Professional Documents

Culture Documents

Basic Components of FMS: FMS Introduction and Description 3

Basic Components of FMS: FMS Introduction and Description 3

Uploaded by

tejap314Copyright:

Available Formats

You might also like

- Shop Floor Control & FMSDocument40 pagesShop Floor Control & FMSMayank kumawatNo ratings yet

- Open CIM Practice Report-Group 3Document13 pagesOpen CIM Practice Report-Group 3Hong Nhung Bui Le0% (1)

- Selection of Materials and Shapes: IIT, BombayDocument23 pagesSelection of Materials and Shapes: IIT, Bombaytejap314No ratings yet

- Module 4Document36 pagesModule 4yashpalsingh80726No ratings yet

- The Basic Components of FMS AreDocument1 pageThe Basic Components of FMS AresukupavanNo ratings yet

- A Flexible Manufacturing System (FMS)Document12 pagesA Flexible Manufacturing System (FMS)pushpanjalijNo ratings yet

- FMS Ans Key PDFDocument7 pagesFMS Ans Key PDFPrakash MNo ratings yet

- Flexible Manufacturing SystemDocument10 pagesFlexible Manufacturing SystemVivek PatelNo ratings yet

- Flexible Manufacturing Systems (FMS)Document39 pagesFlexible Manufacturing Systems (FMS)RINU SATHYANNo ratings yet

- FMS AnswersDocument8 pagesFMS AnswersAnmol SetiaNo ratings yet

- Flexible Manufacturing System.Document11 pagesFlexible Manufacturing System.Yaswanth saiNo ratings yet

- Lecture Notes On Flexible Manufacturing System (ETMT-428)Document40 pagesLecture Notes On Flexible Manufacturing System (ETMT-428)Deepak Kumar100% (1)

- Flexible Manufacturing Systems (FMS) : by Mr. Ankush B. KhansoleDocument27 pagesFlexible Manufacturing Systems (FMS) : by Mr. Ankush B. KhansoleankushNo ratings yet

- Components of Flexible Manufacturing SystemsDocument11 pagesComponents of Flexible Manufacturing SystemsjackNo ratings yet

- CH 1 - Introduction To FMS-MNFGDocument48 pagesCH 1 - Introduction To FMS-MNFGdejenem398No ratings yet

- Unit 6Document14 pagesUnit 6GajananNo ratings yet

- 14 - 15. Modul 11 Flexible Manufacturing SystemDocument68 pages14 - 15. Modul 11 Flexible Manufacturing SystemFakhar Windratama100% (1)

- CH 1 - Introduction To FMS-MNFGDocument47 pagesCH 1 - Introduction To FMS-MNFGAshenafi DressNo ratings yet

- Advantages: 1.3 Basic Components of FmsDocument4 pagesAdvantages: 1.3 Basic Components of FmsBoy LiverpoolNo ratings yet

- FMS Tool Library PDFDocument17 pagesFMS Tool Library PDFflytoanilNo ratings yet

- CH 2-FMS ComponentsDocument59 pagesCH 2-FMS Componentsdejenem398No ratings yet

- Flexible Manufacturing SystemsDocument21 pagesFlexible Manufacturing SystemselkhawadNo ratings yet

- Unit V SFC & FMSDocument40 pagesUnit V SFC & FMSPrabhaharMuthuswamyNo ratings yet

- Flexible Manufacturing System (FMS)Document96 pagesFlexible Manufacturing System (FMS)Jignesh RohitNo ratings yet

- 2.6 FMSDocument33 pages2.6 FMSPritesh MannNo ratings yet

- Flexible Manufacturing SystemsDocument21 pagesFlexible Manufacturing SystemsPrabha KaranNo ratings yet

- Presentation 2Document39 pagesPresentation 2naty fishNo ratings yet

- OpenCim - ProjectDocument12 pagesOpenCim - ProjectHoàng Hải Yến TrầnNo ratings yet

