Professional Documents

Culture Documents

Dust Safety Risks PDF

Dust Safety Risks PDF

Uploaded by

micaziv4786Copyright:

Available Formats

You might also like

- Some Tips About The Classification of Wire Breakages Part A - 2012 PDFDocument2 pagesSome Tips About The Classification of Wire Breakages Part A - 2012 PDFNabeel Ameer100% (1)

- Atlas of Stress-Strain Curves: Second EditionDocument5 pagesAtlas of Stress-Strain Curves: Second EditionLucio MárquezNo ratings yet

- Electrical Panel Load Calculation-22!8!12-1Document33 pagesElectrical Panel Load Calculation-22!8!12-1micaziv4786100% (1)

- Dust Testing For DSEAR and ATEX Complian PDFDocument16 pagesDust Testing For DSEAR and ATEX Complian PDFSawita LertsupochavanichNo ratings yet

- IDEA - Design ProcessDocument72 pagesIDEA - Design Processbambang satryojatiNo ratings yet

- Resistance 2008 PDFDocument213 pagesResistance 2008 PDFPatricio Ariel DuarteNo ratings yet

- Dokumen - Pub - Fatigue and Fracture of Nanostructured Materials 1st Ed 9783030580872 9783030580889Document436 pagesDokumen - Pub - Fatigue and Fracture of Nanostructured Materials 1st Ed 9783030580872 9783030580889nestorNo ratings yet

- Selecting The RightDocument6 pagesSelecting The RightFausto Moya0% (1)

- Flexible Chain Couplings: An American National StandardDocument14 pagesFlexible Chain Couplings: An American National StandardMarko's Brazon'No ratings yet

- The Basis of Dust Explosion Protection by R StahlDocument32 pagesThe Basis of Dust Explosion Protection by R StahlBigbearBigbearNo ratings yet

- International Standard.: ISO Metric Trapezoidal Screw Threads - Basic DimensionsDocument5 pagesInternational Standard.: ISO Metric Trapezoidal Screw Threads - Basic Dimensionslara_rajkumar667No ratings yet

- X 341E CEM Technology Compact Endless Cast and Rolling MillDocument2 pagesX 341E CEM Technology Compact Endless Cast and Rolling MillGowtham VishvakarmaNo ratings yet

- Filters of CompressorsDocument12 pagesFilters of CompressorsWendimagen Meshesha FantaNo ratings yet

- SecadorDocument5 pagesSecadorjulio_cesar_wNo ratings yet

- Solvents-Flammability Guide PDFDocument16 pagesSolvents-Flammability Guide PDF鄭琳祥No ratings yet

- Material Specification Sheet: 1.7102 DIN EN 10089 SAE: 9254 Jis: Sup 12 Material Group: Chemical CompositionDocument1 pageMaterial Specification Sheet: 1.7102 DIN EN 10089 SAE: 9254 Jis: Sup 12 Material Group: Chemical CompositionRichard RodriguezNo ratings yet

- Instruction Sheet: NF EN 13001-1/IN1Document4 pagesInstruction Sheet: NF EN 13001-1/IN1Halil AkaryıldızNo ratings yet

- Aws 5.2Document21 pagesAws 5.2a castroNo ratings yet

- Copper Tube HandbookDocument56 pagesCopper Tube HandbookPatrick John Salalila PaguioNo ratings yet

- Hair PDFDocument100 pagesHair PDFChris LeidleinNo ratings yet

- Arcelormittal Crane Rails enDocument6 pagesArcelormittal Crane Rails enjulius_xNo ratings yet

- Aws 5.4 PDFDocument39 pagesAws 5.4 PDFMaelstormcrowNo ratings yet

- Ethanol Fire Fighter Planning PDFDocument47 pagesEthanol Fire Fighter Planning PDFAnonymous x2kQMSAZJzNo ratings yet

- SMACNA CAD StandardDocument6 pagesSMACNA CAD StandardDenan SaherNo ratings yet

- Hiwin Catalogo - Bs-It 2020 WebDocument104 pagesHiwin Catalogo - Bs-It 2020 WebIvano VerbiNo ratings yet

- BX enDocument46 pagesBX enemadhsobhyNo ratings yet

- MMS Product GuideDocument40 pagesMMS Product GuideFelipe VargasNo ratings yet

- Bekaert Metal Filter 2010Document16 pagesBekaert Metal Filter 2010450gasgasNo ratings yet

