Professional Documents

Culture Documents

Lacron Filter Service Information: A Guide To Changing Filter Media in Lacron Filters

Lacron Filter Service Information: A Guide To Changing Filter Media in Lacron Filters

Uploaded by

Renata ReljacOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lacron Filter Service Information: A Guide To Changing Filter Media in Lacron Filters

Lacron Filter Service Information: A Guide To Changing Filter Media in Lacron Filters

Uploaded by

Renata ReljacCopyright:

Available Formats

Lacron Filter Service Information

Lacron (UK) Limited, Radfield, London Road, Teynham, Sittingbourne, Kent, ME9 9PS, UK. www.waterco.eu

A GUIDE TO CHANGING FILTER MEDIA IN LACRON FILTERS

Introduction We recommend that any servicing of a Lacron filter, (including media changes or the replacement of parts) should be undertaken by a professional pool company, which is an Authorised Lacron Dealer. These pool companies will have the correct equipment and genuine replacement parts to carry out any work required with the minimum amount of downtime. Any service work carried out by the pool owner/caretaker will be done so at their own risk. Health & Safety Used filter media may contain contaminates including: chemical traces and bacteria which could be harmful if in direct contact with skin, or if the fumes are inhaled. We therefore recommend that adequate clothing such as rubber gloves and respiratory masks are worn when changing filter sand. Proper considerations should also be given regarding the disposal of used filter media. We suggest that used filter media should be packaged into biodegradable sacks and safely dispatched to a suitable waste disposal site. Q1 HOW OFTEN SHOULD FILTER MEDIA BE CHANGED?

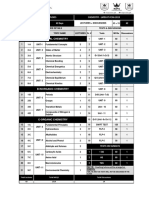

This is dependant on the type of installation and how well the pool water quality has been maintained. For example; if the pool water chemistry has not been regularly monitored, the P.H. balance may have caused calcium to build up in the system, which can make the media solidify or if the pool has been neglected for lengthy periods with inadequate backwashing the media condition will deteriorate more rapidly. Other aspects of the pool installation can also affect the frequency of media changes, such as; pools with a higher pollution level (particularly Koi carp ponds), or pools and spas which run at temperatures above 30c, which often attract a higher level of oily substances. These may make the media clump together forming what we call mud balls. The following table is a guide to backwash & media change frequency for various installations that are typical today. CLASSIFICATION OF POOL 1. Koi Carp Ponds 2. Public Paddling Pools (highly used by children) 3. Commercial Spas.. 4. Hydrotherapy Pools 5. Animal Training Pools 6. Residential Spas 7. School Trainer Pools.. 8. Hotels/sport Club Pools. 9. Large Commercial Swimming Pools.. 10. Residential Swimming Pools (outdoor).. 11. Residential Swimming Pools (indoor) Q2 BACKWASH FREQUENCY 3 10 days Daily Daily Daily 1 3 days... 5 10 days 5 7 days 3 7 days Daily 7 10 days 10 14 days MEDIA CHANGE FREQUENCY 6 18 months 6 18 months 12 24 months 12 24 months 12 24 months 24 36 months 24 36 months 24 36 months 3 5 years 5 10 years 5 7 years

WHAT ARE THE SIGNS THAT THE MEDIA NEEDS CHANGING?

It is vital that all filter systems be fitted with a pressure gauge (normally installed on the main valve), which will indicate the system running pressure. When the filter media is new and immediately after backwashing, the system running pressure should be noted. During normal use, this pressure will rise as dirt becomes trapped in the media bed. Generally, an increase of 25 30% in the normal running pressure will indicate that backwashing is required. Prior to backwashing it may be noticeable that the water flow will have slowed down due to the resistance caused by the trapped dirt in the media bed. The precise frequency of backwashing is determined by the type of installation and its usage. (See above table). When the media is coming to the end of its effective life the following points may be noticed. 2.1 The normal (clean) running pressure may have increased by 10% or more. 2.2 The frequency of backwashing my need to be stepped up. 2.3 Water flow may appear to be less vigorous than when the filter media was new. Page 1 of 4

2.4 Q3

The pool water condition may be difficult to maintain consistently, causing water clarity problems. WHAT TYPE OF FILTER MEDIA SHOULD BE USED?

