Professional Documents

Culture Documents

Vacuum Dewatered Flooring: Material

Vacuum Dewatered Flooring: Material

Uploaded by

chawla20208819Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Vacuum Dewatered Flooring: Material

Vacuum Dewatered Flooring: Material

Uploaded by

chawla20208819Copyright:

Available Formats

Vacuum Dewatered Flooring

This specification defines the material, mixing, placing, curing, constructional and other performance requirements for VACUUM DEWATERING CONCRETE SYSTEM for concrete floor slab. Any other special requirements shown or noted on the drawings and directed by the Engineer-in-Charge shall govern over the provision of this specification. Actual work shall be Carrie out in accordance with this specification and in consultation with specialized firm undertaking the job to suit specific requirement at site such as rise and fall of the floor slab, providing dowels for pedestals etc. In case of conflict between clauses mentioned in this specification and those in any Indian Standard, this specification shall grown. MATERIAL: All materials of construction like cement, aggregate, sand, water etc. GRADE OF CONCRETE: Minimum grade of concrete used shall be M15 conforming to IS-456. Only Design Mix Concrete shall be used. For other details like proportioning, batching, mixing, placing, curing etc. WATER-CEMENT RATIO: Water-cement ratio unto 0.65 shall be allowed to obtain better slump & workability. Actual ratio shall be decided with approval of the Engineer-in-charge. Only measured quantity of water shall be used in the mix. SPECIAL REQUIREMENT: All works covered by this specification shall be carried out by an experienced agency having sufficient expertise in vacuum dewatering concrete system. Only skilled and experienced operators shall be employed for the purpose. Prior approval of the agency shall be obtained from the Engineer-in-Charge before starting the work. All the equipment shall be of approved and proven types and suitable for the work involved. CONCRETE LAYING: Concrete laying pattern shall be decided in consultation with the Engineer-in-Charge and with his approval. The maximum width of a slab strip shall not generally exceed 4 meters and minimum number of construction joints shall be used. Alternate slab strips shall be sequentially laid. Any damage to the already finished top surface shall be avoided. At construction joints no overflow of mortal or slurry on the already hardened surface shall be allowed while concreting the intermediate slab strip. Such construction joints shall be marked with a thread in a straight line while the concrete is still green. Continuity of reinforcement shall be maintained while laying concrete in slab strips. Edges at expansion joints shall be protected and proper arrangement of shear-transfer shall be provided standards.

CONCRETE COMPACTION: After placing concrete in position, it shall be vibrated thoroughly using poker/needle vibrators and thereafter leveled with surface vibrators to produce a homogeneous and smooth concrete surface. In order to achieve a smooth surface to the satisfaction of the Engineering-in-Charge, surface vibrators shall be very carefully used by skilled operators. Over vibration resulting in excess mortar near the surface shall be avoided. DE WATERING: Suction mats shall be spread over the leveled fresh concrete surface and shall be connected by suction hose to the vacuum pumps for De-watering of surplus water in the concrete. During De-watering it shall be ensured that no cement/cement slurry is pumped out. FLOATING & TROWELING: This shall be done after De-watering by using skim floater(power floater. After this, surface shall be toweled with minimum two passes of power trowel to achieve a wear resistant surface to the satisfaction of the Engineer-in-Charge. CURING: However, all care shall be taken to avoid any stain any permanent stain on the surface. Any stain or permanent marking on the top surface shall be removed by approved means. APPROACH WORKING PLATFORM & FORM WORK: The Contractor shall arrange all arrange all approaches, scaffolding, working platforms etc. for carrying out the entire operation safely and in a work-man-like manner. The working area shall be nearly maintained and all the facilities required by the Engineer-inCharge for proper supervision of the work shall be provided. TESTING OF FINISHED FLOOR: Contractor shall arrange for core cutting and testing of finished concrete over and above other field tests. Cores shall be taken after 28 days of concreting and tested as per relevant IS Codes. Core test results shall be compared with the normal cube test results taken from the same concrete. The average compressive strength of cores shall be minimum 40% higher than that of normal cube (15cm x 15cm x 15xm) test results. Minimum three cores for each day's work in the initial stages and as decided later by the Engineer-in-Charge shall be taken. The floor shall be properly rectified after cutting the cores with concrete of same mix using the same cement as earlier used and finished smoothly to match with the existing surface. The cut surface of the floor-concrete shall be coated with proper epoxy-based bonding compound before laying concrete to avoid shrinkage cracks or, alternatively, a non-shrink compound shall be added with concrete. Contact us for buying the vacuum dewatering set. A-55, GT Karnal Road Industrial Area- Delhi-110033 Web: http://www.switechindia.com Mob: 9911855522, Ph:011-64727434

