Professional Documents

Culture Documents

Img 0005

Img 0005

Uploaded by

herasetiawan0 ratings0% found this document useful (0 votes)

5 views1 pagePeriodical verification shall be done at least once a year to ensure the tester's accuracy. If problems occur, contact the manufacturer for assistance. Common issues include the long pointer deviating from its zero point due to loose nuts or screws, insufficient oil causing suction sounds, a damaged indenter, incorrect weight placement, friction between weights and walls, or an unleveled display from a misinstalled dust cover.

Original Description:

time

Original Title

IMG_0005

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentPeriodical verification shall be done at least once a year to ensure the tester's accuracy. If problems occur, contact the manufacturer for assistance. Common issues include the long pointer deviating from its zero point due to loose nuts or screws, insufficient oil causing suction sounds, a damaged indenter, incorrect weight placement, friction between weights and walls, or an unleveled display from a misinstalled dust cover.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

5 views1 pageImg 0005

Img 0005

Uploaded by

herasetiawanPeriodical verification shall be done at least once a year to ensure the tester's accuracy. If problems occur, contact the manufacturer for assistance. Common issues include the long pointer deviating from its zero point due to loose nuts or screws, insufficient oil causing suction sounds, a damaged indenter, incorrect weight placement, friction between weights and walls, or an unleveled display from a misinstalled dust cover.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

Periodical verification shall be done, at least once a year, on the tester so as to

ensure its accuracy. 6.6 Common trouble shooting

It is recommended that the user contact the manufacturer if problems occur with the

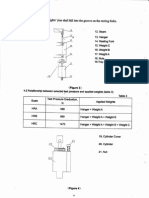

tester. However, the following table

common problems (table 5)

pl{ nelp the user to detect and solve some

Table 5

Refer

Adjustment of disPlaYed

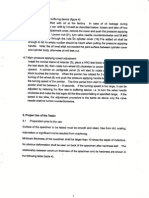

to figure 5.

SlightlY

loosen nut (26) and tum M4

screw (27) tn small increment

to align the Pointer onto its zero

The long pointer deviates

from its zero point.

value may

deviation

pointer.

cause

of the long

point, then fix the screw and

fasten the nut.

lmpact during test pressure applying or empty suction sound when removing the pressure

lnsufiicient oil in

bufiering device

Refillthe cylinder as described

in section 4.6.

1.

Damaged indenter.

Replace diamond indenter

2. Wrong order of

weights Placement'

or ball indenter.

Place weights according to

3. Friction

between

figure 3.

Galibrate the testerwith a

weights and inner

wall of the

Extraordinary

on display unleveled

tester

bY

leveling instrument according to 4.2.4.

eror

occurs

body caused

installation

tester.

of the

Lower the dust-Proof cover

to below the uPPer surface

of the lifting screw and

4.

The dust-Proof

cover is higher than

fasten the screw Select appropriate test

the supporting

ll

You might also like

- Engine, Assembling: Service InformationDocument29 pagesEngine, Assembling: Service Informationducatiss90074% (23)

- Volvo D6D Shop ArmedDocument45 pagesVolvo D6D Shop ArmedBASILIO JARA HUERTA100% (4)

- Reed Prentice ManualDocument25 pagesReed Prentice ManualMikelyn Anderson100% (2)

- SKF Industrial V Belt Tension TesterDocument3 pagesSKF Industrial V Belt Tension TesterJimena Mamani Surco83% (6)

- Skidmore Instructions Model MS ManualsDocument15 pagesSkidmore Instructions Model MS ManualsbwbrockNo ratings yet

- KASTO 016 (로크웰 경도 시험기) PDFDocument27 pagesKASTO 016 (로크웰 경도 시험기) PDFTJNo ratings yet

- Model M ManualsDocument6 pagesModel M ManualsdiegoNo ratings yet

- Pfaff 438 Service ManualDocument38 pagesPfaff 438 Service ManualRonan Nolasco100% (1)

- Strainoptic Stress ManualDocument9 pagesStrainoptic Stress Manualjsrplc7952No ratings yet