- Cim Module IVDocument87 pagesCim Module IVnazalnavazNo ratings yet

- CIM Student ManualDocument22 pagesCIM Student ManualTôn Nữ Minh UyênNo ratings yet

- Flexible Manufacturing System Seminar ReportDocument18 pagesFlexible Manufacturing System Seminar ReportPranav Pandey0% (1)

- FmsDocument37 pagesFmsSumanAgarwal100% (1)

- Golandaz Nazim HasanDocument15 pagesGolandaz Nazim HasanArshad KhanNo ratings yet

- ZA Flexible Manufacturing SystemDocument68 pagesZA Flexible Manufacturing SystemSasiKumar PetchiappanNo ratings yet

- FMS FullDocument92 pagesFMS Fullsmit12soniNo ratings yet

- Flexible Manufacturing SystemDocument21 pagesFlexible Manufacturing SystemRamadan DaniNo ratings yet

- Manufacturing Systems, Automation and FMSDocument67 pagesManufacturing Systems, Automation and FMSPantho PanhoNo ratings yet

- Flexible: Manufacturing SystemsDocument26 pagesFlexible: Manufacturing SystemsSarthakNo ratings yet

- Flexible Manufacturing System ME655Document468 pagesFlexible Manufacturing System ME655peter oumaNo ratings yet

- "Flexible Manufacturing System": K.AMARENDRA (17BME0828) P.GOUTHAM REDDY (17BME0720) Y.V.SIVS PRASANTH (17BME0457)Document27 pages"Flexible Manufacturing System": K.AMARENDRA (17BME0828) P.GOUTHAM REDDY (17BME0720) Y.V.SIVS PRASANTH (17BME0457)Goutham ReddyNo ratings yet

- Flexible Manufacturing SystemDocument10 pagesFlexible Manufacturing SystemShanky JainNo ratings yet

- FMS Case StudyDocument41 pagesFMS Case StudyAdhavanNo ratings yet

- Topic 16Document17 pagesTopic 16lucas100% (1)

- Submitted By: Chithralekha R S4 Mba CETDocument45 pagesSubmitted By: Chithralekha R S4 Mba CETAnish VijayNo ratings yet

- Flexible Manufacturing SystemDocument18 pagesFlexible Manufacturing SystemTp 10No ratings yet

- Advanced Manufacturing Quiz Solution and Course Guide - 2024Document3 pagesAdvanced Manufacturing Quiz Solution and Course Guide - 2024sannikimyoungNo ratings yet

- Transfer Lines and Similar Automated Manufacturing SystemDocument26 pagesTransfer Lines and Similar Automated Manufacturing Systemsnjypraja100% (2)

- Introduction To Mechatronics: JerkDocument5 pagesIntroduction To Mechatronics: Jerkroyal1979No ratings yet

- Fms - Flexible Manufacturing SystemsDocument47 pagesFms - Flexible Manufacturing SystemsYashwanth ReddyNo ratings yet

- FMS 1Document27 pagesFMS 1bishal dattaNo ratings yet

- Cad Cam Comp Integrated MFG FmsDocument5 pagesCad Cam Comp Integrated MFG FmsShobith DsouzaNo ratings yet

- Experiment No. - 6Document11 pagesExperiment No. - 6jay_v9No ratings yet

- Material HandlingDocument3 pagesMaterial Handlingolyad ahmedinNo ratings yet

- FMSDocument6 pagesFMS21UME003 TUSHAR DEBNo ratings yet

- Ch8 FMSDocument39 pagesCh8 FMSImran KhanNo ratings yet

- M.Tech: Automation in Manufacturing: Computer Numerical Control (CNC) MachinesDocument28 pagesM.Tech: Automation in Manufacturing: Computer Numerical Control (CNC) MachinesMohamed Essam MohamedNo ratings yet

- Ch8 FMSDocument39 pagesCh8 FMSKaran Kapoor100% (1)

