Professional Documents

Culture Documents

Cost Estimation For Mass Production Using Jigs and Fixture

Cost Estimation For Mass Production Using Jigs and Fixture

Uploaded by

Praveen KumarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cost Estimation For Mass Production Using Jigs and Fixture

Cost Estimation For Mass Production Using Jigs and Fixture

Uploaded by

Praveen KumarCopyright:

Available Formats

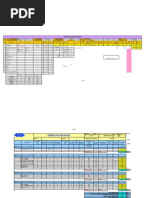

COST ESTIMATION FOR OUR FIXTURE

1. MATERIAL COST Weight = (/4) D2 L = (/4) (6210-3)2 (3010-3) (7850) = 0.710 kg Cost of 1 kg of EN1A LEADED = Rs.60 Cost of 0.710 kg Material cost = 600.710 = Rs.42.65

2. MACHINING COST

a. BAR CUTTING = length of cut cost = 620.08 = 4.96

b. ROUGH MACHINING 19 mm drilling hole in lathe = Rs.2

c. CNC MACHINING Time of machining = 150 sec

Number of components in 1 hour = 3600/150 = 25 Number of components in 8 hours = 248 = 192 Rounding off for practical reasons = 1920.85 Number of components CNC cost of working for 8 hours Cost of 1 component = 160 = Rs.2000 = 2000/160 = Rs.12.5

d. CROSS HOLE DRILLING Time for drilling = (length of drill time) / (feedR.P.M) = (2060)/(0.042500) Time for drilling Total time drilling 4 holes = 12 sec = 60 sec

Number of components in 1 hour = 3600/60 = 60

Number of components in 8 hours = 608 = 480 Rounding off for practical reasons = 4800.85 Number of components Drilling machining cost per shift Cost of drilling for 1 component = 400 = Rs.800 = 800/400 = Rs.2

2. LABOUR COST Time for all operations = 120+120+150+60 = 450sec = 0.125 hour Labour cost per hour Labour cost for 1 component = Rs.60 = 600.125 = Rs.7.5

3. PRIME COST Prime cost = material cost + labour cost + machining cost = 42.62 + (4.96+2+12.5+2) + 7.5 = Rs.71.61

4. OVERHEAD COST = 71.610.2 = Rs.14.32

5. SELLING AND DISTRIBUTION COST = 0.0671.61 = Rs.4.29

6. TOTAL COST Total cost = prime cost + overhead cost + selling and distribution cost = 71.61 + 14.32 + 4.29 = Rs.90.22

7. SELLING PRICE = Rs.110 8. PROFIT = selling price - total cost

= 110 - 90.22 = 19.78

COST ESTIMATION WITH MANUAL VICE

1. MATERIAL COST Weight = (/4) D2 L = (/4) (6210-3)2 (3010-3) (7850) = 0.710 kg Cost of 1 kg of EN1A LEADED = Rs.60 Cost of 0.710 kg Material cost = 600.710 = Rs.42.65

2. MACHINING COST

a. BAR CUTTING = length of cut cost = 620.08 = 4.96

b. ROUGH MACHINING 19 mm drilling hole in lathe = Rs.2

c. CNC MACHINING Time of machining = 150 sec

Number of components in 1 hour = 3600/150 = 25 Number of components in 8 hours = 248 = 192 Rounding off for practical reasons = 1920.85 Number of components CNC cost of working for 8 hours Cost of 1 component = 160 = Rs.2000 = 2000/160 = Rs.12.5

d. CROSS HOLE DRILLING Time for drilling = (length of drill time) / (feedR.P.M) = (2060)/(0.042500) Time for drilling Total time drilling 4 holes = 12 sec = 240 sec

Number of components in 1 hour

= 3600/240 = 15

Number of components in 8 hours = 158 = 120 Rounding off for practical reasons = 1200.85 Number of components Drilling machining cost per shift Cost of drilling for 1 component = 100 = Rs.800 = 800/100 = Rs.8

2. LABOUR COST Time for all operations = 120+120+150+240 = 630sec = 0.175 hour Labour cost per hour Labour cost for 1 component = Rs.60 = 600.175 = Rs.10.5

