Professional Documents

Culture Documents

British Standard Concrete Compressive Strength PDF

British Standard Concrete Compressive Strength PDF

Uploaded by

engsam777Copyright:

Available Formats

You might also like

- BT 358 ConstructionEstimating and Price AnalysisDocument162 pagesBT 358 ConstructionEstimating and Price Analysisengsam777100% (2)

- EN 933 PT 1-12Document22 pagesEN 933 PT 1-12龙琦No ratings yet

- Tank Bottom Plate Weld Sequence To Avoid DistortionDocument1 pageTank Bottom Plate Weld Sequence To Avoid Distortionengsam77782% (11)

- BS 812-103-1 - 1985Document11 pagesBS 812-103-1 - 1985ماقوريNo ratings yet

- (BS EN 1744-1 - 2009+A1 - 2012) - Tests For Chemical Properties of Aggregates. Chemical AnalysisDocument66 pages(BS EN 1744-1 - 2009+A1 - 2012) - Tests For Chemical Properties of Aggregates. Chemical AnalysisIS AA100% (1)

- Casa GrandeDocument6 pagesCasa GrandeXendra AqeylaaNo ratings yet

- BS 812-103 2 - Testing Aggregates - Sedimentation Test PDFDocument12 pagesBS 812-103 2 - Testing Aggregates - Sedimentation Test PDFgonzalez_m_aNo ratings yet

- Bitumen Extraction TestsDocument17 pagesBitumen Extraction Testsmzaim100% (1)

- BS en 12390-2Document10 pagesBS en 12390-2Vaqif Ahmedov100% (1)

- T 304Document4 pagesT 304Judy RangelNo ratings yet

- BS en 12620:2002+a1:2008Document1 pageBS en 12620:2002+a1:2008ss,dddcccc100% (1)

- The Idiots' Guide To Highways MaintenanceDocument24 pagesThe Idiots' Guide To Highways Maintenancemp SinghNo ratings yet

- Civil Quality Control Plan-EarthworksDocument3 pagesCivil Quality Control Plan-Earthworksengsam777100% (3)

- Bs 1881 - 112 (1983) PDFDocument11 pagesBs 1881 - 112 (1983) PDFAdesina AlabiNo ratings yet

- BS 1881-114 Testing Hardened ConcreteDocument13 pagesBS 1881-114 Testing Hardened ConcretePD AWSSIESPNo ratings yet

- BS 812-111 (1990) PDFDocument12 pagesBS 812-111 (1990) PDFwahizanNo ratings yet

- Aggregate Crushing Value BS 812-110 and BS en 1097-2Document3 pagesAggregate Crushing Value BS 812-110 and BS en 1097-2Kwame Asamoa0% (1)

- BS 4550 3.4 PDFDocument17 pagesBS 4550 3.4 PDFMatt IkhramNo ratings yet

- BS 812-102 - 1989Document12 pagesBS 812-102 - 1989ماقوريNo ratings yet

- BS 598-104-1989Document18 pagesBS 598-104-1989hibonardo100% (1)

- BS 1881-110 CONCRETE Making Test Cylinders From Fresh ConDocument12 pagesBS 1881-110 CONCRETE Making Test Cylinders From Fresh ConhajimakNo ratings yet

- BS 812-106 Testing Aggregates - Shell Content in Coarse AggrDocument9 pagesBS 812-106 Testing Aggregates - Shell Content in Coarse AggrGasper ShirimaNo ratings yet

- Fiel Compaction Test - Sand Cone TestDocument8 pagesFiel Compaction Test - Sand Cone Testpennacchietti0% (1)

- BS 1881 1983 Part 101Document10 pagesBS 1881 1983 Part 101paladin7No ratings yet

- BS-01881-125-2013 Mixing of Concrete PDFDocument16 pagesBS-01881-125-2013 Mixing of Concrete PDFandri.kusbiantoro9761100% (1)

- Bsi 6073-2 Concrete Specifying Pre-Cast Masonry UnitsDocument14 pagesBsi 6073-2 Concrete Specifying Pre-Cast Masonry UnitsEngr. Jahanzeb MaharNo ratings yet

- BS-1881-118 Concrete Flexural Strength PDFDocument12 pagesBS-1881-118 Concrete Flexural Strength PDFAshraf TomizehNo ratings yet

- BS 1881 Part 107 83Document4 pagesBS 1881 Part 107 83Faizah SophiNo ratings yet

- BS 3921-1985Document30 pagesBS 3921-1985Peng Swan100% (4)

- BS 1881-PART-111 CONCRETE Method Forn Normal Curing of TestDocument4 pagesBS 1881-PART-111 CONCRETE Method Forn Normal Curing of Testhajimak100% (1)

- BS en 12350-4-2000-Degree of CompactabilityDocument8 pagesBS en 12350-4-2000-Degree of CompactabilityOana CristinaNo ratings yet

- L1-Physical Characteristic of SoilDocument78 pagesL1-Physical Characteristic of SoilTAN PANG ZORNo ratings yet

- Bs 1377 Part 2 Methods of Test For Soils For Civil En80cpdfDocument68 pagesBs 1377 Part 2 Methods of Test For Soils For Civil En80cpdfsamuelNo ratings yet

- BS 1881 Part 120 83Document8 pagesBS 1881 Part 120 83tss13723100% (1)

- Aggregate 10% Fines Value BS 812-111 - BS en 1097 - 2Document4 pagesAggregate 10% Fines Value BS 812-111 - BS en 1097 - 2rajeshji_000100% (1)

- BS 1881 Part 108 83Document10 pagesBS 1881 Part 108 83Anonymous ouZFaSBR0% (1)

- Marshall Test Lab ReportDocument6 pagesMarshall Test Lab ReportFazrul Amin100% (2)

- BS 1881-5Document14 pagesBS 1881-5burner2220% (1)

- IS - Free Swell IndexDocument2 pagesIS - Free Swell IndexDr Wong Kim YuenNo ratings yet