- Ch8 FMSDocument39 pagesCh8 FMSThiru MuruganNo ratings yet

- Operating Systems: Concepts to Save Money, Time, and FrustrationFrom EverandOperating Systems: Concepts to Save Money, Time, and FrustrationNo ratings yet

- Bharat Sanchar Nigam Limited: Receipt DetailsDocument1 pageBharat Sanchar Nigam Limited: Receipt Detailstejap314No ratings yet

- Sl. No Holiday Date Day of Week: Institute Holidays For The Year 2013Document1 pageSl. No Holiday Date Day of Week: Institute Holidays For The Year 2013tejap314No ratings yet

- Cds 2012 1Document2 pagesCds 2012 1tejap314No ratings yet

- Cds 2, 2010 GK Answer For Series ADocument1 pageCds 2, 2010 GK Answer For Series Atejap314No ratings yet

- North American Stainless: Long Products Stainless Steel Grade SheetDocument8 pagesNorth American Stainless: Long Products Stainless Steel Grade Sheettejap314No ratings yet

- Design For Reliability and Quality: IIT, BombayDocument27 pagesDesign For Reliability and Quality: IIT, Bombaytejap314No ratings yet

- 2010 2 Engsentence ImprovementDocument3 pages2010 2 Engsentence Improvementtejap314No ratings yet

- Design For Reliability and Quality: IIT, BombayDocument30 pagesDesign For Reliability and Quality: IIT, Bombaytejap314No ratings yet

- An Experimental Study On The Effect of MIG Welding Parameters On The Weld-Bead Shape CharacteristicsDocument5 pagesAn Experimental Study On The Effect of MIG Welding Parameters On The Weld-Bead Shape Characteristicstejap314No ratings yet

- Design For Reliability and Quality: IIT, BombayDocument14 pagesDesign For Reliability and Quality: IIT, Bombaytejap314No ratings yet

- Design For Reliability and Quality: IIT, BombayDocument12 pagesDesign For Reliability and Quality: IIT, Bombaytejap314No ratings yet

- Module 4 Lecture 8 FinalDocument17 pagesModule 4 Lecture 8 Finaltejap314No ratings yet

- Design For Reliability and Quality: IIT, BombayDocument13 pagesDesign For Reliability and Quality: IIT, Bombaytejap314No ratings yet

- Selection of Manufacturing Processes: Iit BombayDocument14 pagesSelection of Manufacturing Processes: Iit Bombaytejap314No ratings yet

- Selection of Manufacturing ProcessesDocument21 pagesSelection of Manufacturing Processestejap314No ratings yet

- Module 4 Lecture 5 FinalDocument12 pagesModule 4 Lecture 5 Finaltejap314No ratings yet

- Design For Assembly: Iit BombayDocument16 pagesDesign For Assembly: Iit Bombaytejap314No ratings yet

- Module 3 Lecture 8 FinalDocument12 pagesModule 3 Lecture 8 Finaltejap314No ratings yet

- Module 3 Lecture 3 FinalDocument15 pagesModule 3 Lecture 3 Finaltejap314No ratings yet

- Module 3 Lecture 2 FinalDocument22 pagesModule 3 Lecture 2 Finaltejap314No ratings yet

Basic Components of FMS: FMS Introduction and Description 3

Basic Components of FMS: FMS Introduction and Description 3

Uploaded by

tejap314Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Basic Components of FMS: FMS Introduction and Description 3

Basic Components of FMS: FMS Introduction and Description 3

Uploaded by

tejap314Copyright:

