Professional Documents

Culture Documents

Bomba Cop X Presion

Bomba Cop X Presion

Uploaded by

Raúl Francisco Cerda PizarroOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bomba Cop X Presion

Bomba Cop X Presion

Uploaded by

Raúl Francisco Cerda PizarroCopyright:

Available Formats

E Series Piston Pumps

Variable Displacement Series for Mobile Applications Technical Catalog

PVE012 PVE19 PVE21

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 Operating Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 Displacement, Speed, and Pressure Ratings Overspeed Limits PVE012 Model Number System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 Shaft Torque Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 Performance Curves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 Installation Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 Shaft Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 Adjustable Maximum Volume Stop Load Sensing with Pressure Limiter Remote Adjustment Compensator PVE19/21 Model Number System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 Shaft Torque Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 Typical Rear Pumps for Thru-drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Performance Curves. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

PVE19 PVE 21 Installation Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 Side Ports and C-type Control End Ports and C-type Control Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 Adjustable Maximum Volume Stop Load Sensing with Pressure Limiter Remote Adjustment Compensator Unloading Valve Valves - Constant Flow Adapter Proportional Compensator Shaft Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 Thru-drives PVE19/21 SAE A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

PVE19/21 SAE B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Application Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

EATON Vickers E Series Piston Pumps V-PP-MC-0001-E March 2003

Introduction

Eaton PVE piston pumps are inline, variable displacement pumps that are available in three displacement sizes. An assortment of optional controls offer maximum operating flexibility. Pump displacement is varied by means of pressure and/or flow compensator controls.

Housing Shaft Seal Yoke

Compensator

Features and Benefits

Inline, variable displacement pump Displacement is varied by pressure/flow compensator controls Optional controls for maximum operating flexibility Thru-drive available on PVE 19/21

Shaft Bearing Piston Valve Block

PVE012 Section View

Yoke Tapered Roller Bearing Drive Shaft

Wafer Plate

Compensator

Housing Rotating Group PVE012 Section View Figure 1. Sectional Views of the PVE Pumps

EATON Vickers E Series Piston Pumps V-PP-MC-0001-E March 2003

Controls

Pressure Compensator Control, A Option This control automatically varies pump displacement to meet the system flow demand for a constant system pressure. Displacement starts to reduce to zero within 14 bar (200 psi) of the compensator setting. Power draw-off is minimized, therefore, system relief valves should not be required. Pressure Compensator Control with Maximum Displacement Adjustment As indicated for A option above, except there is an independent screw adjustment of maximum displacement from 100% (rated) to 25%.

Load Sensing Compensator and Pressure Limiter, B Option This compensator provides load sensing control under all pressure conditions up to the desired maximum. It automatically adjusts pump flow in response to a remote pressure signal and maintains outlet pressure at approximately 11 bar (160 psi) above load pressure. The integral pressure limiter overrides the load sensing control, reducing pump displacement as the preset maximum operating pressure is reached. Override begins within 14 bar (200 psi) of the preset maximum pressure compensator setting. A 24 bar LS option is also available.

PVE with Pressure Compensator Arranged for Remote Control, D Option or J Option Exactly the same as the A (pressure compensation option) except the machine operator is able to change the compensator setting through the use of a remote pilot relief valve.

Note: Graphic symbols shown with external valve(s) and cylinder to illustrate typical usage.

Note: A kit is available for an electrical dual pressure compensator. This control automatically adjusts pump delivery to maintain system volume requirements at either of two preselected operating pressures. This allows lower settings for low horsepower start-up, equipment testing, etc. This kit also allows for higher pressure settings as required in machine applications. For details refer to service drawing I-3255-S. Note: Optional internal bleed orifice diameter is .015'' and is A option-control special features.

EATON Vickers E Series Piston Pumps V-PP-MC-0001-E March 2003

Operating Data Displacement, Speed, and Pressure Ratings

Preparation for Start-up Before starting a PVE pump, fill the case through the uppermost drain port with clean system hydraulic fluid. The case drain line must be connected to the reservoir below oil level. For multiple pump arrangements that include non-PVE sections, the requirements of the non-PVE units must also be considered. Mounting Eaton Hydraulics recommends these PVE series piston pumps be mounted horizontally.

DISPLACEMENT, SPEED AND PRESSURE RATINGS

Model Number System

Displacement cm3/r (in3/r) Shaft End Pump Cover End Pump

Rated Input Speed (At 0 psig Inlet)

Maximum Pressure bar (psi) Shaft End Cover End

PVE012 PVE19 PVE21

25 (1.54) 41 (2.50) 45 (2.75)

3000 2400 2400

210(3000) 210(3000) 186(2700)

**Shaded product may not be available

PRESSURE LIMITS

Port

Pressure Range

Inlet** Outlet Drain*

0,2 bar to 2,0 bar (5 in. Hg. vacuum to 30 psi) See Maximum Pressures listed above 0,35 bar (5 psig) maximum

**Integral relief valve protects pump by limiting case pressure peaks to 0,7 bar (10 psi) above inlet pressure. Flow from valve returned directly to pump inlet. Case drain line required to limit steady-state case pressure. **See page 6 for Inlet vs. Speed details. For non-intergrated units only

EATON Vickers E Series Piston Pumps V-PP-MC-0001-E March 2003

Operating Data Overspeed Limits

AT FULL FLOW CONDITIONS

Displacement cm /r (in /r)

3 3

Inlet Pressure/Vacuum*

Maximum Speed** rpm

PVE21 full displacement 45 (2.75) PVE19 full displacement 41 (2.50)

PVE19/21 destroked 33 (2.00)

PVE19/21 destroked 25 (1.50)

5 psig 0 psig 5 in. Hg. 5 psig 0 psig 5 in. Hg. 5 psig 0 psig 5 in. Hg.

2800 2400 2100 3100 2750 2500 3200 3000 2850

PVE012 limited to 3000 rpm at full displacement and 0 psig inlet. **Minimum pressure/vacuum required at pump inlet to operate at displacement and speed listed. **Speeds not listed, but within displacements shown above, may be calculated from values listed.

AT LOAD SENSE STANDBY CONDITION B OPTION CONTROLS

Model Number System

Maximum Speed rpm

PVE012 PVE19 PVE21

3600 3200 3200

Pump must be in zero flow, low pressure, standby condition when operated at listed speed. Pump may be damaged if not slowed to normal rated speed before being operated at full flow.

RESPONSE DATA

Control Type

PVE012 On Stroke sec.

Off Stroke sec.

PVE19/21 On Stroke sec.

Off Stroke sec.

Pressure compensator Load sense compensator

0.030 0.040

0.012 0.012

0.050 0.060

0.025 0.020

Yoke response recorded at rated speed and pressure, 0 psi inlet, 82C (180F), SAE 10W oil. Pressure rise was 6900 bar (100,000 psi) per second.

SOUND DATA

Model Number System

1200 rpm, 70 bar (1000 psi) Full Stroke Compensated dB(A) Stroke dB(A)

1500 rpm, 140 bar (2000 psi) Full Stroke Compensated dB(A) Stroke dB(A)

1800 rpm, 210bar (3000 psi) Full Stroke Compensated dB(A) Stroke dB(A)

PVE012 PVE19 PVE21 *2700 psi

71 79 75

65 74 73

76 83 79

72 85 81

77 86 83*

77 87 83*

Sound level dB(A) per ISO 4412-1 standard.

