Professional Documents

Culture Documents

Splines

Splines

Uploaded by

thulasi_krishnaCopyright:

Available Formats

You might also like

- Ansi B92.1Document10 pagesAnsi B92.1idrisbooks0% (2)

- Screw ThreadsDocument2 pagesScrew ThreadsN.PalaniappanNo ratings yet

- OmniGear Tech Info BinderDocument86 pagesOmniGear Tech Info BinderMiguel Matias ReineroNo ratings yet

- Spline Program Ver 1.1Document6 pagesSpline Program Ver 1.1B Srinivasa RaoNo ratings yet

- Calculation of Pipe Reinforcement ASME B31 3Document3 pagesCalculation of Pipe Reinforcement ASME B31 3Brant AkkanNo ratings yet

- Etk Material Curves 20121018Document16 pagesEtk Material Curves 20121018zebra00No ratings yet

- Involute Spline Design: - Tyson Baker F'01Document2 pagesInvolute Spline Design: - Tyson Baker F'01iobb222No ratings yet

- Interference Fits and PressureDocument21 pagesInterference Fits and PressurerwmingisNo ratings yet

- Basic Gear FormulasDocument3 pagesBasic Gear FormulasAshok DevihosurNo ratings yet

- (Tambahan) Tolerances - FitsDocument25 pages(Tambahan) Tolerances - FitsMuhammad Fachry RamadhanyNo ratings yet

- Reinforcement of Openings On Tori-Dish (Trial)Document23 pagesReinforcement of Openings On Tori-Dish (Trial)Sajal KulshresthaNo ratings yet

- Norma de Tallado y Acanalado de EngranajesDocument7 pagesNorma de Tallado y Acanalado de EngranajesJohn Walter RodriguezNo ratings yet

- Spur Gear Calculations and FormulasDocument3 pagesSpur Gear Calculations and FormulasTan Cheehou100% (3)

- Pressure Vessel Design Old (Eugyene F Megysey)Document31 pagesPressure Vessel Design Old (Eugyene F Megysey)David FonsecaNo ratings yet

- Technical Data Sheet For HSV Stud Anchor Technical Information ASSET DOC 2331315Document9 pagesTechnical Data Sheet For HSV Stud Anchor Technical Information ASSET DOC 2331315dcarunchioNo ratings yet

- Elliptical HeadDocument10 pagesElliptical HeadKishore SakhileNo ratings yet

- Elliptical HeadDocument10 pagesElliptical Headsnehal.deshmukhNo ratings yet

- GearDocument14 pagesGearAnimesh ManiNo ratings yet

- Wire EXTERNAL SPUR GEARSDocument1 pageWire EXTERNAL SPUR GEARSMALKIT SINGHNo ratings yet

- Mechanical Anchoring BoltDocument6 pagesMechanical Anchoring BoltMani MaranNo ratings yet

- Asme Viii Shell & Se HeadDocument5 pagesAsme Viii Shell & Se HeadSnr George Racz100% (1)

- Limits, Fits and Tolerances: Prof. S. S. PandeDocument31 pagesLimits, Fits and Tolerances: Prof. S. S. PandeM PankajNo ratings yet

- UG 45 Sample CalculationDocument1 pageUG 45 Sample CalculationAris Purniawan100% (1)

- Dimensi & Toleransi Ulir TrapesiumDocument7 pagesDimensi & Toleransi Ulir TrapesiumHadi HendrariyantoNo ratings yet

- Durable, Long-Lasting Punches & Punch Blanks: Heads-Above-The-Rest PerformanceDocument12 pagesDurable, Long-Lasting Punches & Punch Blanks: Heads-Above-The-Rest PerformanceCristhian Graef100% (1)

- TD - 17-0005 - HIT-RE500-V3 - Annular Gap - Oversized Holes - Do 1,5xd (ETAG)Document5 pagesTD - 17-0005 - HIT-RE500-V3 - Annular Gap - Oversized Holes - Do 1,5xd (ETAG)phamducquangNo ratings yet