- Miller 09Document5 pagesMiller 09Muhammad RaHadian WiranataNo ratings yet

- Operator'S Manual: Tig-250Pl AcdcDocument33 pagesOperator'S Manual: Tig-250Pl AcdcAntonio MaesoNo ratings yet

- Sans1783 2Document19 pagesSans1783 2David Shaw100% (1)

- CPVC SolventsDocument6 pagesCPVC SolventsAhmad AnthonyNo ratings yet

- Ceramic Ball BearingDocument22 pagesCeramic Ball BearingNamratha Cm100% (1)

- Vibration Control in Washing Machine With The Help of Suspension SystemDocument14 pagesVibration Control in Washing Machine With The Help of Suspension Systempradeep eliNo ratings yet

- Material Safety Data SheetDocument13 pagesMaterial Safety Data SheetDhyta_Anne_Hudge_497No ratings yet

- SG TheoryDocument10 pagesSG TheoryvigneshwarimahamuniNo ratings yet

- BR SZ SH en 2107 WebDocument24 pagesBR SZ SH en 2107 WebDaniel SherwinNo ratings yet

- Tubes and PipesDocument40 pagesTubes and PipesRamazan Erdinç100% (1)

- As 4024.3-1998 Safeguarding of Machinery Manufacturing and Testing Requirements For Electro-Sensitive SystemsDocument7 pagesAs 4024.3-1998 Safeguarding of Machinery Manufacturing and Testing Requirements For Electro-Sensitive SystemsSAI Global - APACNo ratings yet

- A Re-Autofrettage Procedure For Mitigation of Bauschinger Effect in Thick CylindersDocument8 pagesA Re-Autofrettage Procedure For Mitigation of Bauschinger Effect in Thick CylindersCan ERTANNo ratings yet

- Evaluation of Water Corrosivity Using A CorrosionDocument11 pagesEvaluation of Water Corrosivity Using A CorrosionrachedNo ratings yet

- As 2848.1-1998 Aluminium and Aluminium Alloys - Compositions and Designations Wrought ProductsDocument6 pagesAs 2848.1-1998 Aluminium and Aluminium Alloys - Compositions and Designations Wrought ProductsSAI Global - APACNo ratings yet

- Scanned From A Xerox Multifunction Printer5Document1 pageScanned From A Xerox Multifunction Printer5Dennis RangwetsiNo ratings yet

- Sp-Eng-004 Rev. 19Document16 pagesSp-Eng-004 Rev. 19fael_fvNo ratings yet

- Iso 17893 2004Document15 pagesIso 17893 2004RAVIKANT SINDHENo ratings yet

- Slurry Erosion StudyDocument26 pagesSlurry Erosion StudyPeter ManosNo ratings yet

- Aluminio ItemDocument630 pagesAluminio ItemIvan Nava EsquivelNo ratings yet

- 1 s2.0 0308016196000117 MainDocument61 pages1 s2.0 0308016196000117 MainHimanshu ChaudhariNo ratings yet

- Aluminum Surface Treatment PDFDocument21 pagesAluminum Surface Treatment PDF이선엽No ratings yet

- ISA-37.8-1982 (R1995) : Specifications and Tests For Strain Gage Force TransducersDocument34 pagesISA-37.8-1982 (R1995) : Specifications and Tests For Strain Gage Force TransducersSergio LungrinNo ratings yet

- 10.1.1.144.9002 SW FatigueDocument13 pages10.1.1.144.9002 SW Fatigueb_wooNo ratings yet

- As 1788.1-1987 Abrasive Wheels Design Construction and SafeguardingDocument8 pagesAs 1788.1-1987 Abrasive Wheels Design Construction and SafeguardingSAI Global - APACNo ratings yet

- Horizontal Lifeline Systems GuidelineDocument4 pagesHorizontal Lifeline Systems GuidelinemohanNo ratings yet

- Atex Explosion GuideDocument12 pagesAtex Explosion GuidejagrutNo ratings yet

- ATEXDocument16 pagesATEXdlebreromNo ratings yet

- F O R U M: Specialist Periodical For LightingDocument12 pagesF O R U M: Specialist Periodical For Lightingmarili_matNo ratings yet

