Professional Documents

Culture Documents

En440 - Engmw Gmaw Wire

En440 - Engmw Gmaw Wire

Uploaded by

spaljeniOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

En440 - Engmw Gmaw Wire

En440 - Engmw Gmaw Wire

Uploaded by

spaljeniCopyright:

Available Formats

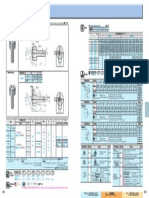

TS 5618

EN 440

Wire electrodes and weld metal for gasgas-shielded metalmetal-arc welding of unalloyed steels and fine

grain structural steels

Example : Wire electrode MG 2

G

42

G3 Si 1

Wire electrode

Table 1

Table 4

Table 3

Table 2

Table 1

Code digits for tensile strength and elongation properties of the weld metal

Minimum yield strength1)

(N/mm2)

355

380

420

460

500

Code digits

35

38

42

46

50

1)

2)

Minimum elongation

(%)

22

20

20

20

18

Tensile strength

(N/mm2)

440-570

470-600

500-640

530-680

560-720

For yield strength the lower (ReL) shall be used if yielding occurs, otherwise the 0,2% proof strength (Rp0,2) shall be applied.

Gauge length is equal to five times the test specimen diameter.

Table 2

Table 3

Symbols for shielding gas

Symbols for impact energy of allall-weld

weld metal

Symbols

Temperature for minimum average

impact energy of 47J

(C)

No requirements

+ 20

-20

-30

-40

-50

-60

Symbols

M

Meaning

This symbol for mixed gas shall be used if

classification has been performed with

shielding gas EN 439-M2, but without

helium.

This symbol shall be used if classification

has been performed with shielding gas EN

439-C1, carbon dioxide.

Table 4

Symbols for the chemical composition of wire electrodes

Symbols

Chemical composition

C

Si

G0

Mn

1) 2) 3)

Ni

Mo

Al

Ti ve Zr

Any chemical composition agreed upon

G2Si1

0.06 0.14

0.50 0.80

0.90 1.30

0.025

0.025

0.15

0.15

0.02

0.15

G3Si1

0.06 0.14

0.70 1.00

1.30 1.60

0.025

0.025

0.15

0.15

0.02

0.15

G4Si1

0.06 0.14

0.80 1.20

1.60 1.90

0.025

0.025

0.15

0.15

0.02

0.15

G3Si2

0.06 0.14

1.00 1.30

1.30 1.60

0.025

0.025

0.15

0.15

0.02

0.15

G2Ti

0.04 0.14

0.40 0.80

0.90 1.40

0.025

0.025

0.15

0.15

0.05 0.20

0.05 0.25

G3Ni1

0.06 0.14

0.50 0.90

1.00 1.60

0.020

0.020

0.80 1.50

0.15

0.02

0.15

G3Ni2

0.06 0.14

0.40 0.80

0.80 1.40

0.020

0.020

2.10 2.70

0.15

0.02

0.15

G2Mo

0.08 0.12

0.30 0.70

0.90 1.30

0.020

0.020

0.15

0.40 0.60

0.02

0.15

G4Mo

0.06 0.14

0.50 0.80

1.70 2.10

0.025

0.025

0.15

0.40 0.60

0.02

0.15

G2Al

0.08 0.14

0.30 0.50

0.90 1.30

0.025

0.025

0.15

0.15

0.35 0.75

0.15

1)

2)

3)

If not specified : Cr 0.15 ; Cu 0.35 and V 0.03. The amount of copper in the steel plus covering shall not exceed 0.35 %.

Single values in this table are maximum values.

The results shall be rounded to the same decimal place as the specified values using the Rule A, Appendix B of ISO 31-O : 1992.

