Professional Documents

Culture Documents

Metric1837 1838

Metric1837 1838

Uploaded by

Hector LascanoCopyright:

Available Formats

You might also like

- Asme Aed-1-2023Document51 pagesAsme Aed-1-2023franz_passariniNo ratings yet

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- Handbook For Installation of Medium Voltage LinesDocument106 pagesHandbook For Installation of Medium Voltage Linesajayi micheal sunday100% (1)

- Asme B5.62M-2016Document55 pagesAsme B5.62M-2016vijay pawarNo ratings yet

- Y14 43Document1 pageY14 43Adrian JoelNo ratings yet

- An Overview of GPS PDFDocument14 pagesAn Overview of GPS PDFjagan VNo ratings yet

- ISO GPS UPG LookinsideDocument17 pagesISO GPS UPG LookinsideDhairyasheel BhutkarNo ratings yet

- GD&T TrainingDocument4 pagesGD&T TrainingSunny SonawaneNo ratings yet

- Surface RoughnessDocument1 pageSurface Roughnessapi-3848892100% (2)

- Surface Roughness ChartDocument1 pageSurface Roughness ChartdmayhillNo ratings yet

- ASME Y1441powerpointDocument45 pagesASME Y1441powerpointAgus GerezNo ratings yet

- Surface RoughnessDocument35 pagesSurface Roughnessds_srinivasNo ratings yet

- Functional Gage DesignDocument32 pagesFunctional Gage DesignnaveedsidhuNo ratings yet

- B89-3-4M R1992 E1985Document47 pagesB89-3-4M R1992 E1985miorNo ratings yet

- Placing DatumsDocument29 pagesPlacing Datumssaravind120% (1)

- External Metric ISO Thread Table Chart Sizes M20 - M55Document8 pagesExternal Metric ISO Thread Table Chart Sizes M20 - M55dilipNo ratings yet

- Geometric TolerancesDocument6 pagesGeometric Tolerancesvaibhavgitevaibhav_9No ratings yet

- Dod STD 100dDocument320 pagesDod STD 100dFlorin NiteNo ratings yet

- Gaston Engineering Drawings 100 GDocument25 pagesGaston Engineering Drawings 100 GPaul MatquisNo ratings yet

- Mu Ltiview and Sectional: DrawingsDocument54 pagesMu Ltiview and Sectional: Drawingschaitanya kulkarniNo ratings yet

- The New Y14.5: We've Improved The Gold StandardDocument9 pagesThe New Y14.5: We've Improved The Gold StandardVignesh PanneerselvamNo ratings yet

- M&I 05-GeometricalTolerancing2017 v01Document20 pagesM&I 05-GeometricalTolerancing2017 v01Akash100% (1)

- Functional Tolerancing & AnnotationDocument44 pagesFunctional Tolerancing & AnnotationSteveNo ratings yet

- BS DD Iso 2FTS 128-71 2011-04-30Document22 pagesBS DD Iso 2FTS 128-71 2011-04-30diego mancilla rodriguezNo ratings yet

- Tolerance Stackup Analysis 2.0Document6 pagesTolerance Stackup Analysis 2.0Leon WangNo ratings yet

- GD&T CylindricityDocument15 pagesGD&T CylindricityjaithilagarajNo ratings yet

- Iso 15787Document36 pagesIso 15787Marta LeoneNo ratings yet

- CETOL by SigmetrixDocument6 pagesCETOL by SigmetrixnmjboseNo ratings yet

- GDT Spring 2010tDocument278 pagesGDT Spring 2010tYanaki HristovNo ratings yet

- American Society of Mechanical Engineers-Chassis Frames, Passenger Car and Light Truck, Ground Vehicle Practices - Asme Y14.32. 1m-1994 (Revision of ANSI Y14.32.1-1974) (American National Standard PDFDocument17 pagesAmerican Society of Mechanical Engineers-Chassis Frames, Passenger Car and Light Truck, Ground Vehicle Practices - Asme Y14.32. 1m-1994 (Revision of ANSI Y14.32.1-1974) (American National Standard PDFGilberto Perez HernandezNo ratings yet