The media that can be used in your filter is either Lacronite or Sand. Lacronite Simply put, LACRONITE is a superior grade of purposely chosen high grade volcanic material for use in pressure vessels. Specifically selected for use as a filter media for swimming pools and spas, Lacronite offers many benefits over traditional materials such as sand and diatomaceous earth for residential and commercial pool builders, managers and users. Some of the many advantages of Lacronite are; superior water clarity remarkable dirt retention properties far better water quality and bather comfort eliminates dry skin, dry hair and red eyes pushes chemical costs down reduces backwashing frequency substantially saves on water make up and associated heating costs improves pool hall environment reduces chemical odour lower water filter pressure and less pump wear easy to install lasts for years. Sand The sand in your filter is specially graded silica sand, suitable for swimming pool or spa use. NEVER use builders sand/sharp sand or ballast, as the filter is not compatible with these materials. The grade of filter sand normally used is: (16/30) grade SILCA SAND. General Media Notes: For residential pool filters it is typical that the media bed is of a uniform grade throughout. For commercial application (particularly deep bed filters) it is recommended that a base layer of 6mm dia. Pea gravel is used to cover the lateral system. The depth of this base layer should be between 50 200mm above the slotted lateral pipes. The use of graded media is to assist with water distribution during the backwash cycle. NOTE: The weight if Lacronite/sand media will need to be reduced to compensate when using gravel base layers. CONSULT YOUR SUPPLIER! Q4 HOW MUCH MEDIA DO YOU REQUIRE?

First of all you need to establish what size your filter is. From the factory, all filters are supplied with a unique serial number label, which would start with a prefix number as follows; (450)16 (457)18 (610)24 (760)30 (900)36 (1100)42 etc. These prefixes refer to the diameter size of the unit: - (mm) inches. The label will also state the amount of media required for a media change. However, on older filters this label may have worn away. If this is the case you will need to accurately measure the filter diameter and height to establish which type of filter you have: The table below lists the filter size and their respective sand content. *Denotes: Often used for residential pools. DIAMETER *(400)-16.. *(457)-18.. *(620)-24.. *(760)-30.. DIAMETER *(450)-16. *(460)-18 . *(610)-24 . *(760)-30 . (900)-36 . (1100)-42 . (1200)-48 . TOP MOUNT FILTERS HEIGHT MEDIA CONTENT 50 KGs 75 KGs 125 KGs 200 KGs

Combi/Compact Filter... ...................... 500mm Combi/Compact Filter... ...................... 575mm Combi/Compact Filter... ...................... 700mm.. Combi/Compact Filter... ...................... 775mm.. SMALL-MEDIUM SIDE MOUNT FILTERS HEIGHT

MEDIA CONTENT 50 KGs 75 KGs 125 KGs 200 KGs 375 KGs 550 KGs 850 KGs

LSC/LSC/LHP Side Mount Filter................................................. 575mm. LSC/LSC/LHP Side Mount Filter ....................... .685mm LSC/LSC/LHP Side Mount Filter .................................. 760mm LSC/LSC/LHP Side Mount Filter .................................. 780mm LSC/LSC/LHP Side Mount Filter. ...................... 945mm . LSC/LSC/LHP Side Mount Filter. ...................... 965mm LSC/LSC/LHP Side Mount Filter ....................... 1315mm

Page 2 of 4

DIAMETER (760)-30.. (900)-36.. (1100)-42.. (1200)-48.. DIAMETER (1400)-55.. (1600)-63.. (1800)-72.. (2000)-80.. DIAMETER (450)-18.. (610)-24.. (760)-30.. (1100)-42 DIAMETER (610)-24.. (760)-30.. (1100)-42 (1200)-48 Q5

