Professional Documents

Culture Documents

Tablica-1-Celicni Livovi PDF

Tablica-1-Celicni Livovi PDF

Uploaded by

serzo75Copyright:

Available Formats

You might also like

- ASME-GB Steel Grades Comparison TableDocument11 pagesASME-GB Steel Grades Comparison TableAsad Hafeez100% (2)

- GOST Steels PDFDocument88 pagesGOST Steels PDFDiogo Roesler MeloNo ratings yet

- Citroen SaxoDocument2 pagesCitroen Saxoserzo75100% (1)

- Product Code:: Pkg/Ro/41 Special SteelsDocument9 pagesProduct Code:: Pkg/Ro/41 Special SteelsPranav TripathiNo ratings yet

- Vergleichstabelle Von Verschiedenen Stahlsorten Nach Werkstoff-NummernDocument6 pagesVergleichstabelle Von Verschiedenen Stahlsorten Nach Werkstoff-NummerndarkquinkNo ratings yet

- JIS DIN ASTM Steel, Alloy, Cast Iron SpecificationsDocument1 pageJIS DIN ASTM Steel, Alloy, Cast Iron SpecificationsBao Duy NguyenNo ratings yet

- SM490 Ya-Yb ChemicalDocument1 pageSM490 Ya-Yb ChemicalJoko TrisnantoNo ratings yet

- En 10025-2 ExtractDocument1 pageEn 10025-2 Extractpalani.djpNo ratings yet

- EN 10213 Material SpecificationsDocument1 pageEN 10213 Material Specifications김창배No ratings yet

- BS EN 10293 InformationDocument2 pagesBS EN 10293 Informationchief_of_stuffNo ratings yet

- Sepction - 2Document4 pagesSepction - 2k koradiaNo ratings yet

- S355J2Document5 pagesS355J2jon perez diezNo ratings yet

- Aluminio BRONMETAL enDocument12 pagesAluminio BRONMETAL enPerica RakićNo ratings yet

- Steel Specification-Kalyani ForgeDocument8 pagesSteel Specification-Kalyani ForgedramiltNo ratings yet

- Soporte Metalico Tipo Cristo SMC Soporte Concreto Durmiente SCDDocument1 pageSoporte Metalico Tipo Cristo SMC Soporte Concreto Durmiente SCDRamon MNo ratings yet

- Steel EquivalentDocument4 pagesSteel EquivalentsudeponnaniNo ratings yet

- Tipos de Acero Inoxidable Inoxfil PDFDocument1 pageTipos de Acero Inoxidable Inoxfil PDFColibrí SaldañaNo ratings yet

- Tipos de Acero Inoxidable Inoxfil PDFDocument1 pageTipos de Acero Inoxidable Inoxfil PDFColibrí SaldañaNo ratings yet

- Tipos de Acero Inoxidable Inoxfil PDFDocument1 pageTipos de Acero Inoxidable Inoxfil PDFColibrí SaldañaNo ratings yet

- Low Alloy Steels Part2Document1 pageLow Alloy Steels Part2fedaquiNo ratings yet

- 300 M Latrobe Special AlloysDocument4 pages300 M Latrobe Special AlloysCristiano BeckNo ratings yet

- Mag General Business: Mill Test CertificateDocument1 pageMag General Business: Mill Test CertificateAnonymous 6LwW4qi6TiNo ratings yet

- Fbjplummer Block HousingsDocument8 pagesFbjplummer Block HousingsSara CorredorNo ratings yet

- Steel Grade: Material Data SheetDocument3 pagesSteel Grade: Material Data Sheetprabhu vijayanNo ratings yet

- En10028 2Document12 pagesEn10028 2Patilea Daniela100% (1)

- WWW Wollastonalloys Com Materials 2Document8 pagesWWW Wollastonalloys Com Materials 2Mark RomeroNo ratings yet

- Aluminium Diecasting MaterialDocument2 pagesAluminium Diecasting MaterialzainudinNo ratings yet

- Model 723 "Saddle-Let" Small Mechanical TeeDocument2 pagesModel 723 "Saddle-Let" Small Mechanical TeemiturraNo ratings yet

- 6-Carbon SteelsDocument20 pages6-Carbon SteelsMunim DarNo ratings yet

- S275 S355 Data Sheet 2021Document1 pageS275 S355 Data Sheet 2021CarloNo ratings yet