- HazardousDocument5 pagesHazardousapi-279752482No ratings yet

- Ilinox Atex LineDocument13 pagesIlinox Atex LineDidit AndiatmokoNo ratings yet

- Apparatus For Potentially Explosive Atmospheres: D" and "M" I" and "E"Document18 pagesApparatus For Potentially Explosive Atmospheres: D" and "M" I" and "E"papa_hetNo ratings yet

- Documents - MX Instalatii Electrice AntiexDocument226 pagesDocuments - MX Instalatii Electrice AntiexTotoliciu Dan CatalinNo ratings yet

- Dust Collection Systems and Solutions for Every Budget: Complete Guide to Protecting Your Lungs and Eyes from Wood, Metal, and Resin Dust in the WorkshopFrom EverandDust Collection Systems and Solutions for Every Budget: Complete Guide to Protecting Your Lungs and Eyes from Wood, Metal, and Resin Dust in the WorkshopNo ratings yet

- CikloheksilaminDocument6 pagesCikloheksilaminmicaziv4786No ratings yet

- VDS Interaction of Water Extinguishing Systems and Smoke and Heat ExtractorsDocument0 pagesVDS Interaction of Water Extinguishing Systems and Smoke and Heat Extractorsmicaziv4786No ratings yet

- Cable Trunking DatasheetDocument1 pageCable Trunking Datasheetmicaziv4786No ratings yet

- Material Safety Data Sheet: 1. Chemical Product and Company InformationDocument8 pagesMaterial Safety Data Sheet: 1. Chemical Product and Company Informationmicaziv4786No ratings yet

- Carbon MonoxideDocument4 pagesCarbon Monoxidemicaziv4786No ratings yet

- CikloheksanonDocument7 pagesCikloheksanonmicaziv4786No ratings yet

- Butil AlkoholDocument6 pagesButil Alkoholmicaziv4786No ratings yet

- ButilacetatDocument6 pagesButilacetatmicaziv4786No ratings yet

- Butil AlkoholDocument6 pagesButil Alkoholmicaziv4786No ratings yet

- BitumenDocument13 pagesBitumenmicaziv4786No ratings yet

- BenzinDocument6 pagesBenzinmicaziv4786No ratings yet

- AmonijakDocument2 pagesAmonijakmicaziv4786No ratings yet

- Superfix 25Document5 pagesSuperfix 25micaziv4786No ratings yet

- Ammonia Aqua 19%Document8 pagesAmmonia Aqua 19%micaziv4786No ratings yet

- Material Safety Data Sheet: Tert-Amyl Alcohol MSDSDocument6 pagesMaterial Safety Data Sheet: Tert-Amyl Alcohol MSDSmicaziv4786No ratings yet

- Material Safety Data Sheet: Acetylene, DissolvedDocument4 pagesMaterial Safety Data Sheet: Acetylene, Dissolvedmicaziv4786No ratings yet

- 3000 N (2000) What's New in The Wiring RulesDocument46 pages3000 N (2000) What's New in The Wiring Rulesmicaziv4786No ratings yet

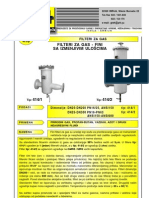

- Filteri Za Gas - Fini Sa Izmenjivim Ulo (CimaDocument6 pagesFilteri Za Gas - Fini Sa Izmenjivim Ulo (Cimamicaziv4786No ratings yet

Dust Safety Risks PDF

Dust Safety Risks PDF

Uploaded by

micaziv4786Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dust Safety Risks PDF

Dust Safety Risks PDF

Uploaded by

micaziv4786Copyright:

Available Formats

Dust - a Safety Risk

Why dust is an explosive subject

One spark may be enough!

A dust explosion needs three things: Air, combustible dust, a source of ignition!

Combustible and explosive dusts occur more often than you think. For example during the processing of wood and ber materials foods, beverages, tobacco and fodder coal metals and metal alloys But technical chemical products of plastic, resin and rubber can create combustible dusts and explosive atmospheres.

The following three conditions must be satised for a dust explosion:

A cloud of combustible substances with a particle size of <0.5 mm. The concentration of this dust cloud must be between the lower explosion limit (LEL) and the upper explosion limit (UEL). The LEL for many food dusts, for example is between 30 and 60 g/m3, the UEL is 2 to 6 kg/m3. A sufcient amount of air oxygen. A suitable ignition source, e.g. an electrical spark which may occur when pulling a plug out of a socket or a hot surface (e.g. 300C to 600 C).

