Professional Documents

Culture Documents

RT Weld Defects.

RT Weld Defects.

Uploaded by

Sai Krishna YellapuCopyright:

Available Formats

You might also like

- RI CW 7Document8 pagesRI CW 7Saut Maruli Tua SamosirNo ratings yet

- Radiography AsntDocument82 pagesRadiography AsntIdeal Naradmuni100% (1)

- Questions & Answers - RT Level 1Document5 pagesQuestions & Answers - RT Level 1Mohan Raj67% (3)

- Magnetic Particle TestingDocument3 pagesMagnetic Particle TestingKurniawanNo ratings yet

- ISO - IsO Standards - IsO - TC 44 - SC 5 - Testing and Inspection of WeldsDocument4 pagesISO - IsO Standards - IsO - TC 44 - SC 5 - Testing and Inspection of Weldssunilsharma853380No ratings yet

- Radiography PresentationDocument28 pagesRadiography PresentationmqasimqasimNo ratings yet

- Radiographic DefectsDocument20 pagesRadiographic Defectshappysekhon86100% (1)

- An Automated Radiographic NDT System For Weld Inspection - Part I - Weld Extraction PDFDocument6 pagesAn Automated Radiographic NDT System For Weld Inspection - Part I - Weld Extraction PDFaliNo ratings yet

- RI CW 8Document8 pagesRI CW 8Saut Maruli Tua SamosirNo ratings yet

- Material SpecificationDocument2 pagesMaterial SpecificationmasrooorNo ratings yet

- AWS Radio Graphic InterpreterDocument5 pagesAWS Radio Graphic InterpreterShrey Gupta0% (1)

- As RI GEN 002 With AnswersDocument6 pagesAs RI GEN 002 With AnswersKarthikeyan GanesanNo ratings yet

- Visual Testing: Level I and II: Course OutlineDocument3 pagesVisual Testing: Level I and II: Course OutlineMohammed Al-Odat100% (1)

- Radiography Testing Level I and II PDFDocument87 pagesRadiography Testing Level I and II PDFIdeal NaradmuniNo ratings yet

- Uphill Versus Downhill Welding PDFDocument4 pagesUphill Versus Downhill Welding PDFPatrick DominguezNo ratings yet

- RI CW 4Document6 pagesRI CW 4Saut Maruli Tua SamosirNo ratings yet

- 1100 Gorman RT-UT Presentation For CTMS Oct 07Document29 pages1100 Gorman RT-UT Presentation For CTMS Oct 07Sagar NaduvinamaniNo ratings yet

- Radiography TestDocument20 pagesRadiography Testkrishna_pipingNo ratings yet

- RI CW 9Document8 pagesRI CW 9Saut Maruli Tua SamosirNo ratings yet

- Astm E562 PDF Free 15 PDFDocument4 pagesAstm E562 PDF Free 15 PDFarjun prajapatiNo ratings yet

- MTDocument65 pagesMTIkram SyedNo ratings yet

- Radiographic TestingDocument42 pagesRadiographic TestingBiNuLAlB75% (8)

- APIRP586 Sec 1 Heat Exch Tubing InspsecondballottrackDocument48 pagesAPIRP586 Sec 1 Heat Exch Tubing InspsecondballottrackUsman NaseemNo ratings yet

- RI CW 1Document6 pagesRI CW 1amalhaj2013No ratings yet

- Creep WavesDocument1 pageCreep WavesCarlos BustamanteNo ratings yet

- Question and Answer For Acoustic Emission Testing MethodDocument16 pagesQuestion and Answer For Acoustic Emission Testing Methodapply19842371100% (3)

- ASNTDocument5 pagesASNTshifaNo ratings yet

- Radiographic Film InterpretationDocument5 pagesRadiographic Film Interpretationponnivalavans_994423No ratings yet

- Paut Calibration Summary Both-Single Side (CS & SS)Document20 pagesPaut Calibration Summary Both-Single Side (CS & SS)prabhu_trichyNo ratings yet

