Professional Documents

Culture Documents

Manual Handling of Loads: Guide For Risk Assessment in Small and Medium Enterprises

Manual Handling of Loads: Guide For Risk Assessment in Small and Medium Enterprises

Uploaded by

XozanCopyright:

Available Formats

You might also like

- Lesson Plan For Teaching GrammarDocument9 pagesLesson Plan For Teaching Grammarruszita75% (4)

- Lifting Operations HandbookDocument80 pagesLifting Operations Handbookzaur baimuratovNo ratings yet

- Guide to Load Analysis for Durability in Vehicle EngineeringFrom EverandGuide to Load Analysis for Durability in Vehicle EngineeringP. JohannessonRating: 4 out of 5 stars4/5 (1)

- Skeleton-Worksheet KEY ANSWERDocument4 pagesSkeleton-Worksheet KEY ANSWERjustine alina50% (2)

- Ergonomic Risk Identification and Assessment - Identification and Assessment ToolDocument54 pagesErgonomic Risk Identification and Assessment - Identification and Assessment Toolhitm357No ratings yet

- Guidelines On Workplace Traffic Safety ManagementDocument22 pagesGuidelines On Workplace Traffic Safety Managementr_sadekarNo ratings yet

- 6 Risk Assessment Handling Loads ENDocument29 pages6 Risk Assessment Handling Loads ENEfari BahcevanNo ratings yet

- 10 Manual Handling: ManagersDocument15 pages10 Manual Handling: ManagersRadita MahendraNo ratings yet

- Ausmite SOP 230 01 Manual Handling TasksDocument5 pagesAusmite SOP 230 01 Manual Handling TasksBhagat DeepakNo ratings yet

- Ausmite SOP 230 01 Manual Handling TasksDocument5 pagesAusmite SOP 230 01 Manual Handling TasksBhagat DeepakNo ratings yet

- Checklist For The Prevention of Manual Handling Risks: Part A: IntroductionDocument13 pagesChecklist For The Prevention of Manual Handling Risks: Part A: IntroductionCharlie Ramirez TorresNo ratings yet

- RULA: A Survey Method For The - Irwestigation of World-Related Upper Limb DisordersDocument10 pagesRULA: A Survey Method For The - Irwestigation of World-Related Upper Limb DisordersSanty SanNo ratings yet

- Rapid Upper Limb Assessment (RULA) - 20221209Document11 pagesRapid Upper Limb Assessment (RULA) - 20221209Mário Silva100% (1)

- RULA Mcatamney 1993 PDFDocument10 pagesRULA Mcatamney 1993 PDFFausto Corsino TorresNo ratings yet

- Nebosh IGC2 Part 3Document38 pagesNebosh IGC2 Part 3MuhammadAkram100% (7)

- Guide To Evaluating Lifting Injury RiskDocument8 pagesGuide To Evaluating Lifting Injury RiskWasemBhatNo ratings yet

- QECDocument7 pagesQECUci Marlina PasaribuNo ratings yet

- Intracom Lifting ProcessDocument4 pagesIntracom Lifting ProcessLamine BounourNo ratings yet

- Manual Handling Procedure HSE PR016Document7 pagesManual Handling Procedure HSE PR016Oladimeji TaiwoNo ratings yet

- RULA - A Survey Method For The Investigation of Work-Related Upper Limb Disorders PDFDocument10 pagesRULA - A Survey Method For The Investigation of Work-Related Upper Limb Disorders PDFAchmad SyukronNo ratings yet

- Manual Handling PDFDocument8 pagesManual Handling PDFMason CPNo ratings yet

- 5 QEC SlidesDocument34 pages5 QEC SlidesKLINIK UNG CENDERAWASIHNo ratings yet

- Element 6Document3 pagesElement 6mohdakramk7No ratings yet

- Safe Handling, Lifting and Moving of Loadssafe Handling, Lifting and Moving of LoadsDocument21 pagesSafe Handling, Lifting and Moving of Loadssafe Handling, Lifting and Moving of LoadsleventozenNo ratings yet

- Manual Handling PolicyDocument13 pagesManual Handling PolicyVibas BNo ratings yet

- MultipLa - A Tool For The Combined Overall Estimation of Various Types of MMHDocument3 pagesMultipLa - A Tool For The Combined Overall Estimation of Various Types of MMHAfirdie FirdausNo ratings yet

- Manual Handling Assessment Guidance BookletDocument6 pagesManual Handling Assessment Guidance BookletWilliam44No ratings yet

- Manual HandlingDocument5 pagesManual HandlingImad A KhanNo ratings yet

- 2005 ACGIH Lifting TLV - Employee Friendly Slides-GuidanceDocument12 pages2005 ACGIH Lifting TLV - Employee Friendly Slides-GuidanceCamilo Alejandro Soto CarrascoNo ratings yet

- Manual Handling 2Document20 pagesManual Handling 2swiezaplesnNo ratings yet

- Er Chapter 5Document29 pagesEr Chapter 5Endi EndrisNo ratings yet

- Assessment of Manual Handling Tasks Based On Key IndicatorsDocument2 pagesAssessment of Manual Handling Tasks Based On Key IndicatorsGeorge Rusu67% (3)

- Revised NIOSHDocument25 pagesRevised NIOSHIhram RachmansyahNo ratings yet

- REBA CalculationDocument19 pagesREBA CalculationAkarshaNo ratings yet

- 2020 Giannini Wearable Sensor Network For Biomechanical Overload Assessment in Manual Material HandlingDocument29 pages2020 Giannini Wearable Sensor Network For Biomechanical Overload Assessment in Manual Material HandlingJohannes SchützNo ratings yet

- Safety in Manual Handling of Loads PDFDocument20 pagesSafety in Manual Handling of Loads PDFhoboslayer97100% (1)

- TSK5UG GWO BST Manual Handling: The National Access and Rescue CentreDocument29 pagesTSK5UG GWO BST Manual Handling: The National Access and Rescue Centreromedic36No ratings yet

- Risk Assetment of Pushing and PullingDocument15 pagesRisk Assetment of Pushing and PullingIsmet Yıldız100% (1)

- Evaluation and Methods For Reducing Posture StrainDocument11 pagesEvaluation and Methods For Reducing Posture StrainMohan RajNo ratings yet

- MANUAL HANDLING GuidanceDocument18 pagesMANUAL HANDLING GuidanceTantely RazafimahatratraNo ratings yet

- Manual Handling WeightsDocument21 pagesManual Handling Weightsbatfink182100% (1)

- Manual Handling Risk AssessmentsDocument2 pagesManual Handling Risk AssessmentsPaulMathewThottanNo ratings yet

- NIOSH Lifting Analysis: Experiment No. 3Document5 pagesNIOSH Lifting Analysis: Experiment No. 3Bai MustaphaNo ratings yet

- Niosh Lifting EquqtionDocument7 pagesNiosh Lifting EquqtionGhanshyam PatelNo ratings yet

- W Hhwsop2 11Document5 pagesW Hhwsop2 11KhairolMizanNo ratings yet

- Manual HandlingDocument4 pagesManual HandlingClark Angelo JuanNo ratings yet

- Manual Handling: Workplace Health, Safety and Compensation Commission of New BrunswickDocument21 pagesManual Handling: Workplace Health, Safety and Compensation Commission of New BrunswickmitualvesNo ratings yet