You might also like

- PQC MethologyDocument5 pagesPQC MethologyQuality JamNo ratings yet

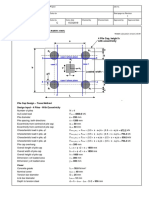

- 4 Piles Cap With Eccentricity ExampleDocument3 pages4 Piles Cap With Eccentricity ExampleSousei No Keroberos100% (1)

- Complete Denture ManualDocument23 pagesComplete Denture ManualCitra PurnamasariNo ratings yet

- Is 5529 1 2013 PDFDocument27 pagesIs 5529 1 2013 PDFAbhishek KumarNo ratings yet

- Entroy and Shaclock Mix Design For HSCDocument9 pagesEntroy and Shaclock Mix Design For HSCvempadareddyNo ratings yet

- Exprimental Study On Permeable Concrete Pavement ForDocument28 pagesExprimental Study On Permeable Concrete Pavement ForVaidyanathan SivasubramanianNo ratings yet

- Specification For Reinforced Soil WallDocument8 pagesSpecification For Reinforced Soil WallChin Thau WuiNo ratings yet

- Git PDFDocument214 pagesGit PDFPrateepNo ratings yet

- Guidelines For Rehabilitation OF Existing Weak Formation: Government of India Ministry of RailwaysDocument42 pagesGuidelines For Rehabilitation OF Existing Weak Formation: Government of India Ministry of RailwaysvpmohammedNo ratings yet

- Well & PileDocument20 pagesWell & PileSURAJ SINHANo ratings yet

- An Experimental Study On Stabilization of Black Cotton Soil by Using Bio PolymersDocument4 pagesAn Experimental Study On Stabilization of Black Cotton Soil by Using Bio PolymersEditor IJTSRDNo ratings yet

- IRC-113-2013 Geosynthetic Reinforced Embankments On Soft SubsoilsDocument57 pagesIRC-113-2013 Geosynthetic Reinforced Embankments On Soft SubsoilsZakee MohamedNo ratings yet

- StabilizationDocument57 pagesStabilizationNurul Izzati Raihan Ramzi100% (1)

- Is 15284 Part I - 2003Document22 pagesIs 15284 Part I - 2003231340No ratings yet

- Flexible Pavement (Bituminous Road) : Compacted Soil SubgradeDocument3 pagesFlexible Pavement (Bituminous Road) : Compacted Soil SubgradeDinesh Kumar PatelNo ratings yet

- A Chip Seal (Also Called A "Seal Coat") Is Essentially A Single Layer of Asphalt Binder That IsDocument24 pagesA Chip Seal (Also Called A "Seal Coat") Is Essentially A Single Layer of Asphalt Binder That IsHalmat GharibNo ratings yet

- Pavement Design and ConstructionDocument44 pagesPavement Design and ConstructionZulqarnain FastNUNo ratings yet

- Investigation On Surface Characteristics of Epoxy Asphalt Concrete PavementDocument8 pagesInvestigation On Surface Characteristics of Epoxy Asphalt Concrete PavementazamNo ratings yet

- Determination of Relative Density or Density Index of Sand (Is-2720-Part-15)Document3 pagesDetermination of Relative Density or Density Index of Sand (Is-2720-Part-15)muhammad iqbalNo ratings yet

- Ravi Sir DLC PresentationDocument13 pagesRavi Sir DLC Presentationসৌগত রায় ঘটকNo ratings yet

- Silo - Tips Case Studies On The Usage of Geosynthetics in Earthen Dams and EmbankmentsDocument6 pagesSilo - Tips Case Studies On The Usage of Geosynthetics in Earthen Dams and Embankmentsrf123_456No ratings yet

- 13-HPCL Vizag Soil Report-VOL.VDocument28 pages13-HPCL Vizag Soil Report-VOL.VDhananjay KumarNo ratings yet

- DLCDocument3 pagesDLCoNo ratings yet

- 02 - Part A - Earth WorkDocument32 pages02 - Part A - Earth Workkartick adhikaryNo ratings yet

- Is 2720 Part-4 Methods of Test For Soils Grain Size Analy.182155414Document40 pagesIs 2720 Part-4 Methods of Test For Soils Grain Size Analy.182155414krityanand19900% (2)