EATON Vickers E Series Piston Pumps V-PP-MC-0001-E March 2003

Model Number System E Series, PVE012 Pump

10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30

31

P

Nos

V E 0

Feature

1 2 R

PV L R 01 05 09

0 1

A U B 0

3 3

2

Nos

4 0 0

Feature

A 1

0 1

0 C D

Code Description

Code Description

1,2 7 8,9

Code title Input shaft rotation Front mounting and input shaft

Open circuit piston pump Left-hand rotation (CCW) Right-hand rotation (CW) 2 Bolt B (SAE J744-101-2) with 22.2 [.88] DIA straight key shaft (SAE J744-22-1), key included 2 Bolt B (SAE J744-101-2) with 13T 16/32DP 41.1 [1.62] long splined shaft 2 Bolt B (SAE J744-101-2) with 26T 32/64DP splined shaft End ports; tube ports per SAE J514, suction 1.625-12 UN-2B SAE, pressure 1.0625-12 UN-2B SAE End ports; tube ports per ISO 6149-1, suction M42 x 2, pressure M27 x 2 M18 metric O-ring port top (D1) M18 metric O-ring port bottom (D2) .750-16 UNF-2B SAE O-ring port top (D1) .750-16 UNF-2B SAE O-ring port bottom (D2) No diagnostic pressure port

15,16

3,4,5,6 Displacement

E012 25.2cm3/r [1.54 in3/r] 17 ,18

Pressure comp./ 00 unloading valve setting 33 Flow comp. setting or unload valve standby Secondary compensator setting 00 11 24 00 04

No pressure compensator setting 206.8-213.7 bar [3000-3100 lbf/in2] No flow compensator setting 9.65-12.41 bar [140-180 lbf/in2] 22.75-25.51 bar [330-370 lbf/in2] No secondary compensator setting 186.2-193.1 bar [2700-2800 lbf/in2] No special features Bleed down orifice, LS only External load-sensing adjustment High rate spring for low pressure setting Bleed down orifice and high rate spring for low pressure setting Standard displacement Adjustable maximum displacement (set at maximum) No auxiliary mounting or output shaft No shaft seal Standard shaft seal (nitrile) Flurocarbon shaft seal No special features Cast iron housing No paint Blue primer STD mark assembly Number, full model code and build data Code on plate First

19,20

21

10,11

Main ports location and size

AU

Control special features

0 A B G J

AV

12

Drain port size

6 7 B C

22

Maximum displacement option Auxiliary mounting and output shaft Shaft seals

1 2 00 0 1 3 00 AF 00 CD 0

23,24 25

13 14

Diagnostic pressure port Controller type

0 A B C D E F K

26,27 Pressure compensator Pressure and flow compensator Electric dual range pressure Compensator with directional control valve Hydraulic remote control pressure compensator Unloading valve (accumulator Circuits) Electric dual range pressure compensator without directional control valve CFD control 12 volt DC

PVE012 SHAFT TORQUE DATA

Special features Paint Customer and unit identification Design code

28,29 30

31

Note: Consult an Eaton representative for additional settings

Shaft Torque Data PVE012

Input Shaft Torque N.m (lb.in.)

Designation

Thru-drive Option

Maximum Input

01 05 09

SAE B straight keyed SAE B spline 13T, 16/32 D.P., FRMDF Special Eaton 26T for use in rear pump of tandem PVE**-PVE12 unit

No No No

135 (1200) 208 (1850) N/A

EATON Vickers E Series Piston Pumps V-PP-MC-0001-E March 2003

Performance Curves PVE012

Oil type: SAE 10W Oil temperature: 49C (180F) Inlet pressure: 0 psi

Effective Flow Versus Speed

11 4 95 Delivery l/min 76

35 bar (500 psi)

30 25 20 15

207 bar (3000 psi)

57 38 19 0 500

10 5 0 3000

1000

1500 Speed rpm

2000

2500

Input Power Versus Speed

30

207 bar (3000 psi)

40 Input Power hp

8

Input Power kW

22.5

140 bar (2000 psi)

30

70 bar (1000 psi) 35 bar (500 psi)

15 7.5 0 500

20 10 0 3000

1000

1500 Speed rpm

2000

2500

Volumetric Efficiency Versus Speed

100 Overall Efficiency % 80

207 bar (3000 psi)

60 40 20 0 500

140 bar (2000 psi) 70 bar (1000 psi) 35 bar (500 psi)

1000

1500 Speed rpm

2000

2500

3000

EATON Vickers E Series Piston Pumps V-PP-MC-0001-E March 2003

Delivery USgpm

Installation Dimensions PVE012 with Pressure Compensator

R.H. rotation 14,53 14,15 (0.572) (0.557) 73,0 (2.87) 146,0 (5.75) 30,0 (1.18) 25,0 (0.98) 14,0 R 2 places (0.55 R) 70,0 (2.76) 140,0 (5.51) 51,5 (2.03) 120,6 ( 4.75) 19,5 R (0.77 R) 9,4 (0.37) max. R 0,76 (0.030) 101,60 101,55 ( 4.000) ( 3.998)

196,6 (7.74) 167,5 (6.59) 14,0 (0.55)

Outlet port (see note) 1.0625-12 UN-2B thd. SAE O-ring boss connection .750 O.D. tubing (shown for R.H. rotation) 44,0 (1.73)

60,0 47,0 (2.36) (1.85) 83,1 (3.27) 162,5 (6.40) 186,1 (7.33) 28,4 (1.12) 77,0 (3.03) 114,1 (4.49) 154,0 (6.06)

Drain port "D2" .750-16 UNF-2B thd. SAE O-ring boss 44,0 connection (1.73) .500 O.D. tubing 56,0 ( 2.20) 2 places 52,0 (2.05) 70,0 73,4 (2.76) (2.89) Inlet port (see note) 1.625-12 UN-2B thd. SAE O-ring boss connection 1.250 O.D. tubing

Note: Ports are reversed for L.H. Rotation

29,5 (1.16) 85,1 (3.35) 170,2 (6.70)

Construction plugs Do not remove 27,0 (1.06)

Compensator position R.H. rotation (reverse for L.H. rotation)

153,5 (6.04)

PVE012 Shaft Options

#01: SAE B Straight Keyed

Alternate drain port "D1" .750 - 16 UNF - 2B thd. SAE ORing boss connection .500 O.D. tubing

#05: SAE B Splined

25,12 24,87 (0.989) (0.979)

22,225 22,200 ( 0.8750) ( 0.8740)

5,5 (0.22) 58,6 (2.31)

5,5 (0.22) 6,375 6,350 x 31,75 long key (0.251) (1.250) (0.250)

30 1.5 x 45 (0.06) 19,0 (0.75)

1.5 x 45 (0.06) 50.8 (2.00)

Note: Applications requiring overhung load or side loading of shaft are subject to Eaton engineering approval.

33,3 (1.31) 41,1 (1.62)

SAE B modified involute spline (0.8585 0.8530 major diameter , 0.715 minimum minor diameter). Flat root, side fit. Class 5 per ANSI B92.1a1976. 13 teeth, 16/32 diameter pitch, 30 pressure angle.

9

EATON Vickers E Series Piston Pumps V-PP-MC-0001-E March 2003

Controls PVE012 Adjustable Maximum Displacement Stop

See installation dimensions page 9 for other details.

Adjustment Loosen the locknut on the adjusting rod. Turn the adjusting rod clockwise to decrease maximum pump delivery, or counterclockwise to increase maximum pump delivery, until the desired setting is obtained. Secure the setting by tightening the locknut. To assist initial priming, the manual adjustment control setting must be at least 40% of the maximum flow position. This control enables maximum pump delivery to be externally adjusted from 25% to 100% while maintaining all the standard features of a pressure compensated pump.