- Method Statement Concrete Coring (ASTM C 142)Document2 pagesMethod Statement Concrete Coring (ASTM C 142)Twin Bulls100% (1)

- BS 5075 3Document17 pagesBS 5075 3Muhammad FazilNo ratings yet

- NBT 492Document4 pagesNBT 492Raja QammarNo ratings yet

- Conrete Mix LabDocument22 pagesConrete Mix LabTarek Cheaib100% (4)

- BS 1217 (1) - 1997Document14 pagesBS 1217 (1) - 1997ماقوريNo ratings yet

- BS 5328 - 2Document12 pagesBS 5328 - 2Sundeep Reddy100% (3)

- Swell Pressure Test: 1. ObjectiveDocument4 pagesSwell Pressure Test: 1. Objectiveraviteja036No ratings yet

- QCS 2010 Section 5 Part 11 ReinforcementDocument10 pagesQCS 2010 Section 5 Part 11 Reinforcementbryanpastor106No ratings yet

- LAB REPORT Rebound Hammer TestDocument24 pagesLAB REPORT Rebound Hammer TestZahidahNo ratings yet

- M 17-07 Filler For Bituminous Paving Mix PDFDocument3 pagesM 17-07 Filler For Bituminous Paving Mix PDFWalticoZegarraHerrera100% (1)

- REBOUND HAMMER TEST ObservationDocument1 pageREBOUND HAMMER TEST ObservationSanjeewani Disna JayamaliNo ratings yet

- BS EN 196 Part3 (Ruso) PDFDocument15 pagesBS EN 196 Part3 (Ruso) PDFRobson de Freitas Werling100% (1)

- 2-Asme BPVC Section Ix-2013Document2 pages2-Asme BPVC Section Ix-2013Reda ElsawyNo ratings yet

- BS IndexDocument11 pagesBS IndexShirleyLiuNo ratings yet

- Bs 1881 122 2011 Water Absorption Test For ConcreteDocument4 pagesBs 1881 122 2011 Water Absorption Test For ConcreteChan Chee YongNo ratings yet

- RMCDocument2 pagesRMCraju_mantripragadaNo ratings yet

- BS 874-3.2 PDFDocument18 pagesBS 874-3.2 PDFAnitha Mj100% (1)

- Metalic Coating PDFDocument7 pagesMetalic Coating PDFshamsabbasNo ratings yet

- 04 BRMCA GUIDE BS EN 13791:2019, Clause 9: Assessment of Compressive Strength Class of Concrete in Case of DoubtDocument9 pages04 BRMCA GUIDE BS EN 13791:2019, Clause 9: Assessment of Compressive Strength Class of Concrete in Case of Doubtfadi talaNo ratings yet

- BS 709 Destructive TestingDocument17 pagesBS 709 Destructive TestingGabrieleNo ratings yet

- BS 709Document17 pagesBS 709vuthuy94No ratings yet

- BS709 1983Document17 pagesBS709 1983Sang SekNo ratings yet

- Astm C685 C685M 10Document6 pagesAstm C685 C685M 10Diego AntonioNo ratings yet

- BS 1881 Part 5 1970Document14 pagesBS 1881 Part 5 1970juzarmatinNo ratings yet

- 3595227,1-Layout GoodsDocument16 pages3595227,1-Layout Goodsengsam777No ratings yet

- Cil Tank 4 - 0620-TK-0672Document3 pagesCil Tank 4 - 0620-TK-0672engsam777No ratings yet

- HOOK en Technical Data SheetDocument2 pagesHOOK en Technical Data Sheetengsam777No ratings yet

- Obuasi South Treatment Plant Makeover Project - Structural CalculationsDocument5 pagesObuasi South Treatment Plant Makeover Project - Structural Calculationsengsam777No ratings yet

- 6 - Equation of Motion of MDOF Elastic SystemsDocument5 pages6 - Equation of Motion of MDOF Elastic Systemsengsam777No ratings yet

- Redis Construction Afrika (Pty) LTD.: Quality Management Systems Punch ListDocument3 pagesRedis Construction Afrika (Pty) LTD.: Quality Management Systems Punch Listengsam777No ratings yet

- Redis Construction Afrika (Pty) LTD.: Quality Management Systems Punch ListDocument4 pagesRedis Construction Afrika (Pty) LTD.: Quality Management Systems Punch Listengsam777No ratings yet

- Redis Construction Afrika (Pty) LTD.: Quality Management Systems Punch ListDocument4 pagesRedis Construction Afrika (Pty) LTD.: Quality Management Systems Punch Listengsam777No ratings yet

- Redis Construction Afrika (Pty) Ltd. Quality Management SystemsDocument1 pageRedis Construction Afrika (Pty) Ltd. Quality Management Systemsengsam777No ratings yet

- Weld Visual Inspection Report-Water TreatmentDocument5 pagesWeld Visual Inspection Report-Water Treatmentengsam777No ratings yet

- Redis Construction Afrika (Pty) LTD.: Quality Management Systems Punch ListDocument3 pagesRedis Construction Afrika (Pty) LTD.: Quality Management Systems Punch Listengsam777No ratings yet

- Weld Visual Inspection-STRIP TANKDocument2 pagesWeld Visual Inspection-STRIP TANKengsam777No ratings yet

- Weld Visual Inspection Report-PRE-OX ATTACHMENTSDocument4 pagesWeld Visual Inspection Report-PRE-OX ATTACHMENTSengsam777No ratings yet

- Weld Visual Inspection TK 1318Document3 pagesWeld Visual Inspection TK 1318engsam777No ratings yet

- Weld Visual Inspection-FLOC MIXING TANKDocument2 pagesWeld Visual Inspection-FLOC MIXING TANKengsam777No ratings yet