3. PRIME COST Prime cost = material cost + machining cost + labour cost

= 42.62 + (4.96 + 2 + 12.5 + 8) + 10.5 = Rs.80.61

4. OVERHEAD COST = 80.61 0.2 = Rs.16.32

5. SELLING AND DISTRIBUTION COST = 0.06 80.61 = Rs.4.836

6. TOTAL COST Total cost = prime cost + overhead cost + selling and distribution cost = 80.61 + 16.32 + 4.86 = Rs.101.77

7. SELLING PRICE = Rs.110

8. PROFIT = selling price - total cost = 110 101.77 = 8.44

You might also like

- Kindness Shawl Jaala Spiro: Skills NeededDocument4 pagesKindness Shawl Jaala Spiro: Skills NeededSandra Reynaldo100% (1)

- Beary Barnita Giraffe DollDocument28 pagesBeary Barnita Giraffe DollJUDITH100% (14)

- MMR - Weekly 29 Jan 2024Document20 pagesMMR - Weekly 29 Jan 2024dishukadam06100% (1)

- Injection Molding: Part Cost EstimatorDocument3 pagesInjection Molding: Part Cost Estimatorpchakkrapani100% (1)

- Lathe and VMC Cycle Time CalculatorDocument5 pagesLathe and VMC Cycle Time CalculatorDhanus KodiNo ratings yet

- Cost BreakupDocument6 pagesCost Breakuppiyush sharma100% (1)

- Cost Estimation - MachiningDocument12 pagesCost Estimation - MachiningAbu Zahid100% (2)

- Vertical Machining Centre (VMC)Document3 pagesVertical Machining Centre (VMC)anil chejaraNo ratings yet

- Tandem Vs Transfer Vs Progressive DiesDocument15 pagesTandem Vs Transfer Vs Progressive DiesMoham'medAlthafAs'lamNo ratings yet

- Die Design ChecklistDocument3 pagesDie Design ChecklistLương TuấnNo ratings yet

- Calculation of Hourly Rate For Laser Cutting Machine - 500W Input of Data Calculations. Yearly Work Capacity 4800Document2 pagesCalculation of Hourly Rate For Laser Cutting Machine - 500W Input of Data Calculations. Yearly Work Capacity 4800Susheel Shukla100% (1)

- Tool Design Calculation: Cutting ForceDocument4 pagesTool Design Calculation: Cutting ForceRaja SathishNo ratings yet

- Final Jigs Fixture ReportDocument25 pagesFinal Jigs Fixture ReportNurul Jannah75% (4)

- Forging Die DesignDocument6 pagesForging Die Designرضوان العادلى100% (2)

- Tool Checklist enDocument5 pagesTool Checklist enpeterjkeller100% (2)

- Cost Estimation in Forging Shop 611Document28 pagesCost Estimation in Forging Shop 611Serajul Haque100% (1)

- How To Calculate Machine Hour RateDocument7 pagesHow To Calculate Machine Hour RateShami Kant86% (7)

- Estimation of Machining TimeDocument6 pagesEstimation of Machining TimeSuhas100% (1)

- Costing Format - Press ToolDocument6 pagesCosting Format - Press ToolVineet Pandey Vlogs67% (3)

- Cost Working of Mechanical Press: Description General Formula CostDocument4 pagesCost Working of Mechanical Press: Description General Formula Costazadsingh1No ratings yet

- Investment Casting Cycle TimeDocument12 pagesInvestment Casting Cycle TimemaheshNo ratings yet

- Clutch HSG Casting CostingDocument18 pagesClutch HSG Casting CostingAjay DeshpandeNo ratings yet

- Unit-Iv Production Cost EstimationDocument58 pagesUnit-Iv Production Cost EstimationmechgokulNo ratings yet

- Tonnage CalculatorDocument2 pagesTonnage CalculatorLoveofyouth ReddyNo ratings yet

- V-Sem DTDMDocument27 pagesV-Sem DTDMVishwas vNo ratings yet

- Part/Material Inputs: Injection Molding Technical Cost Model MIT - Materials Systems LaboratoryDocument13 pagesPart/Material Inputs: Injection Molding Technical Cost Model MIT - Materials Systems LaboratoryEmba MadrasNo ratings yet

- FES MTG Welding Fixture F7222910Document11 pagesFES MTG Welding Fixture F7222910Sekar NaikNo ratings yet

- MHR Calculation 1Document13 pagesMHR Calculation 1RamNo ratings yet

- How To Compute Tonnage RequirementsDocument5 pagesHow To Compute Tonnage RequirementsPrabhat SharmaNo ratings yet

- Mold ChecklistDocument5 pagesMold ChecklistSelvaraj BalasundramNo ratings yet

- Tip Speed Calculation: RPM CalculationDocument13 pagesTip Speed Calculation: RPM CalculationNishant InamdarNo ratings yet