- Slinging and Signals: Know How To Do It Right! Then Do It Right!Document134 pagesSlinging and Signals: Know How To Do It Right! Then Do It Right!saqibNo ratings yet

- Guide On Manual Handling Risk Assessment in The Manufacturing Sector PDFDocument24 pagesGuide On Manual Handling Risk Assessment in The Manufacturing Sector PDFOoi Jun LinNo ratings yet

- ASE Topic 4 Manual HandlingDocument8 pagesASE Topic 4 Manual HandlingJoel ChandlerNo ratings yet

- ErgonomicsDocument18 pagesErgonomicsbalakaleesNo ratings yet

- Thedy11 SEANESIPS 2005Document8 pagesThedy11 SEANESIPS 2005CHOIRNo ratings yet

- Generic Risk Assessment TemplateDocument16 pagesGeneric Risk Assessment TemplateAjith Nair100% (1)

- Ergonomics at Work PlaceDocument10 pagesErgonomics at Work PlacevishwaNo ratings yet

- 7115Document13 pages7115Fuad MohamedNo ratings yet

- Title of The Paper: Ergonomic Risk Assessment of Workers in Garment IndustryDocument7 pagesTitle of The Paper: Ergonomic Risk Assessment of Workers in Garment Industrywendosen seifeNo ratings yet

- Hazard Identification ModuleDocument7 pagesHazard Identification ModuleEmmanuel Milla-gracia GarilNo ratings yet

- Lifting Code of PracticeDocument18 pagesLifting Code of PracticeOnaFajardoNo ratings yet

- Spectral method for fatigue damage estimation with non-zero mean stressFrom EverandSpectral method for fatigue damage estimation with non-zero mean stressNo ratings yet

- Check Weigher: Revolutionizing Quality Control with Computer VisionFrom EverandCheck Weigher: Revolutionizing Quality Control with Computer VisionNo ratings yet

- Personal Protective EquipmentDocument10 pagesPersonal Protective EquipmentXozanNo ratings yet

- FIEF Recommended FA Kit Contents 162295Document2 pagesFIEF Recommended FA Kit Contents 162295XozanNo ratings yet

- OHS Plan 2012 University WideDocument3 pagesOHS Plan 2012 University WideXozanNo ratings yet

- Project NavigatorDocument9 pagesProject NavigatorXozanNo ratings yet

- Electrical Safety AuditDocument19 pagesElectrical Safety AuditXozan100% (2)

- Title Carry Out In-Service Visual Inspections On Substation Equipment For Safe Operation Level 3 Credits 4Document5 pagesTitle Carry Out In-Service Visual Inspections On Substation Equipment For Safe Operation Level 3 Credits 4XozanNo ratings yet

- Siemens XDocument13 pagesSiemens XXozanNo ratings yet

- Step 2 Who Might Be Harmed and How?: What Are You Already Doing? Step 3: What Further Action Is Necessary?Document6 pagesStep 2 Who Might Be Harmed and How?: What Are You Already Doing? Step 3: What Further Action Is Necessary?XozanNo ratings yet

- Lab Hazard Assessment Tool: Applicable PPE Specific Type (Example) Characteristics ApplicationsDocument4 pagesLab Hazard Assessment Tool: Applicable PPE Specific Type (Example) Characteristics ApplicationsXozanNo ratings yet

- 2011 Dam Inspection ChecklistDocument2 pages2011 Dam Inspection ChecklistXozanNo ratings yet

- Personal Protective Equipment: For General IndustryDocument28 pagesPersonal Protective Equipment: For General IndustryXozanNo ratings yet

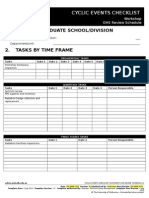

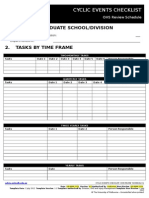

- Cyclic Events Checklist: 1. Faculty/Graduate School/DivisionDocument3 pagesCyclic Events Checklist: 1. Faculty/Graduate School/DivisionXozanNo ratings yet

- Deficiency Checklist: Is There Any Apparent... YES NO If Yes Then..Document1 pageDeficiency Checklist: Is There Any Apparent... YES NO If Yes Then..XozanNo ratings yet

- Cyclic Events Biological Laboratory TemplateDocument3 pagesCyclic Events Biological Laboratory TemplateXozanNo ratings yet

- Cyclic Events Checklist: 1. Faculty/Graduate School/DivisionDocument2 pagesCyclic Events Checklist: 1. Faculty/Graduate School/DivisionXozanNo ratings yet

- Chemical Risk Assessment Worksheet: Printer Toner - MagentaDocument3 pagesChemical Risk Assessment Worksheet: Printer Toner - MagentaXozanNo ratings yet

- Transponder Landing SystemDocument4 pagesTransponder Landing SystemWin MinNo ratings yet

- Modeling Roundabout Intersections - AUGI - The World's Largest CAD & BIM User GroupDocument9 pagesModeling Roundabout Intersections - AUGI - The World's Largest CAD & BIM User GroupSantosh RaiNo ratings yet

- InfosyspdfDocument30 pagesInfosyspdfBrinda BMNo ratings yet

- BS en 01256-1996Document12 pagesBS en 01256-1996Mustafa Ersin EkremNo ratings yet

- CC103 Engineering Surveying 1 Chapter 2Document15 pagesCC103 Engineering Surveying 1 Chapter 2Xendra AqeylaaNo ratings yet

- Protective Coating PhilosophyDocument10 pagesProtective Coating PhilosophyAleem QureshiNo ratings yet

- 1 - Introduction To Accountign - Icap - Questions and Answers PDFDocument202 pages1 - Introduction To Accountign - Icap - Questions and Answers PDFM.Abdullah MBIT100% (1)

- Padlet Crib Sheet v0.2Document2 pagesPadlet Crib Sheet v0.2Abdou OsseniNo ratings yet

- RM Group FormationDocument7 pagesRM Group FormationRaja. KumarNo ratings yet

- advtJRF DIPAS212023Document4 pagesadvtJRF DIPAS212023Rathod Chandra SekharNo ratings yet

- EMC Networker - Setting Up QoreStor As A CIFS, NFS Target On Dell EMC NetworkerDocument36 pagesEMC Networker - Setting Up QoreStor As A CIFS, NFS Target On Dell EMC NetworkerAziz BezzafNo ratings yet

- Grounding and Bonding Testing - Mike LewisDocument117 pagesGrounding and Bonding Testing - Mike LewisAba Emmanuel OcheNo ratings yet

- BiotedadNo 3Document2 pagesBiotedadNo 3Budok MercadoNo ratings yet

- Savemyexams Igcse Biology Photosynthesis and Leaf Structure WorksheetDocument34 pagesSavemyexams Igcse Biology Photosynthesis and Leaf Structure WorksheetkatisspeedNo ratings yet

- The Way of The Worl1Document1 pageThe Way of The Worl1Maria Olivia GonzalezNo ratings yet

- MAON Google SlidesDocument74 pagesMAON Google SlidesavinteumfilmsNo ratings yet

- Kingsley Cv2Document2 pagesKingsley Cv2akwue kingsleyNo ratings yet

- FALLACIESDocument5 pagesFALLACIESJan Christian GarciaNo ratings yet

- Multi Inverter 4TXM6530A-SUB-1GDocument4 pagesMulti Inverter 4TXM6530A-SUB-1GOmar PiñaNo ratings yet