You might also like

- Packet Headers Subnet BreakdownDocument34 pagesPacket Headers Subnet BreakdownParthiban BeemNo ratings yet

- GB3077-1999 English VersionDocument20 pagesGB3077-1999 English VersionHermanto SupuNo ratings yet

- AISI Type 302 Stainless Steel (UNS S30200) : Chemical CompositionDocument4 pagesAISI Type 302 Stainless Steel (UNS S30200) : Chemical CompositionnagboccaNo ratings yet

- Din 17102Document10 pagesDin 17102julio_rocha_1No ratings yet

- Notes On Wire Electrodes EN 440: Table 3Document1 pageNotes On Wire Electrodes EN 440: Table 3raduonoNo ratings yet

- Notes On Wire Electrodes EN 440: Table 3Document1 pageNotes On Wire Electrodes EN 440: Table 3raduonoNo ratings yet

- Iso14341 ADocument2 pagesIso14341 AAluculesei Ciprian100% (1)

- Din 17100Document7 pagesDin 17100Marco Antônio Deitos FilhoNo ratings yet

- 154614Document108 pages154614Danem HalasNo ratings yet

- Wps For Casting Steel With Normal SteelDocument11 pagesWps For Casting Steel With Normal SteelNguyen Huu TriNo ratings yet

- Din 17100Document4 pagesDin 17100Sheby SandyNo ratings yet

- BMW GS 93032-7 - 2019 (Dualp Phase Steels) 5pgDocument5 pagesBMW GS 93032-7 - 2019 (Dualp Phase Steels) 5pgdpfloresNo ratings yet

- Sepction - 2Document4 pagesSepction - 2k koradiaNo ratings yet

- Weld Consumable SelectionDocument25 pagesWeld Consumable SelectionNisarg PandyaNo ratings yet

- Din 17177-79Document8 pagesDin 17177-79savanNo ratings yet

- En10028 2Document12 pagesEn10028 2Patilea Daniela100% (1)

- JIS G 4051 (Translation)Document7 pagesJIS G 4051 (Translation)haharameshNo ratings yet

- ST 37Document7 pagesST 37rendra.farisrNo ratings yet

- St52 Material STD PDFDocument7 pagesSt52 Material STD PDFsardhan.rajender84No ratings yet

- Din 17100Document0 pagesDin 17100df_campos3353No ratings yet

- Geka sg2Document1 pageGeka sg2Jaouad Id BoubkerNo ratings yet

- Din 17100Document4 pagesDin 17100yhszaNo ratings yet

- EN 12070 EN 12070 EN 12070 EN 12070: Exam Exam Exam Example Ple Ple Ple:::: TG 215 TG 215 TG 215 TG 215Document2 pagesEN 12070 EN 12070 EN 12070 EN 12070: Exam Exam Exam Example Ple Ple Ple:::: TG 215 TG 215 TG 215 TG 215spaljeniNo ratings yet

- SteelDocument6 pagesSteelnedunchiNo ratings yet

- Hot Dip Galvanized SheetDocument5 pagesHot Dip Galvanized SheetBrian KnightNo ratings yet

- Structural Steels: High-Quality Steels For Construction ApplicationsDocument3 pagesStructural Steels: High-Quality Steels For Construction Applicationsmaheshmalaichamy007No ratings yet

- DIN 17100 TablasDocument2 pagesDIN 17100 Tablasanonimarium100% (3)

- HPL/TC/T/2010/14127 HPL/TC/T/2010/14127 HPL/TC/T/2010/14127 HPL/TC/T/2010/14127 HPL/TC/T/2010/14127 HPL/TC/T/2010/14127Document4 pagesHPL/TC/T/2010/14127 HPL/TC/T/2010/14127 HPL/TC/T/2010/14127 HPL/TC/T/2010/14127 HPL/TC/T/2010/14127 HPL/TC/T/2010/14127Er Umesh RohitNo ratings yet

- A582 - A582m - 2005 PDFDocument4 pagesA582 - A582m - 2005 PDFPatricio Altavilla100% (2)

- En 10028 P355GHDocument2 pagesEn 10028 P355GHEvriMert RüzgArdaNo ratings yet

- Hot Dip Galvani SheetDocument3 pagesHot Dip Galvani SheetumarNo ratings yet

- Bureau of Indian Standards: Cold-Rolled Steel Strips For SpringsDocument10 pagesBureau of Indian Standards: Cold-Rolled Steel Strips For SpringsPaviter SinghNo ratings yet

- Parametric Study of The TIG Welding Parameter For SS317L SteelDocument6 pagesParametric Study of The TIG Welding Parameter For SS317L SteelIJRASETPublicationsNo ratings yet