72,6 (2.86)

52,0 (2.05)

90,1 (3.55)

Locknut 11,2 across flats (0.44) 123,8 (4.87)

63,8 (2.51)

28,4 (1.12)

Maximum stop adjusting rod (Approx. 2,22 cc/rev change per turn) Compensator position for L.H. rotation

30,0 11,8 max. Compensator position (1.18) (0.43) for R.H. rotation

194,2 (7.65)

218,2 (8.59)

250,1 (9.85)

EATON Vickers E Series Piston Pumps V-PP-MC-0001-E March 2003

10

Controls PVE012 Adjustable Maximum Displacement Stop

See installation dimensions page 9 for other details.

PVE012 Load Sensing with Pressure Limiter A Control Option

Compensator position for R.H. rotation Compensator position for L.H. rotation 52,0 (2.05) Load sensing compensator control port location for R.H. rotation .4375-20 UNF-2B thd. SAE O-ring boss connection .250 O.D. tubing

28,4 ( 1.12)

214,3 (8.44)

19,0 (0.75)

Load sensing compensator control port location for L.H. rotation

70,6 (2.78) 128,3 (5.05)

10,6 (0.42) 191,0 (7.52)

68,3 (2.69)

EATON Vickers E Series Piston Pumps V-PP-MC-0001-E March 2003

11

Controls PVE012 Remote Adjustment Compensator

See installation dimensions page 9 for other details.

Compensator control port location for L.H. rotation

Compensator control port location for R.H. rotation .4375-20 UNF-2B thd. SAE O-ring boss connection .250 O.D. tubing 54,8 (2.16) 75,1 (2.96) 114,8 (4.52) 15,1 (0.59) 54,8 (2.16)

20,9 (0.82)

186,0 (7.32)

EATON Vickers E Series Piston Pumps V-PP-MC-0001-E March 2003

12

Model Number System PVE19/21

10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30

31

P

Nos

V E 1

Feature

9 A R

PV

0 1

A A 1 0

3 3

2

Nos

0 0

A 1 A A 1

Code Description

C D 0

Code Description

Feature

1,2

Code title

Open circuit piston pump

3 3 3 3

12

3,4,5,6 Displacement 7 8,9

E19A 41.0cm /r [2.50 in /r] E21A 45.1cm /r [2.75 in /r] Left-hand rotation (CCW) Right-hand rotation (CW) 2 Bolt B (SAE J744-101-2) with 22.2 [.88] DIA straight key shaft (SAE J744-22-1) (key included) 2 Bolt B-B(SAE J744-101-2) with 25.4 [1.00] DIA straight key shaft (SAE J744-25-1) (key included) 2 Bolt B (SAE J744-101-2) with 25.4 [1.00] DIA tapered key shaft (SAE J744-25-3) (key included) 2 Bolt B (SAE J744-101-2) with 13T 16/32DP 41.1 [1.62] long splined shaft 2 Bolt B-B (SAE J744-101-2) with 15T 16/32DP splined shaft 2 Bolt B (SAE J744-101-2) with 26T 32/64DP splined shaft Side ports; tube ports per SAE J514, suction 1.875-12 UN-2B, pressure 1.3125-12 UN-2B End ports; tube ports per SAE J514, suction 1.875-12 UN-2B, pressure 1.3125-12 UN-2B Side ports; SAE J518 flange, suction 1.500 SAE 4-bolt split flange port (code 61); pressure 1.000 SAE 4-bolt split flange port (code 61) End ports; SAE J518 flange, suction 1.500 SAE 4-bolt split flange port (code 61); pressure 1.000 SAE 4-bolt split flange port (code 61) Side ports; ISO 6149-1 tube, suction M48 X 2, pressure M33 X 2 End ports; ISO 6149-1 tube, suction M48 X 2, pressure M33 X2 End ports; ISO 6162 flange, suction 1.500 SAE 4-bolt split flange port with M12 X 1.75 threads; pressure 1.000 SAE 4-bolt split flange port with M10 X 1.5 threads

Drain port size and location

1 2 6 7

Input shaft rotation L R Front mounting and input shaft 01 02 04 05 08 09

.875-14 UNF-2B SAE O-ring port top (D1) .875-14 UNF-2B SAE O-ring port bottom (D2) M18 X 1.5 metric O-ring port top (D1) M18 X 1.5 metric O-ring port bottom (D2) No diagnostic pressure port .4375-20 UNF-2B SAE O-ring port plugged M14 X 1.5 metric O-ring port plugged Pressure compensator Pressure and flow compensator Electric dual range pressure compensator with directional control valve Hydraulic remote control pressure compensator Unloading valve (accumulator circuits) Electric dual range pressure compensator without directional control valve CFD control 12 volt DC No pressure compensator setting 182.7-189.6 bar [2650-2750 lbf/in2] 206.8-213.7 bar [3000-3100 lbf/in2]

13

Diagnostic pressure port

0 1 2

14

Controller type

A B C D E F K

10,11 Main ports location and size

AA AB AC

15,16 Pressure comp./ unloading valve

00 18 33

AD

Note: Consult an Eaton representative for additional settings

AE AF AS

EATON Vickers E Series Piston Pumps V-PP-MC-0001-E March 2003

13

Model Number System PVE19/21

10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30

31

P

Nos

V E 1

Feature

9 A R

00 11 14 24 00 04 0 A B G J

0 1

A A 1 0

3 3

2

Nos

0 0

A 1 A A 1

Code Description

C D 0

Code Description

Feature

17 ,18 Flow comp. setting or unload valve standby 19,20 Secondary compensator setting 21 Control special features

No flow compensator setting 9.65-12.41 bar [140-180 lbf/in2] 12.41-15.17 bar [180-220 lbf/in2] 22.75-25.51 bar [330-370 lbf/in2] No secondary compensator setting 186.2-193.1 bar [2700-2800 lbf/in2] No special features Bleed down orifice External load-sensing adjustment High rate spring for low pressure setting Bleed down orifice and high rate spring for low pressure setting Standard displacement Adjustable maximum displacement (set at maximum)

25

Shaft seals

0 1 00 AA AF

No shaft seal Standard shaft seal (fluorocarbon) No special features Auxiliary mounting cover plate Cast iron housing

26,27 Special features

28,29 Paint 30

00 No paint CD Blue primer STD mark assembly number, model number up identification to rotation and build date code on plate Mark assembly number, full model code and build data code on plate First design

Customer and unit 0 D

31

Design code

22

Maximum displacement option

1 2

Note: Consult an Eaton representative for additional settings

23,24 Auxiliary mounting 00 output shaft AA

No auxiliary mounting or output shaft 2 Bolt A (SAE J744-82-2) w/ 9T 16/32DP external splined shaft AB 2 Bolt A (SAE J744-82-2) w/ 11T 16/32DP external splined shaft AC 2 Bolt B (SAE J744-101-2) w/ 13T 16/32 DP internal splined coupling AD 2 Bolt B (SAE J744-101-2) w/ 15T 16/32DP internal splined coupling AE 2 Bolt B (SAE J744-101-2) w/ 26T 32/64DP external splined shaft AH 2 Bolt A (SAE J744-82-2) w/ 9T 16/32DP internal splined coupling AJ 2 Bolt A (SAE J744-82-2) w/ 11T 16/32DP internal splined coupling AK 2 Bolt B (SAE J744-101-2) w/ 26T 32/64DP internal splined coupling

EATON Vickers E Series Piston Pumps V-PP-MC-0001-E March 2003

14

Shaft Torque Data PVE19/21

SHAFT TORQUE DATA

Spline Data

Designation

Thru-drive Option

Maximum Input Torque N.m (lb.in.)