Available Formats

BASIC COMPONENTS OF FMS

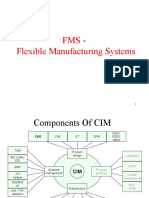

The basic components of FMS are: 1. Workstations 2. Automated Material Handling and Storage system. 3. Computer Control System 1. Workstations: In present day application these workstations are typically computer numerical control (CNC) machine tools that perform machining operation on families of parts. Flexible manufacturing systems are being designed with other type of processing equipments including inspection stations, assembly works and sheet metal presses. The various workstations are (i) Machining centers (ii) Load and unload stations (iii) Assembly work stations (iv) Inspection stations (v) Forging stations (vi) Sheet metal processing, etc. 2. Automated Material Handling and Storage system: The various automated material handling systems are used to transport work parts and subassembly parts between the processing stations, sometimes incorporating storage into function. The various functions of automated material handling and storage system are (i) Random and independent movement of work parts between workstations (ii) Handling of a variety of work part configurations (iii) Temporary storage (iv) Convenient access for loading and unloading of work parts (v) Compatible with computer control FMS Introduction and Description 3 3. Computer Control System: It is used to coordinate the activities of the processing stations and the material handling system in the FMS. The various functions of computer control system are: (i) Control of each work station (ii) Distribution of control instruction to work station (iii) Production control (vi) Traffic control (v) Shuttle control (vi) Work handling system and monitoring (vii) System performance monitoring and reporting The FMS is most suited for the mid variety, mid value production range.

You might also like

- Shop Floor Control & FMSDocument40 pagesShop Floor Control & FMSMayank kumawatNo ratings yet

- Open CIM Practice Report-Group 3Document13 pagesOpen CIM Practice Report-Group 3Hong Nhung Bui Le0% (1)

- Selection of Materials and Shapes: IIT, BombayDocument23 pagesSelection of Materials and Shapes: IIT, Bombaytejap314No ratings yet

- Module 4Document36 pagesModule 4yashpalsingh80726No ratings yet

- The Basic Components of FMS AreDocument1 pageThe Basic Components of FMS AresukupavanNo ratings yet

- A Flexible Manufacturing System (FMS)Document12 pagesA Flexible Manufacturing System (FMS)pushpanjalijNo ratings yet

- FMS Ans Key PDFDocument7 pagesFMS Ans Key PDFPrakash MNo ratings yet

- Flexible Manufacturing SystemDocument10 pagesFlexible Manufacturing SystemVivek PatelNo ratings yet

- Flexible Manufacturing Systems (FMS)Document39 pagesFlexible Manufacturing Systems (FMS)RINU SATHYANNo ratings yet

- FMS AnswersDocument8 pagesFMS AnswersAnmol SetiaNo ratings yet

- Flexible Manufacturing System.Document11 pagesFlexible Manufacturing System.Yaswanth saiNo ratings yet

- Lecture Notes On Flexible Manufacturing System (ETMT-428)Document40 pagesLecture Notes On Flexible Manufacturing System (ETMT-428)Deepak Kumar100% (1)

- Flexible Manufacturing Systems (FMS) : by Mr. Ankush B. KhansoleDocument27 pagesFlexible Manufacturing Systems (FMS) : by Mr. Ankush B. KhansoleankushNo ratings yet

- Components of Flexible Manufacturing SystemsDocument11 pagesComponents of Flexible Manufacturing SystemsjackNo ratings yet

- CH 1 - Introduction To FMS-MNFGDocument48 pagesCH 1 - Introduction To FMS-MNFGdejenem398No ratings yet

- Unit 6Document14 pagesUnit 6GajananNo ratings yet

- 14 - 15. Modul 11 Flexible Manufacturing SystemDocument68 pages14 - 15. Modul 11 Flexible Manufacturing SystemFakhar Windratama100% (1)

- CH 1 - Introduction To FMS-MNFGDocument47 pagesCH 1 - Introduction To FMS-MNFGAshenafi DressNo ratings yet

- Advantages: 1.3 Basic Components of FmsDocument4 pagesAdvantages: 1.3 Basic Components of FmsBoy LiverpoolNo ratings yet

- FMS Tool Library PDFDocument17 pagesFMS Tool Library PDFflytoanilNo ratings yet

- CH 2-FMS ComponentsDocument59 pagesCH 2-FMS Componentsdejenem398No ratings yet

- Flexible Manufacturing SystemsDocument21 pagesFlexible Manufacturing SystemselkhawadNo ratings yet