If you store combustible dusts on hot surfaces such as overheated electric motors, smoldering res may occur which can cause an explosion when the dust is kicked up, for example by opening a window. Dust explosion are particularly dangerous because the shock wave can kick up more dust and trigger a chain reaction. The result is often destruction on a dramatic scale and danger to human life.

Air

Dust is almost everywhere air too! But you can prevent sources of ignition!

In connection with building and organizational measures and by choosing suitable equipment certied for use in dust Ex-areas the risk of an explosion can be minimized. Cooper CrouseHinds GmbH offers you a wide selection of electrical equipment for safe use in dust Ex-areas.

DUST

Always the right equipment

According to their potential risk, dust explosion areas are classied in different zones in the European Union to which equipment categories 1D to 3D are assigned. This zone classication can be demonstrated particularly well by the example of a sack emptying station without dust suction.

Zone 22 Zone 21

Zone 20

Zone 20: Filling hopper of a sack emptying station Zone 21: Close vicinity of the feed opening (e. g. radius 1 m) Zone 22: Area with dust deposits outside zone 21

One spark may be enough!

rd tanda dust s /1/07 New rom 7 f valid

Protect yourself

The new standard EN 61241... supersedes the previously valid dust standard EN 50 281 from July 1, 2007. This new standard EN 61241... must be observed because a high risk potential in dust explosion areas is involved in which peoples lives are in danger. The standard takes into account that the demands on the electrical equipment in areas with a risk of dust explosion are increased in comparison with the industrial standard and the previous standard EN 50281. This obliges the owner to use products which correspond to and conform with the EN 61241 standard exclusively for new installations.

(Fig. 1)

Which individual demands have changed exactly? - Impact strength of the housings - Electrostatic discharge capability of the housings - Aging resistance of the plastics used In order to always be on the safe side in future, the dust Exequipment of the brand comply with the new EN 61241-0 and EN 61241-1 + A1 standards for the dust ignition protection type protection by housing (tD) and are approved accordingly. Dust explosion-protected equipment of the CEAG brand are of course subject to extensive quality assurance measures. We naturally have a quality management certied by DIN EN ISO 9001: 2000 with additional regular auditing by an independent test body (ATEX Audit). (Fig. 1) Our dust explosion-protected light ttings and electrical equipment comply with the latest standards and have all the important national and international approvals. For instance, our products are subjected to a conformity evaluation process for use in dust Ex-areas in which a named independent body tests their technical suitability for use in Ex-areas of zones 20, 21 and 22 (device category 1/2/3D). With the EC type test certicate or type test certicate / declaration of conformity, the test body certies the appropriate suitability and grants approval. (Fig. 2)

(Fig. 2) Fluorescent luminaires in the dust test chamber: Our products are tested rigorously. This gives you safety.

Dust explosions are m - and more common

Approximately 2,000 dust exp the EU with average damages cident. In an explosion at the 14 people died, 17 were injure Euro were caused!

An analysis of almost 600 dam vealed that 31 % were caused der and food dusts, 13 % by dust. Silos, dedusting and con kilns, heatings, saws, carpent are particularly affected.

more dangerous - than you think!

plosions occur every year in s of about 25,000 per acRolandmhle in Bremen alone, ed and damages of 50 million

mage cases in Germany red by wood dust, 25 % by fodplastic dust and 9 % by coal nveyor systems, mills, drying try shops and mixing systems

One spark may be enough!

To make your dust Ex-area safe

Electrical equipment for your safety

Mills, mixers or conveyors in areas where there is a risk of dust explosion require electrical energy reliable, safe and explosion-protected. We provide the safe power supply for your drives with dust explosion-protected switches, motor intermediate terminal boxes and plug devices. And thats not all: Your drives can clearly and visibly be disconnected from the mains supply by our range of plug and sockets. This also makes maintenance of your machines very safe and convenient.

Flexible: eXLink connector with branching socket

Recessed ceiling mounting luminaire

eXLink connector in metal version

Shining examples of explosion protection

Risks can only be recognized and accidents avoided under good visibility conditions. Therefore good lighting is a must, especially in areas where operations favor the development of dust. Our dust explosion-protected light ttings and downlights provide reliable light here whilst emergency exit luminaires safely show the way in case of a power failure.