- Selenium 75Document5 pagesSelenium 75jimmy david espinoza mejiaNo ratings yet

- MT TwiDocument51 pagesMT TwidaemsalNo ratings yet

- RT SafetyDocument157 pagesRT SafetyYasser Abd El FattahNo ratings yet

- Technology - Comparison of MEC MFL For Tank Floor Inspection-MinDocument7 pagesTechnology - Comparison of MEC MFL For Tank Floor Inspection-MinCepi Sindang KamulanNo ratings yet

- RI CW 6Document7 pagesRI CW 6Saut Maruli Tua SamosirNo ratings yet

- Question and Answer For RTDocument70 pagesQuestion and Answer For RTapply19842371No ratings yet

- Astm E747Document3 pagesAstm E747AmithNo ratings yet

- RI CW 2Document6 pagesRI CW 2Saut Maruli Tua Samosir100% (1)

- Penetrants TESTINGDocument86 pagesPenetrants TESTINGsankaran_muthukumarNo ratings yet

- Magnetic Design of A Flux Leakage Assembly For PipesDocument6 pagesMagnetic Design of A Flux Leakage Assembly For PipesPDDELUCA100% (1)

- NDTDocument36 pagesNDTMuhammed SulfeekNo ratings yet

- Question of MPI Module 1 To 4Document11 pagesQuestion of MPI Module 1 To 4Tarek YehiaNo ratings yet

- Excercise & Solutions PDFDocument7 pagesExcercise & Solutions PDFMd Ashikur RahmanNo ratings yet

- Fasnt - Ultrasonic Testing TestDocument3 pagesFasnt - Ultrasonic Testing TestaravindanNo ratings yet

- Ri 2Document42 pagesRi 2Team Piping100% (1)

- Din en Iso 23279-2010Document19 pagesDin en Iso 23279-2010Anbarasan PerumalNo ratings yet

- Bolt Grade Markings and Strength Chart: Head Marking Grade and Material Nominal Size Range Mechanical PropertiesDocument2 pagesBolt Grade Markings and Strength Chart: Head Marking Grade and Material Nominal Size Range Mechanical PropertiesDeepakGawasNo ratings yet

- Radiographic Interpretation Assessment: Multi - Choice Question Paper (MSR-ARI-1) NameDocument5 pagesRadiographic Interpretation Assessment: Multi - Choice Question Paper (MSR-ARI-1) NameSaut Maruli Tua Samosir50% (2)

- RT Weld DefectsDocument2 pagesRT Weld DefectsChristopher BentonNo ratings yet

- Radiograph Interpretation - WeldsDocument7 pagesRadiograph Interpretation - WeldsDanut RusNo ratings yet

- Casestudy FracturedductilecastironbracketDocument2 pagesCasestudy FracturedductilecastironbracketKhin Aung ShweNo ratings yet

- Total Solutions ForDocument2 pagesTotal Solutions ForM Jobayer AzadNo ratings yet

- Analysis of Microcracks in Weld Line of ERW PipeDocument7 pagesAnalysis of Microcracks in Weld Line of ERW PipeAyon RoyNo ratings yet

- Radiograph Interpretation - CastingsDocument5 pagesRadiograph Interpretation - CastingshoscriNo ratings yet

- Tools and Techniques in Failure Analysis: Scanning Electron MicrosDocument10 pagesTools and Techniques in Failure Analysis: Scanning Electron MicrosBaljit SinghNo ratings yet

- Modeling of Ultrasonic Testing For Inspection of Nodular Cast Iron InsertDocument14 pagesModeling of Ultrasonic Testing For Inspection of Nodular Cast Iron InsertCarlos Ortega JonesNo ratings yet

- Welding and Characterization of 5083 Aluminium Alloy PDFDocument6 pagesWelding and Characterization of 5083 Aluminium Alloy PDFPatricio G. ArrienNo ratings yet

- Radiograph InterpretationDocument12 pagesRadiograph InterpretationnithingrmeNo ratings yet

- Leak Testing: Nondestructive Inspection of CastingsDocument1 pageLeak Testing: Nondestructive Inspection of CastingsCARLOS SUNTAXINo ratings yet

- MicroCrack Formation in HFERWDocument9 pagesMicroCrack Formation in HFERWN TanejaNo ratings yet

- How To Avoid Getting Chicken Pox While Helping An Infected PersonDocument10 pagesHow To Avoid Getting Chicken Pox While Helping An Infected PersonSai Krishna YellapuNo ratings yet