- Unit V SFC & FMSDocument40 pagesUnit V SFC & FMSPrabhaharMuthuswamyNo ratings yet

- Flexible Manufacturing System (FMS)Document96 pagesFlexible Manufacturing System (FMS)Jignesh RohitNo ratings yet

- 2.6 FMSDocument33 pages2.6 FMSPritesh MannNo ratings yet

- Flexible Manufacturing SystemsDocument21 pagesFlexible Manufacturing SystemsPrabha KaranNo ratings yet

- Presentation 2Document39 pagesPresentation 2naty fishNo ratings yet

- OpenCim - ProjectDocument12 pagesOpenCim - ProjectHoàng Hải Yến TrầnNo ratings yet

- Cim Module IVDocument87 pagesCim Module IVnazalnavazNo ratings yet

- CIM Student ManualDocument22 pagesCIM Student ManualTôn Nữ Minh UyênNo ratings yet

- Flexible Manufacturing System Seminar ReportDocument18 pagesFlexible Manufacturing System Seminar ReportPranav Pandey0% (1)

- FmsDocument37 pagesFmsSumanAgarwal100% (1)

- Golandaz Nazim HasanDocument15 pagesGolandaz Nazim HasanArshad KhanNo ratings yet

- ZA Flexible Manufacturing SystemDocument68 pagesZA Flexible Manufacturing SystemSasiKumar PetchiappanNo ratings yet

- FMS FullDocument92 pagesFMS Fullsmit12soniNo ratings yet

- Flexible Manufacturing SystemDocument21 pagesFlexible Manufacturing SystemRamadan DaniNo ratings yet

- Manufacturing Systems, Automation and FMSDocument67 pagesManufacturing Systems, Automation and FMSPantho PanhoNo ratings yet

- Flexible: Manufacturing SystemsDocument26 pagesFlexible: Manufacturing SystemsSarthakNo ratings yet

- Flexible Manufacturing System ME655Document468 pagesFlexible Manufacturing System ME655peter oumaNo ratings yet

- "Flexible Manufacturing System": K.AMARENDRA (17BME0828) P.GOUTHAM REDDY (17BME0720) Y.V.SIVS PRASANTH (17BME0457)Document27 pages"Flexible Manufacturing System": K.AMARENDRA (17BME0828) P.GOUTHAM REDDY (17BME0720) Y.V.SIVS PRASANTH (17BME0457)Goutham ReddyNo ratings yet

- Flexible Manufacturing SystemDocument10 pagesFlexible Manufacturing SystemShanky JainNo ratings yet

- FMS Case StudyDocument41 pagesFMS Case StudyAdhavanNo ratings yet

- Topic 16Document17 pagesTopic 16lucas100% (1)

- Submitted By: Chithralekha R S4 Mba CETDocument45 pagesSubmitted By: Chithralekha R S4 Mba CETAnish VijayNo ratings yet

- Flexible Manufacturing SystemDocument18 pagesFlexible Manufacturing SystemTp 10No ratings yet

- Advanced Manufacturing Quiz Solution and Course Guide - 2024Document3 pagesAdvanced Manufacturing Quiz Solution and Course Guide - 2024sannikimyoungNo ratings yet

- Transfer Lines and Similar Automated Manufacturing SystemDocument26 pagesTransfer Lines and Similar Automated Manufacturing Systemsnjypraja100% (2)

- Introduction To Mechatronics: JerkDocument5 pagesIntroduction To Mechatronics: Jerkroyal1979No ratings yet

- Fms - Flexible Manufacturing SystemsDocument47 pagesFms - Flexible Manufacturing SystemsYashwanth ReddyNo ratings yet

- FMS 1Document27 pagesFMS 1bishal dattaNo ratings yet

- Cad Cam Comp Integrated MFG FmsDocument5 pagesCad Cam Comp Integrated MFG FmsShobith DsouzaNo ratings yet