- Ucs617 5Document2 pagesUcs617 5Suprit BeheraNo ratings yet

- Koh, Khee Meng - Tay Eng Guan, - Dong, F. M - Introduction To Graph Theory - Solutions Manual-World Scientific Publishing Company (2008 - 2007)Document262 pagesKoh, Khee Meng - Tay Eng Guan, - Dong, F. M - Introduction To Graph Theory - Solutions Manual-World Scientific Publishing Company (2008 - 2007)vahide khodadiNo ratings yet

- Harpreet Kaur Gill SOP UKDocument2 pagesHarpreet Kaur Gill SOP UKSAHILPREET SINGHNo ratings yet

- Figure Skating Spirals in CompetitionDocument2 pagesFigure Skating Spirals in CompetitionAlexandra PurcaroiuNo ratings yet

- SKB Salary Scale Budget 2013 Vols 1-2Document23 pagesSKB Salary Scale Budget 2013 Vols 1-2Kerine HeronNo ratings yet

- Business Studies Project Class XIIDocument13 pagesBusiness Studies Project Class XIIKanishk Mehrotra67% (15)

- Electrostatic Respirator Filter Media Filter Efficiency and Most Penetrating Particle Size EffectsDocument10 pagesElectrostatic Respirator Filter Media Filter Efficiency and Most Penetrating Particle Size EffectsAdolfo OrozcoNo ratings yet

- Design and Construction of A Structure For A Three Point Bending TestDocument13 pagesDesign and Construction of A Structure For A Three Point Bending TestIñigoNo ratings yet

- MainStage User ManualDocument100 pagesMainStage User Manualjayharden1No ratings yet

Manual Handling of Loads: Guide For Risk Assessment in Small and Medium Enterprises

Manual Handling of Loads: Guide For Risk Assessment in Small and Medium Enterprises

Uploaded by

XozanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Manual Handling of Loads: Guide For Risk Assessment in Small and Medium Enterprises

Manual Handling of Loads: Guide For Risk Assessment in Small and Medium Enterprises

Uploaded by

XozanCopyright:

Available Formats

Guide for Risk Assessment

in Small and Medium Enterprises

6

Manual Handling of Loads

Lifting, Holding, Carrying, Pulling, Pushing

Identication and Evaluation of Hazards; Taking Measures

Section for Electricity

Section for Iron and Metal

Section for Machine and System Safety

Manual Handling of Loads

Lifting, Holding, Carrying, Pulling, Pushing

6

Guide for

Risk Assessment in

Small and Medium Enterprises

Identification and Evaluation

of Hazards;

Taking Measures

Section for Electricity

Section for Iron and Metal

Section for Machine and System Safety

2

Imprint

Autoren: Dieter Schmitter, Suva,

Schweizerische Unfallversicherungsanstalt, Luzern, Switzerland

Ulf Steinberg, Bundesanstalt fr Arbeitsschutz und Arbeitsmedizin,

Dortmund, Germany

Detlef Trippler, ISSA, Section for Iron and Metal, Germany

Michael Wichtl, AUVA,

Allgemeine Unfallversicherungsanstalt, Vienna, Austria

Production: Verlag Technik&Information e.K.,

Wohlfahrtstrasse 153, 44799 Bochum, Germany

Phone +49(0)234-94349-0, Fax +49(0)234-94349-21

Printed in Germany August 2010

ISBN 978-3-941441-64-4

3

This brochure is intended to conform to

the requirement for a risk assessment

during operations with manual load han-

dling.

This brochure is structured as follows:

1. Basic Information Principles

2. Risk Assessment and

Specification of Measures

Annex 1: Assessment Sheet

Lifting, Holding, Carrying

Annex 2: Assessment Sheet

Pulling, Pushing

Note:

The objective of the brochure is to im-

plement the Framework Directive on

the introduction of measures to en-

courage improvements in the safety

and health of workers at work

(89/391/EEC) and the individual Direc-

tives issued thereto.

If relevant regulations implemented in-

to national law exist, they shall imper-

atively be observed.

In addition to this brochure, other guides

are planned/available for the following

topics:

Hazards arising from

machinery and other work

equipment

Hazards arising from electricity

Hazardous substances

Hazards arising from

whole-body and hand-arm

vibrations

Hazards arising from explosions

Slipping and falling from a height

Noise

Mental workload

Introductory Note

4

1. Basic Information Principles

1.1 Legal and normative bases

The bases are the legal regulations of the

respective countries.

On an international level, the Standard

ISO 11 228-1, Ergonomics-Manual han-

dling-Lifting and carrying applies.

For the EU, the Directive 90/269/EEC is

the legal basis for the minimum require-

ments for the protection of workers

against hazards arising from manual han-

dling of loads.

According to Article 4 of the Directive, the

employer is obligated to consider in par-

ticular the characteristics of the load, the

working environment and the require-

ments of the task when identifying and

evaluating hazards likely to occur at the

workplace.

1.2 Manufacturer's regulations

The relevant national regulations for the

limitation of load weights, packing sizes,

ergonomic design etc. shall be taken into

account.

For Europe, especially the Machinery

Directive 2006/42/EC and the Standard

EN 1005, Safety of machinery Human

physical performance apply.

5

2.1 Hazard identification

The first step of a risk assessment is the

identification of risk features.

With the table given on page 6, the most

important features of manual load

handling shall be checked. The check

does not require specialized knowledge.

When a risk feature was identified, a risk

estimation and evaluation shall be carried

out.

In practice, it has proven of value to carry out the risk assessment in three steps:

hazard identification (clause 2.1), risk estimation and risk evaluation (clause 2.2) and

specification of measures (clause 2.3)

2. Risk assessment and Specification

of Measures

Figure 1: Load transport with cart

6

If one or more questions are answered with PARTIALLY or YES, a risk esti-

mation and risk evaluation should be carried out.

Checklist for risk identification (manual load transport)

Note:

Specific regulations apply when operations with manual load handling are

carried out by young persons, older workforce or pregnant women.

Questions Yes Partially No

1. Are loads > 5 kg regularly moved?

Manual load transport may be lifting, holding, carrying, pulling or pushing.

Examples: Setting of building stones, loading of machines, unloading of packages,

holding a portable grinding machine, furniture hauling, putting up scaffoldings,

transfer of patients

2. Is lifting and carrying performed in

unfavourable postures?

All postures which strongly deviate from a normal and comfortable posture are

considered as unfavourable.

Examples: bending far forward, twisting or lateral inclining of the upper part of the body,

load far from body or above shoulder height, hollow-back, kneeling, crouching

3. Is handling made more difficult by the

nature of the load?

Examples: bulky, unshaped, instable, hardly seizable, hot, cold, sharp-edged,

smooth surface, unfavourable balance point

4. Is handling made more difficult by unfavourable

working conditions?

Examples: confined area of movement, small room height,

uneven or soft or slippery floor, long ways, cold or very warm rooms,

poor lighting

5. Are there complaints from the workforce?

Examples: too heavy load weights, back and joint pain, high working speed,

time pressure, increasing exhaustion

7

2.2 Risk estimation and risk evaluation

2.2.1 Key indicator method for lifting, holding and carrying

Key indicator methods may be used for

risk estimation and risk evaluation.