Guiding the way:Emergency Exit luminaire

Mounted luminaire for more light

All from one provider

Our extensive product portfolio of the CEAG brand offers you products for almost all areas of application: Portable light ttings, uorescent light ttings and downlights Emergency exit luminaires Plug devices and branching sockets Switchgear and terminal boxes Command and indicator devices Safety switch with emergency stop function as well as customer-specically congured switching systems and controls.

Plug device for exible energy distribution

Branching socket

Terminal box

Control unit

Safety switch with EMERGENCY STOP Terminal box in stainless steel version

You are responsible

When can dust explode?

Combustible dust-air mixtures have different ignition temperatures. The surface temperature of the equipment in areas with a risk of dust explosion may reach 2/3rd of the minimum ignition temperature of the surrounding dust-air mixture at the maximum and with a 5 mm thick layer of dust must be at least 75 K below the minimum ignition temperature of the dust (glow temperature). It is therefore the owners job to ensure that the cleaning and maintenance intervals of installations with a dust explosion risk are scheduled so that no dust layers thicker than 5 mm are allowed to form. At higher dust deposits the minimum ignition temperature (glow temperature) of the dusts are reduced drastically. Examples for the ignition and glow temperatures can be taken from the table below.

You the owner are responsible for the protection of the work force and safety of your plant according to the new European ATEX directive 1999/92/EC (ATEX 137). This work force protection directive also covers electrical installations in areas where there is a risk of dust explosion. This EC directive has become valid in all member states by national laws and regulations and supplements the product-related (technical) work protection as it is governed by the ATEX directive 94/9/EC among other things (characteristic requirements). The work protection directive 1999/92/EC also governs the carrying out of a risk assessment and division of Ex-areas into zones. In accordance with this directive, only appropriately certied electrical equipment may be used in areas with a risk of dust explosion.

Dust type (name of the solid)

Minimum ignition temperature of a dust layer (glow temperature) in acc. with IEC 61241-2-1 proc. A

Minimum ignition temperature of a dust cloud in acc. with IEC 61241-2-1 proc. B

Natural products (examples) Cellulose Coal Cocoa Cork Cotton Flour Fodder Grain Milk powder (full, spray) Paper Peat Sawdust Starch Sugar Tea Tobacco Chemical-technical products (examples) Laminate (grinding dust) Petrol coke Polyvinyl acetate Polyvinyl chloride Rubber Soot Sulfur Metals (examples) Aluminum Bronze Iron Magnesium Manganese Zinc 280 260 300 410 285 440 530 390 310 610 330 570 330 280 340 430 220 385 280 510 690 500 680 460 620 280 370 270 460 300 350 470 295 290 330 335 320 300 530 360 300 300 500 590 580 470 560 410 520 420 520 570 500 400 380 450 510 450

Source: BIA - Report (excerpt) Combustion and Explosion Variables Issued by: HVBG

Cooper Crouse-Hinds GmbH Neuer Weg Nord 49 D-69412 Eberbach Phone +49(0)6271/806-500 Fax +49(0)6271/806-476 Internet www.ceag.de E-mail info-ex@ceag.de

Cooper Crouse-Hinds S.A. Avda. Santa Eulalia, 290 E - 08223 Terrassa Barcelona Phone +34 (0) 9-37362710 Fax +34 (0) 9-37835055 E-Mail infonortem@nortem.com

COOPER Industries Crouse-Hinds Division Wolf 7th North Streets P. O. Box 4999 USA - Syracuse, NY 13221 Phone +1 (0) 3-154777000 Fax +1 (0) 3-154775717 E-mail crouse.customerctr@ crouse-hinds.com Internet www.crouse-hinds.com

Cooper Crouse-Hinds (UK) Ltd. Unit G, Quinn Close Seven Stars Industrial Estate Whitley GB - Coventry CV 3 4LH Phone +44 247-630-89 30 Fax +44 247-630-10 27 E-mail sales@ceag-crouse-hinds.co.uk

Cooper Crouse-Hinds B. V. Cairostraat 66 NL - 3047 BC Rotterdam Phone +31 (0) 10-2452145 Fax +31 (0) 10-2452121 E-mail mail@ceag.nl

