Professional Documents

Culture Documents

Selecting The Right Injector

Selecting The Right Injector

Uploaded by

xLibelleOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Selecting The Right Injector

Selecting The Right Injector

Uploaded by

xLibelleCopyright:

Available Formats

Selecting the Right Injector

In order to select the correct size injector for your application, you might wish to use one of the following

formulas.

In most cases a naturally aspirated engine will have a B.S.F.C of .50. This means that the engine will use

.50 lbs. of fuel per hour for each horsepower it produces. Supercharged engines will want to be at .60 lbs.

per hour or higher.

Using these numbers as a guideline, you can select the approximate injector size in the following formula

for a four cylinder, naturally aspirated engine at 200 bhp.

Most injectors will max out at 80% duty cycle and this is the accepted industry standard.

B.S.F.C is brake specific fuel consumption - How much fuel you are using per horsepower per hour

Horsepower x B.S.F.C

200 x .50

= 31.25 lbs. / hr. per inj. x 10.50

=

= 328 cc / min

No. of injectors x .80

3.2

(duty cycle)

The proper injector for this application would be 31 lbs. / hr. or 330 cc / min

To find the HP value of the of the above mentioned injectors use this formula:

Inj. size (in lbs. / hr.), 31.25 x (80% duty) / .50 B.S.F.C = 50 hp. per inj. x 4 inj. = 200hp.

To convert cc / min to lbs. / hr. - Divide by 10.5

To convert lbs. / hr to gal. / hr - Divide by 6

To convert cc / min to gal. / hr. - Multiply by .015873

To find the fuel flow change from a fuel pressure change:

New PSI

x Old Flow = New Flow

Old PSI

To convert injector flow rates to horsepower potential - multiply static flow

rates by .80 and then use one of the following formulas:

To convert cc / min to horsepower - multiply by .190476 x number of injectors

To convert lbs. / hr. to horseower - multiply by 2 x number of injectors

You might also like

- VW Transporter T4 ( Diesel - 2000-2004) Workshop Manual: Owners Edition (Owners' Workshop Manuals)From EverandVW Transporter T4 ( Diesel - 2000-2004) Workshop Manual: Owners Edition (Owners' Workshop Manuals)Rating: 1 out of 5 stars1/5 (3)

- BMW Error CodesDocument32 pagesBMW Error CodesSagr96% (45)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Blower CalculationDocument7 pagesBlower CalculationOA AooNo ratings yet

- Diesel Common Rail Injection Electronic Components ExplainedFrom EverandDiesel Common Rail Injection Electronic Components ExplainedRating: 3.5 out of 5 stars3.5/5 (7)

- Calculating Fuel Injector PressureDocument3 pagesCalculating Fuel Injector PressureSapari VelNo ratings yet

- ProperlySelectingEFIComp PDFDocument5 pagesProperlySelectingEFIComp PDFEduardo VilchezNo ratings yet

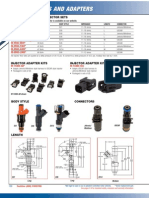

- Fuel Injectors and AdaptorsDocument6 pagesFuel Injectors and AdaptorsPeter Piper100% (1)

- RPM Outlets Formula PageDocument3 pagesRPM Outlets Formula Pagerudey18No ratings yet

- How To Read Pump CurveDocument4 pagesHow To Read Pump Curvebotaqi100% (6)

- Megamanual V4.0: Megasquirt by Bowling & GrippoDocument27 pagesMegamanual V4.0: Megasquirt by Bowling & GrippoCarlos GuerreroNo ratings yet

- Pumps and Pumping SystemsDocument59 pagesPumps and Pumping Systemsluis_may22No ratings yet

- How To Read Pump CurveDocument4 pagesHow To Read Pump CurvenghiemvhNo ratings yet

- Affinity Laws For Centrifugal PumpsDocument5 pagesAffinity Laws For Centrifugal PumpsSeto Tri LaksonoNo ratings yet

- 1.inyectores MegasquietDocument23 pages1.inyectores MegasquietFranco RHNo ratings yet

- Agitator DesignDocument6 pagesAgitator DesignGLENDA CASINONo ratings yet

- How To Read A Pump CurveDocument3 pagesHow To Read A Pump CurvemetropumpsNo ratings yet