- The Most Economical Solution For Drilling!: Indexable DrillDocument20 pagesThe Most Economical Solution For Drilling!: Indexable DrillapulavartyNo ratings yet

- Gears Very BasicDocument5 pagesGears Very BasicpetsatNo ratings yet

- Pipe Reinforcement Calculation (ASME-B31.3)Document3 pagesPipe Reinforcement Calculation (ASME-B31.3)jenshid100% (2)

- Standard Pipe SizesDocument5 pagesStandard Pipe Sizessivak78mduguhaNo ratings yet

- Broaches - Basic CharacteristicDocument5 pagesBroaches - Basic CharacteristicDhan CNo ratings yet

- Drawing of GearboxDocument1 pageDrawing of GearboxRisira Erantha KannangaraNo ratings yet

- Bolt Tensile Stress Area CalcDocument1 pageBolt Tensile Stress Area CalcObydur RahmanNo ratings yet

- Calculation of Pipe Reinforcement ASME B31 3Document4 pagesCalculation of Pipe Reinforcement ASME B31 3ArmandoZacariasAcosta0% (1)

- Design of Flanges - Loose Hub Type 2010Document58 pagesDesign of Flanges - Loose Hub Type 2010bakelly0% (1)

- Shell Inputs: Use Asme Code Section-8 Division I (Ug-37)Document34 pagesShell Inputs: Use Asme Code Section-8 Division I (Ug-37)Bashu PoudelNo ratings yet

- Composit Calculation3Document20 pagesComposit Calculation3s_padu3003@yahoo.comNo ratings yet

- 221 Manualmanual KisssoftDocument1 page221 Manualmanual Kisssoftmail_krkNo ratings yet

- Shaft BendingDocument2 pagesShaft Bendingthulasi_krishna100% (1)

- Tooth ThicknessDocument9 pagesTooth ThicknessPraveen VundrajavarapuNo ratings yet

- How To Measure The Pressure Angle of A Physical Spur GearDocument16 pagesHow To Measure The Pressure Angle of A Physical Spur Gearian_new100% (2)

- Standard Specifications Roll and Cut Groove For Steel Pipe Technical Data General DescriptionDocument4 pagesStandard Specifications Roll and Cut Groove For Steel Pipe Technical Data General DescriptionMohammad SaleemNo ratings yet

- Fittings and TolerancesDocument31 pagesFittings and TolerancesVinay GautamNo ratings yet

- SA 516M GR 485: If Actual Thickness of Head After Forming 9 MMDocument2 pagesSA 516M GR 485: If Actual Thickness of Head After Forming 9 MMMehta MehulNo ratings yet

- Gear FormulaeDocument13 pagesGear Formulaeian_newNo ratings yet

- Inch Bolt: T H e TRFDocument1 pageInch Bolt: T H e TRFFebrian TulusNo ratings yet

- TFP1898 08 2018Document4 pagesTFP1898 08 2018godstime2462No ratings yet

- Tir A9-91 ErrataDocument3 pagesTir A9-91 ErrataAthumizNo ratings yet

- TFP1898 02 2015Document4 pagesTFP1898 02 2015Jun AntonioNo ratings yet

- Boston Eng Info - SpurGearsDocument5 pagesBoston Eng Info - SpurGearsMauro TognocchiNo ratings yet

- Standard Pipe SizesDocument5 pagesStandard Pipe SizesVu Tung LinhNo ratings yet

- Me472 10Document0 pagesMe472 10dreadwarriorNo ratings yet

- Metric Thread - Fine Pitch - M (1 MM - 28 MM)Document4 pagesMetric Thread - Fine Pitch - M (1 MM - 28 MM)enricoNo ratings yet

- Chinese Baby Gender Prediction Excel1Document6 pagesChinese Baby Gender Prediction Excel1thulasi_krishnaNo ratings yet