Cooper Crouse-Hinds Norge A/S Husebysletta 9 N - 3412-Lierstranda Phone +47 32-244600 Fax +47 32-244646 E-mail info@ceag.no

Cooper Crouse-Hinds LLC Ofce No. M1 Sultan Hareeb Building P.O. Box 30861 UAE Al Jadaf, Dubai Phone +971-4-3241519 Fax +971-4-3241640 E-mail rfq@ceagme.ae

Branches of Cooper Crouse-Hinds Pte Ltd. 28 Floor Yu An Building 738 Dong Fang Road Pudong Shanghai 200122, P.R. China Phone +86 (0) 21-5831 6805 Fax +86 (0) 21-5831 6762 E-mail sales@cchspore.com.sg

Cooper Crouse-Hinds Pte. Ltd. 1 Jalan Kilang Timor No. 01-03 Pacic Tech Centre SGP - 159303 Singapore Phone +65 (0) 6297-4849 Fax +65 (0) 6297-4819 E-mail sales@cchspore.com.sg Internet www.cchspore.com.sg/

2007 Cooper Crouse-Hinds GmbH

Cooper Industries, Ltd. 600 Travis, Ste. 5800 Houston, TX 77002-1001 P: 713-209-8400 Internet www.cooperindustries.com

30080002022/4/11.07/LD

Subject to technical modications

You might also like

- Some Tips About The Classification of Wire Breakages Part A - 2012 PDFDocument2 pagesSome Tips About The Classification of Wire Breakages Part A - 2012 PDFNabeel Ameer100% (1)

- Atlas of Stress-Strain Curves: Second EditionDocument5 pagesAtlas of Stress-Strain Curves: Second EditionLucio MárquezNo ratings yet

- Electrical Panel Load Calculation-22!8!12-1Document33 pagesElectrical Panel Load Calculation-22!8!12-1micaziv4786100% (1)

- Dust Testing For DSEAR and ATEX Complian PDFDocument16 pagesDust Testing For DSEAR and ATEX Complian PDFSawita LertsupochavanichNo ratings yet

- IDEA - Design ProcessDocument72 pagesIDEA - Design Processbambang satryojatiNo ratings yet

- Resistance 2008 PDFDocument213 pagesResistance 2008 PDFPatricio Ariel DuarteNo ratings yet

- Dokumen - Pub - Fatigue and Fracture of Nanostructured Materials 1st Ed 9783030580872 9783030580889Document436 pagesDokumen - Pub - Fatigue and Fracture of Nanostructured Materials 1st Ed 9783030580872 9783030580889nestorNo ratings yet

- Selecting The RightDocument6 pagesSelecting The RightFausto Moya0% (1)

- Flexible Chain Couplings: An American National StandardDocument14 pagesFlexible Chain Couplings: An American National StandardMarko's Brazon'No ratings yet

- The Basis of Dust Explosion Protection by R StahlDocument32 pagesThe Basis of Dust Explosion Protection by R StahlBigbearBigbearNo ratings yet

- International Standard.: ISO Metric Trapezoidal Screw Threads - Basic DimensionsDocument5 pagesInternational Standard.: ISO Metric Trapezoidal Screw Threads - Basic Dimensionslara_rajkumar667No ratings yet

- X 341E CEM Technology Compact Endless Cast and Rolling MillDocument2 pagesX 341E CEM Technology Compact Endless Cast and Rolling MillGowtham VishvakarmaNo ratings yet

- Filters of CompressorsDocument12 pagesFilters of CompressorsWendimagen Meshesha FantaNo ratings yet

- SecadorDocument5 pagesSecadorjulio_cesar_wNo ratings yet

- Solvents-Flammability Guide PDFDocument16 pagesSolvents-Flammability Guide PDF鄭琳祥No ratings yet

- Material Specification Sheet: 1.7102 DIN EN 10089 SAE: 9254 Jis: Sup 12 Material Group: Chemical CompositionDocument1 pageMaterial Specification Sheet: 1.7102 DIN EN 10089 SAE: 9254 Jis: Sup 12 Material Group: Chemical CompositionRichard RodriguezNo ratings yet

- Instruction Sheet: NF EN 13001-1/IN1Document4 pagesInstruction Sheet: NF EN 13001-1/IN1Halil AkaryıldızNo ratings yet