- Blower and Motor CalculationsDocument9 pagesBlower and Motor CalculationsChris LaytonNo ratings yet

- Blower Calculation PDFDocument7 pagesBlower Calculation PDFOA Aoo100% (1)

- Engine Design CalculatorDocument3 pagesEngine Design CalculatorNakkolopNo ratings yet

- Turbo Calc SDocument11 pagesTurbo Calc SWembley CandidoNo ratings yet

- SQ - 4.7 - Pumps (Table Format)Document5 pagesSQ - 4.7 - Pumps (Table Format)Amitav MishraNo ratings yet

- Understanding Pump Curves PDFDocument2 pagesUnderstanding Pump Curves PDFumairgul841No ratings yet

- Agitator DesignDocument6 pagesAgitator Designप्रमोद रणपिसेNo ratings yet

- 05 - 3 Piston Cartridge PumpsDocument2 pages05 - 3 Piston Cartridge PumpsJose FernandezNo ratings yet

- Pump BasicsDocument72 pagesPump BasicsVineeth Vs100% (1)

- Pumps Vs Agitators For Tank Mixing Classic Case of CAPEX Vs OPEX White PaperDocument5 pagesPumps Vs Agitators For Tank Mixing Classic Case of CAPEX Vs OPEX White PaperJesse Haney IIINo ratings yet

- Pump Affinity LawsDocument3 pagesPump Affinity LawsmetropumpsNo ratings yet

- Pump Power Calculation FormulaDocument10 pagesPump Power Calculation FormulaMichael Hailu100% (1)

- Engine Math: About Mile Per Hour and Revolutions Per MinuteDocument4 pagesEngine Math: About Mile Per Hour and Revolutions Per MinutexLibelleNo ratings yet

- MEET 422L2 - Prelims - Experiment 2 - HP Eff - Gear Speed RatiosDocument5 pagesMEET 422L2 - Prelims - Experiment 2 - HP Eff - Gear Speed RatiosCj TilamNo ratings yet

- How Much Fuel Does An Excavator Use Per Hour? High ConsumptionDocument8 pagesHow Much Fuel Does An Excavator Use Per Hour? High ConsumptionLacatusu Mircea100% (1)

- Pump Calculations, Pump EquationsDocument3 pagesPump Calculations, Pump EquationsSpataru Marius0% (2)

- ProblemsDocument25 pagesProblemsJohn Paul JuegoNo ratings yet

- Problems Agricultural EngineeringDocument25 pagesProblems Agricultural EngineeringRegan Roldan RolaNo ratings yet

- Some of The Basics You Need To Understand Centrifugal PumpsDocument16 pagesSome of The Basics You Need To Understand Centrifugal PumpsGauravNo ratings yet

- Pump Starup ProcedureDocument23 pagesPump Starup ProcedureKrishnan ManiNo ratings yet

- Assignment 3Document2 pagesAssignment 3Chand PatelNo ratings yet

- Engine Terminologies: Presented by P.Sai Pranay 2019049059Document27 pagesEngine Terminologies: Presented by P.Sai Pranay 2019049059Sai PranayNo ratings yet

- Manual APP Turbo CalcDocument4 pagesManual APP Turbo CalcakawanNo ratings yet

- Asaddff: Pumps vs. Agitators For Tank Mixing, Classic Case of CAPEX Vs OPEX: White PaperaDocument5 pagesAsaddff: Pumps vs. Agitators For Tank Mixing, Classic Case of CAPEX Vs OPEX: White PaperaMARK LESTER REALNo ratings yet

- Pumpsandpumpingsystems 150309110148 Conversion Gate01Document58 pagesPumpsandpumpingsystems 150309110148 Conversion Gate01AltairNo ratings yet

- Flujo de Aire PDFDocument10 pagesFlujo de Aire PDFJoffre Lautaro Benavides Seminario100% (1)

- Centrifugal Pump.......... Very ImpDocument22 pagesCentrifugal Pump.......... Very Impavi07me4u100% (2)

- Pumps and Pumping SystemsDocument59 pagesPumps and Pumping SystemssrinuNo ratings yet