COMMERICAL-HORIZONTAL FILTERS

HEIGHT

MEDIA CONTENT 750 KGs 950 KGs 1200 KGs 1600 KGs

HRZ (horizontal Filter)..... ....................... 1115mm HRZ (horizontal Filter)... ......................... 1225mm HRZ (horizontal Filter)... ......................... 1335mm.. HRZ (horizontal Filter)..... ....................... 1450mm.. LARGE COMMERCIAL FILTERS HEIGHT

MEDIA CONTENT 1900 KGs 2600 KGs 3500 KGs 4500 KGs

LC Hi Flow............................. 1510mm. LC Hi Flow............................. 1725mm. LC Hi Flow............................. 1860mm. LC Hi Flow............................. 2100mm. DBF-FINAFLOW COMMERCIAL FILTERS HEIGHT

MEDIA CONTENT 300 KGs 575 KGs 1050 KGs 1825 KGs

Deep Bed Commercial............................ 1625mm. Deep Bed Commercial............................ 1775mm. Deep Bed Commercial............................ 1910mm. Deep Bed Commercial............................ 2010mm. DBK-SUREFLOW COMMERCIAL FILTERS HEIGHT

SAND CONTENT 725 KGs 925 KGs 2100 KGs 2300 KGs

Deep Bed/Plate & Hatch......................... 2255mm . Deep Bed/Plate & Hatch......................... 2275mm Deep Bed/Plate & Hatch......................... 2425mm. Deep Bed/Plate & Hatch......................... 2550mm.

WHERE TO BUY FILTER MEDIA?

Either contact the company who built your pool or your current supplier of chemicals and other pool equipment. If you are a new owner of a pool, perhaps inheriting the pool by purchasing a new house etc., we suggest that you refer to your local yellow pages under the Swimming Pool section and contact the closest pool equipment supplier. Before you contact your pool equipment supplier it is important that you know the size of your filter and its respective media content. You should also consider (depending on the amount or weight of media you require) whether to collect it yourself or have them deliver it to you. For residential and light commercial pools the filter media is generally supplied in either 25 kg or 50 kg sacks. NOTE: 25 kg sacks are much easier to handle! For large commercial applications, filter media can be delivered in bulk. Q6 SAND CHANGE PROCEDURE

Having received the correct amount of filter media, the following procedure should be followed:6.1 Make sure the pool water is in good condition and at an adequate level. Ensure skimmer and pump baskets are free from debris. Backwash filter for 3 minutes then rinse for 20 seconds Repeat procedure to ensure the old media is as clean as possible, before you attempt removal. Set ALL valves to closed position. Isolate from the mains supply the circulation pump and all other on line electrical/gas appliance. Remove filter drain plug cap, situated just above the filter base level. NOTE: Once the drain plug cap is removed, the water contained in the filter will be released. Ensure that any exiting water will not damage surrounding equipment or decor. Use suitable drainage trays or hoses as required. For filters fitted with the valve at the side (side mount) remove the top lid, this will speed up the out flowing water from the drain plug.

6.2 6.3

6.4

Page 3 of 4

6.5

Threaded lids can sometimes be difficult to unscrew particularly if they have not been removed for some time. If this is so, we suggest that you use a purpose made Lacron lid tool. Alternatively, it is possible to make your own tool from two 750mm lengths of 50 x 50 timber, each drilled with a 10mm diameter hole 70mm from the end. Loosely join the two timber pieces using a 10mm nut and bolt to form an unequal cross. This can then be fitted over the filter lid and used to push against the fins to give far greater leverage. Avoid hammering the lid as this will cause damage. Having removed the lid of your filter, you will need to lift off the air bleed cap and rose distributor then remove distributor pipework. This can be disconnected by unscrewing the stainless steel cross head screw, which is situated inside the filter at 45 on the edge of the top bulkhead. Once the screw is removed the header pipe can be eased out of the bulkhead and carefully slipped off of the black airbleed tube. For filters fitted with a valve at the top, the valve must be removed to gain access to the interior of the filter. Top mount filters have a central collector pipe unlike the side mount type. Provided the media is free running a commercial type wet and dry vacuum cleaner can be used to suck out the old media. NOTE: You may need to use water from a hose pipe to help fluidise the media when vacuuming. Alternatively, it may be more appropriate to simply bail out the media using a plastic bowl approximately of 150mm diameter or smaller.