- Engineering Drawing Abbreviations and SymbolsDocument18 pagesEngineering Drawing Abbreviations and SymbolsDhinesh Kumar R (Baju)No ratings yet

- M&I 04-Dimensional Chains Stack Up2017 V02uncovDocument20 pagesM&I 04-Dimensional Chains Stack Up2017 V02uncovMritunjay SharmaNo ratings yet

- Michigan Metrology Surface Texture Parameters Glossary PDFDocument102 pagesMichigan Metrology Surface Texture Parameters Glossary PDFSula Mendonça100% (1)

- Stack Up With GD&TDocument2 pagesStack Up With GD&TBadarinath KnNo ratings yet

- Technical Drawing Dimensions PDFDocument38 pagesTechnical Drawing Dimensions PDFYatin NgadiyonoNo ratings yet

- Basics of GD&TDocument75 pagesBasics of GD&TGopalGD100% (1)

- 11 Iso 10110Document28 pages11 Iso 10110fmeylanNo ratings yet

- Iso 14660 2 1999Document6 pagesIso 14660 2 1999LipikaNo ratings yet

- Handbook ISO GPS Tolerancing Cetim CVDL EN V1.02d PDFDocument76 pagesHandbook ISO GPS Tolerancing Cetim CVDL EN V1.02d PDFhüseyin demir100% (2)

- Tolerance Analysis of 2-D and 3-D AssembliesDocument30 pagesTolerance Analysis of 2-D and 3-D AssembliesKvs PhaniNo ratings yet

- G4 - Advance GD&T and Tolerance Stack-UpDocument9 pagesG4 - Advance GD&T and Tolerance Stack-UpAnkit NaphadeNo ratings yet

- 04 GD&T IntroTutorialDocument73 pages04 GD&T IntroTutorialrust_02No ratings yet

- Surface Finish TerminologyDocument30 pagesSurface Finish TerminologyXin YuNo ratings yet

- Tolerances For Frame Side Members (RLT) : Accuracy of ShapeDocument8 pagesTolerances For Frame Side Members (RLT) : Accuracy of ShapeAkmal NizametdinovNo ratings yet

- CMM Verification Version 2Document111 pagesCMM Verification Version 2Sandrock_01sr2No ratings yet

- Integrated Computational Materials Engineering (ICME) for Metals: Concepts and Case StudiesFrom EverandIntegrated Computational Materials Engineering (ICME) for Metals: Concepts and Case StudiesNo ratings yet

- Surface RoughnessDocument1 pageSurface RoughnesswholenumberNo ratings yet

- Surface Roughness Drawing Indications of Surface TextureDocument1 pageSurface Roughness Drawing Indications of Surface TextureSIVA 1010No ratings yet

- Surface Roughness JIS B 0601 (1994)Document1 pageSurface Roughness JIS B 0601 (1994)Tú Nguyễn MinhNo ratings yet

- Measuring Surface Roughness: Drawing Symbols (DIN EN ISO 1302:2002)Document1 pageMeasuring Surface Roughness: Drawing Symbols (DIN EN ISO 1302:2002)SudhagarNo ratings yet

- Surface Roughness enDocument4 pagesSurface Roughness enHNo ratings yet

- Analysing Surface Texture by Stratification Using R Parameters of Bearing Area Curve of Roughness ProfileDocument7 pagesAnalysing Surface Texture by Stratification Using R Parameters of Bearing Area Curve of Roughness ProfilesahasanNo ratings yet

- Surface Roughness by Different Processing MethodsDocument1 pageSurface Roughness by Different Processing Methodsapi-3848892100% (1)

- pr1169 1170 PDFDocument1 pagepr1169 1170 PDFrahulmuleNo ratings yet

- Propeller Methodical Series Data: AppendixDocument7 pagesPropeller Methodical Series Data: AppendixMKS3006No ratings yet

- Test2 (B) WithGuidesToSolutions PDFDocument8 pagesTest2 (B) WithGuidesToSolutions PDFChoi TomNo ratings yet