02 08 05 01 09

SAE BB straight keyed SAE BB spline 15T, 16/32 D.P., FRSF SAE B spline 13T, 16/32 D.P., FRSF SAE B straight keyed Special Eaton 26T for use in rear pump of tandem PVE**-PVE** unit Note: See page 22 for more details.

Yes Yes Yes No No

215 (1900) 337 (2987) 208 (1850) 135 (1200) N/A

Typical Rear Pumps for Thru-drives PVE19/21

TYPICAL REAR PUMPS FOR THRU-DRIVES

Model Code

Typical Rear Pump Model

Rear Pump Shaft Code

PVE** Thru-drive Coupling

AH

AC

AD AK

PVQ10/13 PVB5/6 V10 V20 PVE012 PVE19/21 PVQ20/32 PVQ40/45 V2010 or V2020 20V(Q) PVE19/21 PVQ40/45 2520V(Q) PVE012 PVE19/21 N/C PVQ40/45

3 Suffix -S214 11 62 5 5 3 5 11 151 8 8 166 9

864224 (9T / 9T Straight)

864307 (26T / 13T Step) 475134 (26T / 15T Step) 627168 / 26T Straight)

EATON Vickers E Series Piston Pumps V-PP-MC-0001-E March 2003

15

Performance Curves PVE19

Oil type: SAE 10W Oil temperature: 82C (180F) Inlet pressure: 0 psi

Effective Flow Versus Speed

11 4 95

35 bar (500 psi)

30 25 20

207 bar (3000 psi)

Delivery l/min

76 57 38 19 0 500

15 10 5 0 2500

1000

1500 Speed rpm

2000

Input Power Versus Speed

37,5 30 Input Power kW 22,5 15 7,5 0 500

207 bar (3000 psi) 140 bar (2000 psi) 70 bar (1000 psi) 35 bar (500 psi)

50 40 30 20 10 0 2500 Input Power hp

16

1000

1500 Speed rpm

2000

Overall Efficiency Versus Speed

100 80 Overall Efficiency % 60 40 20 0 500

207 bar (3000 psi) 140 bar (2000 psi) 70 bar (1000 psi) 35 bar (500 psi)

1000

1500 Speed rpm

2000

2500

EATON Vickers E Series Piston Pumps V-PP-MC-0001-E March 2003

Delivery USgpm

Performance Curves PVE21

Oil type: SAE 10W Oil temperature: 82C (180F) Inlet pressure: 0 psi

Effective Flow Versus Speed

11 4 95 Delivery l/min

35 bar (500 psi)

30 25 20

186 bar (2700 psi)

76 57 38 19 500

15 10 5 2500

1000

1500 Speed rpm

2000

Input Power Versus Speed

45 37,5 Input Power kW 30 22,5 15 7,5 0 500

186 bar (2700 psi) 140 bar (2000 psi) 70 bar (1000 psi) 35 bar (500 psi)

60 50 Input Power hp

17

40 30 20 10 0 2500

1000

1500 Speed rpm

2000

Overall Efficiency Versus Speed

100 90 Overall Efficiency %

80 70 60 50 40 500

186 bar (2700 psi) 140 bar (2000 psi) 70 bar (1000 psi) 35 bar (500 psi)

1000

1500 Speed rpm

2000

2500

EATON Vickers E Series Piston Pumps V-PP-MC-0001-E March 2003

Delivery USgpm

Installation Dimensions PVE19/21 with Side Ports

Millimeters (inches)

191,0 (7.52) 41,7 (1.64)

Outlet port (see note) 1.3125-12 UN-2B thd. SAE O-ring boss connection 1.000 O.D. tubing (Shown for R.H. rotation) 95,2 (3.75)

98,6 (3.88) 197,4 (7.77)

101,60 101,55 ( 4.000) ( 3.998) 25,4 (1.00)

50,8 (2.00)

190,5 (7.50)

0,76 R max. (0.030 R)

14,2 (0.56)

176,3 (6.94)

Drain port "D1" .875-14 UNF-2B thd. SAE O-ring boss connection 0.625 O.D. tubing Inlet port (see note) 1.875-12 UN-2B thd. SAE O-ring boss connection 1.500 O.D. tubing (Shown for R.H. rotation)

Note: Ports are reversed for L.H. Rotation

173,7 (6.84) R.H. rotation 34,0 (1.34) 20,3 R (0.80 R) 56,9 (2.24) 14,15 14,53 (0.557) (0.572) 73,02 (2.875) 146,05 (5.750) 184,9 (7.28) 218,2 (8.59) 120,6 (4.75) 19,7 (0.38) 211,1 (8.31) Compensator position R.H. rotation (reverse for L.H. rotation) 84,8 62,7 (3.34) (2.47) 55,6 (2.19) 63,5 88,1 (2.50) (3.47) Alternate drain port "D2" .875-14 UNF-2B thd. SAE O-ring boss connection 0.625 O.D. tubing

28,4 (1.12) 63,5 (2.50) 52,8 (2.08)

86,9 (3.42) 118,9 (4.68) 91,4 (3.60)

91,4 (3.60) 98,3 (3.87) 196,6 (7.74)

EATON Vickers E Series Piston Pumps V-PP-MC-0001-E March 2003

18

Installation Dimensions PVE19/21 with End Ports

Millimeters (inches)

41,7 (1.64)

98,6 (3.88) 197,4 (7.77) 101,60 101,55 ( 4.000) ( 3.998) 25,4 (1.00) Drain port "D1 ".875-14 UNF-2B thd. SAE O-ring boss connection 0.625 O.D. tubing 176,3 (6.94)

50,8 (2.00)

0,76 R max. (0.030 R)

14,2 (0.56)

Note: Ports are reversed for L.H. Rotation

173,7 (6.84) 19,7 (0.38) 120,6 (4.75) 21 1,1 (8.31) 28,4 (1.12) 84,8 (3.34) 62,7 55,6 (2.47) (2.19) 3,8 (0.15) 91,4 (3.60) Compensator position R.H. rotation (reverse for L.H. rotation) 86,9 (3.42) 118,9 (4.68) 5,3 (0.21)

R.H. rotation 34,0 (1.34) 20,3 R (0.80 R)

14,15 14,53 (0.557) (0.572) 56,9 (2.24) 73,02 (2.875) 146,05 (5.750) Alternate drain port "D2 ".875-14 UNF-2B thd. SAE O-ring boss connection 0.625 O.D. tubing 184,9 (7.28) 218,2 (8.71) 3,0 (0.12)

88,1 (3.47)

73,7 (2.90)

91,4 (3.60)

Inlet port (see note) 1.875-12 UN-2B thd. SAE O-ring boss connection 1.500 O.D. tubing (Shown for R.H. rotation)

47,8 (1.88) 95,5 (3.76)

Outlet port (see note) 1.3125-12 UN-2B thd. SAE O-ring boss connection 1.000 O.D. tubing (Shown for R.H. rotation)

EATON Vickers E Series Piston Pumps V-PP-MC-0001-E March 2003

19

Controls PVE19/21 Adjustable Maximum Displacement Stop

Adjustment Loosen the locknut on the adjusting rod. Turn the adjusting rod clockwise to decrease maximum pump delivery, or counterclockwise to increase maximum pump delivery, until the desired setting is obtained. Secure the setting by tightening the locknut. To assist initial priming, the manual adjustment control setting must be at least 40% of the maximum flow position. This control enables maximum pump delivery to be externally adjusted from 25% to 100% (it is not recommended below 50%) while maintaining all the standard features of a pressure compensated pump.

