Professional Documents

Culture Documents

Input:: The Member Is Found To Be

Input:: The Member Is Found To Be

Uploaded by

Divyesh MistryOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Input:: The Member Is Found To Be

Input:: The Member Is Found To Be

Uploaded by

Divyesh MistryCopyright:

Available Formats

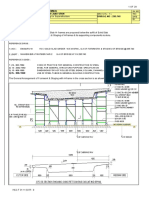

DESIGN / ADEQUACY CHECK FOR TOWER BRACING MEMBERS: BASIC DATA : Design basic wind speed : Design codes

: AISC , TIA/EIA 222F, ASCE-10-90. Steel grade: E =

45 m/sec

36 29000

248.2

Bracing member properties : Single L-3.5"x2.5"x 1/4th In. STAAD-III member ID: 313 Worst load combination considered.

The member is found to be

compact 1

From AISC tables.

INPUT :

rMIN

2.517 Load in Memb= Memb.Length=

A 22.050 15.42 1.550

DESIGN : From ASCE: 10-90

Radii of Gyration: w (In) = 2.517 1.8860

rMIN

END CONDITIONS AS PER TIA/EIA-222F CURVES :

t (In) = 0.2500 w/t = 7.544 w/t is <25..OK ( w / t )lim = 15.83 ( w / t )max = 25 OK

KL/R=46.2+0.615xL/R 84.068 Slenderness ratio ( KL/R)= Slenderness is< 200

Cc =

Cc= 126.116 is < Cc- Eqn. 1 is valid See Equations 1 and 2 for "Fa" below. fy= E= 36 29000 ,(KL / r)

= 84.06752 Cc= 126.116 /Cc = 0.667

Due to the compactness of

bracing, Qs is not applicabe. Say Fa= 102.717 From equation ..2 Qs= 1 (Say) Since kl/r> 120-Fas is Fas' calculated as below = FasxQs Fas' Fas= Fa/(1.6-(KL/200R) = 87.073 = 87.073 .Allowable compressive load capacity of the bracing member ( Fac=Fas' x A = 192.00 Fac). Allowable compressive load capacity of the bracing member can be increased by 33 % to acountfor wind loaded members, ( Refer Item 3.1.1.1 of TIA/EIA-222F) the allowable compressive load capacity of the bracing member is= Unity factor Compressive load in bracing = 15.42 =

255.35 0.06 0

You might also like

- Leanbody - Labrada - Calendar + ExeDocument10 pagesLeanbody - Labrada - Calendar + ExeDivyesh Mistry0% (1)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Switching Power Supply Design: A Concise Practical HandbookFrom EverandSwitching Power Supply Design: A Concise Practical HandbookNo ratings yet

- Claulation For Check Suitability of IPSDocument45 pagesClaulation For Check Suitability of IPSannuvyas100% (1)

- Stiffner13-Steel Beam Web Stiffeener AnalysisDocument12 pagesStiffner13-Steel Beam Web Stiffeener AnalysisRafael ReyesNo ratings yet

- Lug 31-50 Ton DesignDocument6 pagesLug 31-50 Ton DesignkalpanaadhiNo ratings yet

- Contoh Proteksi Katodik PerhitunganDocument6 pagesContoh Proteksi Katodik PerhitunganDeo Harita100% (1)

- RCC11 Element DesignDocument6 pagesRCC11 Element DesignMuhammad IshaqNo ratings yet

- Marine Electrical Practice: Marine Engineering SeriesFrom EverandMarine Electrical Practice: Marine Engineering SeriesRating: 4 out of 5 stars4/5 (8)

- Pipe&Shell Design Tool 600KLDocument1 pagePipe&Shell Design Tool 600KLJoshua Rivera100% (1)

- 01A Design Criteria For TowersDocument3 pages01A Design Criteria For TowersNisarg TrivediNo ratings yet

- Shutter DesignDocument28 pagesShutter DesignRajendra Prasad GubbalaNo ratings yet