- Steel Grade: Material Data SheetDocument3 pagesSteel Grade: Material Data SheetBouremana AnèsNo ratings yet

- Steel Grade: Material Data SheetDocument3 pagesSteel Grade: Material Data Sheetdinesh kumarNo ratings yet

- Aisi 4140Document8 pagesAisi 4140ViruzTrisnaNo ratings yet

- Tieu Chuan Ky Thuat Thep PominaDocument3 pagesTieu Chuan Ky Thuat Thep PominaColombus ChristopherNo ratings yet

- Aceros Tabla DipticoDocument1 pageAceros Tabla DipticoBeatriz Ruiz UrueñaNo ratings yet

- EN 16983 (Ex DIN 2093) Dim 2Document3 pagesEN 16983 (Ex DIN 2093) Dim 2Roby MastreNo ratings yet

- Carbon Steel Pipes Dimensions + Mass KG-MDocument1 pageCarbon Steel Pipes Dimensions + Mass KG-Ma_roghibNo ratings yet

- Composition of Steel (Astm Standard) (Chemical Composition) : Sr. # Grade C% Si% MN% P% S% CR% Mo% NL% Cu%Document2 pagesComposition of Steel (Astm Standard) (Chemical Composition) : Sr. # Grade C% Si% MN% P% S% CR% Mo% NL% Cu%4lm1nNo ratings yet

- Wuhan Jianheng Metal Technology CO - LTD 20201015Document20 pagesWuhan Jianheng Metal Technology CO - LTD 20201015梁庆民No ratings yet

- C11000 (Electrolytic Tough Pitch)Document2 pagesC11000 (Electrolytic Tough Pitch)Giang NguyenNo ratings yet

- Steel GradesDocument12 pagesSteel GradesDidar Singh Thethi100% (1)

- Astm A653a 653M 4Document1 pageAstm A653a 653M 4Barbado BlancoNo ratings yet

- Table 1. Chemical Composition of Carbon Steel (Chinese Standard: GB/T 17107-1997) Chemical Contents / %Document1 pageTable 1. Chemical Composition of Carbon Steel (Chinese Standard: GB/T 17107-1997) Chemical Contents / %raobabar21No ratings yet

- GB 17107Document20 pagesGB 17107Qiuo ShenNo ratings yet

- Certificado Reduccion Concentrica 3 X 2Document1 pageCertificado Reduccion Concentrica 3 X 2juan aguilarNo ratings yet

- Material Specifications and Mechanical PropertiesDocument1 pageMaterial Specifications and Mechanical PropertiesSagarKBLNo ratings yet

- Steel Grade: Material Data SheetDocument8 pagesSteel Grade: Material Data SheetSlobodan NocajNo ratings yet

- Equivalent TableDocument1 pageEquivalent Tableliamcs88% (8)

- Wire Rod ENDocument2 pagesWire Rod ENEltjon PumiNo ratings yet

- Columbus Castings Metal Grades PDFDocument1 pageColumbus Castings Metal Grades PDFksangeeth2000No ratings yet

- Chemical PropertiesDocument1 pageChemical PropertiesDanny TriwibowoNo ratings yet

- Tabel Pemilihan Bahan Dan ProsesDocument2 pagesTabel Pemilihan Bahan Dan Prosesrahmid fareziNo ratings yet

- Steel Grade: Material Data SheetDocument6 pagesSteel Grade: Material Data SheetFlorinFlorinNo ratings yet

- 42crmo4 - HardnessDocument8 pages42crmo4 - HardnessavijayakumarsamyNo ratings yet

- Rail Lexicon Mk24Document60 pagesRail Lexicon Mk24serzo75No ratings yet

- Maryland Metrics - Fastener Technical DataDocument92 pagesMaryland Metrics - Fastener Technical Dataserzo75100% (1)

- Sect 08 Rail Freight Vehicle Underframe and Body Structures Incl New As Id1Document9 pagesSect 08 Rail Freight Vehicle Underframe and Body Structures Incl New As Id1serzo75No ratings yet

- Tech List enDocument17 pagesTech List enserzo75No ratings yet

- S235J0Document1 pageS235J0serzo75No ratings yet

- Annex CDocument101 pagesAnnex Cserzo75No ratings yet

- Wagons On StockDocument10 pagesWagons On Stockserzo75100% (1)