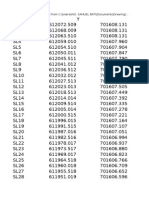

- Coordinates From C:/Users/Ing. Samuel Bati/Documents/Drawing1.Dwg Exported by Cadstudio Click2Xls On 20150819.1951Document4 pagesCoordinates From C:/Users/Ing. Samuel Bati/Documents/Drawing1.Dwg Exported by Cadstudio Click2Xls On 20150819.1951engsam777No ratings yet

- Weld Visual Inspection-Floc Storage and Distr. TankDocument2 pagesWeld Visual Inspection-Floc Storage and Distr. Tankengsam777No ratings yet

- Edusah's ProfileDocument7 pagesEdusah's Profileengsam777No ratings yet

British Standard Concrete Compressive Strength PDF

British Standard Concrete Compressive Strength PDF

Uploaded by

engsam777Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

British Standard Concrete Compressive Strength PDF

British Standard Concrete Compressive Strength PDF

Uploaded by

engsam777Copyright:

Available Formats

TPS 43

EDITION 2

DECEMBER 2004

Testing Hardened Concrete - Guidance on Accreditation to BS EN 12390

CONTENTS

SECTION Purpose and Duration General Requirement for Transition Specific Requirements PAGE 2 2 3

1 2 3

CHANGES SINCE LAST EDITION

Clarification of guidance. Reporting of machine class limited to class 3 machines. All altered text marked by a line in the margin.

United Kingdom Accreditation Service, 21-47 High Street, Feltham, Middlesex, TW13 4UN Website: www.ukas.com Publication requests Tel: 020 8917 8421 (9am 1pm) Fax: 020 8917 8500

United Kingdom Accreditation Service 2004. UKAS Copyright exists in all UKAS publications

PAGE 1 OF 6

EDITION 2 | DECEMBER 2004

Testing Hardened Concrete Guidance on Accreditation to BS EN 12390

TPS 43 | EDITION 2 | DECEMBER 2004

1 PURPOSE AND DURATION

1.1 1.2 The purpose of this Statement is to advise laboratories and assessors of the requirements for gaining accreditation for the various hardened concrete tests described in the parts of BS EN 12390. BS EN 12390, Testing hardened concrete, specifies a series of tests for hardened concrete, which replace the equivalent tests in BS 1881, Testing concrete, the conflicting parts of which were formally withdrawn in December 2003. There are nine parts to BS EN 12390, one of which is still in draft, which replace parts of BS 1881 as indicated in Table 1. BS EN 12390 Part BS EN 12390-1:2000 BS EN 12390-2:2000 BS EN 12390-3:2002 BS EN 12390-4:2000 BS EN 12390-5:2000 BS EN 12390-6:2000 BS EN 12390-7:2000 BS EN 12390-8:2000 BS EN 12390-9 in draft Equivalent BS 1881 Parts BS 1881-108, 109 & 110:1983 BS 1881-108, 109, 110 & 111:1983 BS 1881-116:1983 BS 1881-115:1986 BS 1881-118:1983 BS 1881-117:1983 BS 1881-114:1983 No equivalent No equivalent Contents Dimensional specifications Making and curing specimens Compressive strength Testing machine specifications Flexural strength Tensile splitting strength Density Water penetration under pressure Freeze-thaw resistance

Table 1 Summary of Standard Equivalence 1.3 Many accredited laboratories hold accreditation for BS 1881 methods, and will seek transition to equivalent BS EN 12390 methods. The purpose of this Statement is to provide UKAS policy to ensure a smooth and consistent transfer of such laboratories to the new standards, whilst ensuring the technical requirements of BS EN 12390 and BS EN ISO/IEC 17025, General requirements for the competence of testing and calibration laboratories are met. This Statement will remain in force at least until all BS EN 12390 transitions have been assessed, and will be reviewed by 31 December 2005.

1.4

2 GENERAL REQUIREMENTS FOR TRANSITION

2.1 Laboratories cannot assume that, because they are accredited for the BS 1881 test, they will automatically be accredited for the equivalent BS EN 12390 test, and can issue accredited reports for that test. Many of the equivalent BS EN 12390 methods will be familiar to BS 1881 practitioners, but all include differences significant enough to necessitate a detailed review before accreditation can be granted. Accreditation for the BS EN 12390 methods cannot be claimed until the laboratory has received an accreditation schedule including these tests. In particular, all laboratories will need to provide evidence of personnel competence and equipment suitability with respect to each BS EN 12390 test for which accreditation is sought. In certain cases BS EN 12390 methods may require supplementing with additional detail to ensure consistent application. Laboratories seeking accreditation for entirely new BS EN 12390 methods, or for methods for which they do not currently hold the equivalent BS 1881 accreditation, will be required to apply for an extension of scope, followed by onsite assessment. Laboratories seeking transition from BS 1881 to the equivalent BS EN 12390 methods will be required to demonstrate compliance with both the appropriate part of BS EN 12390 and BS EN ISO/IEC 17025. This may be carried out by document submission, followed by assessment of the test methods on-site at the next scheduled visit. Details of requirements for document submission are given in the following Section of this Statement. UKAS recognises that many laboratories will require both BS and BS EN methods to coexist on accreditation schedules to satisfy contractual obligations. Until requested otherwise by a laboratory, accreditation schedules will continue to show currently accredited BS 1881 test methods. The laboratory must be prepared to demonstrate these methods at visits, if so requested. UKAS proposes to allow this situation until this Statement is reviewed. After this time any extension to this concession will be considered on a case-bycase basis.