- TC 1419 McnallyDocument2 pagesTC 1419 McnallymtlhwhNo ratings yet

- Aitc 407 2005Document3 pagesAitc 407 2005Ayman IssaNo ratings yet

- Aisi 4140Document8 pagesAisi 4140ViruzTrisnaNo ratings yet

- Table of MaterialsDocument28 pagesTable of MaterialsMilos KosticNo ratings yet

- Nachi Bearing MaterialDocument5 pagesNachi Bearing Materialtradingview2hourlyNo ratings yet

- S275 S355 Data Sheet 2021Document1 pageS275 S355 Data Sheet 2021CarloNo ratings yet

- Material CladeadoDocument13 pagesMaterial Cladeadowilian_coelho3309No ratings yet

- Caracteristicas API 2HGr50 PDFDocument3 pagesCaracteristicas API 2HGr50 PDFFernandoBarreraDominguezNo ratings yet

- Steel PropertiesDocument8 pagesSteel PropertiesRob MorienNo ratings yet

- AMTP - Seamless Structural Mechanical Pipe BrochureDocument8 pagesAMTP - Seamless Structural Mechanical Pipe BrochuremasterumNo ratings yet

- Mag-Welding of Repair Structures of Main Gas Pipelines.Document12 pagesMag-Welding of Repair Structures of Main Gas Pipelines.MaksimovNo ratings yet

- A 582Document3 pagesA 582Gustavo SuarezNo ratings yet

- EN10025 - Steel Grades SpecificationsDocument6 pagesEN10025 - Steel Grades SpecificationsFYNo ratings yet

- Steel Grade: Material Data SheetDocument2 pagesSteel Grade: Material Data Sheetsorin robertNo ratings yet

- New 4340 Alloy SteelDocument3 pagesNew 4340 Alloy Steeljimmy julian pava vargasNo ratings yet

- Spring Wire: Patented Cold-Drawn Steel Wire For Mechanical SpringDocument10 pagesSpring Wire: Patented Cold-Drawn Steel Wire For Mechanical SpringGage Floyd BitayoNo ratings yet

- Sprue Bushing JIS B Type 635-636Document1 pageSprue Bushing JIS B Type 635-636NazriNo ratings yet

- 1414 Ev 50 PDFDocument1 page1414 Ev 50 PDFbabaaromeNo ratings yet

- Stainless Steel PropertiesDocument3 pagesStainless Steel Propertieskiwanis_lamNo ratings yet

- MIP Bohler Welding Austria 63Document1 pageMIP Bohler Welding Austria 63thod3rNo ratings yet

- ALLOY 7075 Plate and Sheet: All Around Consistent PerformanceDocument4 pagesALLOY 7075 Plate and Sheet: All Around Consistent PerformanceSarat SrinivasNo ratings yet

- RG RM RGH DatasheetDocument3 pagesRG RM RGH DatasheetMomogi ForeverhappyNo ratings yet

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryFrom EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNo ratings yet

- Metal Tanks (Heavy Gauge) World Summary: Market Values & Financials by CountryFrom EverandMetal Tanks (Heavy Gauge) World Summary: Market Values & Financials by CountryNo ratings yet

- Lapped Flange ANSI B 16.5 - 2500LBSDocument1 pageLapped Flange ANSI B 16.5 - 2500LBSspaljeniNo ratings yet

- Lapped Flange ANSI B 16.5 - 600LBSDocument1 pageLapped Flange ANSI B 16.5 - 600LBSspaljeniNo ratings yet

- EN 12070 EN 12070 EN 12070 EN 12070: Exam Exam Exam Example Ple Ple Ple:::: TG 215 TG 215 TG 215 TG 215Document2 pagesEN 12070 EN 12070 EN 12070 EN 12070: Exam Exam Exam Example Ple Ple Ple:::: TG 215 TG 215 TG 215 TG 215spaljeniNo ratings yet

- Drawing Guide Weld SymbolsDocument3 pagesDrawing Guide Weld SymbolsspaljeniNo ratings yet

- Cen TR 14633 (E)Document9 pagesCen TR 14633 (E)consssNo ratings yet

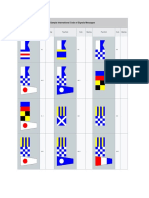

- Sample International Code of Signals MessagesDocument4 pagesSample International Code of Signals MessagesTJames PaulinNo ratings yet