- Aws 5.2Document21 pagesAws 5.2a castroNo ratings yet

- Copper Tube HandbookDocument56 pagesCopper Tube HandbookPatrick John Salalila PaguioNo ratings yet

- Hair PDFDocument100 pagesHair PDFChris LeidleinNo ratings yet

- Arcelormittal Crane Rails enDocument6 pagesArcelormittal Crane Rails enjulius_xNo ratings yet

- Aws 5.4 PDFDocument39 pagesAws 5.4 PDFMaelstormcrowNo ratings yet

- Ethanol Fire Fighter Planning PDFDocument47 pagesEthanol Fire Fighter Planning PDFAnonymous x2kQMSAZJzNo ratings yet

- SMACNA CAD StandardDocument6 pagesSMACNA CAD StandardDenan SaherNo ratings yet

- Hiwin Catalogo - Bs-It 2020 WebDocument104 pagesHiwin Catalogo - Bs-It 2020 WebIvano VerbiNo ratings yet

- BX enDocument46 pagesBX enemadhsobhyNo ratings yet

- MMS Product GuideDocument40 pagesMMS Product GuideFelipe VargasNo ratings yet

- Bekaert Metal Filter 2010Document16 pagesBekaert Metal Filter 2010450gasgasNo ratings yet

- Miller 09Document5 pagesMiller 09Muhammad RaHadian WiranataNo ratings yet

- Operator'S Manual: Tig-250Pl AcdcDocument33 pagesOperator'S Manual: Tig-250Pl AcdcAntonio MaesoNo ratings yet

- Sans1783 2Document19 pagesSans1783 2David Shaw100% (1)

- CPVC SolventsDocument6 pagesCPVC SolventsAhmad AnthonyNo ratings yet

- Ceramic Ball BearingDocument22 pagesCeramic Ball BearingNamratha Cm100% (1)

- Vibration Control in Washing Machine With The Help of Suspension SystemDocument14 pagesVibration Control in Washing Machine With The Help of Suspension Systempradeep eliNo ratings yet

- Material Safety Data SheetDocument13 pagesMaterial Safety Data SheetDhyta_Anne_Hudge_497No ratings yet

- SG TheoryDocument10 pagesSG TheoryvigneshwarimahamuniNo ratings yet

- BR SZ SH en 2107 WebDocument24 pagesBR SZ SH en 2107 WebDaniel SherwinNo ratings yet

- Tubes and PipesDocument40 pagesTubes and PipesRamazan Erdinç100% (1)

- As 4024.3-1998 Safeguarding of Machinery Manufacturing and Testing Requirements For Electro-Sensitive SystemsDocument7 pagesAs 4024.3-1998 Safeguarding of Machinery Manufacturing and Testing Requirements For Electro-Sensitive SystemsSAI Global - APACNo ratings yet

- A Re-Autofrettage Procedure For Mitigation of Bauschinger Effect in Thick CylindersDocument8 pagesA Re-Autofrettage Procedure For Mitigation of Bauschinger Effect in Thick CylindersCan ERTANNo ratings yet

- Evaluation of Water Corrosivity Using A CorrosionDocument11 pagesEvaluation of Water Corrosivity Using A CorrosionrachedNo ratings yet

- As 2848.1-1998 Aluminium and Aluminium Alloys - Compositions and Designations Wrought ProductsDocument6 pagesAs 2848.1-1998 Aluminium and Aluminium Alloys - Compositions and Designations Wrought ProductsSAI Global - APACNo ratings yet

- Scanned From A Xerox Multifunction Printer5Document1 pageScanned From A Xerox Multifunction Printer5Dennis RangwetsiNo ratings yet

- Sp-Eng-004 Rev. 19Document16 pagesSp-Eng-004 Rev. 19fael_fvNo ratings yet

- Iso 17893 2004Document15 pagesIso 17893 2004RAVIKANT SINDHENo ratings yet

- Slurry Erosion StudyDocument26 pagesSlurry Erosion StudyPeter ManosNo ratings yet

- Aluminio ItemDocument630 pagesAluminio ItemIvan Nava EsquivelNo ratings yet

- 1 s2.0 0308016196000117 MainDocument61 pages1 s2.0 0308016196000117 MainHimanshu ChaudhariNo ratings yet

- Aluminum Surface Treatment PDFDocument21 pagesAluminum Surface Treatment PDF이선엽No ratings yet