- Webster User's ManualDocument7 pagesWebster User's ManualAngel Alvarez CarrilloNo ratings yet

- Clean & Adjusting The Tension On Most 600 Series MachinesDocument2 pagesClean & Adjusting The Tension On Most 600 Series MachinesStar ZoneNo ratings yet

- H-3860D - Man - 0816 DesgasteDocument8 pagesH-3860D - Man - 0816 Desgastealvaro almendarezNo ratings yet

- Sezione 1 Pag. 11-24 PDFDocument14 pagesSezione 1 Pag. 11-24 PDFMAZZI1978100% (1)

- Torque Screwdriver RepairDocument16 pagesTorque Screwdriver RepairFrancisco Ros AlvaradoNo ratings yet

- Kbu KBZ2Document8 pagesKbu KBZ2Andrew VNo ratings yet

- 1757 1988Document4 pages1757 1988Ramesh BNo ratings yet

- Force MeasurementDocument18 pagesForce MeasurementKali DasNo ratings yet

- Bolt Load MeterDocument12 pagesBolt Load MeterrzepedacNo ratings yet

- Testing Concrete: BS 1881: Part 116: 1983Document8 pagesTesting Concrete: BS 1881: Part 116: 1983Muhammad AmmarNo ratings yet

- 04 Hydraulic Deadweight Testers-09-24-2015Document12 pages04 Hydraulic Deadweight Testers-09-24-2015BolWolNo ratings yet

- BASF Angular Variation of Vibration Weld Joint StrengthDocument7 pagesBASF Angular Variation of Vibration Weld Joint Strength28192175No ratings yet

- 1.1 Care and Adjustment of Apparatus - Buhler Miag Disc Mill, DLFUDocument3 pages1.1 Care and Adjustment of Apparatus - Buhler Miag Disc Mill, DLFUFabio Luis Da Silva Faria OliveiraNo ratings yet

- Ball Injector O&m InstructionDocument12 pagesBall Injector O&m InstructionArgonauta_navegadorNo ratings yet

- Lab 1 HydraulicDocument12 pagesLab 1 HydraulicRuHuiNo ratings yet

- Use and Care of The Level and Transit-LevelDocument27 pagesUse and Care of The Level and Transit-LevelprotobooksNo ratings yet

- Procedures For Rotational Capacity Testing of Galvanized ASTM A325 ..Document14 pagesProcedures For Rotational Capacity Testing of Galvanized ASTM A325 ..Sayed Diab AlsayedNo ratings yet

- Grid Coupling Installation InstructionsDocument2 pagesGrid Coupling Installation Instructionsakashwsl92No ratings yet

- Shear Stud Welding Process PDFDocument4 pagesShear Stud Welding Process PDFVinicius Geraldini PiantolaNo ratings yet

- Shear Stud Welding Process PDFDocument4 pagesShear Stud Welding Process PDFVinicius Geraldini PiantolaNo ratings yet

- Clisis 9Document15 pagesClisis 9fortroniNo ratings yet

- Table Saw AlingmentDocument8 pagesTable Saw AlingmentEd BozmanNo ratings yet

- Reparación Inyectores DensoDocument22 pagesReparación Inyectores DensoMarcoNo ratings yet

- Impact TestDocument15 pagesImpact TestNathaniel Adam DavidNo ratings yet

- Rotating Fatigue PDFDocument2 pagesRotating Fatigue PDFMia FarhanaNo ratings yet

- Buku Petunjuk Barcoll HT-10 USADocument11 pagesBuku Petunjuk Barcoll HT-10 USAAlat Pengukur Dan PengujiNo ratings yet

- BS 1881 Part 116 Concrete CubesDocument8 pagesBS 1881 Part 116 Concrete Cubesnolanjc100% (2)

- Work Instruction FOR: Calibration of Pressure Gauge by Dead Weight TesterDocument3 pagesWork Instruction FOR: Calibration of Pressure Gauge by Dead Weight TestermahendraNo ratings yet

- Disc Pack Coupling STCDocument2 pagesDisc Pack Coupling STCYudo ArdianNo ratings yet