- Body ModelDocument145 pagesBody ModelDipika PandaNo ratings yet

- Rubber Component Cost Estimation SheetDocument1 pageRubber Component Cost Estimation SheetVenkateswaran venkateswaran100% (2)

- Product or Service Technical Design Specifications, Including Unit of Measure (UOM)Document1 pageProduct or Service Technical Design Specifications, Including Unit of Measure (UOM)Priyaprasad PandaNo ratings yet

- Data Cycle Time & Target Produksi Die CastingDocument7 pagesData Cycle Time & Target Produksi Die CastingHeri SutiknoNo ratings yet

- Summary-Costing Sheet For Shell & Tube Heat ExchangerDocument19 pagesSummary-Costing Sheet For Shell & Tube Heat ExchangerAnonymous LKi1w1uNo ratings yet

- Die CalculationsDocument13 pagesDie CalculationsDhinakaran R100% (1)

- Moulds and Dies Manufacturers / Moulded + Pressed Parts: Manufacturers in The CBI Export Coaching ProgrammesDocument4 pagesMoulds and Dies Manufacturers / Moulded + Pressed Parts: Manufacturers in The CBI Export Coaching Programmesprasad_kcpNo ratings yet

- Partcost With Freight Table Rev. 7Document3 pagesPartcost With Freight Table Rev. 7RJLockNo ratings yet

- Internal Costing Sheet: C45 - 36 Dia QT+ IH 1,400.00 400.00Document2 pagesInternal Costing Sheet: C45 - 36 Dia QT+ IH 1,400.00 400.00ramabhplNo ratings yet

- Press Tool CalculationDocument76 pagesPress Tool CalculationPrashant AmbadekarNo ratings yet

- Machine Cost & Set Up TimeDocument11 pagesMachine Cost & Set Up TimeGanesh SunderNo ratings yet

- Injection Molded Plastic Part Cost Estimator: Design Organizatio Date Part EvaluatedDocument4 pagesInjection Molded Plastic Part Cost Estimator: Design Organizatio Date Part EvaluatedTiago CerqueiraNo ratings yet

- Tool Life SheetDocument4 pagesTool Life SheetYam Udhai100% (1)

- KSS713 - Die Casting Tool Standard - Rev.03Document17 pagesKSS713 - Die Casting Tool Standard - Rev.03Adrian Doru100% (2)

- Tool and Die Maker PDFDocument9 pagesTool and Die Maker PDFArun PrasathNo ratings yet

- Strip LayoutDocument35 pagesStrip LayoutJay PatelNo ratings yet

- Costing Sheet 500632403736Document6 pagesCosting Sheet 500632403736Sourabh PradhanNo ratings yet

- Casting Cost EstimationDocument3 pagesCasting Cost EstimationSreenath S KallaaraNo ratings yet

- Sheet Metal Per Stroke Cost CalculationDocument1 pageSheet Metal Per Stroke Cost CalculationBharat100% (2)

- Injection Molding Part CostingDocument4 pagesInjection Molding Part Costingfantinno100% (1)

- Design and Analysis of Progressive Tool For An Automobile ComponentDocument9 pagesDesign and Analysis of Progressive Tool For An Automobile ComponentAnna100% (1)

- Fixtures Cost Break UpDocument23 pagesFixtures Cost Break UpAshok AroraNo ratings yet

- 20me702 - Process Planning and Cost Estimation Unit 5 2023-24Document65 pages20me702 - Process Planning and Cost Estimation Unit 5 2023-24CAD With RaoNo ratings yet

- Welding Cost Formula For Different Welding ProcessesDocument2 pagesWelding Cost Formula For Different Welding ProcessesmekoxxxNo ratings yet

- Abs - Injection Mould Component Cost EstimationDocument7 pagesAbs - Injection Mould Component Cost EstimationVenkateswaran venkateswaranNo ratings yet

- Costing FormatDocument3 pagesCosting FormatdavNo ratings yet

- Cupola Melting CostDocument3 pagesCupola Melting CostnirevievNo ratings yet

- Costing: 23013030w D Mounting SleeveDocument32 pagesCosting: 23013030w D Mounting Sleevevijayasarathy_2010No ratings yet

- Stoppers: Stop PositionDocument44 pagesStoppers: Stop PositionSubodh KumarNo ratings yet