2.2

2.3

2.4

United Kingdom Accreditation Service, 21-47 High Street, Feltham, Middlesex, TW13 4UN Website: www.ukas.com Publication requests Tel: 020 8917 8421 (9am 1pm) Fax: 020 8917 8500

United Kingdom Accreditation Service 2004. UKAS Copyright exists in all UKAS publications

PAGE 2 OF 6

Testing Hardened Concrete Guidance on Accreditation to BS EN 12390

TPS 43 | EDITION 2 | DECEMBER 2004

3 SPECIFIC REQUIREMENTS

3.1 3.1.1

BS EN 12390-1:2000 - Shape, dimensions and other requirements for specimens and moulds BS EN 12390-1 supersedes BS 1881-108, Method for making test cubes from fresh concrete, BS 1881-109, Method for making test beams from fresh concrete and BS 1881-110, Method for making test cylinders from fresh concrete. BS EN 12390-1 specifies requirements for the shape, dimensions and tolerances of cast concrete test specimens in the form of cubes, cylinders and prisms, and of the moulds required to produce them. The mould tolerances specified are primarily based on the needs of strength testing. The standard introduces two alternative approaches towards obtaining test specimens of the correct sizes and shapes. The first is to use moulds whose life is limited and to measure the specimens to ensure conformity. The second is to cast specimens in calibrated metal moulds which meet tighter tolerances than required for specimens. The use of calibrated moulds allows relaxation of requirements for measuring the specimens. Laboratories will need to need to decide whether they control specimen dimension conformity through use of calibrated moulds, specimen measurement or use both methods as appropriate. Laboratories who have control over moulds used for casting specimens will need to check new and existing mould dimensions against BS EN 12390-1 requirements. Laboratories currently accredited for BS 1881-108, BS 1881-109 or BS 1881-110 will be required to provide evidence of mould compliance to BS EN 12390-1. BS EN 12390-2:2000 - Making and curing specimens for strength tests BS EN 12390-2 supersedes BS 1881-108, Method for making test cubes from fresh concrete , BS 1881-109, Method for making test beams from fresh concrete, BS 1881-110, Method for making test cylinders from fresh concrete and BS 1881-111, Method of normal curing of test specimens (20 C method). BS EN 123902 specifies methods for making and curing test specimens for strength tests. It covers the preparation and filling of moulds, compaction, levelling, curing and transporting test specimens. Although this standard is under the hardened concrete BS EN 12390 series, it describes the manufacture of specimens from fresh concrete. BS EN 12390-2 differs in detail from the BS 1881 methods it replaces in equipment options and usage, sample preparation, specimen manufacture procedure and curing requirements. Laboratories operating mist chamber curing should note the 95% relative humidity requirements. BS EN 12390-2 Clause 5.5.3 states that forms of curing differing from the standard water or mist chamber methods described may be factorised to the standard methods. No advice on factorisation is given. Laboratories will need to confirm compaction procedures and provide evidence of equipment compliance for these procedures, which are different to those covered by existing BS 1881-108 accreditations. Laboratories will be expected to retain records of the chosen curing regimes ability to meet BS EN 12390-2 requirements on a day -to-day basis, as required previously for BS 1881-111. Evidence of compliance with 95% relative humidity w ill be required where mist chamber curing is utilised. Laboratories that wish to introduce factorised curing will need to validate this appropriately before introduction, and obtain the agreement of clients, as required by BS EN ISO/IEC 17025 Clause 5.4.4. UKAS must be informed of any intention to implement factorised curing. BS EN 12390-3:2002 - Compressive strength of test specimens BS EN 12390-3 supersedes BS 1881-116, Method for determination of compressive strength of concrete cubes . BS EN 12390-3 specifies a method for the determination of the compressive strength of cube, cylinder and core test specimens of hardened concrete. Specimens with dimensions which are outside the tolerances of the designated sizes of BS EN 12390-1 are to be tested in accordance with BS EN 12390-3 Annex B. BS EN 12390-1 designated size tolerances, at less than 0.5% of designated size, are more onerous than those of BS 1881-116. Specimens with flatness or perpendicularity which are outside the tolerances of Clause 4.2.3 of BS EN 12390-1, or with dimensions more than 2% from the designated size (BS EN 12390-3 Annex B Clause B.3.1.1), are required to be rejected or adjusted in accordance with BS EN 12390-3 Annex A. Adjustment procedures for dimensionally non-conforming cubes are not current practice for laboratories accredited for BS 1881-116, and it is considered that they are unlikely to be implemented because of their cost implications. However, it is likely that clients will still wish to receive test results for dimensionally non-conforming cubes. UKAS will allow such results to be reported, provided that there is evidence that the client has requested testing to be carried out even though the cube does not meet the specified dimensional tolerances, and that the following disclaimer is included on the test report. Alternative wording will not be acceptable without the agreement of the laboratorys Assessment Manager:

3.1.2

3.1.3 3.2 3.2.1

3.2.2

3.2.3 3.2.4

3.2.5

3.3 3.3.1

3.3.2

3.3.3

United Kingdom Accreditation Service, 21-47 High Street, Feltham, Middlesex, TW13 4UN Website: www.ukas.com Publication requests Tel: 020 8917 8421 (9am 1pm) Fax: 020 8917 8500

United Kingdom Accreditation Service 2004. UKAS Copyright exists in all UKAS publications