- Module 6: Radiographic Techniques: Lesson 16: Periapical Radiographs & Intraoral SurveysDocument101 pagesModule 6: Radiographic Techniques: Lesson 16: Periapical Radiographs & Intraoral SurveysSai Krishna YellapuNo ratings yet

- PAUT 22.8mm Scan PlanDocument3 pagesPAUT 22.8mm Scan PlanSai Krishna YellapuNo ratings yet

- Haisamuddin Patwekar: Curriculum VitaeDocument3 pagesHaisamuddin Patwekar: Curriculum VitaeSai Krishna YellapuNo ratings yet

- 2011 Abstract Book-1Document292 pages2011 Abstract Book-1Sai Krishna YellapuNo ratings yet

- Pipeline Integrity Management ExternalDocument36 pagesPipeline Integrity Management ExternalJavierfox98100% (6)

- Radiography EnclosureDocument1 pageRadiography EnclosureSai Krishna YellapuNo ratings yet

- TOFD PresentationDocument18 pagesTOFD PresentationSai Krishna Yellapu100% (7)

RT Weld Defects.

RT Weld Defects.

Uploaded by

Sai Krishna YellapuOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RT Weld Defects.

RT Weld Defects.

Uploaded by

Sai Krishna YellapuCopyright:

Available Formats

T.O.

33B-1-1

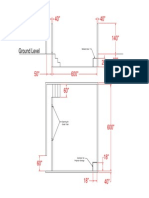

Figure 6-45. Radiographic Examples of Welds (Sheet 1 of 2)

6-104

T.O. 33B-1-1

Figure 6-45.

Radiographic Examples of Welds (Sheet 2 of 2)

6.8.17.17

Aluminum and Magnesium Welds.

Radiographic technique and equipment for examining welds in aluminum and magnesium alloys are no different than methods used for steel welds. The discontinuities produced by fusion welding of aluminum and revealed on f ilm by radiography include: a. b. Entrapped gas, ranging from f ine gas porosity to large gas holes. The porosity may be in line or at random. Inclusions of tungsten particles, foreign materials, f lux and oxide. Since the density of oxide f ilms is nearly the same as that of aluminum, they will not produce a detailed indication on a radiograph unless present in large quantities. Inadequate penetration. Incomplete fusion. Cracks. Surface irregularities. Spot Welds.

c. d. e. f. 6.8.18

A special exposure technique is necessary for the inspection of spot welds. The welded areas are X-rayed with a low-voltage, high-intensity, beryllium-window X-ray tube on extremely f ine grained f ilms. Spot welds and seam welds produce X-ray images of aluminum and its alloys that are entirely different from those of any other welding technique. Because of the rather large percentage of radiographically dense alloying constituents that produce informative patterns, some of the high strength aluminum alloys are well suited for spot weld radiography. The images show positive indications of the following: a. b. c. d. e. f. g. Variations in weld nugget shape (oversize, undersize, absence, misshapen, doughnut and crescent shaped). Extrusion and expulsion of metal from nugget. Cracks. Foreign materials (for example, tip pickup). Porosity. Segregation of the alloying elements. Electrode impressions.

Change 3

6-105

You might also like

- RI CW 7Document8 pagesRI CW 7Saut Maruli Tua SamosirNo ratings yet

- Radiography AsntDocument82 pagesRadiography AsntIdeal Naradmuni100% (1)

- Questions & Answers - RT Level 1Document5 pagesQuestions & Answers - RT Level 1Mohan Raj67% (3)

- Magnetic Particle TestingDocument3 pagesMagnetic Particle TestingKurniawanNo ratings yet

- ISO - IsO Standards - IsO - TC 44 - SC 5 - Testing and Inspection of WeldsDocument4 pagesISO - IsO Standards - IsO - TC 44 - SC 5 - Testing and Inspection of Weldssunilsharma853380No ratings yet

- Radiography PresentationDocument28 pagesRadiography PresentationmqasimqasimNo ratings yet

- Radiographic DefectsDocument20 pagesRadiographic Defectshappysekhon86100% (1)