6.6

6.7 6.8

6.9

Whatever method of media removal chosen, particular care should be taken as you excavate around the lower underdrain pipework. This pipework can become brittle during years of service and any damage that may occur could result in sand being passed back to the pool once the filter is re-commissioned. It may help to wash around the underdrain pipework with a garden hose to assist with removing ALL the old media. Once the filter is completely empty of old media, it is advisable to fill the filter with water by about one third of the tank depth. This water will break the fall of the fresh media, reducing its impact on the underdrain pipework. Cover the end of the airbleed tube with adhesive tape or similar to prevent sand blocking the pipe bore. Make sure that the NEW fresh media is dry and free running. Open the sacks carefully to avoid wastage and to assist in making the flow more controllable. Pour the media in slowly, and continue until half of the required amount is in place. At which point you should push the media around inside the filter making the surface roughly level. Pour the remainder of the media in, but keep a careful check on the media height level. On most residential filters, the correct height is about 30 50mm above the centre of the filter. This level may be higher on commercial filters refer to filter technical specifications. NEVER FILL THE FILTER COMPLETELY WITH MEDIA!

6.10

6.11

6.12

6.13

Once the correct amount of media is in the filter, again push the surface layer around until roughly level. Then clean the lid area, paying particular attention to the threads which must be completely free of any media or dirt etc. Remove the tape from the airbleed tube and clean and refit the distributor pipework, rose and airbleed cap. Thoroughly clean the lid and o ring. Check to ensure that all dirt and grit is removed by screwing the lid into the filter. If dirt is still present you will hear a grating sound. Once you are sure that the lid and threads are totally clean you can then apply a liberal amount of Vaseline to the lid threads and o ring. Then refit the lid hand tight only! Open appropriate valves and reset to BACKWASH. Re-activate the main circulating pump. BACKWASH for at least 3 minutes. You will notice that the backwash water contains a colour stain this is normal but must be completely clear before filtering can commence. Stop the system then rinse for 1 minute. Stop the system and manually re-tighten the lid by another one-third turn. Then do a further backwash and rinse until the out flowing water is completely clean. Re-set the valve to filter position, switch the pump on and observe the water flowing back to the pool, which should be noticeably, more vigorous. Once you are satisfied that the filter is running correctly you should re-set all other on line equipment, re-setting or adjusting timers etc., as required.

Page 4 of 4

6.14

6.15 6.16

6.17

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Experiment 2 - Preparation of Cis and Trans IsomerDocument7 pagesExperiment 2 - Preparation of Cis and Trans IsomerAbdulRahim059100% (3)

- ETP Technical Hand Book - Chemical Treatment System1 PDFDocument42 pagesETP Technical Hand Book - Chemical Treatment System1 PDFmasud.imtiaz3290100% (1)

- Pas-Priručnik Za VlasnikeDocument145 pagesPas-Priručnik Za VlasnikeRenata ReljacNo ratings yet

- Alert 9 1Document14 pagesAlert 9 1Renata ReljacNo ratings yet

- Peaks Spa Brochure GKDocument8 pagesPeaks Spa Brochure GKRenata ReljacNo ratings yet

- Landscape Irrigation Products 2009/2010Document1 pageLandscape Irrigation Products 2009/2010Renata ReljacNo ratings yet

- 21 20Document1 page21 20Renata ReljacNo ratings yet

- Operation InstDocument14 pagesOperation InstAleksandrNo ratings yet

- Materials and HardwareDocument364 pagesMaterials and Hardwarekls070376100% (10)