- A158997404492 PDFDocument97 pagesA158997404492 PDFJames Karl AluraNo ratings yet

- Application of GeosyntheticsDocument30 pagesApplication of GeosyntheticsKiprono VincentNo ratings yet

- A Case Study On Ground Improvement Techniques and Its ApplicationsDocument18 pagesA Case Study On Ground Improvement Techniques and Its Applicationsmennahossam8820100% (1)

- A Study of Black Cotton Soil Stabilization With Lime and Waste Plastic Bottle StirrupDocument8 pagesA Study of Black Cotton Soil Stabilization With Lime and Waste Plastic Bottle StirrupIJRASETPublicationsNo ratings yet

- The Authorised Representative,: ST ND RDDocument2 pagesThe Authorised Representative,: ST ND RDAmit MaityNo ratings yet

- Ac-Corroguard: Inhibitor Solution For Reinforcement BarDocument1 pageAc-Corroguard: Inhibitor Solution For Reinforcement BarbhagwatpatilNo ratings yet

- Foundations On Soft Soils For Khulna MedicalDocument6 pagesFoundations On Soft Soils For Khulna MedicalJahid Jahidul Islam KhanNo ratings yet

- Soil Improvement Layer (A Simple Approach) by Structural Engineer AyyappadhasDocument3 pagesSoil Improvement Layer (A Simple Approach) by Structural Engineer AyyappadhasstructuralengineersNo ratings yet

- Study On Mechanism of Strength Distribution DevelopmentDocument19 pagesStudy On Mechanism of Strength Distribution DevelopmentnadirshahNo ratings yet

- Sample Report - Paver BlockDocument1 pageSample Report - Paver BlockPinnacle InfraNo ratings yet

- Classifications of SoilDocument6 pagesClassifications of Soilpriodeep chowdhuryNo ratings yet

- CRRI Presentation On GeosyntheticsDocument51 pagesCRRI Presentation On GeosyntheticsGautam RaiNo ratings yet

- Complete WorkDocument51 pagesComplete WorkOdell Arome Darian100% (3)

- TDS - Polyalk CP 293+Document1 pageTDS - Polyalk CP 293+Anonymous ouZFaSBRNo ratings yet

- Soil MechanicsDocument3 pagesSoil MechanicsPradum Kumar GuptaNo ratings yet

- Unit7 SKP PDFDocument36 pagesUnit7 SKP PDFAGT 6BNo ratings yet

- Dynamic Soil Properties 2015 PDFDocument122 pagesDynamic Soil Properties 2015 PDFChristopher TanjungNo ratings yet

- Methodology For Capliary Cut-OffDocument5 pagesMethodology For Capliary Cut-OffMarees KumarNo ratings yet

- Cochin College: Soil Reinforcement Using ParawebDocument30 pagesCochin College: Soil Reinforcement Using ParawebRowbina Machinchery100% (1)

- Anna UniversityDocument131 pagesAnna UniversityDilipKumarAkkaladeviNo ratings yet

- Irc SP 62 2014.CONSTRUCTION OF CEMENT CONCRETE Roads For Low Volume Roads PDFDocument40 pagesIrc SP 62 2014.CONSTRUCTION OF CEMENT CONCRETE Roads For Low Volume Roads PDFVikaskumar ReddyNo ratings yet

- Geotechnical Checklist-Geocon - Runwal PinncleDocument5 pagesGeotechnical Checklist-Geocon - Runwal PinncleKOMAL JOSHINo ratings yet

- Floating Solar PV Report TERIDocument68 pagesFloating Solar PV Report TERIAbhinav Daga100% (1)

- Chapter-I-Soil Investigation or Soil ExplorationDocument54 pagesChapter-I-Soil Investigation or Soil ExplorationVijaykumar NagnaikNo ratings yet

- Final RerortDocument14 pagesFinal Rerortsrigirisetty208No ratings yet

- Development of New Air Port at SikkimDocument21 pagesDevelopment of New Air Port at SikkimmanideepNo ratings yet

- DCPT TestDocument10 pagesDCPT TestMonirul Islam BadalNo ratings yet

- Unit - IV Consolidation of SoilDocument64 pagesUnit - IV Consolidation of Soilgopierode4100% (1)

- 2212 Brick WorksDocument27 pages2212 Brick WorksDeven PatleNo ratings yet

- Methodology For Convreting WorksDocument7 pagesMethodology For Convreting WorksLokesh SaranNo ratings yet

- Method Statement ConcreteDocument7 pagesMethod Statement ConcreteArthur Ruhinda100% (1)