- Check Fixture Standards Rev 4 Dated 9-10-2019Document11 pagesCheck Fixture Standards Rev 4 Dated 9-10-2019SasiNo ratings yet

- Dasher CaseDocument3 pagesDasher CasewwwNo ratings yet

- "Christmas Ornaments": Rocking Horse, Reindeer, Penguin and Angel by RnataDocument6 pages"Christmas Ornaments": Rocking Horse, Reindeer, Penguin and Angel by Rnataana milena100% (6)

- Ceramic Tiles Ceramic TilesDocument3 pagesCeramic Tiles Ceramic Tilesnaughty_angel18071989No ratings yet

- A. Nagy - Forging Samian Ware in The Pannonian Way - The Case of Stamped Pottery. RCRF 43 (2014) 119-127 PDFDocument10 pagesA. Nagy - Forging Samian Ware in The Pannonian Way - The Case of Stamped Pottery. RCRF 43 (2014) 119-127 PDFDragan GogicNo ratings yet

- GMKDocument7 pagesGMKNKay AndroidNo ratings yet

- Leopold Bench PlansDocument8 pagesLeopold Bench PlanshammerloNo ratings yet

- Tooling Maintenance ManualDocument92 pagesTooling Maintenance ManualLokesh Basappa100% (1)

- Jigs and FixturesDocument20 pagesJigs and FixturesRenjith RajendraprasadNo ratings yet

- 5 Shop Made Clamps - SSCDocument1 page5 Shop Made Clamps - SSCjuan olivaNo ratings yet

- Fitter Iii Semester Question - New 1-4 PDFDocument11 pagesFitter Iii Semester Question - New 1-4 PDFGangadharam MademNo ratings yet

- Velleman VTSS4 - User ManualDocument15 pagesVelleman VTSS4 - User Manualerdnase1902No ratings yet

- Simple Baby HatDocument2 pagesSimple Baby HatadinaNo ratings yet

- Training Suggestion System (SS)Document38 pagesTraining Suggestion System (SS)Ibnu AlfiansyahNo ratings yet

- Hitachi Tool - ASR PicoDocument2 pagesHitachi Tool - ASR Picojunior_radaicNo ratings yet

- Cutting Data Milling Boring 2019 ITL E LowDocument60 pagesCutting Data Milling Boring 2019 ITL E LowRoberto RosasNo ratings yet

- Valentine Teddy: Absolutely Adorable BearsDocument12 pagesValentine Teddy: Absolutely Adorable BearsCheri Pettit100% (1)

- Metal Processes: V L C K ND of Proc H T Ca Ar HDocument2 pagesMetal Processes: V L C K ND of Proc H T Ca Ar HTere Romero50% (2)

- Homework Solution# 3 I&ME 471 Due 3/31: Hint: You Will Need To Calculate The NDocument4 pagesHomework Solution# 3 I&ME 471 Due 3/31: Hint: You Will Need To Calculate The NBizuayehu TadesseNo ratings yet

- Woodworker's Journal - June 2016Document76 pagesWoodworker's Journal - June 2016ashishojha1980100% (4)

- Comparing Quality Parameters of Yarn Produced by Ring, Rotor, and Compact Spinning SystemDocument17 pagesComparing Quality Parameters of Yarn Produced by Ring, Rotor, and Compact Spinning SystemMetasebia GizawNo ratings yet

- Landscape PhotographyDocument148 pagesLandscape PhotographyBasanta BhandariNo ratings yet

- 2 هندسة الانتاج والمعادن ملزمة طرق تصنيع مرحلةDocument23 pages2 هندسة الانتاج والمعادن ملزمة طرق تصنيع مرحلةAhmed KhalidNo ratings yet

- VMC1000IIPARTSLISTPL97Document105 pagesVMC1000IIPARTSLISTPL97Nica BogdanNo ratings yet

- Fabric Structure AND DesignDocument113 pagesFabric Structure AND DesignMollaNo ratings yet

- VandinhaDocument19 pagesVandinhaCelia Regina Dantas100% (1)

- Consew HVP-60Document49 pagesConsew HVP-60Luis Caba Ramirez100% (1)

- Log GazeboDocument62 pagesLog Gazebomadrid7613100% (1)

- My Sample Different Stitches (Description and Its Function)Document10 pagesMy Sample Different Stitches (Description and Its Function)Karla Therese LicosNo ratings yet

- FREE Bear Lovey Pattern 2018Document15 pagesFREE Bear Lovey Pattern 2018Jorge Lourenço100% (3)