- Experiment No. - 6Document11 pagesExperiment No. - 6jay_v9No ratings yet

- Material HandlingDocument3 pagesMaterial Handlingolyad ahmedinNo ratings yet

- FMSDocument6 pagesFMS21UME003 TUSHAR DEBNo ratings yet

- Ch8 FMSDocument39 pagesCh8 FMSImran KhanNo ratings yet

- M.Tech: Automation in Manufacturing: Computer Numerical Control (CNC) MachinesDocument28 pagesM.Tech: Automation in Manufacturing: Computer Numerical Control (CNC) MachinesMohamed Essam MohamedNo ratings yet

- Ch8 FMSDocument39 pagesCh8 FMSKaran Kapoor100% (1)

- Ch8 FMSDocument39 pagesCh8 FMSThiru MuruganNo ratings yet

- Operating Systems: Concepts to Save Money, Time, and FrustrationFrom EverandOperating Systems: Concepts to Save Money, Time, and FrustrationNo ratings yet

- Bharat Sanchar Nigam Limited: Receipt DetailsDocument1 pageBharat Sanchar Nigam Limited: Receipt Detailstejap314No ratings yet

- Sl. No Holiday Date Day of Week: Institute Holidays For The Year 2013Document1 pageSl. No Holiday Date Day of Week: Institute Holidays For The Year 2013tejap314No ratings yet

- Cds 2012 1Document2 pagesCds 2012 1tejap314No ratings yet

- Cds 2, 2010 GK Answer For Series ADocument1 pageCds 2, 2010 GK Answer For Series Atejap314No ratings yet

- North American Stainless: Long Products Stainless Steel Grade SheetDocument8 pagesNorth American Stainless: Long Products Stainless Steel Grade Sheettejap314No ratings yet

- Design For Reliability and Quality: IIT, BombayDocument27 pagesDesign For Reliability and Quality: IIT, Bombaytejap314No ratings yet

- 2010 2 Engsentence ImprovementDocument3 pages2010 2 Engsentence Improvementtejap314No ratings yet

- Design For Reliability and Quality: IIT, BombayDocument30 pagesDesign For Reliability and Quality: IIT, Bombaytejap314No ratings yet

- An Experimental Study On The Effect of MIG Welding Parameters On The Weld-Bead Shape CharacteristicsDocument5 pagesAn Experimental Study On The Effect of MIG Welding Parameters On The Weld-Bead Shape Characteristicstejap314No ratings yet

- Design For Reliability and Quality: IIT, BombayDocument14 pagesDesign For Reliability and Quality: IIT, Bombaytejap314No ratings yet

- Design For Reliability and Quality: IIT, BombayDocument12 pagesDesign For Reliability and Quality: IIT, Bombaytejap314No ratings yet

- Module 4 Lecture 8 FinalDocument17 pagesModule 4 Lecture 8 Finaltejap314No ratings yet

- Design For Reliability and Quality: IIT, BombayDocument13 pagesDesign For Reliability and Quality: IIT, Bombaytejap314No ratings yet

- Selection of Manufacturing Processes: Iit BombayDocument14 pagesSelection of Manufacturing Processes: Iit Bombaytejap314No ratings yet

- Selection of Manufacturing ProcessesDocument21 pagesSelection of Manufacturing Processestejap314No ratings yet

- Module 4 Lecture 5 FinalDocument12 pagesModule 4 Lecture 5 Finaltejap314No ratings yet

- Design For Assembly: Iit BombayDocument16 pagesDesign For Assembly: Iit Bombaytejap314No ratings yet

- Module 3 Lecture 8 FinalDocument12 pagesModule 3 Lecture 8 Finaltejap314No ratings yet

- Module 3 Lecture 3 FinalDocument15 pagesModule 3 Lecture 3 Finaltejap314No ratings yet

- Module 3 Lecture 2 FinalDocument22 pagesModule 3 Lecture 2 Finaltejap314No ratings yet