- Series: Surface Texture and Contour Integrated Measuring InstrumentsDocument20 pagesSeries: Surface Texture and Contour Integrated Measuring InstrumentsJosè Luis Gòmez SandovalNo ratings yet

- Veeam Backup 9 5 Explorers User GuideDocument217 pagesVeeam Backup 9 5 Explorers User Guideanhtuan206No ratings yet

- Research ThesisDocument99 pagesResearch ThesisEvangelist Kabaso SydneyNo ratings yet

- Digestive-System QADocument6 pagesDigestive-System QASageNo ratings yet

- Java 8 - Functional InterfacesDocument3 pagesJava 8 - Functional InterfacesNahom DiresNo ratings yet

- Salt Solution Larutan Garam Lead (II) Oxide Powder Serbuk Plumbum (II) Oksida 50 CM of 1.0 Moldm Nitric Acid 50 CM Asid Nitrik 1.0 MoldmDocument4 pagesSalt Solution Larutan Garam Lead (II) Oxide Powder Serbuk Plumbum (II) Oksida 50 CM of 1.0 Moldm Nitric Acid 50 CM Asid Nitrik 1.0 MoldmTENGKU AHMAD NAQIUDDIN BIN TENGKU NADZUAN MoeNo ratings yet

- A. Technical MalversationDocument8 pagesA. Technical MalversationDinosaur Korean100% (1)

- Conduct A SeminarDocument5 pagesConduct A SeminarChristine Joy SistosoNo ratings yet

- PATANJALIDocument16 pagesPATANJALIAbhishek PandeyNo ratings yet

- CSS Syllabus 2023 PDF Download - FPSCDocument8 pagesCSS Syllabus 2023 PDF Download - FPSCshahid Ramzan0% (1)

- Jesse Anderson Resume UpdatedDocument1 pageJesse Anderson Resume Updatedapi-336053367No ratings yet

- HTW-1390 T5: Tunge Modeller Standard StatiskDocument6 pagesHTW-1390 T5: Tunge Modeller Standard StatiskjhonnyNo ratings yet

- X-Plane Installer LogDocument3 pagesX-Plane Installer LogMarsala NistoNo ratings yet

- The Surprising Incidence of Tax Credits For The Toyota PriusDocument32 pagesThe Surprising Incidence of Tax Credits For The Toyota PriusAkandNo ratings yet

- HIP ChecklistDocument2 pagesHIP ChecklistVathzala KrishnasamyNo ratings yet

- 1.1 Engl 1010Document3 pages1.1 Engl 1010Joey ÁlvarezNo ratings yet

- Flexible Budgets and Performance AnalysisDocument37 pagesFlexible Budgets and Performance AnalysisSana IjazNo ratings yet

- Installing BI Apps 11.1.1.8Document78 pagesInstalling BI Apps 11.1.1.8tonNo ratings yet

- Kore Wa Zombie Desuka Volume 01Document252 pagesKore Wa Zombie Desuka Volume 01randydodson1993No ratings yet

- Nist Fips 201-2Document87 pagesNist Fips 201-2Mohammad Reza NazariNo ratings yet

- Job Hunting-Modul 6 E2Document26 pagesJob Hunting-Modul 6 E2Heri RudiNo ratings yet

- Nche211 Exp1Document8 pagesNche211 Exp1Mbali MdlaloseNo ratings yet

- City of Makati Vs Nippon ExpressDocument8 pagesCity of Makati Vs Nippon ExpressMarie Mariñas-delos ReyesNo ratings yet

- Full Ebook of Atkins Physical Chemistry Peter Atkins Online PDF All ChapterDocument69 pagesFull Ebook of Atkins Physical Chemistry Peter Atkins Online PDF All Chapterjessaeynmaei100% (5)

- Impedance Adaptive Dual-Mode Control of Grid-Connected Inverters With Large Fluctuation of SCR and Its Stability Analysis Based On D-Partition MethodDocument16 pagesImpedance Adaptive Dual-Mode Control of Grid-Connected Inverters With Large Fluctuation of SCR and Its Stability Analysis Based On D-Partition Method张明No ratings yet