- Calculation B14 039Document158 pagesCalculation B14 039Apichartj JusuayNo ratings yet

- Company Name: Calculation SheetDocument4 pagesCompany Name: Calculation SheetAlexandra DumitrescuNo ratings yet

- EC3 - Steel-Prof WalkerDocument42 pagesEC3 - Steel-Prof WalkerAhmad Farhan HamzahNo ratings yet

- FTPower Cable Size (1089 - 21)Document3 pagesFTPower Cable Size (1089 - 21)Nishu JainNo ratings yet

- Sk-cl-c-130 Rev.c Steel Connection (Beam Connection)Document25 pagesSk-cl-c-130 Rev.c Steel Connection (Beam Connection)Zulfikar N JoelNo ratings yet

- 3 Bus Bar Sizing CalculationDocument42 pages3 Bus Bar Sizing CalculationAnonymous OKkHA0NzNo ratings yet

- Tightening Lug PDFDocument1 pageTightening Lug PDFM. Ali ZouhairyNo ratings yet

- RCC41 Continuous Beams (A & D)Document28 pagesRCC41 Continuous Beams (A & D)aminjoles100% (1)

- TXR To 11kv Ais Cab SizeDocument16 pagesTXR To 11kv Ais Cab Sizejm.mankavil6230No ratings yet

- M2 CV ST D 002 (R0)Document13 pagesM2 CV ST D 002 (R0)ksshashidhar100% (1)

- 05 CalDocument53 pages05 Calnatarajan RavisankarNo ratings yet

- ASME SpreaderBar CalcsDocument5 pagesASME SpreaderBar Calcsganesh100% (1)

- Wind Loading On Lighting Steel Column - en 40-3-1:2013 AssumptionsDocument12 pagesWind Loading On Lighting Steel Column - en 40-3-1:2013 Assumptions6BisnagaNo ratings yet

- CraneBeam v1 1Document44 pagesCraneBeam v1 1harry_1981No ratings yet

- BTB 24 TriacDocument10 pagesBTB 24 Triacagus2kNo ratings yet

- Element Thickness 3Document24 pagesElement Thickness 3Vipul GandhiNo ratings yet

- Element Thickness 2Document20 pagesElement Thickness 2Vipul GandhiNo ratings yet

- API 650 Pipe Column DesignDocument4 pagesAPI 650 Pipe Column DesignJoselito CalagosNo ratings yet

- T40n03g PDFDocument7 pagesT40n03g PDFsandor9116No ratings yet

- Saddle CalculationDocument7 pagesSaddle CalculationMichael HaiseNo ratings yet

- RCC Details Design of Bridge No. 422 of N F RailwayDocument26 pagesRCC Details Design of Bridge No. 422 of N F Railwayshashibhushan singhNo ratings yet

- Design Criteria TowerDocument7 pagesDesign Criteria TowerAli Syaputra0% (1)

- StiffNer 13Document7 pagesStiffNer 13NEONo ratings yet

- Airfoil Selection: - Aerodynamic Characteristics (K, C, Stall Characteristics) - Structural ReasonsDocument30 pagesAirfoil Selection: - Aerodynamic Characteristics (K, C, Stall Characteristics) - Structural Reasonsae311No ratings yet

- TK-02 Supported Roof - Calculo Soporte TechoDocument5 pagesTK-02 Supported Roof - Calculo Soporte Techojoaquin torrano veraNo ratings yet

- Shell CalculationsDocument3 pagesShell CalculationsBaher Elsheikh100% (7)

- MC Tanque 3500 Bls Rev 04Document95 pagesMC Tanque 3500 Bls Rev 04maurizio109No ratings yet

- Cable Sizing CWPH PDFDocument21 pagesCable Sizing CWPH PDFsouheil boussaidNo ratings yet

- 4.3 Eg. Box Girder DesignDocument24 pages4.3 Eg. Box Girder Designananiya dawitNo ratings yet

- Beam Shear TabDocument13 pagesBeam Shear TabGautam SharmaNo ratings yet

- Design of TowerDocument4 pagesDesign of Towersyedbaseer100% (1)