PAGE 3 OF 6

Testing Hardened Concrete Guidance on Accreditation to BS EN 12390

TPS 43 | EDITION 2 | DECEMBER 2004

These test results relate to cubes which do not meet the dimensional and/or shape requirements of BS EN 12390-1. 3.3.4 BS EN 12390-3 Annex B Clause B.2 requires callipers or rules capable of determining specimen dimensions to an accuracy of 0.5%. The use of a steel rule complying with BS 4372, or otherwise suitably calibrated, is considered acceptable for use when measuring specimens 100 mm designated size. The use of a rule measuring to the nearest 0.5 mm will be accepted for 150 mm cubes, as 0.5 mm is less than 0.5% of 150 mm. Other methods of measurement may be accepted, provided that an accuracy of 0.5% can be demonstrated, and the requirements of BS EN 12390-3 Annex B Clause B.3 are met. All specimens require testing on platens with dimensions greater than, or equal to, those of the faces of the specimens in contact with them (BS EN 12390-4 Clause 4.1.5). Specimens must be centred with respect to the lower platen to an accuracy of 1% of designated size. BS EN 12390-3 allows loading rates within the range 0.2 to 1.0 N/mm.s as opposed to the BS 1881-116 range of 0.2 to 0.4 N/mm.s. The selected rate of loading has to be achieved to an accuracy of 10% throughout the test. For transfer to accreditation against BS EN 12390-3 for concrete cube compressive strength testing, a laboratory will be required to submit documentation to demonstrate, as a minimum, the items in Figure 1. The phrase calibrated mould, as used in Figure 1, shall be taken to mean either a mould with a current calibration certificate from a BS EN ISO/IEC 17025 accredited calibration laboratory, or a mould used only by the staff of a BS EN ISO/IEC 17025 testing laboratory which is accredited for making concrete cubes in internally calibrated moulds. Either: (a) or: (b) cubes have been checked for compliance with designated size, flatness and perpendicularity requirements (BS EN 12390-1, Clauses 4.5.1, 4.2.3.1, 4.2.3.2, 4.2.3.3 and 4.2.3.4).

3.3.5

3.3.6

3.3.7 3.3.8

1.

cubes for test have been made in calibrated moulds, and that their dimensions have been checked for compliance with designated size requirements (BS EN 12390-1, Clauses 4.5.2, 4.2.3.1 and 4.2.3.2)

Acceptable evidence that a cube has been made in a calibrated mould may consist of either: (i) a report in compliance with Clause 6 of BS EN 12390-2 from an organisation (that may be the laboratory itself) that is accredited for making concrete cubes in accordance with BS EN 12390-2 or: (ii) a statement from an organisation that can demonstrate accredited certification to BS EN ISO 9001:2000 for a scope that encompasses conformity a ssessment for making concrete cubes. The essential requirements of such a statement are given in Figure 2.

2.

Procedures are in place to ensure that staff are aware of: (a) when flatness and perpendicularity measurements are required, and the procedures to be used for those measurements (b) when the requirements of Annex B of BS EN 12390-3 are to be implemented. Note that it will not be acceptable to implement the requirements of Annex B for specimens which conform to the designated size requirements of Clauses 4.2.3.1 and 4.2.3.2 of BS EN 12390-1 (c) what action should be taken when cubes cannot be tested without prior adjustment of size (BS EN 12390-3 Annex B Clause B.3.1.1). All compression testing machines are calibrated for all items in Clauses 4.4 and 5.1 of BS EN 12390-4 (accuracy of force indication, force transfer, flatness of platens and rate of application of force) at the frequency defined in Clause 5.2 of BS EN 12390-4. Platens are available to meet the requirements of Annex B Clause B.3.3 of BS EN 12390-3 and Clauses 4.1.5 and 4.1.6 of BS EN 12390-4. The pacer has been calibrated for the rate of loading that is to be employed for testing. In addition to the reporting requirements of BS EN 12390-3, reports indicate if a class 3 machine has been used (BS EN 12390-4), include the rate of loading employed (BS EN 12390-3 Clause 6.2), indicate whether documentation has been received to show that the cube has been made in a calibrated mould (BS EN 12390-1 Clause 4.5.1), and state when the procedures of Annex B of BS EN 12390-3 have been used. Figure 1 Minimum Requirements for Transfer of Accreditation to BS EN 12390-3:2000

3.

4. 5. 6.

United Kingdom Accreditation Service, 21-47 High Street, Feltham, Middlesex, TW13 4UN Website: www.ukas.com Publication requests Tel: 020 8917 8421 (9am 1pm) Fax: 020 8917 8500

United Kingdom Accreditation Service 2004. UKAS Copyright exists in all UKAS publications

PAGE 4 OF 6

Testing Hardened Concrete Guidance on Accreditation to BS EN 12390

TPS 43 | EDITION 2 | DECEMBER 2004

Identity of organisation making cubes Statement that cubes were made in moulds with current calibration certificates from a BS EN ISO/IEC 17025 accredited calibration laboratory by staff operating under a BS EN ISO 9001:2000 quality system that encompasses conformity assessment for making concrete cubes, and have been inspected as suitable for testing List of cubes covered by statement with, for each cube: Cube identity Mould identity Date and time of manufacture Descriptive information, such as concrete mix details, location, etc.

Date of release to testing laboratory Authorised legible name and signature to confirm above information Figure 2 Essential Requirements of a Statement to Confirm the Manufacture of Cubes in Calibrated Moulds 3.4 3.4.1 BS EN 12390-4:2000 - Compressive strength - Specification for testing machines BS EN 12390-4 supersedes BS 1881-115, Specification for compression testing machines for concrete. BS EN 12390-4 specifies the requirements for the performance of compression testing machines for the measurement of hardened concrete compressive strength. BS EN 12390-4 recognises three classes of testing machine corresponding to scale accuracies of 1%, 2% and 3%. BS 1881-115 limited the scale accuracy to 1% or 2% in the range specimens were expected to fail. BS EN 12390-3 does not impose such restrictions, thus allowing the use of a 3% scale accuracy machine. As this will have a direct impact upon the accuracy of the test result, when compared to previous BS 1881115 requirements, UKAS will require the client to be informed at contract review if a class 3 machine is to be used, and the use of a class 3 machine to be reported. Transitional arrangements are in place to accept valid calibrations carried out in accordance with BS 1881115 until such time as recalibration against the requirements of BS EN 12390-4 is due. It should be noted, however, that calibration in accordance with BS 1881-115 will not cover loading rates greater than 0.4 N/mm.s. BS EN 12390-5:2000 - Flexural strength of test specimens BS EN 12390-5 supersedes BS 1881-118, Method for the determination of flexural strength. BS EN 12390-5 specifies two methods for the determination of flexural strength of concrete by either centre- or two-point loading of cast or sawn prisms. The two -point loading test is essentially the same as the test specified in BS 1881-118, except in detail, whilst the centre-point loading test was not included in BS1881. Some of the requirements of BS EN 12390-5 allow greater tolerances than those specified by BS1881-118, but in three areas requirements are more onerous. Tolerances on prism specimen dimensions, given in Clause 4.4 of BS EN 12390-1, are significantly smaller than those allowed by BS 1881-118. BS EN 12390-5 specifies that, for the two-point test, both upper rollers shall be capable of free rotation; BS 1881-118 allowed any one of the four rollers to be fixed. Most significantly, the range of the rate of load application has been reduced from 0.02 to 0.10 N /mm.s in BS 1881-118 to 0.04 to 0.06 N/mm.s in BS EN 12390-5, and the selected rate of loading has to be achieved to an accuracy of 10% throughout the test. The figure of 1% given in the standard has been acknowledged as an error by CEN. Laboratories currently accredited for BS 1881-118 will be required to demonstrate that their test machine is capable of achieving the required constant loading rate, and that dimensional tolerances are checked appropriately. Laboratories wishing to carry out centre-point loading will need to submit full calibration details for this apparatus. BS EN 12390-6:2000 - Tensile splitting strength of test specimens BS EN 12390-6 supersedes BS 1881-117, Method for the determination of tensile splitting strength. BS EN 12390-6 specifies a single method for determining the tensile splitting strength of concrete cylinders as the reference method. This is essentially equivalent to the apparatus A method of BS 1881-117, except in detail. The BS 1881-117 apparatus A method for cubes and prisms is included in the normative Annex A of BS EN 12390-6. The BS 1881-117 apparatus B method for cubes and prisms is not included in BS EN 12390.