- ISA-37.8-1982 (R1995) : Specifications and Tests For Strain Gage Force TransducersDocument34 pagesISA-37.8-1982 (R1995) : Specifications and Tests For Strain Gage Force TransducersSergio LungrinNo ratings yet

- 10.1.1.144.9002 SW FatigueDocument13 pages10.1.1.144.9002 SW Fatigueb_wooNo ratings yet

- As 1788.1-1987 Abrasive Wheels Design Construction and SafeguardingDocument8 pagesAs 1788.1-1987 Abrasive Wheels Design Construction and SafeguardingSAI Global - APACNo ratings yet

- Horizontal Lifeline Systems GuidelineDocument4 pagesHorizontal Lifeline Systems GuidelinemohanNo ratings yet

- Atex Explosion GuideDocument12 pagesAtex Explosion GuidejagrutNo ratings yet

- ATEXDocument16 pagesATEXdlebreromNo ratings yet

- F O R U M: Specialist Periodical For LightingDocument12 pagesF O R U M: Specialist Periodical For Lightingmarili_matNo ratings yet

- HazardousDocument5 pagesHazardousapi-279752482No ratings yet

- Ilinox Atex LineDocument13 pagesIlinox Atex LineDidit AndiatmokoNo ratings yet

- Apparatus For Potentially Explosive Atmospheres: D" and "M" I" and "E"Document18 pagesApparatus For Potentially Explosive Atmospheres: D" and "M" I" and "E"papa_hetNo ratings yet

- Documents - MX Instalatii Electrice AntiexDocument226 pagesDocuments - MX Instalatii Electrice AntiexTotoliciu Dan CatalinNo ratings yet

- Dust Collection Systems and Solutions for Every Budget: Complete Guide to Protecting Your Lungs and Eyes from Wood, Metal, and Resin Dust in the WorkshopFrom EverandDust Collection Systems and Solutions for Every Budget: Complete Guide to Protecting Your Lungs and Eyes from Wood, Metal, and Resin Dust in the WorkshopNo ratings yet

- CikloheksilaminDocument6 pagesCikloheksilaminmicaziv4786No ratings yet

- VDS Interaction of Water Extinguishing Systems and Smoke and Heat ExtractorsDocument0 pagesVDS Interaction of Water Extinguishing Systems and Smoke and Heat Extractorsmicaziv4786No ratings yet

- Cable Trunking DatasheetDocument1 pageCable Trunking Datasheetmicaziv4786No ratings yet

- Material Safety Data Sheet: 1. Chemical Product and Company InformationDocument8 pagesMaterial Safety Data Sheet: 1. Chemical Product and Company Informationmicaziv4786No ratings yet

- Carbon MonoxideDocument4 pagesCarbon Monoxidemicaziv4786No ratings yet

- CikloheksanonDocument7 pagesCikloheksanonmicaziv4786No ratings yet

- Butil AlkoholDocument6 pagesButil Alkoholmicaziv4786No ratings yet

- ButilacetatDocument6 pagesButilacetatmicaziv4786No ratings yet

- Butil AlkoholDocument6 pagesButil Alkoholmicaziv4786No ratings yet

- BitumenDocument13 pagesBitumenmicaziv4786No ratings yet

- BenzinDocument6 pagesBenzinmicaziv4786No ratings yet

- AmonijakDocument2 pagesAmonijakmicaziv4786No ratings yet

- Superfix 25Document5 pagesSuperfix 25micaziv4786No ratings yet

- Ammonia Aqua 19%Document8 pagesAmmonia Aqua 19%micaziv4786No ratings yet

- Material Safety Data Sheet: Tert-Amyl Alcohol MSDSDocument6 pagesMaterial Safety Data Sheet: Tert-Amyl Alcohol MSDSmicaziv4786No ratings yet

- Material Safety Data Sheet: Acetylene, DissolvedDocument4 pagesMaterial Safety Data Sheet: Acetylene, Dissolvedmicaziv4786No ratings yet

- 3000 N (2000) What's New in The Wiring RulesDocument46 pages3000 N (2000) What's New in The Wiring Rulesmicaziv4786No ratings yet

- Filteri Za Gas - Fini Sa Izmenjivim Ulo (CimaDocument6 pagesFilteri Za Gas - Fini Sa Izmenjivim Ulo (Cimamicaziv4786No ratings yet