219,5 (8.64) 279,1 (10.99)

Maximum stop adjusting rod (Approx. 2,22 cc/rev change per turn)

59,7 (2.35) 34,0 (1.34) 15,0 max. (0.59)

Compensator position for R.H. rotation

28,4 (1.12)

127,8 (5.03)

Compensator position for L.H. rotation

93,7 (3.69)

55,6 (2.19) 11,2 across flats (0.44)

Locknut

EATON Vickers E Series Piston Pumps V-PP-MC-0001-E March 2003

20

Controls

PVE19/21 Load Sensing with Pressure Limiter Control B Option

See page 16 for other details and dimensions.

PVE19/21 Remote Adjustment Compensator Control D Option

239,3 (9.42)

215,9 (8.50)

215,9 (8.50)

Compensator control port location for R.H. rotation .4375-20 UNF-2B thd. SAE O-ring boss connection .250 O.D. tubing

6,6 (0.26) 63,5 (2.50)

22,4 Load sensing compensator control port location for R.H. (0.88) rotation .4375-20 UNF-2B thd. SAE O-ring boss connection .250 O.D. tubing

6,6 (0.26) 50,8 (2.00)

19,0 (0.75)

28,4 (1.12)

131,6 (5.18) 74,7 (2.94)

Loadsensing compensator control port location for L.H. rotation

28,4 (1.12)

118,9 (4.68) 78,7 (3.12)

55,6 (2.19)

55,6 (2.19)

Compensator control port location for L.H. rotation

EATON Vickers E Series Piston Pumps V-PP-MC-0001-E March 2003

21

Controls Unloading Valve Control E Option

With the unloading valve control the variable pump will unload at a preset pressure. The pump will maintain this no flow, low pressure (approximately 14 bar [200 psi]) standby condition, until system pressure drops to about 85% of the preset unloading pressure. The pump will then return on stroke and provide full flow until the preset unloading pressure is reached again. With this control, an efficient accumulator charging circuit is obtained. The pump will provide full flow to fill the accumulator until the maximum charging pressure is reached. The pump then goes to a standby condition until the accumulator pressure drops to 85% of the desired maximum. The accumulator is then recharged as the cycle starts over again. A separate right angle check valve must be provided to maintain the accumulator hydraulic charge and prevent back flow when the pump is unloaded. The check valves internal leakage must not exceed five drops per minute. The control port must be connected to system pressure, downstream of the check valve.

Adjustment range PVE19 PVE21 100-210 bar (1500-3000 psi) 100-186 bar (1500-2700 psi)

Unload valve control port To load Inlet Check Valve

Cut-in pressure is 85% of unloading pressure, minimum. Setting Pressures 1. Back out accumulator unloading pressure adjustment screw to below desired unloading pressure. 2. Adjust desired standby pressure. 3. Set accumulator pressure by screwing in the accumulator unloading adjustment screw. Accumulator recharge (cut-in) pressure is a function of the maximum accumulator pressure and is not adjustable. 4. Check pressure settings and re-adjust if necessary.

Outlet Drain

219,4 (8.64) 184.9 (7.28)

91.4 (3.60)

Standby pressure Control Port .4375-20 adjustment UNF-2B thd. SAE O-ring boss connection .25 OD tubing Accumulator unloading pressure adjustment 145,5 (5.95)

74,7 (2.94) 55,6 (2.19)

EATON Vickers E Series Piston Pumps V-PP-MC-0001-E March 2003

22

Controls Valves Constant Flow Adapter

This control is designed to automatically adjust the PVE outlet flow in response to an internal pressure signal. It will adjust the pump displacement to maintain the outlet flow at a preset level regardless of Input RPM. Contact your Eaton representative for further detail. This option will fit into the Model code under position 26, 27 - Special features. 6, 7 8 GPM constant , flow settings available.

Outlet Ports

PVE

Inlet Port Circuit Diagram 5.60

Drain Port

5.32 3.88

7.77

6.94 To C of Drain 7.52 To C Of Inlet & Outlet Ports

1.34

3.60

EATON Vickers E Series Piston Pumps V-PP-MC-0001-E March 2003

23

Controls Valves Proportional Compensator

This control is designed to automatically adjust the PVE outlet pressure in response to an external electric signal. Contact your Eaton representative for further detail.

34 {1.34}

54.4 {2.14} 13.7 {.54}

41.7 {1.64}

225.8 {8.89}

182.6 {7.19}

EATON Vickers E Series Piston Pumps V-PP-MC-0001-E March 2003

24

Shaft Options PVE19/21

No. 04 Shaft: Tapered Key shaft

6.35 {.250} 6.35 {.250} 69.8 {2.75} 61.9 {2.44} 3.20 {.126} .750-16 UNF-2A 4.09 3.89 THRU {.161}.153 1.5 X 45 {.06} 12.7 {.50} 23.5 {.93} 27 {1.06} 1.500:12 19.05 {.750} 25.37 25.35 { .999 } .998

No. 02 Shaft: SAE BB Straight Keyed

No. 08 Shaft: SAE BB Splined

46.0 (1.81) 6.37 31.75 6.35 long key x (0.251) (1.250) (0.250) 28.22 27.97 (1.111) (1.101) 38.10 (1.500) 23.75 (0.935)

SAE "BB" involute spline, 15T, 16/32 DP flat root side fit

25.37 25.35 ( 0.999) ( 0.998) 30 1.5 x 45 (0.06)

o

1.5 x 45 (0.06) 50.80 (2.000) 58.7 (2.31)

No. 05 Shaft: SAE B Splined

No. 01 Shaft: SAE B Straight Keyed

SAE "B" involute spline, 13T, 16/32 DP flat root side fit

18.9 (0.74)

6.37 22.22 6.35 x long key (0.251) (0.875) (0.250) 22.22 22.20 ( 0.875) ( 0.874) 25.12 24.87 (0.989) (0.979)

1.5 (0.06) x 45

33.3 (1.31)

1.5 x 45 (0.06)

33.32 (1.312) 41.1 (1.62) 44.4 (1.75)

EATON Vickers E Series Piston Pumps V-PP-MC-0001-E March 2003

25

Thru-drives PVE19/21 SAE A Thru-drives

Millimeters (inches)

PVE 19/21 SAE A THRU-DRIVES

Thrushaft

Spline Data

DIM. A mm (in.)

DIM. B mm (in.)

DIM. C mm (in.)

Max Torque Rating N.m (In. lbs.)

Coupling Length Dim D mm (in.)

AA

864224 62,7 (2.47) 62,2 (2.45) AB 11 teeth 16/32DP 50,8 14,5 22,6 123 864325 Flat Root Side Fit (2.00) (0.57) (0.89) (1100) 60,9 (2.40) 60,7 (2.39) Note: Couplings, screws and washers must be ordered separately to mount rear pump. A O-ring (AS568-042) is included with each thru-drive pump.