- Laser in Conservative Dentistry & EndodonticsDocument75 pagesLaser in Conservative Dentistry & EndodonticsVinisha Vipin SharmaNo ratings yet

- AD-55295-01-CT - F-MDR STERRAD Consumables Catalogue - 14202NL - FINAL - TM - NDocument2 pagesAD-55295-01-CT - F-MDR STERRAD Consumables Catalogue - 14202NL - FINAL - TM - NAbdessamad ZaherNo ratings yet

- Contemporary Technology: 1. E-CommerceDocument3 pagesContemporary Technology: 1. E-CommerceSAUGHAT GHISINGNo ratings yet

- Catalog Lanturi de Transmisie SKFDocument18 pagesCatalog Lanturi de Transmisie SKFjo_rz_57No ratings yet

- Embedded Coder Users Guide R2018a PDFDocument3,766 pagesEmbedded Coder Users Guide R2018a PDFFrancisco Javier Buenavida DuránNo ratings yet

- Java in Mobile ComputingDocument15 pagesJava in Mobile ComputingAnshul MehrotraNo ratings yet

- Proceedings Isdrs2019 Full PaperDocument832 pagesProceedings Isdrs2019 Full PaperAngie CepedaNo ratings yet

- Number of Groups - IEEE-SBM WIE Codathon Question - Contests - HackerRankDocument2 pagesNumber of Groups - IEEE-SBM WIE Codathon Question - Contests - HackerRankSayali SachinNo ratings yet

- AA12 - Experience With Particle Breakdown in Gas Suspension CalcinersDocument10 pagesAA12 - Experience With Particle Breakdown in Gas Suspension CalcinerskalaiNo ratings yet

- Operation Manual: SERIES IZ15E-100 (RS232)Document40 pagesOperation Manual: SERIES IZ15E-100 (RS232)mihaita-gabriel basoiNo ratings yet

- VMware HealthAnalyzer Install and User Guide v5.0.6Document48 pagesVMware HealthAnalyzer Install and User Guide v5.0.6Thirumal KannanNo ratings yet

- Viking: Product ManualDocument26 pagesViking: Product ManualMailson Apaza KatataNo ratings yet

- PMP 6 SummaryDocument8 pagesPMP 6 SummaryjoNo ratings yet

- Coro CleanDocument18 pagesCoro Cleanlaminar ersNo ratings yet

- A Review of Design of Binary Golay Code and Extended Binary Golay Code For Error CorrectionDocument5 pagesA Review of Design of Binary Golay Code and Extended Binary Golay Code For Error CorrectionEditor IJTSRDNo ratings yet

- Expt 1 Pre-Lab - Intro To SIMetrixDocument4 pagesExpt 1 Pre-Lab - Intro To SIMetrixCarlo JimenezNo ratings yet

- Hcit End of Cluster Test Practical 1Document4 pagesHcit End of Cluster Test Practical 1api-2478715820% (1)

- ELVIC Superwinch Hidraulico Manual ModelosH8P H10P PRODocument12 pagesELVIC Superwinch Hidraulico Manual ModelosH8P H10P PROorlinNo ratings yet

- Beach BrochureDocument2 pagesBeach Brochureapi-353157815No ratings yet

- DSP Lab Question BankDocument6 pagesDSP Lab Question BankGaurav ReddyNo ratings yet

- 89 Series Coupler - MoellerDocument3 pages89 Series Coupler - Moellermayadin yadin100% (1)

- 4 - Neutron DensityDocument44 pages4 - Neutron DensityHarits PamitranNo ratings yet

- Lesson-Plan-Ubd-Es20-Soil FormationDocument2 pagesLesson-Plan-Ubd-Es20-Soil Formationapi-351677864No ratings yet

- Colophons - 2 SamplesDocument2 pagesColophons - 2 Samplesapi-251011903No ratings yet

- 65-Muffle Furnace Calibration CartificateDocument1 page65-Muffle Furnace Calibration CartificateCustomer SupportNo ratings yet

- Performance of The Capstone C30 Microturbine On Biodiesel BlendsDocument11 pagesPerformance of The Capstone C30 Microturbine On Biodiesel BlendsVoicu StaneseNo ratings yet

- Eccentric Swage NippleDocument1 pageEccentric Swage NipplekrishnaNo ratings yet