Hence, orientating evaluations are possi-

ble. They take into account the most im-

portant features of manual working oper-

ations. Due to different types of physical

stress and working features, risk estima-

tion and risk evaluation with key indica-

tors are carried out separately for

The result points to deficiencies in

design and shows whether physical

overload is possible or probable for

the activity concerned. From this, direct

measures for technical, organizational

and person related design can be de-

rived.

For evaluating the features, it is abso-

lutely necessary to have a good know-

ledge of the activity to be evaluated.

If this is not the case, an evaluation must

not be made.

Rough estimates or presumptions will

yield wrong results. More detailed esti-

mates require special ergonomic analy-

ses.

The key indicator method describes the

type and characteristic of relevant work-

ing features. These are features having

an important influence on the physical

strain:

time duration, frequency

load weight

posture

working conditions

The description of the activitiy is supple-

mented by a risk evaluation, which pic-

tures the probability of physical over-

load.

Figure 2: Manual lifting and carrying at a

bakery

Lifting holding carrying

and

Pulling pushing

8

Operating procedures for the key indica-

tor method lifting, holding, carrying

Evaluation is principally made for par-

tial activities and is to be based on

one working day. If during a partial ac-

tivity load weight and/or postures change,

the values shall be averaged.

If within a total activity several partial ac-

tivities with clearly differing load handling

operations occur, they shall be estimated

and documented separately.

The assessment sheet for lifting,

holding and carrying can be found in

Annex 1.

3 steps are necessary for the evaluation:

Step 1: Determination of the

time rating points

Step 2: Determination of

the key indicator rating

points

Step 3: Evaluation

When determining the rating points, the

establishment of intermediate steps

(interpolation) is in principle allowed. A

frequency of 40 results, for example, in

a time rating point of 3

The sole exception is an effective load

of 40 kg for a man and 25 kg for

a woman. These loads give uncompro-

misingly a load rating point of 25.

Step 1:

Determination of the time rating point

Determination of the time rating point

is made on the basis of the table sepa-

rately for three possible types of load

handling:

For partial activities characterised by

regular repeating of short lifting,

lowering or moving operations, the

number of operations is decisive for

the time rating.

For partial activities characterised by

holding a load, the total time of hold-

ing is taken as basis.

Total time = number of

holding operations x time for an

individual holding operation

For partial activities characterised by

carrying a load, the total way covered

with the load is taken as basis. Amean

walking speed of 4 km/h 1 m/s is

assumed.

9

Step 2:

Determination of rating points

of load, posture and working

conditions

Load weight

Determination of the load weight is

made on the basis of the table, sepa-

rately for men and women.

If different loads are handled during

the activity under evaluation, a mean

value may be calculated, as long

as the individual load does not exceed

40 kg for men and 25 kg for women.

For comparison, also peak values may

be used. Then it is the reduced fre-

quency of these peak values which

shall be taken as basis and by no

means the total frequency.

For lifting/holding/carrying/lowering

activities the effective load shall be

taken as basis. Effective load means

the real action force which is neces-

sary for the workforce for moving the

load.

This action force does not correspond

to the load mass in each case. When

tilting a carton, only 50 % of the load

mass will have an effect.

Posture

Determination of the rating points of pos-

ture is made on the basis of the pic-

tograms contained in the table. The pos-

tures during load handling which are

characteristic for the partial activity shall

be used.

If due to the sequence of the working

progress different postures are taken, a

mean value may be calculated from the

rating points of posture for the partial ac-

tivity being evaluated.

Working conditions

For determining the rating points of

working conditions, the working con-

ditions prevailing in time shall be

taken. Occasional discomfort without

any safety relevance shall not be con-

sidered.

Safety-related features shall be docu-

mented in the description field Check

of the workplace necessary for other

reasons.

Step 3:

Evaluation

The evaluation of each partial activity is

made by means of a point value relat-

ed to the partial activity (calculation by

addition of the rating points of key indi-

cators and by multiplication with the time

rating points).

Evaluation basis are bio-mechanic

effect mechanisms in connection with

dose models.

It is taken into account that the inter-

nal strain of the lumbar spine crucial-

ly depends on the bending forward of

the upper part of the body and on the

load weight and that it rises with in-

creasing strain duration and/or fre-

quency, lateral inclination and/or

twisting.

Summarising evaluations for se-

veral partial activities are proble-

matic, because they are beyond

the informational value of this orien-

tating analysis.

In general, they require more detailed

work related analytical procedures

for risk assessment.

Assessment Sheet Lifting, Holding, Carrying

Where there are a number of individual activities with considerable physical strains, they must be estimated separately.

Workplace/Activity:

1

Palletizing packages

4

p

Lifting or displacement

operations (< 5 s)

H

Number

on working day

Time rating

points

T

< 10 1 < 5 min 1 < 300 m 1

10 to < 40 2 5 to < 15 min 2 300 m to < 1 km 2

40 to < 200 4 15 min to < 1 hr 4 1 km to < 4 km 4

200 to < 500 6 1 hr to < 2 hrs 6 4 km to < 8 km 6

500 to < 1000 8 2 hrs to < 4 hrs 8 8 km to < 16 km 8

10

Examples: laying bricks,

p

E

Effective load

1

) for women Load rating point

< < 5 kg 1

1 5 to < 10 kg 2

2 10 to < 15 kg 4

3 15 to < 25 kg 7

NJ 25

or moving load. This action force does not correspond to the load mass in each case.

W

, p g

3 When lifting, holding, carrying und lowering load is near to medium to body

2

3 Low bending or far bending forward

3 Slightly bending forward with simultaneous twisting of trunk

3 Load far from the body or above shoulder height

4

3 B ding far forward with simultaneous twisting of trunk

g g g g pp g

Space for movement restricted and unfavourable ergonomic conditions:

e. g. 1.: space for movement restricted by too low high or working area less than 1,5 m

2

or

2.: posture stability impaired by uneven foor or soft ground

1

1

st

step

Determination

of time rating

points

2

nd

step

Determination

of rating points

of load, posture

and working

conditions

Using Assessment sheet (Lifting, Holding, Carrying), see Annex 1, one finds:

10

At a packing place of a company pack-

ages with a load weight of 14 kg are

moved from the packing table to a pallet

on the floor. This activity is carried out by

a female workforce

The following marginal conditions occur:

180 moving operations per shift

14 kg load weight

low bending or far bending forward

during lowering

bad gripping conditions

Figure 3: Work at packing place

Derivable design necessities

From this risk estimation design

necessities and approaches can

immediately be seen. In principle,

the causes of high rating points shall

be abolished. In detail, this means

organisational regulations in case

of high time rating points, reduction

of the load weight or the use of lifting

means in case of high load rating

points and the improvement of

the workplace design in case of high

posture rating points.

Evaluation example

11

Step 2:

Determination of rating points

of mass, positioning accuracy,

speed, posture and working

conditions

Transport means

There are different ways of moving

loads by pulling or pushing:

without auxiliary means, the load is

rolled or pulled with sliding

barrows (wheelbarrow, one-axle

barrow)

Roll containers, rollers without

drawbar and trolleys with drawbar,

hand pallet trucks

Manipulators, suspension and

guide rails

It is important that the auxiliary means

are suited for the working task. Type,

size, and weight of the goods to be

conveyed, distance covered and quali-

ty of the road, tilting stability and fre-

quency of use shall be taken into ac-

count.