- An Automated Radiographic NDT System For Weld Inspection - Part I - Weld Extraction PDFDocument6 pagesAn Automated Radiographic NDT System For Weld Inspection - Part I - Weld Extraction PDFaliNo ratings yet

- RI CW 8Document8 pagesRI CW 8Saut Maruli Tua SamosirNo ratings yet

- Material SpecificationDocument2 pagesMaterial SpecificationmasrooorNo ratings yet

- AWS Radio Graphic InterpreterDocument5 pagesAWS Radio Graphic InterpreterShrey Gupta0% (1)

- As RI GEN 002 With AnswersDocument6 pagesAs RI GEN 002 With AnswersKarthikeyan GanesanNo ratings yet

- Visual Testing: Level I and II: Course OutlineDocument3 pagesVisual Testing: Level I and II: Course OutlineMohammed Al-Odat100% (1)

- Radiography Testing Level I and II PDFDocument87 pagesRadiography Testing Level I and II PDFIdeal NaradmuniNo ratings yet

- Uphill Versus Downhill Welding PDFDocument4 pagesUphill Versus Downhill Welding PDFPatrick DominguezNo ratings yet

- RI CW 4Document6 pagesRI CW 4Saut Maruli Tua SamosirNo ratings yet

- 1100 Gorman RT-UT Presentation For CTMS Oct 07Document29 pages1100 Gorman RT-UT Presentation For CTMS Oct 07Sagar NaduvinamaniNo ratings yet

- Radiography TestDocument20 pagesRadiography Testkrishna_pipingNo ratings yet

- RI CW 9Document8 pagesRI CW 9Saut Maruli Tua SamosirNo ratings yet

- Astm E562 PDF Free 15 PDFDocument4 pagesAstm E562 PDF Free 15 PDFarjun prajapatiNo ratings yet

- MTDocument65 pagesMTIkram SyedNo ratings yet

- Radiographic TestingDocument42 pagesRadiographic TestingBiNuLAlB75% (8)

- APIRP586 Sec 1 Heat Exch Tubing InspsecondballottrackDocument48 pagesAPIRP586 Sec 1 Heat Exch Tubing InspsecondballottrackUsman NaseemNo ratings yet

- RI CW 1Document6 pagesRI CW 1amalhaj2013No ratings yet

- Creep WavesDocument1 pageCreep WavesCarlos BustamanteNo ratings yet

- Question and Answer For Acoustic Emission Testing MethodDocument16 pagesQuestion and Answer For Acoustic Emission Testing Methodapply19842371100% (3)

- ASNTDocument5 pagesASNTshifaNo ratings yet

- Radiographic Film InterpretationDocument5 pagesRadiographic Film Interpretationponnivalavans_994423No ratings yet

- Paut Calibration Summary Both-Single Side (CS & SS)Document20 pagesPaut Calibration Summary Both-Single Side (CS & SS)prabhu_trichyNo ratings yet

- Selenium 75Document5 pagesSelenium 75jimmy david espinoza mejiaNo ratings yet

- MT TwiDocument51 pagesMT TwidaemsalNo ratings yet

- RT SafetyDocument157 pagesRT SafetyYasser Abd El FattahNo ratings yet

- Technology - Comparison of MEC MFL For Tank Floor Inspection-MinDocument7 pagesTechnology - Comparison of MEC MFL For Tank Floor Inspection-MinCepi Sindang KamulanNo ratings yet

- RI CW 6Document7 pagesRI CW 6Saut Maruli Tua SamosirNo ratings yet

- Question and Answer For RTDocument70 pagesQuestion and Answer For RTapply19842371No ratings yet

- Astm E747Document3 pagesAstm E747AmithNo ratings yet

- RI CW 2Document6 pagesRI CW 2Saut Maruli Tua Samosir100% (1)

- Penetrants TESTINGDocument86 pagesPenetrants TESTINGsankaran_muthukumarNo ratings yet

- Magnetic Design of A Flux Leakage Assembly For PipesDocument6 pagesMagnetic Design of A Flux Leakage Assembly For PipesPDDELUCA100% (1)

- NDTDocument36 pagesNDTMuhammed SulfeekNo ratings yet

- Question of MPI Module 1 To 4Document11 pagesQuestion of MPI Module 1 To 4Tarek YehiaNo ratings yet