- Matrix Training Safety PT Acset Indonusa TBKDocument6 pagesMatrix Training Safety PT Acset Indonusa TBKonyo sjariefNo ratings yet

- SDS (Safety Data Sheet) For LRV Vehicle Cleaning and OMSF Facilities Expired SheetsDocument4 pagesSDS (Safety Data Sheet) For LRV Vehicle Cleaning and OMSF Facilities Expired SheetsmilandivacNo ratings yet

- Gulf County Sheriff's Office Law Enforcement Weekly SummaryDocument3 pagesGulf County Sheriff's Office Law Enforcement Weekly SummaryMichael AllenNo ratings yet

- Report RUSADocument16 pagesReport RUSApawan kumar100% (1)

- Exercise Questions On Regular Language and Regular ExpressionDocument56 pagesExercise Questions On Regular Language and Regular ExpressionAnonymous t1W5G4UZw100% (1)

Metric1837 1838

Metric1837 1838

Uploaded by

Hector LascanoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Metric1837 1838

Metric1837 1838

Uploaded by

Hector LascanoCopyright:

Available Formats

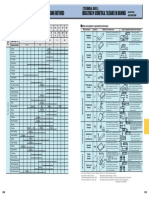

Technical Data

Surface Roughness

1. Varieties of Surface Roughness Indicators

Excerpt from JIS B 0601(1994) and JIS B 0031(1994)

Technical Data

Drawing Indication of Surface Texture

1. Positions of Auxiliary Symbols for Surface Symbol

Excerpt from JIS B 0031(1994)

Definitions and presentations of arithmetic average roughness Ra) maximum height Ry) 10-spot average roughness Rz) ( , ( , ( , , average concave-to-convex distance Sm) average distance between local peaks(S)and load length rate(tp)are given as ( parameters indicating the surface roughness of an industrial product. Surface roughness is the arithmetic average of values at randomly extracted spots on the surface of an object. Center-line average roughness(Ra 75)is defined in the supplements to JIS B 0031 and JIS B 0601. Typical Calculations of Surface Roughness Arithmetical Average Roughness, Ra

A portion stretching over a reference length in the direction in which the average line extends is cut out from the roughness curve. This portion is presented in a new graph with the X axis extending in the same direction as the average line and the Y axis representing the magnitude. Ra is represented by the equation shown at right, in m). microns(O Y

m

A surface roughness value, cut-off value or reference length, processing method, grain direction, surface undulation, etc. are indicated around the surface symbol as shown in Fig. 1 below.

Fig. 1. Positions of Auxiliary Symbols a :Ra Value b :Machining Method

b f cV g

cV :Cut-off Value, Evaluation Length c :Reference Length, Evaluation Length d :Grain Direction f :Parameter other than Ra(tp:Parameter/Cut-Off Level) g :Surface Undulation(according to JIS B 0610)

Ra= r

f() d x

a e d

c g e d

Ra

X r

Remark: These symbols except a and f are provided when they are needed. Remark: Symbol Under ISO 1302, a finish range should be indicated as e in Fig. 1. Meaning The trace left by a cutting instrument is parallel to the projection plane in the drawing. Ex. Shaped Surface

Trace Left by a Cutting Instrument

Illustration

IExamples

Surface Symbol

Maximum Height, Ry

A portion stretching over a reference length in the direction in which the average line extends is cut out from the roughness curve. The gap between the peak line and the trough line is measured in the direction in which the magnitude axis extends, in microns(Om).

Remark:A portion without an abnormally high peak or abnormally low trough, which may be regarded as a flaw, is cut out over the reference length.

m

Rp Ry

Rv

Removal of Material by Machining is Required

Ry=Rp+Rv

Ten-Spot Average Roughness, Rz

Yp 1 Yp 2 Yp 4

m

Yp 5 Yp 3

A portion stretching over a reference length in the direction in which the average line extends is cut out from the roughness curve. The average of the levels(Yp)of the highest peak to the fifth highest peak as measured from the average line and the average of the levels(Yv)of the lowest trough to the fifth lowest trough similarly measured in the said portion are added together. Rz is this sum, in microns(Om).