2.2.2 Key indicator method for pulling and pushing

Manual load handling also covers trans-

port on trolleys, roller belts or with han-

dling aids.

Instead of being carried, loads are

pushed or pulled.

Thus, transport of high load weights be-

comes possible and transport of load

weights between 10 and 50 kg is effec-

tively facilitated.

However, important basic rules shall be

observed in order to prevent possible

hazards.

Operational procedures for

the key indicator method pulling,

pushing

The assessment sheet for pulling and

pushing is given in Annex 2.

Step 1:

Determination of time rating points

Operating sequence, time duration,

frequency and distances covered are

ascertained.

3

rd

step: Evaluation

The rating points relevant to this activity are to be entered and calculated in the diagram.

Load rating points

+

Posture rating points

+

Working conditions rating points

=

Total

x

Time rating points

=

Risk score

4

4

1

9 4 36

The evaluation result shows an increased stress. The essential design deficiency is the un-

favourable posture

3

rd

step

Evaluation

12

Regard shall also be paid to the er-

gonomic design of the handles with

protection against hand injuries and,

if necessary, brake mechanisms.

Load weight

Weights of the transported load and

the transport means moved simul-

taneously are ascertained. Rough refer-

ence values are sufficient. In case

the weight was not given, it can be esti-

mated.

In most cases, the weight of

barrows and trolleys is given on the

type plate.

If the load weight cannot be estimated

or if weight specifications are missing

(e.g. for manipulators), an extended

analysis should be performed.

Figure 6: Use of roll containers

Figure 4: Stair climbing barrow

Figure 5: Transport trolley

13

Speed of motion

It is determined how quick and how

exact pulling and pushing is perform-

ed.

Quick movements and high accuracy

of motion is not only very exhaust-

ing but also increases the risk of acci-

dents.

Posture

During pulling and pushing the posture

should be upright with low inclination

and without twisting of the trunk.

This is possible by an ergonomic instal-

lation of the handles. Drawbars, spars

at barrows which are too short, missing

handles or loads blocking the view can

lead to unfavourable postures. Twisting,

bending and inclining of the trunk

reduce possible physical forces and

put severe strain on the muscular-

skeletal system.

Working conditions

The most important influencing vari-

ables, i. e. the distance covered (travel-

ling distance) and the technical state of

the transport means are determined.

Soft floors, rough pavement, potholes,

gutters, steps as well as up-slopes and

down-slopes may strongly aggravate

transport and make it impossible to a

certain extent.

The same impeding effects are given

by sliding or tight rolls, deformed hand-

les and defective brakes. Attention shall

also be paid to obstacles on the drive-

way, unsecured differences in altitude

and lateral inclinations which may cause

tilting over.

Step 3:

Evaluation

For evaluation, the results of step 1

and step 2 shall be summarized and

three complex questions shall be

answered:

Is the ratio between the required

action forces and the available phy-

sical forces adequate?

Is application of the forces always

safe and does no excessive exhaus-

tion arise?

Are favourable postures possible?

Do unfavourable postures only occur

occasionally and are is twisting and

bending during pulling and pushing

avoided?

Are the conditions safe?

Is there no accident hazard due to

slipping or tilting over of the load,

falls or crushing of the hands?

14

ers or in narrow passages occur fre-

quently.

Passages are often not wide

enough, in parts poorly lightened and

not free from obstacles.

Assessment Sheet Pulling, Pushing

The overall activity must be broken down into individual activities. Each individual activity involving major physical strain must be assessed separately.

Workplace/Activity:

1

t

t D t i tion of time rating points (Select only one column!)

Roll container loaded

more than 5 metres)

N y Time rating points

< 1

2

4

6

8

10

E n furniture transport in buildings

o

0,5 0,5 0,5

1

2

3

4

5

G

Speed of motion

slow (< 0,8 m/s) fast (0,8 to 1,3 m/s)

1 2

H

2 4

Trunk slightly bending forward or slightly twisted (one-sided pulling) 2

ypassed, , g y, bearings worn

2

DifcuIt:

unpaved or roughly paved roadway, potholes, severe soiling, inclines of 2 to 5,

industrial trucks have to be torn loose when starting up rollers or wheels soiled, bearings run sluggishly

4

Complicated:

Evaluation example

A truck is charged with commissioned

goods in roll containers. The weight of

the roll containers is between 40 and

190 kg.

Design deficiencies are:

Roll containers are not adapted

to the conditions of use.

Rolls are too small and often

get stuck in driveway irregulari-

ties.

Roll containers have no tilting

stability during driving as the balance

point is too high.

The required physical forces are

already too high at slight up-slopes

and down-slopes.

Ergonomic handles with protection

against hand injuries are not avail-

able. Crushing at other roll contain-

Using Assessment sheet (Pulling, Pushing), see Annex 2, one finds:

Figure 7: Transport with roll container

1

st

step

Determination

of time rating

points

2

nd

step

Determination

of rating points of

mass, positioning

accuracy, speed,

posture and

working conditions

15

2.3 Specification of Measures

Based on the risks determined in

clause 2.2, concrete measures can be

derived.

That means planning of load trans-

port operations, provision of auxiliary

means for manual load transport

and measures for health-oriented be-

haviour and for training and super-

vision.

The following clauses are based on the

Suva Check List "Moving heavy loads

by hand" (www.suva.ch/waswo/67089).

Further analysis

The risk assessment made with key

indicator methods does not always lead

to final evaluations.

For example, in case of complicated

operating cycles, when preparing invest-

ment plans or during work of persons

under difficult conditions (e.g. firefighters)

further analyses are necessary.

These analyses require more time and

workforce and specialised ergonomic

knowledge.

Contact partners are national authorities

and special health and safety at work

institutions.

The evaluation result shows an increased strain. The essential design deficiency is the un-

favourable driveway with ramps, narrow points and irregularities.

3

rd

step: Evaluation

Die fr diese Ttigkeit zutreffenden Wichtungen sind in das Schema einzutragen und auszurechnen.

Mass/industrial truck

+

Positioning accuracy/speed of motion

+

Posture rating points

+

Working conditions rating points

=

Total

x

Total ratings

points

x 1,3 = Risk score

for

women

employees

2

2

2

4

10 4 40

3

rd

step

Evaluation

16

2.3.2 Aids for manual load transport

When purchasing aids, it is imperative

to let the persons who are to work

with them later on have a say. They

are the specialists and may contribute

to the procurement of the correct

equipment.

Important for superiors:

to appoint competent person or body

responsible for the procurement of

transport equipment

to check auxiliary transport means

for suitability prior to procurement

to let the workforce have a say in the

procurement of transport equipment

to train the workforce in the use of

new transport equipment

to give the necessary period of famil-

iarization during the introduction of

new transport equipment

Figure 8: Moving of loads with a vacuum

lifting device

to check and maintain transport equip-

ment regularly

2.3.1 Planning of transport operations

Transport operations shall be taken as

seriously as production flows.

Good planning saves unnecessa-

ry, risky, awkward or improvised

transports with inadequate transport

means.