3.4.2

3.4.3

3.5 3.5.1

3.5.2

3.5.3

3.6 3.6.1

United Kingdom Accreditation Service, 21-47 High Street, Feltham, Middlesex, TW13 4UN Website: www.ukas.com Publication requests Tel: 020 8917 8421 (9am 1pm) Fax: 020 8917 8500

United Kingdom Accreditation Service 2004. UKAS Copyright exists in all UKAS publications

PAGE 5 OF 6

Testing Hardened Concrete Guidance on Accreditation to BS EN 12390

TPS 43 | EDITION 2 | DECEMBER 2004

3.6.2

BS 1881-117 placed no essential dimensional requirements on the tests specimens. For cylinders, BS EN 12390-6 requires compliance with the dimensional requirements of Clause 4.3 of BS EN 12390-1. The required hardboard packing strips are different in both conformity and dimensional requirements. Most significantly the range of the rate of load application has been changed from 0.02 to 0.04 N/mm.s in BS 1881-117 to 0.04 to 0.06 N/mm.s in BS EN 12390-6, and thus the BS 1881-117 loading rate is no longer acceptable. The selected rate of loading has to be achieved to an accuracy of 10% throughout the test; the figure of 1% given in the standard has been acknowledged as an error by CEN. It should be noted that the equation for the required loading rate, given in Clause 6.3 of BS EN 12390-6, is also in error. The correct equation is: R= S xp xLxd 2

3.6.3

3.6.4

Laboratories currently accredited for the apparatus A method of BS 1881-117 will be required to demonstrate that their test machine is capable of achieving the required constant loading rate, and that dimensional tolerances are checked appropriately. Laboratories currently accredited for the apparatus B method of BS 1881-117 wishing to gain accreditation for BS EN 12390-6 will need to submit full apparatus calibration details. BS EN 12390-7:2000 - Density of hardened concrete BS EN 12390-7 supersedes BS 1881-114, Method for determination of density of hardened concrete . BS EN 12390-7 specifies a method for determining the density of hardened concrete. The standard differentiates between hardened concrete in the as-received, water saturated and oven-dried states. The standard recognises three methods for determining the volume of the specimen: by water displacement (reference method), by calculation using actual measurements and, for cubes, by calculation using checked designated dimensions. The latter two methods are described in BS EN 12390-1. The BS EN 12390-7 methods are essentially those covered by BS 1881-114, but with differences in detail. The requirements of BS EN 12390-7 Clause 3.3 for the water tank call for the use of a device to maintain the water at a constant level. The use of a vertically adjustable tank, or any similar means, to maintain the water level at a fixed point on a suspension stirrup during testing is also considered acceptable. The use of calculations, or other means of compensation for water displacement that do not involve a constant water level, are not acceptable. No detailed measurement procedures for determining density from actual measurements or checked designated dimensions are included in either BS EN 12390-7 or BS EN 12390-1. Laboratories using these options will need to produce additional documentation to supplement BS EN 12390 to ensure consistent application. BS EN 12390-8:2000 - Depth of penetration of water under pressure BS EN 12390-8 is a new test method, and thus does not supersede any part of BS 1881. It specifies an apparently straightforward test to determine the depth of penetration of water at a pressure of 500 kPa into a concrete specimen Laboratories seeking accreditation for this method will be required to apply for an extension of scope, followed by on-site assessment. Laboratories will need to produce additional documentation to supplement BS EN 12390-8 to ensure consistent application of the test method.

3.7 3.7.1

3.7.2

3.7.3

3.8 3.8.1

3.8.2

Contact For further information about this Statement, please contact your Assessment Manager or: Dr Paul Chapman Tel: 020 8917 8580 Fax: 020 8917 8780 e-mail: paul.chapman@ukas.com

United Kingdom Accreditation Service, 21-47 High Street, Feltham, Middlesex, TW13 4UN Website: www.ukas.com Publication requests Tel: 020 8917 8421 (9am 1pm) Fax: 020 8917 8500

United Kingdom Accreditation Service 2004. UKAS Copyright exists in all UKAS publications

PAGE 6 OF 6

You might also like

- BT 358 ConstructionEstimating and Price AnalysisDocument162 pagesBT 358 ConstructionEstimating and Price Analysisengsam777100% (2)