- Excercise & Solutions PDFDocument7 pagesExcercise & Solutions PDFMd Ashikur RahmanNo ratings yet

- Fasnt - Ultrasonic Testing TestDocument3 pagesFasnt - Ultrasonic Testing TestaravindanNo ratings yet

- Ri 2Document42 pagesRi 2Team Piping100% (1)

- Din en Iso 23279-2010Document19 pagesDin en Iso 23279-2010Anbarasan PerumalNo ratings yet

- Bolt Grade Markings and Strength Chart: Head Marking Grade and Material Nominal Size Range Mechanical PropertiesDocument2 pagesBolt Grade Markings and Strength Chart: Head Marking Grade and Material Nominal Size Range Mechanical PropertiesDeepakGawasNo ratings yet

- Radiographic Interpretation Assessment: Multi - Choice Question Paper (MSR-ARI-1) NameDocument5 pagesRadiographic Interpretation Assessment: Multi - Choice Question Paper (MSR-ARI-1) NameSaut Maruli Tua Samosir50% (2)

- RT Weld DefectsDocument2 pagesRT Weld DefectsChristopher BentonNo ratings yet

- Radiograph Interpretation - WeldsDocument7 pagesRadiograph Interpretation - WeldsDanut RusNo ratings yet

- Casestudy FracturedductilecastironbracketDocument2 pagesCasestudy FracturedductilecastironbracketKhin Aung ShweNo ratings yet

- Total Solutions ForDocument2 pagesTotal Solutions ForM Jobayer AzadNo ratings yet

- Analysis of Microcracks in Weld Line of ERW PipeDocument7 pagesAnalysis of Microcracks in Weld Line of ERW PipeAyon RoyNo ratings yet

- Radiograph Interpretation - CastingsDocument5 pagesRadiograph Interpretation - CastingshoscriNo ratings yet

- Tools and Techniques in Failure Analysis: Scanning Electron MicrosDocument10 pagesTools and Techniques in Failure Analysis: Scanning Electron MicrosBaljit SinghNo ratings yet

- Modeling of Ultrasonic Testing For Inspection of Nodular Cast Iron InsertDocument14 pagesModeling of Ultrasonic Testing For Inspection of Nodular Cast Iron InsertCarlos Ortega JonesNo ratings yet

- Welding and Characterization of 5083 Aluminium Alloy PDFDocument6 pagesWelding and Characterization of 5083 Aluminium Alloy PDFPatricio G. ArrienNo ratings yet

- Radiograph InterpretationDocument12 pagesRadiograph InterpretationnithingrmeNo ratings yet

- Leak Testing: Nondestructive Inspection of CastingsDocument1 pageLeak Testing: Nondestructive Inspection of CastingsCARLOS SUNTAXINo ratings yet

- MicroCrack Formation in HFERWDocument9 pagesMicroCrack Formation in HFERWN TanejaNo ratings yet

- How To Avoid Getting Chicken Pox While Helping An Infected PersonDocument10 pagesHow To Avoid Getting Chicken Pox While Helping An Infected PersonSai Krishna YellapuNo ratings yet

- Module 6: Radiographic Techniques: Lesson 16: Periapical Radiographs & Intraoral SurveysDocument101 pagesModule 6: Radiographic Techniques: Lesson 16: Periapical Radiographs & Intraoral SurveysSai Krishna YellapuNo ratings yet

- PAUT 22.8mm Scan PlanDocument3 pagesPAUT 22.8mm Scan PlanSai Krishna YellapuNo ratings yet

- Haisamuddin Patwekar: Curriculum VitaeDocument3 pagesHaisamuddin Patwekar: Curriculum VitaeSai Krishna YellapuNo ratings yet

- 2011 Abstract Book-1Document292 pages2011 Abstract Book-1Sai Krishna YellapuNo ratings yet

- Pipeline Integrity Management ExternalDocument36 pagesPipeline Integrity Management ExternalJavierfox98100% (6)

- Radiography EnclosureDocument1 pageRadiography EnclosureSai Krishna YellapuNo ratings yet

- TOFD PresentationDocument18 pagesTOFD PresentationSai Krishna Yellapu100% (7)