- Grade S275JRDocument1 pageGrade S275JRserzo75No ratings yet

- Non Alloy Structural Steels S275J2 NDocument1 pageNon Alloy Structural Steels S275J2 Nserzo75No ratings yet

- S355J0Document1 pageS355J0serzo75No ratings yet

- RIVKLEDocument56 pagesRIVKLEserzo75No ratings yet

- Rivkle: Stainless Steel Blind Rivet Nuts Hexagonal Body, Extra-Small Countersunk Head AdvantagesDocument1 pageRivkle: Stainless Steel Blind Rivet Nuts Hexagonal Body, Extra-Small Countersunk Head Advantagesserzo75No ratings yet

- Mazalice: Mazalice I Kuglice Januar 2013Document1 pageMazalice: Mazalice I Kuglice Januar 2013serzo75No ratings yet

- Pojedini Tipovi VijakaDocument4 pagesPojedini Tipovi Vijakaserzo75No ratings yet

- Msds - Mol Calton G 3 - GBDocument8 pagesMsds - Mol Calton G 3 - GBserzo75No ratings yet

- Iso 7040Document1 pageIso 7040serzo75No ratings yet

- Uputstvo Central 17 23 24 28 24M 28MDocument19 pagesUputstvo Central 17 23 24 28 24M 28Mserzo75100% (1)

Tablica-1-Celicni Livovi PDF

Tablica-1-Celicni Livovi PDF

Uploaded by

serzo75Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tablica-1-Celicni Livovi PDF

Tablica-1-Celicni Livovi PDF

Uploaded by

serzo75Copyright:

Available Formats

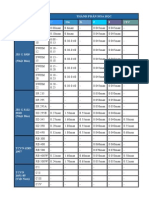

- PRODUCTION PROGRAMME

MARK -

JUS

DIN

CHEMICAL STRUCTURE - %

%C

%SI

Steel cast for general use

CL. 0300

Gs-38

0,12-0.20

030-0.50

CL. 0400

Gs-45

0,18-0.25

030-0.50

CL. 0500

Gs-52

0,27-0.35

0,30-0,50

CL. 0600

Gs-60

0,38-0,49

0.30-0.50

Gs-70

0.50-0.62

0,30-0.50

Steel cast for improvement

CL. 1330

GS-C25

0,18-0.23

030-0.60

CL. 1331

Gs-Kc24

0,20-0.28

O30-0.60

CL. 1430

C-35

0.32-0,39

0.15-035

CL. 1530

C-45

0,42-0.50

0.15-035

CL. 1730

C-60

0.57-0.60

0.15-0,35

CL. 7431

Gs-17CrMo55

0,15-0,20

030-0,60

CL. 3132

Gs-20Mn5

0,17-0,23

030-0.60

CL. 4730

Gs-25CrMo4

0.22-0.29

0.15-0.40

CL. 4731

Gs-34CrMo4

0,30-0,37

0.15-0,40

CL. 4732

Gs-42CrMo4

0,38-0.45

0.15-0.40

Steel cast for cementation

CL. 1220

C-15

0,12-0,18

0,15-035

CL. 4320

16MnCr5

0.14-0,19

0.15-0.40

CL. 5420

15CrNi6

0,12-0,17

0.15-0.40

Wear resistant steel cast

CL. 3134

50Mn7

0.45-0.55

0.15-0.40

CL. 3160

G-x120Mn12

1,1-1,3

0.30-0.50

CL. 3460

G-x120MnCr12.1. 1.1-1.3

0,30-0,50

18%Mn

G-x130MnCr18.2

1.1-U

0,30-0,50

20%Mn

G-x140MnCr20,3

1.1-1.4

0.30-0.50

Higher Chrome steel

CL. 4576

G-x40CrSiNi274

0.30-0.50

1,00-2,50

CL. 4577

G-x40CrNtSi2512 0,30-0,50

1,00-2,50

CL. 4578

G-x40CrNiSi2520 0.30-0,50

1,00-2.50

HS-I

Internal

1.4

1,4

HS-II

Internal

1.3

1,3

G-x300CrMol5.3.