The trace left by a cutting instrument is perpendicular to the projection plane in the drawing. Ex. Shaped Surface (Side View) Circular Cut, Cylindrical Cut

Trace Left by a Cutting Instrument

Removal of Material is Prohibited

Y V1

Y V2

Y V3

Y V4

Y V5

Rz=

Yp 1 +Yp 2 +Yp 3 +Yp 4 +Yp 5 + Yv 1 +Yv 2 +Yv 3 +Yv 4 +Yv 5

5

Yp1, 2, 3, 4, 5 Yp Yp Yp Yp Levels of the highest peak to the fifth highest peak in the said portion with the lengthr.

The pattern left by a cutting instrument diagonally crosses the projection plane in the drawing. Ex. Honed Surface

Trace Left by a Cutting Instrument

Upper Limit of Ra

(a) 25 (b) 6.3 (c) 25

Yv1, 2, 3, 4, 5 :Levels of the lowest trough to the fifth highest trough in the Yv Yv Yv Yv said portion with the lengthr.

25

6.3

25

Reference:Relation between Arithmetic Average Roughness(Ra)and Conventional Parameters

Arithmetic Average Roughness Ra Standard Series 0.012 0.025 0.05 0.1 0.2 0.4 0.8 1.6 3.2 6.3 12.5 25 50 100 a a a a a a a a a a a a a a

Cut-Off Value ( c mm)

The pattern left by a cutting instrument crosses in various directions or has no grain direction. Conventional Finish Symbol Ex. Lapped Surface, Superfinished Surface and Surface Finished with a Front Mill or End Mill Grain Direction

Max.Height Ry

Ten-Spot Average Roughness Rz

Reference Ry/Rz Length r (mm)

Graphical Representation of Surface Texture

Standard Series 0.05 0.1 0.2 0.4 0.8 s s s s s 0.05 0.1 0.2 0.4 0.8 z z z z z

0.08 0.25 0.012 ~ 0.2

0.08 0.25 The pattern left by a cutting instrument is virtually concentric around the center of the plane in the drawing. Ex. Faced Surface Upper and Lower Limits of Ra

(a) 6.3 1.6 6.3 1.6 (b)

0.8 0.4

~ 1.6 ~ 6.3 ~ 25

1.6 s 3.2 s 6.3 s 12.5 s 25 s 50 100 200 400 s s s s

1.6 z 3.2 z 6.3 z 12.5 z 25 z 50 100 200 400 z z z z

0.8

2.5

3.2 12.5 50

2.5

The pattern left by a cutting instrument is virtually radial around the center of the plane in the drawing. ~

Machining Method

(a) Milling 3.2 3.2 (b) M

*Interrelations among the three varieties shown here are not precise, and are presented for convenience only. *Ra:The evaluated values of Ry and Rz are the cut-off values and the reference length each multiplied by five, respectively.

~ 100

1837

1838

You might also like

- Asme Aed-1-2023Document51 pagesAsme Aed-1-2023franz_passariniNo ratings yet

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- Handbook For Installation of Medium Voltage LinesDocument106 pagesHandbook For Installation of Medium Voltage Linesajayi micheal sunday100% (1)

- Asme B5.62M-2016Document55 pagesAsme B5.62M-2016vijay pawarNo ratings yet

- Y14 43Document1 pageY14 43Adrian JoelNo ratings yet

- An Overview of GPS PDFDocument14 pagesAn Overview of GPS PDFjagan VNo ratings yet

- ISO GPS UPG LookinsideDocument17 pagesISO GPS UPG LookinsideDhairyasheel BhutkarNo ratings yet

- GD&T TrainingDocument4 pagesGD&T TrainingSunny SonawaneNo ratings yet

- Surface RoughnessDocument1 pageSurface Roughnessapi-3848892100% (2)