- Pumps Vs AgitatorAsd F DsfsDocument5 pagesPumps Vs AgitatorAsd F DsfsMARK LESTER REALNo ratings yet

- Power and Torque - : Home About EPI Site Map Contact UsDocument6 pagesPower and Torque - : Home About EPI Site Map Contact UsTerefe TadesseNo ratings yet

- Pump Calculations, Pump EquationsDocument3 pagesPump Calculations, Pump EquationsKehinde AdebayoNo ratings yet

- Cálculo de InjetoresDocument3 pagesCálculo de InjetoreslucianofcaNo ratings yet

- Pumps Vs AgitatorAsdsad SadDocument5 pagesPumps Vs AgitatorAsdsad SadMARK LESTER REALNo ratings yet

- Z Purlin Data SheetDocument17 pagesZ Purlin Data SheetErshadNo ratings yet

- Formulas de Calculo de Potenciacion de Motocicletas y AutomovilesDocument5 pagesFormulas de Calculo de Potenciacion de Motocicletas y AutomovilesLuis Armando Fierro LaraNo ratings yet

- Pumps Vs AgitatorAsdds FDSFSDDocument5 pagesPumps Vs AgitatorAsdds FDSFSDMARK LESTER REALNo ratings yet

- Pump Curve UnderstandingDocument7 pagesPump Curve UnderstandingViệt Đặng Xuân100% (1)

- How to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesFrom EverandHow to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesRating: 5 out of 5 stars5/5 (1)

- Southern Marine Engineering Desk Reference: Second Edition Volume IiFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IiNo ratings yet

- VW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004From EverandVW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004Rating: 3 out of 5 stars3/5 (1)

- Southern Marine Engineering Desk Reference: Second Edition Volume IFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume INo ratings yet

- Operator’S Guide to Centrifugal Pumps: What Every Reliability-Minded Operator Needs to KnowFrom EverandOperator’S Guide to Centrifugal Pumps: What Every Reliability-Minded Operator Needs to KnowRating: 2 out of 5 stars2/5 (1)

- Comparison of Diesel and Petrol EnginesFrom EverandComparison of Diesel and Petrol EnginesRating: 2.5 out of 5 stars2.5/5 (3)

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualFrom EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualRating: 3.5 out of 5 stars3.5/5 (2)

- Fuel InjectorsDocument2 pagesFuel InjectorsxLibelleNo ratings yet

- Fuse CodingDocument2 pagesFuse CodingxLibelleNo ratings yet

- Internal Combustion Engines Solution - v1Document13 pagesInternal Combustion Engines Solution - v1xLibelle100% (4)

- Reglarea FarurilorDocument5 pagesReglarea FarurilorMic UtuNo ratings yet

- Engine Math: About Mile Per Hour and Revolutions Per MinuteDocument4 pagesEngine Math: About Mile Per Hour and Revolutions Per MinutexLibelleNo ratings yet

- Engine WeightsDocument13 pagesEngine WeightsxLibelle75% (4)

- BMW Motronic CodesDocument6 pagesBMW Motronic CodesxLibelle100% (3)

- Distributor Less Ignition SystemsDocument4 pagesDistributor Less Ignition SystemsxLibelle100% (5)

- BMW EnginesDocument8 pagesBMW EnginesxLibelle100% (7)

- BMW Engine DesignationsDocument13 pagesBMW Engine DesignationsxLibelle100% (4)

- BMW Color Codes and InformationDocument5 pagesBMW Color Codes and InformationxLibelleNo ratings yet

- Rateing Coil SpringsDocument1 pageRateing Coil SpringsxLibelleNo ratings yet

- Turbocharger BalancingDocument2 pagesTurbocharger BalancingxLibelle100% (3)

- Turbo AntilagDocument3 pagesTurbo AntilagxLibelle100% (1)

- TerminalDocument1 pageTerminalxLibelleNo ratings yet

- Option CodesDocument19 pagesOption CodesxLibelleNo ratings yet

- Engine Math: About Mile Per Hour and Revolutions Per MinuteDocument4 pagesEngine Math: About Mile Per Hour and Revolutions Per MinutexLibelleNo ratings yet

![VW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004](https://imgv2-1-f.scribdassets.com/img/word_document/282876773/149x198/5fb74bd6e1/1675169638?v=1)