- Expense Tracker: Date Purpose Payment Method Transaction # Payee Expense Category Notes Amount Total ExpensesDocument9 pagesExpense Tracker: Date Purpose Payment Method Transaction # Payee Expense Category Notes Amount Total Expensesthulasi_krishnaNo ratings yet

- CarboTherm TB2 0213 R02Document2 pagesCarboTherm TB2 0213 R02thulasi_krishnaNo ratings yet

- Seals and Gaskets: 3.0 Table of ContentsDocument40 pagesSeals and Gaskets: 3.0 Table of Contentsthulasi_krishnaNo ratings yet

- Project Status Dashboard Xl2007Document22 pagesProject Status Dashboard Xl2007Jkjiwani AccaNo ratings yet

- Mil DTL 38999 Series IIIDocument10 pagesMil DTL 38999 Series IIIthulasi_krishnaNo ratings yet

- Seal Design Considerations Using Kalrez PartsDocument4 pagesSeal Design Considerations Using Kalrez Partsthulasi_krishnaNo ratings yet

- LaminateDocument3 pagesLaminatethulasi_krishnaNo ratings yet

- Lecture6 - Losses in Electric MachinesDocument24 pagesLecture6 - Losses in Electric Machinesthulasi_krishnaNo ratings yet

- Lecture3 - Three Phase Power Converter Control Strategies For Three Machine TypesDocument26 pagesLecture3 - Three Phase Power Converter Control Strategies For Three Machine Typesthulasi_krishnaNo ratings yet

- Lecture2 - Basic Electric Motor & Generator TheoryDocument21 pagesLecture2 - Basic Electric Motor & Generator Theorythulasi_krishnaNo ratings yet

- Theory & Practice of Electromagnetic Design of DC Motors & Actuators George P. Gogue & Joseph J. Stupak, Jr. G2 Consulting, Beaverton, OR 97007Document24 pagesTheory & Practice of Electromagnetic Design of DC Motors & Actuators George P. Gogue & Joseph J. Stupak, Jr. G2 Consulting, Beaverton, OR 97007thulasi_krishna100% (1)

- Lecture1 - History & IntroductionDocument20 pagesLecture1 - History & Introductionramaswamykama786100% (1)

- Profile Comparison: Velocity - Profile - StudyDocument2 pagesProfile Comparison: Velocity - Profile - Studythulasi_krishnaNo ratings yet

- Lecture2 - Basic Electric Motor & Generator TheoryDocument21 pagesLecture2 - Basic Electric Motor & Generator Theorythulasi_krishnaNo ratings yet

- Kinematic Coupling 3groove DesignDocument6 pagesKinematic Coupling 3groove Designthulasi_krishnaNo ratings yet

- FNL Ewt FNL WT L at L L A L LB T T: Parasitic PitchDocument2 pagesFNL Ewt FNL WT L at L L A L LB T T: Parasitic Pitchthulasi_krishnaNo ratings yet

- Max Torque, Gammax (N-MM) Max Speed, Wmax (RPM, Rad/sec) Torque Speed Slope Constant, K WincDocument7 pagesMax Torque, Gammax (N-MM) Max Speed, Wmax (RPM, Rad/sec) Torque Speed Slope Constant, K Wincthulasi_krishnaNo ratings yet

Splines

Splines

Uploaded by

thulasi_krishnaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Splines

Splines

Uploaded by

thulasi_krishnaCopyright:

Available Formats

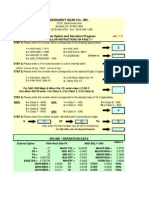

Involute Spline Design - Tyson Baker F'01

Enter desired values for the following: Number of Teeth Nt 48 Diametral Pitch P 16 Applied Torque (in-lb.) T 15000 di Internal diameter (if hollow) 0 Pressure angle f 37.5

teeth/in. in-lb. in. degrees

(Between 6 and 50 teeth) (Standard sizes: 2.5, 3, 4, 5, 6, 8, 10, 12, 16, 20, 24, 32, 40

(Typically 30, 37.5, or 45 degrees)

Dimensional Relations Circular pitch p Pitch diameter d Addendum a db Base circle diameter Circular tooth thickness t Diametral Pitch doi (Major dia. internal) dre (Minor dia. External) b1i (Dedendum internal) b1e (Dedendum ext.) 1 thru 12 3.113 2.888 0.056 0.056

0.196 3.000 0.031 2.380 0.098 16 thru 48

in./tooth in. in. in. in.