- Surface Roughness ChartDocument1 pageSurface Roughness ChartdmayhillNo ratings yet

- ASME Y1441powerpointDocument45 pagesASME Y1441powerpointAgus GerezNo ratings yet

- Surface RoughnessDocument35 pagesSurface Roughnessds_srinivasNo ratings yet

- Functional Gage DesignDocument32 pagesFunctional Gage DesignnaveedsidhuNo ratings yet

- B89-3-4M R1992 E1985Document47 pagesB89-3-4M R1992 E1985miorNo ratings yet

- Placing DatumsDocument29 pagesPlacing Datumssaravind120% (1)

- External Metric ISO Thread Table Chart Sizes M20 - M55Document8 pagesExternal Metric ISO Thread Table Chart Sizes M20 - M55dilipNo ratings yet

- Geometric TolerancesDocument6 pagesGeometric Tolerancesvaibhavgitevaibhav_9No ratings yet

- Dod STD 100dDocument320 pagesDod STD 100dFlorin NiteNo ratings yet

- Gaston Engineering Drawings 100 GDocument25 pagesGaston Engineering Drawings 100 GPaul MatquisNo ratings yet

- Mu Ltiview and Sectional: DrawingsDocument54 pagesMu Ltiview and Sectional: Drawingschaitanya kulkarniNo ratings yet

- The New Y14.5: We've Improved The Gold StandardDocument9 pagesThe New Y14.5: We've Improved The Gold StandardVignesh PanneerselvamNo ratings yet

- M&I 05-GeometricalTolerancing2017 v01Document20 pagesM&I 05-GeometricalTolerancing2017 v01Akash100% (1)

- Functional Tolerancing & AnnotationDocument44 pagesFunctional Tolerancing & AnnotationSteveNo ratings yet

- BS DD Iso 2FTS 128-71 2011-04-30Document22 pagesBS DD Iso 2FTS 128-71 2011-04-30diego mancilla rodriguezNo ratings yet

- Tolerance Stackup Analysis 2.0Document6 pagesTolerance Stackup Analysis 2.0Leon WangNo ratings yet

- GD&T CylindricityDocument15 pagesGD&T CylindricityjaithilagarajNo ratings yet

- Iso 15787Document36 pagesIso 15787Marta LeoneNo ratings yet

- CETOL by SigmetrixDocument6 pagesCETOL by SigmetrixnmjboseNo ratings yet

- GDT Spring 2010tDocument278 pagesGDT Spring 2010tYanaki HristovNo ratings yet

- American Society of Mechanical Engineers-Chassis Frames, Passenger Car and Light Truck, Ground Vehicle Practices - Asme Y14.32. 1m-1994 (Revision of ANSI Y14.32.1-1974) (American National Standard PDFDocument17 pagesAmerican Society of Mechanical Engineers-Chassis Frames, Passenger Car and Light Truck, Ground Vehicle Practices - Asme Y14.32. 1m-1994 (Revision of ANSI Y14.32.1-1974) (American National Standard PDFGilberto Perez HernandezNo ratings yet

- Engineering Drawing Abbreviations and SymbolsDocument18 pagesEngineering Drawing Abbreviations and SymbolsDhinesh Kumar R (Baju)No ratings yet

- M&I 04-Dimensional Chains Stack Up2017 V02uncovDocument20 pagesM&I 04-Dimensional Chains Stack Up2017 V02uncovMritunjay SharmaNo ratings yet

- Michigan Metrology Surface Texture Parameters Glossary PDFDocument102 pagesMichigan Metrology Surface Texture Parameters Glossary PDFSula Mendonça100% (1)

- Stack Up With GD&TDocument2 pagesStack Up With GD&TBadarinath KnNo ratings yet

- Technical Drawing Dimensions PDFDocument38 pagesTechnical Drawing Dimensions PDFYatin NgadiyonoNo ratings yet

- Basics of GD&TDocument75 pagesBasics of GD&TGopalGD100% (1)