- CatalogoDocument43 pagesCatalogoGuillermo de la Fuente SantiagoNo ratings yet

- Steel Structure Course FileDocument24 pagesSteel Structure Course FileMaryam AsimNo ratings yet

- Soil Stabilization Pavements PDFDocument57 pagesSoil Stabilization Pavements PDFabhinav7373No ratings yet

- Eucalyptus OilDocument2 pagesEucalyptus Oilsheenali0% (1)

- Wing Wall DesignDocument3 pagesWing Wall DesignDhaivatNo ratings yet

- Lily Pads and SunlightDocument15 pagesLily Pads and Sunlightbilalnuman1No ratings yet

- Pharmacokinetics: Biochemical Pharmacology September 2013Document29 pagesPharmacokinetics: Biochemical Pharmacology September 2013thasyaNo ratings yet

- Piping and Equipment InsulationDocument22 pagesPiping and Equipment InsulationRampal Rahul Rampal RahulNo ratings yet

- Cube TestDocument10 pagesCube Testridhuanzainal100% (1)

- 7-2011 Benzene Awareness PPT - 01Document31 pages7-2011 Benzene Awareness PPT - 01jiks_i4uNo ratings yet

- Module 4 HIgh Cycle and Low Cycle FatigueDocument21 pagesModule 4 HIgh Cycle and Low Cycle FatiguerohanNo ratings yet

- 545 2 NLSC Sample 24Document5 pages545 2 NLSC Sample 24namulindwajosephine37No ratings yet

- 3 Advanced Mechanics of Solids ME S4 B.tech KTU 2017Document3 pages3 Advanced Mechanics of Solids ME S4 B.tech KTU 2017Hari650No ratings yet

- Guoys MethodDocument4 pagesGuoys Methodnano_girl100% (1)

- BOC Complete 1 To 5 DPPDocument5 pagesBOC Complete 1 To 5 DPPBhawna SharmaNo ratings yet

- Design of Thrust Blocks: A) 150 Dia 90 Degree BendDocument7 pagesDesign of Thrust Blocks: A) 150 Dia 90 Degree BendRajesh Babu100% (1)

- 14 Gos Wksp1 007 Presentation DOE MalaysiaDocument91 pages14 Gos Wksp1 007 Presentation DOE MalaysiaknabpshoNo ratings yet

- 02 SOS Chemistry LMDCAT-FCNA-19 Plan A-4Document1 page02 SOS Chemistry LMDCAT-FCNA-19 Plan A-4FabehaNo ratings yet

- Semi-Detailed Lesson Plan in Science Grade 9: The Learners Demonstrate An Understanding ofDocument1 pageSemi-Detailed Lesson Plan in Science Grade 9: The Learners Demonstrate An Understanding ofSitty Salma Hadji Abbas100% (2)

- Synthalat A 077Document2 pagesSynthalat A 077Luis Angel MendozaNo ratings yet

- Applicability of Biodegradable Fibres On The Geotechnical Properties of A Subgrade MaterialDocument18 pagesApplicability of Biodegradable Fibres On The Geotechnical Properties of A Subgrade MaterialHAMPO OBINNANo ratings yet

- The Fundamental Problems Regarding The Relative Hydrogen (RH) Score in Biochemistry by Gârban - ZenoDocument8 pagesThe Fundamental Problems Regarding The Relative Hydrogen (RH) Score in Biochemistry by Gârban - ZenoScutul_CrestinNo ratings yet

- Simple Stresses and Strains PDFDocument2 pagesSimple Stresses and Strains PDFSai Krishna SK100% (1)

- The Origin of Life - A.I.-OPARIN PDFDocument1 pageThe Origin of Life - A.I.-OPARIN PDFMARIO IVAN ALEMAN DUARTENo ratings yet

- Shell Omala 100Document7 pagesShell Omala 100PN RaoNo ratings yet

- Check Your Grasp Exercise-I: SolutionDocument16 pagesCheck Your Grasp Exercise-I: SolutionRoshan MNo ratings yet