- EN 933 PT 1-12Document22 pagesEN 933 PT 1-12龙琦No ratings yet

- Tank Bottom Plate Weld Sequence To Avoid DistortionDocument1 pageTank Bottom Plate Weld Sequence To Avoid Distortionengsam77782% (11)

- BS 812-103-1 - 1985Document11 pagesBS 812-103-1 - 1985ماقوريNo ratings yet

- (BS EN 1744-1 - 2009+A1 - 2012) - Tests For Chemical Properties of Aggregates. Chemical AnalysisDocument66 pages(BS EN 1744-1 - 2009+A1 - 2012) - Tests For Chemical Properties of Aggregates. Chemical AnalysisIS AA100% (1)

- Casa GrandeDocument6 pagesCasa GrandeXendra AqeylaaNo ratings yet

- BS 812-103 2 - Testing Aggregates - Sedimentation Test PDFDocument12 pagesBS 812-103 2 - Testing Aggregates - Sedimentation Test PDFgonzalez_m_aNo ratings yet

- Bitumen Extraction TestsDocument17 pagesBitumen Extraction Testsmzaim100% (1)

- BS en 12390-2Document10 pagesBS en 12390-2Vaqif Ahmedov100% (1)

- T 304Document4 pagesT 304Judy RangelNo ratings yet

- BS en 12620:2002+a1:2008Document1 pageBS en 12620:2002+a1:2008ss,dddcccc100% (1)

- The Idiots' Guide To Highways MaintenanceDocument24 pagesThe Idiots' Guide To Highways Maintenancemp SinghNo ratings yet

- Civil Quality Control Plan-EarthworksDocument3 pagesCivil Quality Control Plan-Earthworksengsam777100% (3)

- Bs 1881 - 112 (1983) PDFDocument11 pagesBs 1881 - 112 (1983) PDFAdesina AlabiNo ratings yet

- BS 1881-114 Testing Hardened ConcreteDocument13 pagesBS 1881-114 Testing Hardened ConcretePD AWSSIESPNo ratings yet

- BS 812-111 (1990) PDFDocument12 pagesBS 812-111 (1990) PDFwahizanNo ratings yet

- Aggregate Crushing Value BS 812-110 and BS en 1097-2Document3 pagesAggregate Crushing Value BS 812-110 and BS en 1097-2Kwame Asamoa0% (1)

- BS 4550 3.4 PDFDocument17 pagesBS 4550 3.4 PDFMatt IkhramNo ratings yet

- BS 812-102 - 1989Document12 pagesBS 812-102 - 1989ماقوريNo ratings yet

- BS 598-104-1989Document18 pagesBS 598-104-1989hibonardo100% (1)

- BS 1881-110 CONCRETE Making Test Cylinders From Fresh ConDocument12 pagesBS 1881-110 CONCRETE Making Test Cylinders From Fresh ConhajimakNo ratings yet

- BS 812-106 Testing Aggregates - Shell Content in Coarse AggrDocument9 pagesBS 812-106 Testing Aggregates - Shell Content in Coarse AggrGasper ShirimaNo ratings yet

- Fiel Compaction Test - Sand Cone TestDocument8 pagesFiel Compaction Test - Sand Cone Testpennacchietti0% (1)

- BS 1881 1983 Part 101Document10 pagesBS 1881 1983 Part 101paladin7No ratings yet

- BS-01881-125-2013 Mixing of Concrete PDFDocument16 pagesBS-01881-125-2013 Mixing of Concrete PDFandri.kusbiantoro9761100% (1)

- Bsi 6073-2 Concrete Specifying Pre-Cast Masonry UnitsDocument14 pagesBsi 6073-2 Concrete Specifying Pre-Cast Masonry UnitsEngr. Jahanzeb MaharNo ratings yet

- BS-1881-118 Concrete Flexural Strength PDFDocument12 pagesBS-1881-118 Concrete Flexural Strength PDFAshraf TomizehNo ratings yet

- BS 1881 Part 107 83Document4 pagesBS 1881 Part 107 83Faizah SophiNo ratings yet

- BS 3921-1985Document30 pagesBS 3921-1985Peng Swan100% (4)

- BS 1881-PART-111 CONCRETE Method Forn Normal Curing of TestDocument4 pagesBS 1881-PART-111 CONCRETE Method Forn Normal Curing of Testhajimak100% (1)

- BS en 12350-4-2000-Degree of CompactabilityDocument8 pagesBS en 12350-4-2000-Degree of CompactabilityOana CristinaNo ratings yet

- L1-Physical Characteristic of SoilDocument78 pagesL1-Physical Characteristic of SoilTAN PANG ZORNo ratings yet

- Bs 1377 Part 2 Methods of Test For Soils For Civil En80cpdfDocument68 pagesBs 1377 Part 2 Methods of Test For Soils For Civil En80cpdfsamuelNo ratings yet

- BS 1881 Part 120 83Document8 pagesBS 1881 Part 120 83tss13723100% (1)

- Aggregate 10% Fines Value BS 812-111 - BS en 1097 - 2Document4 pagesAggregate 10% Fines Value BS 812-111 - BS en 1097 - 2rajeshji_000100% (1)

- BS 1881 Part 108 83Document10 pagesBS 1881 Part 108 83Anonymous ouZFaSBR0% (1)

- Marshall Test Lab ReportDocument6 pagesMarshall Test Lab ReportFazrul Amin100% (2)

- BS 1881-5Document14 pagesBS 1881-5burner2220% (1)

- IS - Free Swell IndexDocument2 pagesIS - Free Swell IndexDr Wong Kim YuenNo ratings yet

- Method Statement Concrete Coring (ASTM C 142)Document2 pagesMethod Statement Concrete Coring (ASTM C 142)Twin Bulls100% (1)

- BS 5075 3Document17 pagesBS 5075 3Muhammad FazilNo ratings yet

- NBT 492Document4 pagesNBT 492Raja QammarNo ratings yet

- Conrete Mix LabDocument22 pagesConrete Mix LabTarek Cheaib100% (4)