2.3-3.6

0,2-0.8

G-x270CrMn20

2.5-2.9

0.5-0.8

H2Mx

Inlemal

0.45-0.55

0.4-0.8

G-x290CrMn15.1. 2.5-2,8

0.2-0.8

(sphere)

- MECHANICAL CHARACTERISICS

%Mn

%Pmax%Smax

0,50-0.80

030-0.80

0,50-0.80

0.50-0.80

0.50-0.80

0,02

0,02

0.020

0,02

0.020

0,015

0.015

0,015

0.015

0.015

0.50-0,80

0.50-0.80

0.50-0,80

0,50-0.80

0.60-0.90

0.50-0.80

1,0-1,3

0.50-0.80

0.50-0.80

0.50-0.80

0.020

0.020

0.020

0,02

0.020

0,02

0,03

0.030

0,03

0.030

0.015

0.015

0.015

0.015

0.015

0.015

0.020

0.020

0.020

0.020

0.30-0,60

1.0-1.3

0.40-0,60

0,03

0.030

0.030

0.020

0,02

0.020

1.5-2.0

11.5-13.5

11.5-13,5

18.00

20.00

0.030

0,02

<0,10

<0,040

<0,10<0 <0.040 1,0-1,5

10<0,10 <0.040

1.9

<0,040 2.5%Cf

0.5-1.5

0.5-1,5

0.5-1.5

0,6

0,75

0.5-1,0

0,8-1,2

1.0-1,5

0.5-1.0

0,03

0,03

0.030

0.030

0.030

-

0.030

0.030

0.030

0.030

0.020

0,02

%Cr

%NI

%Mo

<030

<0.30

1,0-1.5

<0.30

0.9-1.2

0.9-1.2

0.9-1.2

0.8-1.1

1.4-1,7

26-28

24026

24-26

30.00

25.00

14-17.0

18-20

0.80-1,3

16-18

0.45-0.55

0.15-030

0,15-0,30

0.15-0.30

1,4-1.7

N/mm2

Re0.2

N/mm2 Rm

%As

%Z

JOUL ISO- HB V

HARDNESS

DELIVERY STATE -

215-235

235-285

275-355

345-365

360-440

410-530

490-610

590-710

690-840

25

22

20

15

10

40

31

25

21

35

27

27

27

20-27

N

N

N

N

N

235 (245)

235 (245)

275 (365)

335(410)

380 (490)

315

280 min.

345 (590)

440 (665)

490 (765)

410-520(440-590)

410-520(440-590)

490-640 (580-730)

590-740(660-810)

690-890 (780-930)

490-640

500-650

540-690 (780-930)

690-830(880-1080)

690-830(980-1180)

27(22)

27(22)

21 (19)

17(14)

14(13)

20

22

16(14)

12(12)

11 (11)

-(45)

-(50)

-(40)

-(35)

-(30)

35

-(55)

-(50)

-(45)

-(27)

-(27)

-(41)

-(27)

53HRC

27

27 (-45 C)

41 (55)

27(48)

21(41)

355

590

635

590-700

780-1080

880-1180

14

10

40

40

17(7)

30

339(1050) 580-700(1200-1400)

350

800-1000

Bending

test

3,5-5.5

11-14

19-21

43

0.7-1.0

1,8-2.2

1.9-2.1

0.5

3.0

0.4

0.4-0.6

<0,4

127-169

140-183

145-185

170-210

170-210

220 (340-430)

175-240

175-240

190-260

190-260

N(P)

58060 HRC

58-60 HRC

45-55 HRC

58-60 HRC

.

.

.

.

fireproof prochrom

50-100 G/ton

consumption 50-100 G/ton

N(P)

N(P)

N(P)

N(P)

N(P)

P

N 22 HRC

N(P)

N(P)

N(P)

You might also like

- ASME-GB Steel Grades Comparison TableDocument11 pagesASME-GB Steel Grades Comparison TableAsad Hafeez100% (2)

- GOST Steels PDFDocument88 pagesGOST Steels PDFDiogo Roesler MeloNo ratings yet

- Citroen SaxoDocument2 pagesCitroen Saxoserzo75100% (1)

- Product Code:: Pkg/Ro/41 Special SteelsDocument9 pagesProduct Code:: Pkg/Ro/41 Special SteelsPranav TripathiNo ratings yet

- Vergleichstabelle Von Verschiedenen Stahlsorten Nach Werkstoff-NummernDocument6 pagesVergleichstabelle Von Verschiedenen Stahlsorten Nach Werkstoff-NummerndarkquinkNo ratings yet

- JIS DIN ASTM Steel, Alloy, Cast Iron SpecificationsDocument1 pageJIS DIN ASTM Steel, Alloy, Cast Iron SpecificationsBao Duy NguyenNo ratings yet