Important for superiors:

to make sure during planning and

work preparation that appropria-

te and sufficient transport equipment

is available

to make sure that regularly re-

peated transport is automated, if

possible

to take account of the time needed

for transports during planning of

work and production flows

to take care during ordering of

operating resources and materials

that the packs can be transport-

ed without problems

to give the instruction that operating

resources and materials that need

to be transported manually are

only purchased in units of 25 kg at

maximum

17

During lifting and carrying of loads,

the risk of physical overload frequent-

ly occurs. To avoid this, it is of special

importance that the loads lifted are

not too heavy and that the workforce

uses correct lifting and carrying tech-

niques.

Important for superiors:

to consider age, gender and constitu-

tion of the persons involved during

workforce planning

to limit load weights

to calculate and arrange for recreation

breaks for activities requiring frequent

load transport

to always mark loads, which are

heavier than 10 kg with their actual

weight

to train the workforce in correct lifting

and carrying

to inform the workforce on possible

consequences of incorrect lifting

2.3.3 Lifting and carrying

Figure 9: Good body posture during lifting

of loads

Generally, a single training on the cor-

rect handling of loads is not sufficient.

Superiors shall supervise observance of

the instructions

Important for superiors:

to carry out training courses on load

transport consistently with all the

workforce concerned

to address and correct the work-

force, when they behave incorrect-

ly during load transport

to ensure that existing transport

equipment are being used consis-

tently

to encourage the workforce to notify

deficiencies and to suggest improve-

ment measures

2.3.4 Training and supervision

Lift, push, load or carry in a way well-thought-out you'll be okay.

Figure 10: Prevention of lifting and

carrying activities through verti-

cally adjustable work tables

and roller conveyors

18

Annex 1

A

s

s

e

s

s

m

e

n

t

S

h

e

e

t

L

i

f

t

i

n

g

,

H

o

l

d

i

n

g

,

C

a

r

r

y

i

n

g

W

h

e

r

e

t

h

e

r

e

a

r

e

a

n

u

m

b

e

r

o

f

i

n

d

i

v

i

d

u

a

l

a

c

t

i

v

i

t

i

e

s

w

i

t

h

c

o

n

s

i

d

e

r

a

b

l

e

p

h

y

s

i

c

a

l

s

t

r

a

i

n

s

,

t

h

e

y

m

u

s

t

b

e

e

s

t

i

m

a

t

e

d

s

e

p

a

r

a

t

e

l

y

.

W

o

r

k

p

l

a

c

e

/

A

c

t

i

v

i

t

y

:

1

s

t

s

t

e

p

:

D

e

t

e

r

m

i

n

a

t

i

o

n

o

f

t

i

m

e

r

a

t

i

n

g

p

o

i

n

t

s

(

S

e

l

e

c

t

o

n

l

y

o

n

e

c

o

l

u

m

n

!

)

L

i

f

t

i

n

g

o

r

d

i

s

p

l

a

c

e

m

e

n

t

o

p

e

r

a

t

i

o

n

s

(

<

5

s

)

H

o

l

d

i

n

g

(

>

5

s

)

C

a

r

r

y

i

n

g

(

>

5

m

)

N

u

m

b

e

r

o

n

w

o

r

k

i

n

g

d

a

y

T

i

m

e

r

a

t

i

n

g

p

o

i

n

t

s

T

o

t

a

l

d

u

r

a

t

i

o

n

o

n

w

o

r

k

i

n

g

d

a

y

T

i

m

e

r

a

t

i

n

g

p

o

i

n

t

O

v

e

r

a

l

l

l

e

n

g

t

h

o

n

w

o

r

k

i

n

g

d

a

y

T

i

m

e

r

a

t

i

n

g

p

o

i

n

t

s

<

1

0

1

<

5

m

i

n

1

<

3

0

0

m

1

1

0

t

o

<

4

0

2

5

t

o

<

1

5

m

i

n

2

3

0

0

m

t

o

<

1

k

m

2

4

0

t

o

<

2

0

0

4

1

5

m

i

n

t

o

<

1

h

r

4

1

k

m

t

o

<

4

k

m

4

2

0

0

t

o

<

5

0

0

6

1

h

r

t

o

<

2

h

r

s

6

4

k

m

t

o

<

8

k

m

6

5

0

0

t

o

<

1

0

0

0

8

2

h

r

s

t

o

<

4

h

r

s

8

8

k

m

t

o

<

1

6

k

m

8

<

1

0

0

0

1

0

<

4

S

t

u

n

d

e

n

1

0

<

1

6

k

m

1

0

E

x

a

m

p

l

e

s

:

l

a

y

i

n

g

b

r

i

c

k

s

,

p

l

a

c

i

n

g

w

o

r

k

p

i

e

c

e

s

i

n

t

o

a

m

a

c

h

i

n

e

,

t

a

k

i

n

g

b

o

x

e

s

o

u

t

o

f

a

c

o

n

t

a

i

n

e

r

a

n

d

p

u

t

t

i

n

g

t

h

e

m

o

n

t

o

a

c

o

n

v

e

y

o

r

b

e

l

t

E

x

a

m

p

l

e

s

:

h

o

l

d

i

n

g

a

n

d

g

u

i

d

i

n

g

a

c

a

s

t

i

r

o

n

s

l

u

g

w

h

i

l

e

w

o

r

k

i

n

g

o

n

a

w

h

e

e

l

s

t

a

n

d

,

o

p

e

r

a

t

i

n

g

a

h

a

n

d

g

r

i

n

d

i

n

g

m

a

c

h

i

n

e

,

o

p

e

r

a

t

i

n

g

a

w

e

e

d

-

e

a

t

e

r

E

x

a

m

p

l

e

s

:

f

u

r

n

i

t

u

r

e

r

e

m

o

v

a

l

,

d

e

l

i

v

e

r

i

n

g

s

c

a

f

f

o

l

d

i

n

g

p

a

r

t

s

t

o

a

b

u

i

l

d

i

n

g

s

i

t

e

19

T

y

p

i

c

a

l

p

o

s

t

u

r

e

,

p

o

s

i

t

i

o

n

o

f

l

o

a

d

2

)