- Use Again: Thrust Washer ReusabilityDocument19 pagesUse Again: Thrust Washer ReusabilityGanbat JargalNo ratings yet

- Sinowon Rockwell Hardness Tester SHR-187.5 Installation and Operation - enDocument19 pagesSinowon Rockwell Hardness Tester SHR-187.5 Installation and Operation - enJohnny DaiNo ratings yet

- Unprotected A3702003a 20Document1 pageUnprotected A3702003a 20kaveh-bahiraeeNo ratings yet

- Kbu KBZ7Document7 pagesKbu KBZ7Andrew VNo ratings yet

- Expt - No: Date: Dead Weight Pressure GaugeDocument2 pagesExpt - No: Date: Dead Weight Pressure GaugeMadhumathiNo ratings yet

- September 2015: Setting or Driving Solid RivetsDocument8 pagesSeptember 2015: Setting or Driving Solid Rivetsraj mohanNo ratings yet

- D6E AssemblingDocument30 pagesD6E AssemblingRio SetiawanNo ratings yet

- Acoples FLOWSERVE - Instalación PDFDocument12 pagesAcoples FLOWSERVE - Instalación PDFJenny Cecilia Ureña ZuriNo ratings yet

- Repairs Manual GV 124 GV Av 12 GV Av 14 GV Av 17Document10 pagesRepairs Manual GV 124 GV Av 12 GV Av 14 GV Av 17Juan Carlos Aldea GriñenNo ratings yet

- TighteningofStructuralBolts 31-35Document5 pagesTighteningofStructuralBolts 31-35masaud akhtarNo ratings yet

- KASTO 094 (금속용 Charpy 충격시험기) PDFDocument52 pagesKASTO 094 (금속용 Charpy 충격시험기) PDFTJNo ratings yet

- 3 - 05 Biela Motor L7044Document13 pages3 - 05 Biela Motor L7044Javier LeonidasNo ratings yet

- Bulletin #D1 EDocument4 pagesBulletin #D1 EΑΠΟΣΤΟΛΙΑ ΜΑΤΣΟΥΚΑNo ratings yet

- Calibration of Digital Burette IIIDocument10 pagesCalibration of Digital Burette IIIWaleed MedhatNo ratings yet

- Almen Gage Calibration: Electronics Inc, Mishawaka, USADocument7 pagesAlmen Gage Calibration: Electronics Inc, Mishawaka, USAQuality controllerNo ratings yet

- Manual Instalacion Mantencion y Operacion FlujometroDocument8 pagesManual Instalacion Mantencion y Operacion Flujometrosolar2507No ratings yet

- File 94catalogo SumitomoDocument28 pagesFile 94catalogo SumitomoJaime Arreola100% (1)

- Model MS ManualsDocument15 pagesModel MS ManualsbarrettshawnNo ratings yet

- smhs 7727 Special Instruction-проверка установки гильз 3400Document5 pagessmhs 7727 Special Instruction-проверка установки гильз 3400Евгений АбрамовNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Mathematics (12 - 13 Credit Units)Document1 pageMathematics (12 - 13 Credit Units)herasetiawanNo ratings yet

- Engineering Vibration (2 - 4 Credit Units) : Unit of Competency Learning Outcomes Autodesk Learning Material(s)Document1 pageEngineering Vibration (2 - 4 Credit Units) : Unit of Competency Learning Outcomes Autodesk Learning Material(s)herasetiawanNo ratings yet

- Mechanical Engineering Design - Cad: Technical DescriptionDocument16 pagesMechanical Engineering Design - Cad: Technical DescriptionherasetiawanNo ratings yet

- Common Metallographic EtchantsDocument1 pageCommon Metallographic EtchantsherasetiawanNo ratings yet

- Is Oil Factory. Oil: at LN ofDocument1 pageIs Oil Factory. Oil: at LN ofherasetiawanNo ratings yet

- Img 0010Document1 pageImg 0010herasetiawanNo ratings yet

- Img 0006Document1 pageImg 0006herasetiawanNo ratings yet

- Img 0001Document1 pageImg 0001herasetiawanNo ratings yet