- SM490 Ya-Yb ChemicalDocument1 pageSM490 Ya-Yb ChemicalJoko TrisnantoNo ratings yet

- En 10025-2 ExtractDocument1 pageEn 10025-2 Extractpalani.djpNo ratings yet

- EN 10213 Material SpecificationsDocument1 pageEN 10213 Material Specifications김창배No ratings yet

- BS EN 10293 InformationDocument2 pagesBS EN 10293 Informationchief_of_stuffNo ratings yet

- Sepction - 2Document4 pagesSepction - 2k koradiaNo ratings yet

- S355J2Document5 pagesS355J2jon perez diezNo ratings yet

- Aluminio BRONMETAL enDocument12 pagesAluminio BRONMETAL enPerica RakićNo ratings yet

- Steel Specification-Kalyani ForgeDocument8 pagesSteel Specification-Kalyani ForgedramiltNo ratings yet

- Soporte Metalico Tipo Cristo SMC Soporte Concreto Durmiente SCDDocument1 pageSoporte Metalico Tipo Cristo SMC Soporte Concreto Durmiente SCDRamon MNo ratings yet

- Steel EquivalentDocument4 pagesSteel EquivalentsudeponnaniNo ratings yet

- Tipos de Acero Inoxidable Inoxfil PDFDocument1 pageTipos de Acero Inoxidable Inoxfil PDFColibrí SaldañaNo ratings yet

- Tipos de Acero Inoxidable Inoxfil PDFDocument1 pageTipos de Acero Inoxidable Inoxfil PDFColibrí SaldañaNo ratings yet

- Tipos de Acero Inoxidable Inoxfil PDFDocument1 pageTipos de Acero Inoxidable Inoxfil PDFColibrí SaldañaNo ratings yet

- Low Alloy Steels Part2Document1 pageLow Alloy Steels Part2fedaquiNo ratings yet

- 300 M Latrobe Special AlloysDocument4 pages300 M Latrobe Special AlloysCristiano BeckNo ratings yet

- Mag General Business: Mill Test CertificateDocument1 pageMag General Business: Mill Test CertificateAnonymous 6LwW4qi6TiNo ratings yet

- Fbjplummer Block HousingsDocument8 pagesFbjplummer Block HousingsSara CorredorNo ratings yet

- Steel Grade: Material Data SheetDocument3 pagesSteel Grade: Material Data Sheetprabhu vijayanNo ratings yet

- En10028 2Document12 pagesEn10028 2Patilea Daniela100% (1)

- WWW Wollastonalloys Com Materials 2Document8 pagesWWW Wollastonalloys Com Materials 2Mark RomeroNo ratings yet

- Aluminium Diecasting MaterialDocument2 pagesAluminium Diecasting MaterialzainudinNo ratings yet

- Model 723 "Saddle-Let" Small Mechanical TeeDocument2 pagesModel 723 "Saddle-Let" Small Mechanical TeemiturraNo ratings yet

- 6-Carbon SteelsDocument20 pages6-Carbon SteelsMunim DarNo ratings yet

- S275 S355 Data Sheet 2021Document1 pageS275 S355 Data Sheet 2021CarloNo ratings yet

- Steel Grade: Material Data SheetDocument3 pagesSteel Grade: Material Data SheetBouremana AnèsNo ratings yet

- Steel Grade: Material Data SheetDocument3 pagesSteel Grade: Material Data Sheetdinesh kumarNo ratings yet

- Aisi 4140Document8 pagesAisi 4140ViruzTrisnaNo ratings yet

- Tieu Chuan Ky Thuat Thep PominaDocument3 pagesTieu Chuan Ky Thuat Thep PominaColombus ChristopherNo ratings yet

- Aceros Tabla DipticoDocument1 pageAceros Tabla DipticoBeatriz Ruiz UrueñaNo ratings yet

- EN 16983 (Ex DIN 2093) Dim 2Document3 pagesEN 16983 (Ex DIN 2093) Dim 2Roby MastreNo ratings yet

- Carbon Steel Pipes Dimensions + Mass KG-MDocument1 pageCarbon Steel Pipes Dimensions + Mass KG-Ma_roghibNo ratings yet

- Composition of Steel (Astm Standard) (Chemical Composition) : Sr. # Grade C% Si% MN% P% S% CR% Mo% NL% Cu%Document2 pagesComposition of Steel (Astm Standard) (Chemical Composition) : Sr. # Grade C% Si% MN% P% S% CR% Mo% NL% Cu%4lm1nNo ratings yet

