuideDocument25 pagesTroubleshooting GuideIjabiNo ratings yet

- Type IV Gold AlloysDocument18 pagesType IV Gold Alloysasop06No ratings yet

- MSDS Er70s-6Document3 pagesMSDS Er70s-6Bagus SetiyawanNo ratings yet

- Rules For SolderingDocument3 pagesRules For SolderingMichelle ArellanoNo ratings yet

- Welding GAS ReportDocument11 pagesWelding GAS Report15 thn50% (2)

- Help On SolderingDocument7 pagesHelp On SolderingmarcusolivusNo ratings yet

- 34 5381 01 Instructions Cable CableDocument2 pages34 5381 01 Instructions Cable Cabletecknotron2072No ratings yet

- INVESTING AND CASTING-handoutDocument13 pagesINVESTING AND CASTING-handoutSara M AminNo ratings yet

- Metrotect Acothane TU Brush GradeDocument3 pagesMetrotect Acothane TU Brush GradeandyvaughanNo ratings yet

- DS 164 02 ZincAnode304 MZSDocument2 pagesDS 164 02 ZincAnode304 MZSPower PowerNo ratings yet

- Interview QuestionDocument22 pagesInterview QuestionsugeshNo ratings yet

- Stainless Steel Technical PresentationDocument23 pagesStainless Steel Technical PresentationRavi Teja100% (1)

- LemljenjeDocument2 pagesLemljenjeTolić BrankoNo ratings yet

- Soldering TechniquesDocument26 pagesSoldering TechniquesAsep Deden Rahmat SNo ratings yet

- Manual Plancha Hamilton BeachDocument32 pagesManual Plancha Hamilton BeachEduardoEnriqueCadenaLopezNo ratings yet

- Licensed Toxic Waste Collectors in SingaporeDocument27 pagesLicensed Toxic Waste Collectors in Singaporecolin_m_chanNo ratings yet

- Qut 23.05.2013Document2 pagesQut 23.05.2013Moorthy RamNo ratings yet

- Stainless Steel CatalogueDocument109 pagesStainless Steel Cataloguelingot123@yahoo.comNo ratings yet

- Guidelines For Welding Cast IronDocument3 pagesGuidelines For Welding Cast IronNguyễn Thanh SơnNo ratings yet

- Nps 64 AFDocument1 pageNps 64 AFRahul GuptaNo ratings yet

- Assemble Information SheetDocument18 pagesAssemble Information SheetLeon AtsilegnaveNo ratings yet

- Casting Procedure-December 15th, 2016Document5 pagesCasting Procedure-December 15th, 2016Николай СидоренкоNo ratings yet

- Titanium Welding ProcedureDocument5 pagesTitanium Welding ProcedureHarminder KumarNo ratings yet

- Assignment 4 Inplant TrainingDocument14 pagesAssignment 4 Inplant TrainingRajas BiliyeNo ratings yet

- Elkem 04 Inoculation PracticesDocument2 pagesElkem 04 Inoculation Practicesmarcotulio123No ratings yet

- The Silversmith's Handbook: Containing full instructions for the alloying and working of silverFrom EverandThe Silversmith's Handbook: Containing full instructions for the alloying and working of silverNo ratings yet

- Blacksmithing on the Farm - With Information on the Materials, Tools and Methods of the BlacksmithFrom EverandBlacksmithing on the Farm - With Information on the Materials, Tools and Methods of the BlacksmithNo ratings yet

- Boiler Making for Boiler Makers - A Practical Treatise on Work in the ShopFrom EverandBoiler Making for Boiler Makers - A Practical Treatise on Work in the ShopRating: 4.5 out of 5 stars4.5/5 (2)

- Magical Metal Clay: Amazingly Simple No-Kiln Techniques For Making Beautiful AccessoriesFrom EverandMagical Metal Clay: Amazingly Simple No-Kiln Techniques For Making Beautiful AccessoriesRating: 4 out of 5 stars4/5 (4)

- Linotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeFrom EverandLinotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeNo ratings yet

- Power Spectral DensityDocument18 pagesPower Spectral DensityNoir HamannNo ratings yet

- Sensor Actuator T211Document22 pagesSensor Actuator T211Noir HamannNo ratings yet

- PneumaticTire - HS 810 561Document707 pagesPneumaticTire - HS 810 561Scott KimbroughNo ratings yet

- A Study On The Contact Force Between Catenary and PantographDocument6 pagesA Study On The Contact Force Between Catenary and PantographNoir Hamann100% (1)

- Motion Related Comfort in Tilting TrainsDocument68 pagesMotion Related Comfort in Tilting TrainsNoir HamannNo ratings yet

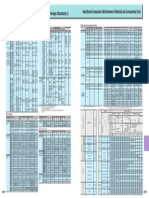

- International Material Grade Comparison TableDocument9 pagesInternational Material Grade Comparison Tablenyamuk06100% (4)

- Inspection: 1. Charcoal Canister AssyDocument5 pagesInspection: 1. Charcoal Canister AssyNoir HamannNo ratings yet

- Brake Fluid PDFDocument2 pagesBrake Fluid PDFNoir HamannNo ratings yet

- Material ComparisonDocument1 pageMaterial ComparisonNoir HamannNo ratings yet

- BIOS Update ProceduresDocument6 pagesBIOS Update ProceduresNoir HamannNo ratings yet

- Inspection: - Ignition SystemDocument2 pagesInspection: - Ignition SystemNoir HamannNo ratings yet