- Method of Statement For Concreting and Safety MeasuresDocument5 pagesMethod of Statement For Concreting and Safety MeasuresDivya ShahNo ratings yet

- MS Concrete Works - Method StatementDocument6 pagesMS Concrete Works - Method Statementmemekenya100% (1)

- Gracel'S Enterprises: General SpecificationsDocument17 pagesGracel'S Enterprises: General SpecificationsRhanie Nitsuga GnoldubatNo ratings yet

- R105Document1 pageR105Francisco Javier López BarrancoNo ratings yet

- Sec 3 Welding Imperfections (Defects)Document31 pagesSec 3 Welding Imperfections (Defects)Abdullah100% (1)

- Assingment 1 Mobile RobotDocument12 pagesAssingment 1 Mobile Robotiqbal105No ratings yet

- List - Parts of Bahay Na Bato - Filipiniana 101Document7 pagesList - Parts of Bahay Na Bato - Filipiniana 101Eriellynn Liza100% (1)

- Fuschi Et Al 2022 Microplastics in The Great Lakes Environmental Health and Socioeconomic Implications and FutureDocument18 pagesFuschi Et Al 2022 Microplastics in The Great Lakes Environmental Health and Socioeconomic Implications and FuturecriscazanNo ratings yet

- Vedic Astrolgy Paet - 4Document64 pagesVedic Astrolgy Paet - 4krumiaaNo ratings yet

- Acct Lesson 9Document9 pagesAcct Lesson 9Gracielle EspirituNo ratings yet

- Approval Sheet and Evaluation FormDocument8 pagesApproval Sheet and Evaluation FormDannet Frondozo DelmonteNo ratings yet

- BSN Ay 2021-2022Document63 pagesBSN Ay 2021-2022Crystal AnnNo ratings yet

- Experimental Research Designs & Quasi Research DesignsDocument58 pagesExperimental Research Designs & Quasi Research DesignsAcademic CommitteNo ratings yet

- Andrew Mickunas - Teaching Resume PortfolioDocument3 pagesAndrew Mickunas - Teaching Resume PortfolioAndrewNo ratings yet

- Yoga For Modern Age - 1Document181 pagesYoga For Modern Age - 1GayathriNo ratings yet

- Oblicon Reviewer Q and ADocument13 pagesOblicon Reviewer Q and ARussel SirotNo ratings yet

- Activity 3.module 1Document4 pagesActivity 3.module 1Juedy Lala PostreroNo ratings yet

- PHP Security CPanelDocument5 pagesPHP Security CPanelManiMegalaiNo ratings yet

- Security SolutionsDocument3 pagesSecurity SolutionsclubedovarNo ratings yet

- Sansulin R Suspensi Injeksi 100 IU, ML - Rekombinan Insulin Manusia - DKI0708100443A1 - 2016Document2 pagesSansulin R Suspensi Injeksi 100 IU, ML - Rekombinan Insulin Manusia - DKI0708100443A1 - 2016Yessi VirginiaNo ratings yet

- Consumers, Producers, and The Efficiency of MarketsDocument43 pagesConsumers, Producers, and The Efficiency of MarketsRoland EmersonNo ratings yet

- Fluoridi U Amb CanadaDocument122 pagesFluoridi U Amb CanadasonecuNo ratings yet

- Summary WordingDocument5 pagesSummary WordingDaniel JenkinsNo ratings yet

- BS en 1713 - UtDocument20 pagesBS en 1713 - UtBoranAlouaneNo ratings yet

- The Kinston Waterfront Now!Document46 pagesThe Kinston Waterfront Now!Kofi BooneNo ratings yet

- Bicycle Owner's Manual: ImportantDocument55 pagesBicycle Owner's Manual: ImportantAnderson HenriqueNo ratings yet

- SyllabusDocument6 pagesSyllabusMadhu ChauhanNo ratings yet

- Scorpio SCDC LHD Mhawk Eiii v2 Mar12Document154 pagesScorpio SCDC LHD Mhawk Eiii v2 Mar12Romel Bladimir Valenzuela ValenzuelaNo ratings yet

- Art AppreciationDocument41 pagesArt AppreciationVEA CENTRONo ratings yet

- Group Assignment 2Document2 pagesGroup Assignment 2zinilNo ratings yet

- DAF Electric Trucks XF XD Driving Zero Emissions ENDocument6 pagesDAF Electric Trucks XF XD Driving Zero Emissions ENStefan ChirutaNo ratings yet