- 11 Iso 10110Document28 pages11 Iso 10110fmeylanNo ratings yet

- Iso 14660 2 1999Document6 pagesIso 14660 2 1999LipikaNo ratings yet

- Handbook ISO GPS Tolerancing Cetim CVDL EN V1.02d PDFDocument76 pagesHandbook ISO GPS Tolerancing Cetim CVDL EN V1.02d PDFhüseyin demir100% (2)

- Tolerance Analysis of 2-D and 3-D AssembliesDocument30 pagesTolerance Analysis of 2-D and 3-D AssembliesKvs PhaniNo ratings yet

- G4 - Advance GD&T and Tolerance Stack-UpDocument9 pagesG4 - Advance GD&T and Tolerance Stack-UpAnkit NaphadeNo ratings yet

- 04 GD&T IntroTutorialDocument73 pages04 GD&T IntroTutorialrust_02No ratings yet

- Surface Finish TerminologyDocument30 pagesSurface Finish TerminologyXin YuNo ratings yet

- Tolerances For Frame Side Members (RLT) : Accuracy of ShapeDocument8 pagesTolerances For Frame Side Members (RLT) : Accuracy of ShapeAkmal NizametdinovNo ratings yet

- CMM Verification Version 2Document111 pagesCMM Verification Version 2Sandrock_01sr2No ratings yet

- Integrated Computational Materials Engineering (ICME) for Metals: Concepts and Case StudiesFrom EverandIntegrated Computational Materials Engineering (ICME) for Metals: Concepts and Case StudiesNo ratings yet

- Surface RoughnessDocument1 pageSurface RoughnesswholenumberNo ratings yet

- Surface Roughness Drawing Indications of Surface TextureDocument1 pageSurface Roughness Drawing Indications of Surface TextureSIVA 1010No ratings yet

- Surface Roughness JIS B 0601 (1994)Document1 pageSurface Roughness JIS B 0601 (1994)Tú Nguyễn MinhNo ratings yet

- Measuring Surface Roughness: Drawing Symbols (DIN EN ISO 1302:2002)Document1 pageMeasuring Surface Roughness: Drawing Symbols (DIN EN ISO 1302:2002)SudhagarNo ratings yet

- Surface Roughness enDocument4 pagesSurface Roughness enHNo ratings yet

- Analysing Surface Texture by Stratification Using R Parameters of Bearing Area Curve of Roughness ProfileDocument7 pagesAnalysing Surface Texture by Stratification Using R Parameters of Bearing Area Curve of Roughness ProfilesahasanNo ratings yet

- Surface Roughness by Different Processing MethodsDocument1 pageSurface Roughness by Different Processing Methodsapi-3848892100% (1)

- pr1169 1170 PDFDocument1 pagepr1169 1170 PDFrahulmuleNo ratings yet

- Propeller Methodical Series Data: AppendixDocument7 pagesPropeller Methodical Series Data: AppendixMKS3006No ratings yet

- Test2 (B) WithGuidesToSolutions PDFDocument8 pagesTest2 (B) WithGuidesToSolutions PDFChoi TomNo ratings yet

- Series: Surface Texture and Contour Integrated Measuring InstrumentsDocument20 pagesSeries: Surface Texture and Contour Integrated Measuring InstrumentsJosè Luis Gòmez SandovalNo ratings yet

- Veeam Backup 9 5 Explorers User GuideDocument217 pagesVeeam Backup 9 5 Explorers User Guideanhtuan206No ratings yet

- Research ThesisDocument99 pagesResearch ThesisEvangelist Kabaso SydneyNo ratings yet

- Digestive-System QADocument6 pagesDigestive-System QASageNo ratings yet

- Java 8 - Functional InterfacesDocument3 pagesJava 8 - Functional InterfacesNahom DiresNo ratings yet

- Salt Solution Larutan Garam Lead (II) Oxide Powder Serbuk Plumbum (II) Oksida 50 CM of 1.0 Moldm Nitric Acid 50 CM Asid Nitrik 1.0 MoldmDocument4 pagesSalt Solution Larutan Garam Lead (II) Oxide Powder Serbuk Plumbum (II) Oksida 50 CM of 1.0 Moldm Nitric Acid 50 CM Asid Nitrik 1.0 MoldmTENGKU AHMAD NAQIUDDIN BIN TENGKU NADZUAN MoeNo ratings yet