3.113 in. 2.875 in. 0.056 in. 0.063 in.

Effective Spline Length Shear Stress

Le t

0.094 3173.185

in. psi

*Shear stress and spline length are calculated based on the assumption that only 25% of the teeth make contact at any given moment.

References: Deutschman, Michels, Wilson. Machine Design: Theory and Practice. Macmillan, 1975. Pp. 374-376.

8, 10, 12, 16, 20, 24, 32, 40, 48)

You might also like

- Ansi B92.1Document10 pagesAnsi B92.1idrisbooks0% (2)

- Screw ThreadsDocument2 pagesScrew ThreadsN.PalaniappanNo ratings yet

- OmniGear Tech Info BinderDocument86 pagesOmniGear Tech Info BinderMiguel Matias ReineroNo ratings yet

- Spline Program Ver 1.1Document6 pagesSpline Program Ver 1.1B Srinivasa RaoNo ratings yet

- Calculation of Pipe Reinforcement ASME B31 3Document3 pagesCalculation of Pipe Reinforcement ASME B31 3Brant AkkanNo ratings yet

- Etk Material Curves 20121018Document16 pagesEtk Material Curves 20121018zebra00No ratings yet

- Involute Spline Design: - Tyson Baker F'01Document2 pagesInvolute Spline Design: - Tyson Baker F'01iobb222No ratings yet

- Interference Fits and PressureDocument21 pagesInterference Fits and PressurerwmingisNo ratings yet

- Basic Gear FormulasDocument3 pagesBasic Gear FormulasAshok DevihosurNo ratings yet

- (Tambahan) Tolerances - FitsDocument25 pages(Tambahan) Tolerances - FitsMuhammad Fachry RamadhanyNo ratings yet

- Reinforcement of Openings On Tori-Dish (Trial)Document23 pagesReinforcement of Openings On Tori-Dish (Trial)Sajal KulshresthaNo ratings yet

- Norma de Tallado y Acanalado de EngranajesDocument7 pagesNorma de Tallado y Acanalado de EngranajesJohn Walter RodriguezNo ratings yet

- Spur Gear Calculations and FormulasDocument3 pagesSpur Gear Calculations and FormulasTan Cheehou100% (3)

- Pressure Vessel Design Old (Eugyene F Megysey)Document31 pagesPressure Vessel Design Old (Eugyene F Megysey)David FonsecaNo ratings yet

- Technical Data Sheet For HSV Stud Anchor Technical Information ASSET DOC 2331315Document9 pagesTechnical Data Sheet For HSV Stud Anchor Technical Information ASSET DOC 2331315dcarunchioNo ratings yet

- Elliptical HeadDocument10 pagesElliptical HeadKishore SakhileNo ratings yet

- Elliptical HeadDocument10 pagesElliptical Headsnehal.deshmukhNo ratings yet

- GearDocument14 pagesGearAnimesh ManiNo ratings yet

- Wire EXTERNAL SPUR GEARSDocument1 pageWire EXTERNAL SPUR GEARSMALKIT SINGHNo ratings yet

- Mechanical Anchoring BoltDocument6 pagesMechanical Anchoring BoltMani MaranNo ratings yet

- Asme Viii Shell & Se HeadDocument5 pagesAsme Viii Shell & Se HeadSnr George Racz100% (1)

- Limits, Fits and Tolerances: Prof. S. S. PandeDocument31 pagesLimits, Fits and Tolerances: Prof. S. S. PandeM PankajNo ratings yet