- Wuhan Jianheng Metal Technology CO - LTD 20201015Document20 pagesWuhan Jianheng Metal Technology CO - LTD 20201015梁庆民No ratings yet

- C11000 (Electrolytic Tough Pitch)Document2 pagesC11000 (Electrolytic Tough Pitch)Giang NguyenNo ratings yet

- Steel GradesDocument12 pagesSteel GradesDidar Singh Thethi100% (1)

- Astm A653a 653M 4Document1 pageAstm A653a 653M 4Barbado BlancoNo ratings yet

- Table 1. Chemical Composition of Carbon Steel (Chinese Standard: GB/T 17107-1997) Chemical Contents / %Document1 pageTable 1. Chemical Composition of Carbon Steel (Chinese Standard: GB/T 17107-1997) Chemical Contents / %raobabar21No ratings yet

- GB 17107Document20 pagesGB 17107Qiuo ShenNo ratings yet

- Certificado Reduccion Concentrica 3 X 2Document1 pageCertificado Reduccion Concentrica 3 X 2juan aguilarNo ratings yet

- Material Specifications and Mechanical PropertiesDocument1 pageMaterial Specifications and Mechanical PropertiesSagarKBLNo ratings yet

- Steel Grade: Material Data SheetDocument8 pagesSteel Grade: Material Data SheetSlobodan NocajNo ratings yet

- Equivalent TableDocument1 pageEquivalent Tableliamcs88% (8)

- Wire Rod ENDocument2 pagesWire Rod ENEltjon PumiNo ratings yet

- Columbus Castings Metal Grades PDFDocument1 pageColumbus Castings Metal Grades PDFksangeeth2000No ratings yet

- Chemical PropertiesDocument1 pageChemical PropertiesDanny TriwibowoNo ratings yet

- Tabel Pemilihan Bahan Dan ProsesDocument2 pagesTabel Pemilihan Bahan Dan Prosesrahmid fareziNo ratings yet

- Steel Grade: Material Data SheetDocument6 pagesSteel Grade: Material Data SheetFlorinFlorinNo ratings yet

- 42crmo4 - HardnessDocument8 pages42crmo4 - HardnessavijayakumarsamyNo ratings yet

- Rail Lexicon Mk24Document60 pagesRail Lexicon Mk24serzo75No ratings yet

- Maryland Metrics - Fastener Technical DataDocument92 pagesMaryland Metrics - Fastener Technical Dataserzo75100% (1)

- Sect 08 Rail Freight Vehicle Underframe and Body Structures Incl New As Id1Document9 pagesSect 08 Rail Freight Vehicle Underframe and Body Structures Incl New As Id1serzo75No ratings yet

- Tech List enDocument17 pagesTech List enserzo75No ratings yet

- S235J0Document1 pageS235J0serzo75No ratings yet

- Annex CDocument101 pagesAnnex Cserzo75No ratings yet

- Wagons On StockDocument10 pagesWagons On Stockserzo75100% (1)

- Grade S275JRDocument1 pageGrade S275JRserzo75No ratings yet

- Non Alloy Structural Steels S275J2 NDocument1 pageNon Alloy Structural Steels S275J2 Nserzo75No ratings yet

- S355J0Document1 pageS355J0serzo75No ratings yet

- RIVKLEDocument56 pagesRIVKLEserzo75No ratings yet

- Rivkle: Stainless Steel Blind Rivet Nuts Hexagonal Body, Extra-Small Countersunk Head AdvantagesDocument1 pageRivkle: Stainless Steel Blind Rivet Nuts Hexagonal Body, Extra-Small Countersunk Head Advantagesserzo75No ratings yet

- Mazalice: Mazalice I Kuglice Januar 2013Document1 pageMazalice: Mazalice I Kuglice Januar 2013serzo75No ratings yet

- Pojedini Tipovi VijakaDocument4 pagesPojedini Tipovi Vijakaserzo75No ratings yet

- Msds - Mol Calton G 3 - GBDocument8 pagesMsds - Mol Calton G 3 - GBserzo75No ratings yet

- Iso 7040Document1 pageIso 7040serzo75No ratings yet

- Uputstvo Central 17 23 24 28 24M 28MDocument19 pagesUputstvo Central 17 23 24 28 24M 28Mserzo75100% (1)