- 03 CalDocument56 pages03 Calnatarajan RavisankarNo ratings yet

- E4.5 Flange Cover CalcDocument10 pagesE4.5 Flange Cover CalcTanCM100% (1)

- RCC71 Stair Flight & Landing - SingleDocument4 pagesRCC71 Stair Flight & Landing - SingleKourosh KhalpariNo ratings yet

- Stresses in Cylinder WallDocument9 pagesStresses in Cylinder WallAarzoo ShahNo ratings yet

- Grade Slab ACI-150thkDocument7 pagesGrade Slab ACI-150thkMUTHUKKUMARAM100% (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)

- Physics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to DisplaysFrom EverandPhysics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to DisplaysNo ratings yet

- Rechargeable Batteries Applications HandbookFrom EverandRechargeable Batteries Applications HandbookRating: 2 out of 5 stars2/5 (1)

- Small Unmanned Fixed-wing Aircraft Design: A Practical ApproachFrom EverandSmall Unmanned Fixed-wing Aircraft Design: A Practical ApproachNo ratings yet

- Ageing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityFrom EverandAgeing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityNo ratings yet

- Structural Steel Design to Eurocode 3 and AISC SpecificationsFrom EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNo ratings yet

- Annexure-A: Extent of WorkDocument1 pageAnnexure-A: Extent of WorkDivyesh MistryNo ratings yet

- CYPEDocument2 pagesCYPEDivyesh MistryNo ratings yet

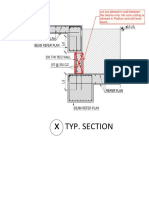

- Typ. Stilt Loby SecctionDocument1 pageTyp. Stilt Loby SecctionDivyesh MistryNo ratings yet

- How Are Column Moments Extracted at Diaphragm Locations?Document1 pageHow Are Column Moments Extracted at Diaphragm Locations?Divyesh MistryNo ratings yet

- Calculations Gravity Wind Point Loads With References DFGSDFGSDFGDSF SDFGDocument2 pagesCalculations Gravity Wind Point Loads With References DFGSDFGSDFGDSF SDFGDivyesh MistryNo ratings yet

- Trammo Inc Interview FormDocument1 pageTrammo Inc Interview FormDivyesh MistryNo ratings yet

- Methodology For The Design of Lightweight Concrete With Expanded Clay AggregatesDocument12 pagesMethodology For The Design of Lightweight Concrete With Expanded Clay AggregatesDivyesh MistryNo ratings yet

- Nepal Hazard Risk Assessment: Progress Report July-August 2010Document5 pagesNepal Hazard Risk Assessment: Progress Report July-August 2010Divyesh MistryNo ratings yet

- ETABS 2013 Concrete Frame Design: ETABS 2013 13.1.5 License # 19WLLET6AVGLBFLDocument2 pagesETABS 2013 Concrete Frame Design: ETABS 2013 13.1.5 License # 19WLLET6AVGLBFLDivyesh MistryNo ratings yet

- Corbel-S&T: Contri Bute To Scrib Dto Acces S This Docu MentDocument6 pagesCorbel-S&T: Contri Bute To Scrib Dto Acces S This Docu MentDivyesh MistryNo ratings yet

- Draft For Cracks and Honeycombing ResponseDocument1 pageDraft For Cracks and Honeycombing ResponseDivyesh MistryNo ratings yet

- Adfp RequeDocument1 pageAdfp RequeDivyesh MistryNo ratings yet

- Once You Upload An Approved DocumentDocument1 pageOnce You Upload An Approved DocumentDivyesh MistryNo ratings yet

- Conversions Conversions: (UDL) (UDL) (UDL) (UDL) (Moments) (Moments) (Reactions) (Reactions) (Area) (Area)Document1 pageConversions Conversions: (UDL) (UDL) (UDL) (UDL) (Moments) (Moments) (Reactions) (Reactions) (Area) (Area)Divyesh MistryNo ratings yet