- A. Technical MalversationDocument8 pagesA. Technical MalversationDinosaur Korean100% (1)

- Conduct A SeminarDocument5 pagesConduct A SeminarChristine Joy SistosoNo ratings yet

- PATANJALIDocument16 pagesPATANJALIAbhishek PandeyNo ratings yet

- CSS Syllabus 2023 PDF Download - FPSCDocument8 pagesCSS Syllabus 2023 PDF Download - FPSCshahid Ramzan0% (1)

- Jesse Anderson Resume UpdatedDocument1 pageJesse Anderson Resume Updatedapi-336053367No ratings yet

- HTW-1390 T5: Tunge Modeller Standard StatiskDocument6 pagesHTW-1390 T5: Tunge Modeller Standard StatiskjhonnyNo ratings yet

- X-Plane Installer LogDocument3 pagesX-Plane Installer LogMarsala NistoNo ratings yet

- The Surprising Incidence of Tax Credits For The Toyota PriusDocument32 pagesThe Surprising Incidence of Tax Credits For The Toyota PriusAkandNo ratings yet

- HIP ChecklistDocument2 pagesHIP ChecklistVathzala KrishnasamyNo ratings yet

- 1.1 Engl 1010Document3 pages1.1 Engl 1010Joey ÁlvarezNo ratings yet

- Flexible Budgets and Performance AnalysisDocument37 pagesFlexible Budgets and Performance AnalysisSana IjazNo ratings yet

- Installing BI Apps 11.1.1.8Document78 pagesInstalling BI Apps 11.1.1.8tonNo ratings yet

- Kore Wa Zombie Desuka Volume 01Document252 pagesKore Wa Zombie Desuka Volume 01randydodson1993No ratings yet

- Nist Fips 201-2Document87 pagesNist Fips 201-2Mohammad Reza NazariNo ratings yet

- Job Hunting-Modul 6 E2Document26 pagesJob Hunting-Modul 6 E2Heri RudiNo ratings yet

- Nche211 Exp1Document8 pagesNche211 Exp1Mbali MdlaloseNo ratings yet

- City of Makati Vs Nippon ExpressDocument8 pagesCity of Makati Vs Nippon ExpressMarie Mariñas-delos ReyesNo ratings yet

- Full Ebook of Atkins Physical Chemistry Peter Atkins Online PDF All ChapterDocument69 pagesFull Ebook of Atkins Physical Chemistry Peter Atkins Online PDF All Chapterjessaeynmaei100% (5)

- Impedance Adaptive Dual-Mode Control of Grid-Connected Inverters With Large Fluctuation of SCR and Its Stability Analysis Based On D-Partition MethodDocument16 pagesImpedance Adaptive Dual-Mode Control of Grid-Connected Inverters With Large Fluctuation of SCR and Its Stability Analysis Based On D-Partition Method张明No ratings yet

- Matrix Training Safety PT Acset Indonusa TBKDocument6 pagesMatrix Training Safety PT Acset Indonusa TBKonyo sjariefNo ratings yet

- SDS (Safety Data Sheet) For LRV Vehicle Cleaning and OMSF Facilities Expired SheetsDocument4 pagesSDS (Safety Data Sheet) For LRV Vehicle Cleaning and OMSF Facilities Expired SheetsmilandivacNo ratings yet

- Gulf County Sheriff's Office Law Enforcement Weekly SummaryDocument3 pagesGulf County Sheriff's Office Law Enforcement Weekly SummaryMichael AllenNo ratings yet

- Report RUSADocument16 pagesReport RUSApawan kumar100% (1)

- Exercise Questions On Regular Language and Regular ExpressionDocument56 pagesExercise Questions On Regular Language and Regular ExpressionAnonymous t1W5G4UZw100% (1)