- BS 1217 (1) - 1997Document14 pagesBS 1217 (1) - 1997ماقوريNo ratings yet

- BS 5328 - 2Document12 pagesBS 5328 - 2Sundeep Reddy100% (3)

- Swell Pressure Test: 1. ObjectiveDocument4 pagesSwell Pressure Test: 1. Objectiveraviteja036No ratings yet

- QCS 2010 Section 5 Part 11 ReinforcementDocument10 pagesQCS 2010 Section 5 Part 11 Reinforcementbryanpastor106No ratings yet

- LAB REPORT Rebound Hammer TestDocument24 pagesLAB REPORT Rebound Hammer TestZahidahNo ratings yet

- M 17-07 Filler For Bituminous Paving Mix PDFDocument3 pagesM 17-07 Filler For Bituminous Paving Mix PDFWalticoZegarraHerrera100% (1)

- REBOUND HAMMER TEST ObservationDocument1 pageREBOUND HAMMER TEST ObservationSanjeewani Disna JayamaliNo ratings yet

- BS EN 196 Part3 (Ruso) PDFDocument15 pagesBS EN 196 Part3 (Ruso) PDFRobson de Freitas Werling100% (1)

- 2-Asme BPVC Section Ix-2013Document2 pages2-Asme BPVC Section Ix-2013Reda ElsawyNo ratings yet

- BS IndexDocument11 pagesBS IndexShirleyLiuNo ratings yet

- Bs 1881 122 2011 Water Absorption Test For ConcreteDocument4 pagesBs 1881 122 2011 Water Absorption Test For ConcreteChan Chee YongNo ratings yet

- RMCDocument2 pagesRMCraju_mantripragadaNo ratings yet

- BS 874-3.2 PDFDocument18 pagesBS 874-3.2 PDFAnitha Mj100% (1)

- Metalic Coating PDFDocument7 pagesMetalic Coating PDFshamsabbasNo ratings yet

- 04 BRMCA GUIDE BS EN 13791:2019, Clause 9: Assessment of Compressive Strength Class of Concrete in Case of DoubtDocument9 pages04 BRMCA GUIDE BS EN 13791:2019, Clause 9: Assessment of Compressive Strength Class of Concrete in Case of Doubtfadi talaNo ratings yet

- BS 709 Destructive TestingDocument17 pagesBS 709 Destructive TestingGabrieleNo ratings yet

- BS 709Document17 pagesBS 709vuthuy94No ratings yet

- BS709 1983Document17 pagesBS709 1983Sang SekNo ratings yet

- Astm C685 C685M 10Document6 pagesAstm C685 C685M 10Diego AntonioNo ratings yet

- BS 1881 Part 5 1970Document14 pagesBS 1881 Part 5 1970juzarmatinNo ratings yet

- 3595227,1-Layout GoodsDocument16 pages3595227,1-Layout Goodsengsam777No ratings yet

- Cil Tank 4 - 0620-TK-0672Document3 pagesCil Tank 4 - 0620-TK-0672engsam777No ratings yet

- HOOK en Technical Data SheetDocument2 pagesHOOK en Technical Data Sheetengsam777No ratings yet

- Obuasi South Treatment Plant Makeover Project - Structural CalculationsDocument5 pagesObuasi South Treatment Plant Makeover Project - Structural Calculationsengsam777No ratings yet

- 6 - Equation of Motion of MDOF Elastic SystemsDocument5 pages6 - Equation of Motion of MDOF Elastic Systemsengsam777No ratings yet

- Redis Construction Afrika (Pty) LTD.: Quality Management Systems Punch ListDocument3 pagesRedis Construction Afrika (Pty) LTD.: Quality Management Systems Punch Listengsam777No ratings yet

- Redis Construction Afrika (Pty) LTD.: Quality Management Systems Punch ListDocument4 pagesRedis Construction Afrika (Pty) LTD.: Quality Management Systems Punch Listengsam777No ratings yet

- Redis Construction Afrika (Pty) LTD.: Quality Management Systems Punch ListDocument4 pagesRedis Construction Afrika (Pty) LTD.: Quality Management Systems Punch Listengsam777No ratings yet

- Redis Construction Afrika (Pty) Ltd. Quality Management SystemsDocument1 pageRedis Construction Afrika (Pty) Ltd. Quality Management Systemsengsam777No ratings yet

- Weld Visual Inspection Report-Water TreatmentDocument5 pagesWeld Visual Inspection Report-Water Treatmentengsam777No ratings yet

- Redis Construction Afrika (Pty) LTD.: Quality Management Systems Punch ListDocument3 pagesRedis Construction Afrika (Pty) LTD.: Quality Management Systems Punch Listengsam777No ratings yet

- Weld Visual Inspection-STRIP TANKDocument2 pagesWeld Visual Inspection-STRIP TANKengsam777No ratings yet

- Weld Visual Inspection Report-PRE-OX ATTACHMENTSDocument4 pagesWeld Visual Inspection Report-PRE-OX ATTACHMENTSengsam777No ratings yet

- Weld Visual Inspection TK 1318Document3 pagesWeld Visual Inspection TK 1318engsam777No ratings yet

- Weld Visual Inspection-FLOC MIXING TANKDocument2 pagesWeld Visual Inspection-FLOC MIXING TANKengsam777No ratings yet

- Coordinates From C:/Users/Ing. Samuel Bati/Documents/Drawing1.Dwg Exported by Cadstudio Click2Xls On 20150819.1951Document4 pagesCoordinates From C:/Users/Ing. Samuel Bati/Documents/Drawing1.Dwg Exported by Cadstudio Click2Xls On 20150819.1951engsam777No ratings yet

- Weld Visual Inspection-Floc Storage and Distr. TankDocument2 pagesWeld Visual Inspection-Floc Storage and Distr. Tankengsam777No ratings yet

- Edusah's ProfileDocument7 pagesEdusah's Profileengsam777No ratings yet