- UG 45 Sample CalculationDocument1 pageUG 45 Sample CalculationAris Purniawan100% (1)

- Dimensi & Toleransi Ulir TrapesiumDocument7 pagesDimensi & Toleransi Ulir TrapesiumHadi HendrariyantoNo ratings yet

- Durable, Long-Lasting Punches & Punch Blanks: Heads-Above-The-Rest PerformanceDocument12 pagesDurable, Long-Lasting Punches & Punch Blanks: Heads-Above-The-Rest PerformanceCristhian Graef100% (1)

- TD - 17-0005 - HIT-RE500-V3 - Annular Gap - Oversized Holes - Do 1,5xd (ETAG)Document5 pagesTD - 17-0005 - HIT-RE500-V3 - Annular Gap - Oversized Holes - Do 1,5xd (ETAG)phamducquangNo ratings yet

- The Most Economical Solution For Drilling!: Indexable DrillDocument20 pagesThe Most Economical Solution For Drilling!: Indexable DrillapulavartyNo ratings yet

- Gears Very BasicDocument5 pagesGears Very BasicpetsatNo ratings yet

- Pipe Reinforcement Calculation (ASME-B31.3)Document3 pagesPipe Reinforcement Calculation (ASME-B31.3)jenshid100% (2)

- Standard Pipe SizesDocument5 pagesStandard Pipe Sizessivak78mduguhaNo ratings yet

- Broaches - Basic CharacteristicDocument5 pagesBroaches - Basic CharacteristicDhan CNo ratings yet

- Drawing of GearboxDocument1 pageDrawing of GearboxRisira Erantha KannangaraNo ratings yet

- Bolt Tensile Stress Area CalcDocument1 pageBolt Tensile Stress Area CalcObydur RahmanNo ratings yet

- Calculation of Pipe Reinforcement ASME B31 3Document4 pagesCalculation of Pipe Reinforcement ASME B31 3ArmandoZacariasAcosta0% (1)

- Design of Flanges - Loose Hub Type 2010Document58 pagesDesign of Flanges - Loose Hub Type 2010bakelly0% (1)

- Shell Inputs: Use Asme Code Section-8 Division I (Ug-37)Document34 pagesShell Inputs: Use Asme Code Section-8 Division I (Ug-37)Bashu PoudelNo ratings yet

- Composit Calculation3Document20 pagesComposit Calculation3s_padu3003@yahoo.comNo ratings yet

- 221 Manualmanual KisssoftDocument1 page221 Manualmanual Kisssoftmail_krkNo ratings yet

- Shaft BendingDocument2 pagesShaft Bendingthulasi_krishna100% (1)

- Tooth ThicknessDocument9 pagesTooth ThicknessPraveen VundrajavarapuNo ratings yet

- How To Measure The Pressure Angle of A Physical Spur GearDocument16 pagesHow To Measure The Pressure Angle of A Physical Spur Gearian_new100% (2)

- Standard Specifications Roll and Cut Groove For Steel Pipe Technical Data General DescriptionDocument4 pagesStandard Specifications Roll and Cut Groove For Steel Pipe Technical Data General DescriptionMohammad SaleemNo ratings yet

- Fittings and TolerancesDocument31 pagesFittings and TolerancesVinay GautamNo ratings yet

- SA 516M GR 485: If Actual Thickness of Head After Forming 9 MMDocument2 pagesSA 516M GR 485: If Actual Thickness of Head After Forming 9 MMMehta MehulNo ratings yet

- Gear FormulaeDocument13 pagesGear Formulaeian_newNo ratings yet

- Inch Bolt: T H e TRFDocument1 pageInch Bolt: T H e TRFFebrian TulusNo ratings yet

- TFP1898 08 2018Document4 pagesTFP1898 08 2018godstime2462No ratings yet

- Tir A9-91 ErrataDocument3 pagesTir A9-91 ErrataAthumizNo ratings yet

- TFP1898 02 2015Document4 pagesTFP1898 02 2015Jun AntonioNo ratings yet

- Boston Eng Info - SpurGearsDocument5 pagesBoston Eng Info - SpurGearsMauro TognocchiNo ratings yet