9 teeth 16/32DP Flat Root Side Fit

50,8 (2.00)

12,7 (0.50)

22,6 (0.89)

58 (517)

142,4 (5.61) 98,6 (3.88) 197,4 (7.77) 101,60 101,55 ( 4.000) ( 3.998) #2 SHAFT SAE B B 42,1 (1.66)

Dim."D" Dim."C" Coupling 82,67 82,57 (3.253) (3.251) 87,42 87,37 (3.442) (3.440) View A A .500-13 UNC 2B thd. 26,9 (1.06 deep) 8 plcs. for 38,1 (1.50) bolt flange

176,3 (6.94) 191,2 (7.53)

Dim. "B"

Drain port "D1" .875-14 UNF-2B thd. SAE O-ring boss connection 0.625 O.D. tubing Dim. "A"

Note: Ports are reversed for R.H. Rotation

L.H. rotation 34,0 (1.34) 20,3 R (0.80 R) 56,9 (2.24) 120,6 (4.75) 45,9 (1.81)

Load sensing control port .4375-20 UNF-2B thd. SAE Oring boss connection .250 O.D. tubing

69,8 (1.37) Inlet Port 1.50 SAE J518 4 bolt flange 34,9 std pressure (1.37) series 17,8 (.703) 35,7 (1.41) .375-16 UNC 2 plcs. 18,2 (.72) deep) 95,2 (3.75) D1 A

14,15 14,53 (0.557) (0.572)

73,02 (2.875) 146,05 (5.750)

101,6 101,5 (4.000 3.998)

Port1.00 outlet SAE J518 4 bolt flange Std. pressure series (L.H.) SAE "A" Mtg flg. .375-16 UNC-2B thd. 22,3 (.88) deep 4 plcs. 84,8 (3.34) 52,4 (2.06) 73,6 88.1 (3.47) (2.90) 84,8 (3.34) Alternate drain port "D2" .875-14 UNF-2B thd. SAE O-ring boss connection 0.625 O.D. tubing

91,4 A (3.60) 53,1 (2.09) 106,3 (4.18) 91,9 (3.62) 184,1 (7.25)

26

73,02 (2.875) 242,1 (9.53)

EATON Vickers E Series Piston Pumps V-PP-MC-0001-E March 2003

Thru-drives PVE 19/21 SAE B Thru-drives

Millimeters (inches)

PVE 19/21 SAE B THRU-DRIVES

Thrushaft

Spline Data

Max Torque Rating N.m (In. lbs.)

DIM. A mm (in.)

Coupling Length Dim D mm (in.)

10,9 864307 (0.43) 26T/13T 20,6 475134 (0.81) 26T/15T 24,9 627168 (0.98) 26T/26T Note: Couplings, screws and washers must be ordered separately to mount rear pump. A O-ring (AS568-155) is included with each thru-drive pump. * Total input to front pump must not exceed input shaft limit! Thru shaft tongue maybe less baied on maximum input tongue to front pump.

AE

Special Eaton 26 tooth 32/64DP Flat Root Side Fit

179 (1587)

191,0 (7.52) 142,4 (5.61) 98,6 (3.88) 197,4 (7.77) 101,60 101,55 ( 4.000) ( 3.998)

Outlet port 1.3125-12 UF-2B thd. SAE O-ring boss connection 1.000 O.D. tubing 95,3 (3.75)

#2 SHAFT SAE BB 42,1 (1.66)

95,3 (3.75) Drain port "D1" .875-14 UNF-2B thd. SAE O-ring boss connection 0.625 O.D. tubing Inlet port 1.875 12 UN2B thd. SAE O-ring boss connection 1.500 O.D. tubing Coupling (See table)

Note: Ports are reversed for L.H. Rotation

176,3 (6.94)

34,0 (1.34)

120,6 (4.75) 137,2 (5.40)

Load sensing control port .4375-20 UNF-2B thd. SAE Oring boss connection .250 O.D. tubing 45,9 (1.81) 9.6 (.38)

101,67 101,62 ( 4.003) ( 4.001) 107,31 107,06 ( 4.225) (4.215) 12,0 (4.75) 84,8 (3.34) 63,5 84,8 (2.50) (3.34) D1

20,3 R (0.80 R) 56,9 (2.24)

Dim. "A"

14,15 14,53 (0.557) (0.572)

73,02 (2.875) 146,05 (5.750) R.H. rotation

101,6 101,5 (4.000 3.998) Alternate drain port "D2" .875-14 UNF-2B thd. SAE O-ring boss connection 0.625 O.D. tubing

95,7 (3.77)

91,4 (3.60)

19,8 (0.78) 12,7 (0.50) 57,1 (2.825 254,7 (10.03)

73,0 (2.87) 146,0 (5.75) 98,3 (3.87) 196,6 (7.74)

EATON Vickers E Series Piston Pumps V-PP-MC-0001-E March 2003

27

Thru-drives PVE 19/21 SAE B Thru-drives

Millimeters (inches)

Thru-drive Pump Support Bracket An optional support bracket should be used when a heavy second pump is mounted to a thru-drive PVE19/21. The support bracket (627179), two screws (199740), and two washers (427700) must be ordered separately.

11,6 (0.46) 33,7 82,5 55,3 (1.33) (3.25) (2.18) 19,0 (0.75) 28,5 (1.125)

171,4 (6.75) 147,8 (5.82) 85,8 (3.38) 17,27 R (0.68)

10,41 2 (0.410) holes 10,29 (0.405) 12,85 2 (0.506) holes 12,73 (0.501) 19,0 (0.75) 28,5 (1.12)

85,85 (3.38)

19,05 (0.75) 114,3 (4.50)

EATON Vickers E Series Piston Pumps V-PP-MC-0001-E March 2003

28

Application Data

Fluid Cleanliness Proper fluid condition is essential for long and satisfactory life of hydraulic components and systems. Hydraulic fluid must have the correct balance of cleanliness, materials, and additives for protection against wear of components, elevated viscosity, and inclusion of air. Essential information on the correct methods for treating hydraulic fluid is included in

Eaton publication 561 Eaton Guide to Systemic Contamination Control available from your local Eaton distributor or by contacting Eaton Hydraulics. Recommendations on filtration and the selection of products to control fluid condition are included in 561. Recommended cleanliness levels, using petroleum oil under common conditions, are based

on the highest fluid pressure levels in the system and are coded in the chart below. Fluids other than petroleum, severe service cycles, or temperature extremes are cause for adjustment of these cleanliness codes. See Eaton publication 561 for exact details. Eaton products, as any components, will operate with apparent satisfaction in fluids

with higher cleanliness codes than those described. Other manufacturers will often recommend levels above those specified. Experience has shown, however, that life of any hydraulic component is shortened in fluids with higher cleanliness codes than those listed below. These codes have been proven to provide a long, trouble-free service life for the products shown, regardless of the manufacturer.

FLUID CLEANLINESS

System Pressure Level

Product Piston Pumps Variable Vane Pumps Fixed

bar (psi) <70 (<1000) 18/16/14

70-210 (1000-3000) 17/15/13

210+ (3000+) 16/14/12

Fire resistant fluids Water glycol, phosphate ester and polyol ester fluids may be used with PVE pumps. With the PVE012 and PVE19, system pressure and input speed should not exceed 140 bar (2000 psi) and 1800 r/min. System temperature should not exceed 54C (130F). Inlet vacuum should not exceed 101,6 millibar (3 in. Hg.).

Hydraulic fluids and temperature ranges Use antiwear hydraulic oil, or automotive type crankcase oil designations SC, SD, SE or SF per SAE J183FEB80. Select a viscosity grade that will allow optimum viscosity, between 40 cSt (180 SUS) and 16 cST (80 SUS), to be achieved within the optimum performance envelope shown. For further information, see Eaton Hydraulic Hints and Trouble Shooting Guide.

Ordering procedure Order PVE pumps by the full model designation. Pump displacement, mounting flange type, direction of rotation, pump configuration, shaft end type, seals, pressure adjustment range, specific control functions are all specified in the full model code.