P

o

s

t

u

r

e

,

p

o

s

i

t

i

o

n

o

f

l

o

a

d

P

o

s

t

u

r

e

r

a

t

i

n

g

p

o

i

n

t

3

U

p

p

e

r

b

o

d

y

u

p

r

i

g

h

t

,

n

o

t

t

w

i

s

t

e

d

3

W

h

e

n

l

i

f

t

i

n

g

,

h

o

l

d

i

n

g

,

c

a

r

r

y

i

n

g

u

n

d

l

o

w

e

r

i

n

g

t

h

e

l

o

a

d

i

s

c

l

o

s

e

t

o

b

o

d

y

1

3

S

l

i

g

h

t

l

y

b

e

n

d

i

n

g

f

o

r

w

a

r

d

o

r

t

w

i

s

t

i

n

g

t

h

e

t

r

u

n

k

3

W

h

e

n

l

i

f

t

i

n

g

,

h

o

l

d

i

n

g

,

c

a

r

r

y

i

n

g

u

n

d

l

o

w

e

r

i

n

g

l

o

a

d

i

s

n

e

a

r

t

o

m

e

d

i

u

m

t

o

b

o

d

y

2

3

L

o

w

b

e

n

d

i

n

g

o

r

f

a

r

b

e

n

d

i

n

g

f

o

r

w

a

r

d

3

S

l

i

g

h

t

l

y

b

e

n

d

i

n

g

f

o

r

w

a

r

d

w

i

t

h

s

i

m

u

l

t

a

n

e

o

u

s

t

w

i

s

t

i

n

g

o

f

t

r

u

n

k

3

L

o

a

d

f

a

r

f

r

o

m

t

h

e

b

o

d

y

o

r

a

b

o

v

e

s

h

o

u

l

d

e

r

h

e

i

g

h

t

4

3

B

e

n

d

i

n

g

f

a

r

f

o

r

w

a

r

d

w

i

t

h

s

i

m

u

l

t

a

n

e

o

u

s

t

w

i

s

t

i

n

g

o

f

t

r

u

n

k

3

L

o

a

d

f

a

r

f

r

o

m

b

o

d

y

3

R

e

s

t

r

i

c

t

e

d

s

t

a

b

i

l

i

t

y

o

f

p

o

s

t

u

r

e

w

h

e

n

s

t

a

n

d

i

n

g

3

C

r

o

u

c

h

i

n

g

o

r

k

n

e

e

l

i

n

g

8

2

)

T

o

d

e

t

e

r

m

i

n

e

t

h

e

p

o

s

t

u

r

e

r

a

t

i

n

g

p

o

i

n

t

s

t

h

e

t

y

p

i

c

a

l

p

o

s

t

u

r

e

d

u

r

i

n

g

m

a

n

u

a

l

h

a

n

d

l

i

n

g

m

u

s

t

b

e

u

s

e

d

.

F

o

r

e

x

a

m

p

l

e

w

h

e

n

t

h

e

r

e

a

r

e

d

i

f

f

e

r

e

n

t

p

o

s

t

u

r

e

s

w

i

t

h

l

o

a

d

a

m

e

a

n

v

a

l

u

e

m

u

s

t

b

e

u

s

e

d

n

o

t

o

c

c

a

s

i

o

n

a

l

e

x

t

r

e

m

e

v

a

l

u

e

s

.

E

f

f

e

c

t

i

v

e

l

o

a

d

1

)

f

o

r

m

e

n

L

o

a

d

r

a

t

i

n

g

p

o

i

n

t

E

f

f

e

c

t

i

v

e

l

o

a

d

1

)

f

o

r

w

o

m

e

n

L

o

a

d

r

a

t

i

n

g

p

o

i

n

t

<

1

0

k

g

1

<

5

k

g

1

1

0

t

o

<

2

0

k

g

2

5

t

o

<

1

0

k

g

2

2

0

t

o

<

3

0

k

g

4

1

0

t

o

<

1

5

k

g

4

3

0

t

o

<

4

0

k

g

7

1

5

t

o

<

2

5

k

g

7

N

J

2

5

N

J

2

5

1

)

E

f

f

e

c

t

i

v

e

l

o

a

d

m

e

a

n

s

i

n

t

h

i

s

c

o

n

t

e

x

t

t

h

e

r

e

a

l

a

c

t

i

o

n

f

o

r

c

e

w

h

i

c

h

i

s

n

e

c

e

s

s

a

r

y

f

o

r

m

o

v

i

n

g

l

o

a

d

.

T

h

i

s

a

c

t

i

o

n

f

o

r

c

e

d

o

e

s

n

o

t

c

o

r

r

e

s

p

o

n

d

t

o

t

h

e

l

o

a

d

m

a

s

s

i

n

e

a

c

h

c

a

s

e

.

W

h

e

n

t

i

l

t

i

n

g

a

c

a

r

t

o

n

,

o

n

l

y

5

0

%

o

f

t

h

e

l

o

a

d

m

a

s

s

w

i

l

l

h

a

v

e

a

n

e

f

f

e

c

t

o

n

w

o

r

k

e

r

a

n

d

w

h

e

n

u

s

i

n

g

a

c

a

r

t

o

n

l

y

1

0

%

.

2

n

d

s

t

e

p

:

D

e

t

e

r

m

i

n

a

t

i

o

n

o

f

r

a

t

i

n

g

p

o

i

n

t

s

o

f

l

o

a

d

,

p

o

s

t

u

r

e

a

n

d

w

o

r

k

i

n

g

c

o

n

d

i

t

i

o

n

s

20

3

r

d

s

t

e

p

:

E

v

a

l

u

a

t

i

o

n

T

h

e

r

a

t

i

n

g

p

o

i

n

t

s

r

e

l

e

v

a

n

t

t

o

t

h

i

s

a

c

t

i

v

i

t

y

a

r

e

t

o

b

e

e

n

t

e

r

e

d

a

n

d

c

a

l

c

u

l

a

t

e

d

i

n

t

h

e

d

i

a

g

r

a

m

.

L

o

a

d

r

a

t

i

n

g

p

o

i

n

t

s

+

P

o

s

t

u

r

e

r

a

t

i

n

g

p

o

i

n

t

s

+

W

o

r

k

i

n

g

c

o

n

d

i

t

i

o

n

s

r

a

t

i

n

g

p

o

i

n

t

s

=

T

o

t

a

l

x

T

i

m

e

r

a

t

i

n

g

p

o

i

n

t

s

=

R

i

s

k

s

c

o

r

e

Annex 1

W

o

r

k

i

n

g

c

o

n

d

i

t

i

o

n

s

W

o

r

k

i

n

g

c

o

n

d

i

t

i

o

n

s

r

a

t

i

n

g

p

o

i

n

t

G

o

o

d

e

r

g

o

n

o

m

i

c

c

o

n

d

i

t

i

o

n

s

:

e

.

g

.

s

u

f

f

c

i

e

n

t

s

p

a

c

e

,

n

o

p

h

y

s

i

c

a

l

o

b

s

t

a

c

l

e

s

w

i

t

h

i

n

t

h

e

w

o

r

k

s

p

a

c

e

,

e

v

e

n

l

e

v

e

l

a

n

d

s

o

l

i

d

f

o

o

r

i

n

g

,

s

u

f

f

c

i

e

n

t

l

i

g

h

t

i

n

g

,

g

o

o

d

g

r

i

p

p

i

n

g

c

o

n

d

i

t

i

o

n

s

0

S

p

a

c

e

f

o

r

m

o

v

e

m

e

n

t

r

e

s

t

r

i

c

t

e

d

a

n

d

u

n

f

a

v

o

u

r

a

b

l

e

e

r

g

o

n

o

m

i

c

c

o

n

d

i

t

i

o

n

s

:

e

.

g

.

1

.

:

s

p

a

c

e

f

o

r

m

o

v

e

m

e

n

t

r

e

s

t

r

i

c

t

e

d

b

y

t

o

o

l

o

w

h

i

g

h

o

r

w

o

r

k

i

n

g

a

r

e

a

l

e

s

s

t

h

a

n

1

,

5

m

2

o

r

2

.