- Standard Pipe SizesDocument5 pagesStandard Pipe SizesVu Tung LinhNo ratings yet

- Me472 10Document0 pagesMe472 10dreadwarriorNo ratings yet

- Metric Thread - Fine Pitch - M (1 MM - 28 MM)Document4 pagesMetric Thread - Fine Pitch - M (1 MM - 28 MM)enricoNo ratings yet

- Chinese Baby Gender Prediction Excel1Document6 pagesChinese Baby Gender Prediction Excel1thulasi_krishnaNo ratings yet

- Expense Tracker: Date Purpose Payment Method Transaction # Payee Expense Category Notes Amount Total ExpensesDocument9 pagesExpense Tracker: Date Purpose Payment Method Transaction # Payee Expense Category Notes Amount Total Expensesthulasi_krishnaNo ratings yet

- CarboTherm TB2 0213 R02Document2 pagesCarboTherm TB2 0213 R02thulasi_krishnaNo ratings yet

- Seals and Gaskets: 3.0 Table of ContentsDocument40 pagesSeals and Gaskets: 3.0 Table of Contentsthulasi_krishnaNo ratings yet

- Project Status Dashboard Xl2007Document22 pagesProject Status Dashboard Xl2007Jkjiwani AccaNo ratings yet

- Mil DTL 38999 Series IIIDocument10 pagesMil DTL 38999 Series IIIthulasi_krishnaNo ratings yet

- Seal Design Considerations Using Kalrez PartsDocument4 pagesSeal Design Considerations Using Kalrez Partsthulasi_krishnaNo ratings yet

- LaminateDocument3 pagesLaminatethulasi_krishnaNo ratings yet

- Lecture6 - Losses in Electric MachinesDocument24 pagesLecture6 - Losses in Electric Machinesthulasi_krishnaNo ratings yet

- Lecture3 - Three Phase Power Converter Control Strategies For Three Machine TypesDocument26 pagesLecture3 - Three Phase Power Converter Control Strategies For Three Machine Typesthulasi_krishnaNo ratings yet

- Lecture2 - Basic Electric Motor & Generator TheoryDocument21 pagesLecture2 - Basic Electric Motor & Generator Theorythulasi_krishnaNo ratings yet

- Theory & Practice of Electromagnetic Design of DC Motors & Actuators George P. Gogue & Joseph J. Stupak, Jr. G2 Consulting, Beaverton, OR 97007Document24 pagesTheory & Practice of Electromagnetic Design of DC Motors & Actuators George P. Gogue & Joseph J. Stupak, Jr. G2 Consulting, Beaverton, OR 97007thulasi_krishna100% (1)

- Lecture1 - History & IntroductionDocument20 pagesLecture1 - History & Introductionramaswamykama786100% (1)

- Profile Comparison: Velocity - Profile - StudyDocument2 pagesProfile Comparison: Velocity - Profile - Studythulasi_krishnaNo ratings yet

- Lecture2 - Basic Electric Motor & Generator TheoryDocument21 pagesLecture2 - Basic Electric Motor & Generator Theorythulasi_krishnaNo ratings yet

- Kinematic Coupling 3groove DesignDocument6 pagesKinematic Coupling 3groove Designthulasi_krishnaNo ratings yet

- FNL Ewt FNL WT L at L L A L LB T T: Parasitic PitchDocument2 pagesFNL Ewt FNL WT L at L L A L LB T T: Parasitic Pitchthulasi_krishnaNo ratings yet

- Max Torque, Gammax (N-MM) Max Speed, Wmax (RPM, Rad/sec) Torque Speed Slope Constant, K WincDocument7 pagesMax Torque, Gammax (N-MM) Max Speed, Wmax (RPM, Rad/sec) Torque Speed Slope Constant, K Wincthulasi_krishnaNo ratings yet