EATON Vickers E Series Piston Pumps V-PP-MC-0001-E March 2003

29

Eaton 14615 Lone Oak Road Eden Prairie, MN 55344 USA Tel: 952 937-9800 Fax: 952 974-7722 www.hydraulics.eaton.com

Eaton 20 Rosamond Road Footscray Victoria 3011 Australia Tel: (61) 3 9319 8222 Fax: (61) 3 9318 5714

Eaton Dr.-Reckeweg-Str. 1 D-76532 Baden-Baden Germany Tel: (49) 7221 682-0 Fax: (49) 7221 682-788

Vickers

2003 Eaton Corporation All Rights Reserved Printed in USA Document No. V-PP-MC-0001-E Supercedes 11-06-0001-EN-0801 March 2003

You might also like

- GREAT WRITING 1: Great Sentences For Great Paragraphs: Unit 1 Sentence BasicsDocument19 pagesGREAT WRITING 1: Great Sentences For Great Paragraphs: Unit 1 Sentence Basicssara90% (30)

- DH and DS Series 1 Repair InstructionsDocument12 pagesDH and DS Series 1 Repair InstructionsServicio TLMNo ratings yet

- Reyco PDFDocument44 pagesReyco PDFJavier Yandun100% (1)

- Valve Ls LindeDocument24 pagesValve Ls Lindele100% (2)

- 314Document65 pages314dim4erema100% (3)

- Giraffe Blood CirculationDocument9 pagesGiraffe Blood Circulationthalita asriandinaNo ratings yet

- BioPsychoSocial JongsmaDocument4 pagesBioPsychoSocial Jongsmarredmond100% (2)

- MINI Cooper Service Manual: 2002-2006 - Table of ContentsDocument2 pagesMINI Cooper Service Manual: 2002-2006 - Table of ContentsBentley Publishers40% (5)

- Especificacion Pve21 PDFDocument28 pagesEspecificacion Pve21 PDFarmando vara chavezNo ratings yet

- Eaton Hidraulic PumpsDocument28 pagesEaton Hidraulic Pumpspecirepi100% (1)

- Eaton Medium Pressure Closed Circuit Servo Controlled Piston Pump Model72400 Parts Information e Pupi tp009 e en UsDocument17 pagesEaton Medium Pressure Closed Circuit Servo Controlled Piston Pump Model72400 Parts Information e Pupi tp009 e en Usخالد العتيبي100% (1)

- C Molo TM003 eDocument8 pagesC Molo TM003 ejcclaNo ratings yet

- Orbit RolDocument12 pagesOrbit RolFabio MartinsNo ratings yet

- Re15209 03-95Document8 pagesRe15209 03-95Kaushik GhoshNo ratings yet

- HM (HD) B 200: Staffa Fixed Displacement Hydraulic MotorDocument16 pagesHM (HD) B 200: Staffa Fixed Displacement Hydraulic MotorUsama PopatiaNo ratings yet

- Re15206 2009-07 PDFDocument18 pagesRe15206 2009-07 PDFВладиславМасарскийNo ratings yet

- H1 New Hydrostatics: of - The GenerationDocument69 pagesH1 New Hydrostatics: of - The GenerationJose Manuel Barroso PantojaNo ratings yet

- Series 45 Frame F 74-90 Parts ManualDocument160 pagesSeries 45 Frame F 74-90 Parts ManualArko RoosNo ratings yet

- Re15205 02-98Document12 pagesRe15205 02-98Timon2005100% (1)

- 510B Backhoe Loader: Engine PerformanceDocument5 pages510B Backhoe Loader: Engine PerformancebalajimetturNo ratings yet

- Eaton: Parts InformationDocument2 pagesEaton: Parts InformationFernando SabinoNo ratings yet

- Transmission - Valve, Regulator and Oil PumpDocument2 pagesTransmission - Valve, Regulator and Oil PumpSilvio Roman100% (1)

- Spicer C9000 Series Torque Converter SpecificationDocument2 pagesSpicer C9000 Series Torque Converter SpecificationFranklin LabbeNo ratings yet

- Exc 9030B Mod. Controlador Nexsb00800 - 60KBDocument3 pagesExc 9030B Mod. Controlador Nexsb00800 - 60KBIngeniero Electromecanico100% (1)

- 432d Signal Resolver Network - CheckDocument6 pages432d Signal Resolver Network - CheckDiego CatariNo ratings yet

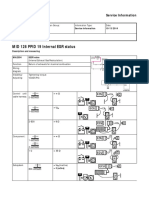

- MID 128 PPID 19 Internal EGR Status: Service InformationDocument1 pageMID 128 PPID 19 Internal EGR Status: Service Informationargya AwangNo ratings yet

- Service Manual SM - B110-B115 - 35 - ENDocument128 pagesService Manual SM - B110-B115 - 35 - ENaritmeticsNo ratings yet

- Axial Piston Fixed Motor A4Fm: Replaces: - . - English Series 1 and 3Document48 pagesAxial Piston Fixed Motor A4Fm: Replaces: - . - English Series 1 and 3Anonymous bVi38aVNo ratings yet

- Korota Brochure EngDocument5 pagesKorota Brochure EngKorotaSANo ratings yet

- Series 42 4T: Axial Piston Tandem PumpsDocument56 pagesSeries 42 4T: Axial Piston Tandem PumpsRachid KerdidiNo ratings yet

- Series 40 M46 Axial Piston Pump Parts Manual PDFDocument2 pagesSeries 40 M46 Axial Piston Pump Parts Manual PDFVAHAGNNo ratings yet

- M25 Axial Piston Pump: Series 40Document20 pagesM25 Axial Piston Pump: Series 40Miguel100% (1)

- H1P 147 165 Parts List 2015 PDFDocument132 pagesH1P 147 165 Parts List 2015 PDFArko RoosNo ratings yet

- Manual de Reparacion MCR Serie 32-33Document34 pagesManual de Reparacion MCR Serie 32-33Fernando Tapia Gibson100% (2)

- Great Plains Parts Manual NTA-907 & NTA-3007Document170 pagesGreat Plains Parts Manual NTA-907 & NTA-3007a04205No ratings yet

- Series 90 42cc Pump - PM - 520L0838 - Rev BB - April 2008Document68 pagesSeries 90 42cc Pump - PM - 520L0838 - Rev BB - April 2008Jose Manuel Barroso PantojaNo ratings yet

- Orbitrol 2752 HGB ServiceDocument24 pagesOrbitrol 2752 HGB ServiceHenry Valeriano MaqueraNo ratings yet

- M4 Spool Replacement PDFDocument11 pagesM4 Spool Replacement PDFMira RedaNo ratings yet

- Service Manual 300050007500 PermconDocument19 pagesService Manual 300050007500 PermconMiguel Angel Santos PintadoNo ratings yet

- 45 Series F Frame 74cc and 90cc Parts Manual (11007197 Rev AA Feb 2007)Document48 pages45 Series F Frame 74cc and 90cc Parts Manual (11007197 Rev AA Feb 2007)Alaa saidNo ratings yet

- 004443896W Level 0 1 2 2 2 2 2 2 2 3 3 3 3 2 2 3 3 1 2 2 2 1 2 2 2 2 2 2 2 3 3 3 4 4 4 4 4 2 3 3 3 4 4 4 4Document6 pages004443896W Level 0 1 2 2 2 2 2 2 2 3 3 3 3 2 2 3 3 1 2 2 2 1 2 2 2 2 2 2 2 3 3 3 4 4 4 4 4 2 3 3 3 4 4 4 4Partagon PowNo ratings yet

- OMH - RI - Repair InstructionsDocument16 pagesOMH - RI - Repair Instructionsjose manuel barroso pantoja100% (1)