:

p

o

s

t

u

r

e

s

t

a

b

i

l

i

t

y

i

m

p

a

i

r

e

d

b

y

u

n

e

v

e

n

f

o

o

r

o

r

s

o

f

t

g

r

o

u

n

d

1

S

t

r

o

n

g

l

y

r

e

s

t

r

i

c

t

e

d

s

p

a

c

e

o

f

m

o

v

e

m

e

n

t

a

n

d

/

o

r

i

n

s

t

a

b

i

l

i

t

y

o

f

c

e

n

t

r

e

o

f

g

r

a

v

i

t

y

o

f

l

o

a

d

:

e

.

g

.

t

r

a

n

s

f

e

r

o

f

p

a

t

i

e

n

t

s

2

I

n

t

h

e

t

a

b

l

e

n

o

t

m

e

n

t

i

o

n

e

d

c

h

a

r

a

c

t

e

r

i

s

t

i

c

s

a

r

e

c

o

m

p

l

e

m

e

n

t

a

r

y

i

n

s

p

i

r

i

t

.

21

E

d

.

b

y

F

e

d

e

r

a

l

I

n

s

t

i

t

u

t

e

f

o

r

O

c

c

u

p

a

t

i

o

n

a

l

S

a

f

e

t

y

a

n

d

H

e

a

l

t

h

,

V

e

r

s

i

o

n

2

0

0

1

d

o

w

n

l

o

a

d

a

b

l

e

:

w

w

w

.

h

a

n

d

l

i

n

g

l

o

a

d

s

.

e

u

R

i

s

k

r

a

n

g

e

R

i

s

k

s

c

o

r

e

D

e

s

c

r

i

p

t

i

o

n

1

<

1

0

L

o

w

l

o

a

d

s

i

t

u

a

t

i

o

n

,

p

h

y

s

i

c

a

l

o

v

e

r

l

o

a

d

u

n

l

i

k

e

l

y

t

o

a

p

p

e

a

r

.

2

1

0

t

o

<

2

5

I

n

c

r

e

a

s

e

d

l

o

a

d

s

i

t

u

a

t

i

o

n

,

p

h

y

s

i

c

a

l

o

v

e

r

l

o

a

d

i

s

p

o

s

s

i

b

l

e

f

o

r

l

e

s

s

r

e

s

i

l

e

n

t

p

e

r

s

o

n

s

4

)

.

F

o

r

t

h

a

t

g

r

o

u

p

r

e

d

e

s

i

g

n

o

f

w

o

r

k

p

l

a

c

e

i

s

h

e

l

p

f

u

l

.

3

2

5

t

o

<

5

0

H

i

g

h

l

y

i

n

c

r

e

a

s

e

d

l

o

a

d

s

i

t

u

a

t

i

o

n

,

p

h

y

s

i

c

a

l

o

v

e

r

l

o

a

d

a

l

s

o

p

o

s

s

i

b

l

e

f

o

r

n

o

r

m

a

l

p

e

r

s

o

n

s

.

R

e

d

e

s

i

g

n

o

f

t

h

e

w

o

r

k

p

l

a

c

e

i

s

r

e

c

o

m

m

e

n

d

e

d

5

)

.

4

<

5

0

H

i

g

h

l

o

a

d

s

i

t

u

a

t

i

o

n

,

p

h

y

s

i

c

a

l

o

v

e

r

l

o

a

d

i

s

l

i

k

e

l

y

t

o

a

p

p

e

a

r

.

W

o

r

k

p

l

a

c

e

r

e

d

e

s

i

g

n

i

s

n

e

c

e

s

s

a

r

y

5

)

.

3

)

B

a

s

i

c

a

l

l

y

i

t

m

u

s

t

b

e

a

s

s

u

m

e

d

t

h

a

t

a

s

t

h

e

n

u

m

b

e

r

o

f

p

o

i

n

t

r

a

t

i

n

g

r

i

s

e

s

,

s

o

t

h

e

r

i

s

k

o

f

o

v

e

r

l

o

a

d

i

n

g

t

h

e

m

u

s

c

u

l

a

r

-

s

k

e

l

e

t

a

l

s

y

s

t

e

m

i

n

c

r

e

a

s

e

s

.

T

h

e

b

o

u

n

d

a

r

i

e

s

b

e

t

w

e

e

n

t

h

e

r

i

s

k

r

a

n

g

e

s

a

r

e

f

u

i

d

b

e

c

a

u

s

e

o

f

t

h

e

i

n

d

i

v

i

d

u

a

l

w

o

r

k

i

n

g

t

e

c

h

n

i

q

u

e

s

a

n

d

p

e

r

f

o

r

m

a

n

c

e

c

o

n

d

i

t

i

o

n

s

.

T

h

e

c

l

a

s

s

i

f

c

a

t

i

o

n

m

a

y

t

h

e

r

e

f

o

r

e

o

n

l

y

b

e

r

e

g

a

r

d

e

d

a

s

a

n

o

r

i

e

n

t

a

t

i

o

n

a

i

d

.

M

o

r

e

e

x

a

c

t

a

n

a

l

y

s

e

s

r

e

q

u

i

r

e

s

p

e

c

i

a

l

i

s

t

e

r

g

o

n

o

m

i

c

k

n

o

w

l

e

d

g

e

.

4

)

L

e

s

s

r

e

s

i

l

e

n

t

p

e

r

s

o

n

s

i

n

t

h

i

s

c

o

n

t

e

x

t

a

r

e

p

e

r

s

o

n

s

o

l

d

e

r

t

h

a

n

4

0

o

r

y

o

u

n

g

e

r

t

h

a

n

2

1

y

e

a

r

s

,

n

e

w

c

o

m

e

r

s

i

n

t

h

e

j

o

b

o

r

p

e

o

p

l

e

s

u

f

f

e

r

i

n

g

f

r

o

m

i

l

l

n

e

s

s

.

5

)

D

e

s

i

g

n

r

e

q

u

i

r

e

m

e

n

t

s

c

a

n

b

e

d

e

t

e

r

m

i

n

a

t

e

d

w

i

t

h

r

e

f

e

r

e

n

c

e

t

o

t

h

e

n

u

m

b

e

r

o

f

p

o

i

n

t

i

n

t

h

e

t

a

b

l

e

.

B

y

r

e

d

u

c

i

n

g

t

h

e

w

e

i

g

h

t

,

i

m

p

r

o

v

i

n

g

t

h

e

e

x

e

c

u

t

i

o

n

c

o

n

d

i

t

i

o

n

s

o

r

s

h

o

r

t

e

n

i

n

g

t

h

e

s

t

r

a

i

n

t

i

m

e

,

e

l

e

v

a

t

e

d

s

t

r

e

s

s

c

a

n

b

e

a

v

o

i

d

e

d

.

O

n

t

h

e

b

a

s

i

s

o

f

t

h

e

r

a

t

i

n

g

c

a

l

c

u

l

a

t

e

d

a

n

d

t

h

e

t

a

b

l

e

b

e

l

o

w

i

t

i

s

p

o

s

s

i

b

l

e

t

o

m

a

k

e

a

r

o

u

g

h

e

v

a

l

u

a

t

i

o

n

3

)

.

R

e

g

a

r

d

l

e

s

s

o

f

t

h

i

s

p

r

o

v

i

s

i

o

n

s

o

f

t

h

e

M

a

t

e

r

n

i

t

y

L

e

a

v

e

A

c

t

a

p

p

l

y

.

22

P

u

l

l

i

n

g

a

n

d

p

u

s

h

i

n

g

o

v

e

r

s

h

o

r

t

d

i

s

t

a

n

c

e

s

o

r

f

r

e

q

u

e

n

t

s

t

o

p

p

i

n

g

(

s

i

n

g

l