- Manual T650 y T950Document20 pagesManual T650 y T950furtanNo ratings yet

- C & D Series Backhoe Loader Diagnostics: Service TrainingDocument25 pagesC & D Series Backhoe Loader Diagnostics: Service TrainingFaustoNo ratings yet

- Service Training Parker PV Series 42Document39 pagesService Training Parker PV Series 42Javier PeñaNo ratings yet

- 林德HPR 02 RegulatingDocument24 pages林德HPR 02 RegulatingxxshNo ratings yet

- 005 Joystick 2Document8 pages005 Joystick 2JonathanDavidDeLosSantosAdornoNo ratings yet

- MS83 PDFDocument32 pagesMS83 PDFSubhash KediaNo ratings yet

- 520L0586 MMF044Document48 pages520L0586 MMF044vendas servicosNo ratings yet

- Service Manual BL70B 3 Electrical and Information Systems Description and Troubleshooting PDFDocument149 pagesService Manual BL70B 3 Electrical and Information Systems Description and Troubleshooting PDFВалентин МитовNo ratings yet

- Great Plains Parts Manual NTA607HD & NTA2007HDDocument176 pagesGreat Plains Parts Manual NTA607HD & NTA2007HDa04205No ratings yet

- Servodirectii OrbitaleDocument12 pagesServodirectii OrbitaleIonescu AngelNo ratings yet

- Hydraulic Excavator R 906 Classic / R 916 Classic / R 926 ClassicDocument6 pagesHydraulic Excavator R 906 Classic / R 916 Classic / R 926 ClassicRiza DS100% (1)

- Kaltfrase - BM - 1000 - 1200 - 1300 - 30 - 2 - & - 2 - PB - BK HidraulicoDocument249 pagesKaltfrase - BM - 1000 - 1200 - 1300 - 30 - 2 - & - 2 - PB - BK Hidraulicosebastian blancoNo ratings yet

- T6CC/T6DC/T6EC/T6ED Series: Parker Denison T6 Double Hydraulic Vane PumpDocument56 pagesT6CC/T6DC/T6EC/T6ED Series: Parker Denison T6 Double Hydraulic Vane Pumpbadawai sallamNo ratings yet

- Parker Cylinder PDFDocument84 pagesParker Cylinder PDFRavi Chaitanya VelamarthyNo ratings yet

- Service Parts Manual: Series 40 M25 Axial Piston MotorDocument24 pagesService Parts Manual: Series 40 M25 Axial Piston Motorjose manuel barroso pantoja100% (1)

- Eaton Steering UnitDocument1 pageEaton Steering UnitAndresz A SimbaquebaNo ratings yet

- Mini Cargado 440 7-9733-CD PDFDocument1,820 pagesMini Cargado 440 7-9733-CD PDFoscar el carevergaNo ratings yet

- K3VL Parts List Updated 8-19-09 PDFDocument17 pagesK3VL Parts List Updated 8-19-09 PDFrjan7pe100% (1)

- Section 35 - Hydraulic System Chapter 4 - Hydraulic PumpDocument28 pagesSection 35 - Hydraulic System Chapter 4 - Hydraulic PumpHelver Alonso MancipeNo ratings yet

- PVEO12Document30 pagesPVEO12Elvin DomingoNo ratings yet

- Hydrokraft Transmission Closed Loop Piston Pumps: Technical Catalog TVXDocument52 pagesHydrokraft Transmission Closed Loop Piston Pumps: Technical Catalog TVXbrunosamaeianNo ratings yet

- Vickers H SeriesDocument27 pagesVickers H Serieskaoblekstena100% (1)

- Eaton Hydrokraft Transmission Closed Loop TVW Series Piston Pump Technical Catalog V Pupi tm002 e en UsDocument56 pagesEaton Hydrokraft Transmission Closed Loop TVW Series Piston Pump Technical Catalog V Pupi tm002 e en UsPartagon PowNo ratings yet

- Mechanical Waves Class 11 JEE Handwritten NotesDocument66 pagesMechanical Waves Class 11 JEE Handwritten Notessmeet mehtaNo ratings yet

- Single-Phase Half-Bridge InverterDocument29 pagesSingle-Phase Half-Bridge InverterSwati MishraNo ratings yet

- Media Converter Datasheet: HighlightsDocument2 pagesMedia Converter Datasheet: HighlightsJames JamesNo ratings yet

- Lab 16 - Law of Definite CompositionDocument6 pagesLab 16 - Law of Definite CompositionMicah YapNo ratings yet

- Curriculum Vitae (CV) : Data PribadiDocument2 pagesCurriculum Vitae (CV) : Data Pribadingurah.gde.ariNo ratings yet

- 01 eLMS Activity 1 Network TechnologyDocument2 pages01 eLMS Activity 1 Network Technologybasahara sengokuNo ratings yet

- Machine Learning in GeoscienceDocument22 pagesMachine Learning in GeoscienceAde PrayudaNo ratings yet

- Industrial Crops & ProductsDocument10 pagesIndustrial Crops & ProductsShield YggdrasilNo ratings yet

- Meng 310 Exam 01 Spring 2010Document4 pagesMeng 310 Exam 01 Spring 2010Abdulrahman AlzahraniNo ratings yet

- Market SegmentationDocument30 pagesMarket Segmentationmldc2011No ratings yet

- Exam Ib: MECH 230 DynamicDocument3 pagesExam Ib: MECH 230 Dynamickamal saadNo ratings yet

- Screencast RubricDocument2 pagesScreencast Rubricapi-272483612No ratings yet

- 1) What Is Budgetary Control?Document6 pages1) What Is Budgetary Control?abhiayushNo ratings yet

- Part Ii: A BC ACB ABC Ø XyzDocument2 pagesPart Ii: A BC ACB ABC Ø XyzHamza NagraNo ratings yet

- BUS 500 Skills in Business Communication PDFDocument8 pagesBUS 500 Skills in Business Communication PDFrakin tajwarNo ratings yet

- Des-F1025p-E DSDocument3 pagesDes-F1025p-E DSNaing Win ZawNo ratings yet

- Hi-Scan 180180-2is Pro: Heimann X-Ray TechnologyDocument2 pagesHi-Scan 180180-2is Pro: Heimann X-Ray Technologyraza514100% (1)

- Language On Music Beethoven, Mann and The Absolute Francois Verster PDFDocument209 pagesLanguage On Music Beethoven, Mann and The Absolute Francois Verster PDFPetar VujicinNo ratings yet

- IMC 151 - PAIR AssignmentDocument37 pagesIMC 151 - PAIR Assignmentfarishaemylia40No ratings yet

- Prepared By:: Dr. Shamsad AhmedDocument29 pagesPrepared By:: Dr. Shamsad AhmedNusrat Jahan NafisaNo ratings yet

- Codemap - 2021 No-Code Market ReportDocument34 pagesCodemap - 2021 No-Code Market ReportLogin AppsNo ratings yet

- SIP Presentation On MSMEDocument15 pagesSIP Presentation On MSMEShradha KhandareNo ratings yet

- Repair-Training Quotation: Dododo Medical Equipment Service Co.,LtdDocument1 pageRepair-Training Quotation: Dododo Medical Equipment Service Co.,LtdPhong DoNo ratings yet

- Cabin Crew Prepare Take Off Webinar PresentationDocument23 pagesCabin Crew Prepare Take Off Webinar PresentationTakele KalebNo ratings yet

- NURS FPX 6614 Assessment 1 Defining A Gap in PracticeDocument6 pagesNURS FPX 6614 Assessment 1 Defining A Gap in PracticeCarolyn HarkerNo ratings yet