Professional Documents

Culture Documents

A006-Wire Forming Production PDF

A006-Wire Forming Production PDF

Uploaded by

eng13Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A006-Wire Forming Production PDF

A006-Wire Forming Production PDF

Uploaded by

eng13Copyright:

Available Formats

CASE STUDY

WIRE FORMING PRODUCTION

Challenge

A wire forming manufacturer was experiencing constant bearing failures on its wire drawing roller bearings. Typically, the company was performing 75 changes each month, which resulted in excessive downtime and maintenance.

Result

Actual Cost SavingS

$1,183,255

Cost Saving Description:

Material Substitution Corrective Measures

After analysis by NSK, it was discovered that an incorrect graphite-based grease was being used to lubricate the bearings. NSK advised the company to use Lithium Complex grease which resulted in a 40% improvement on bearing life.

Extended Product Life Productivity Improvement Technical Service: Application Engineering A006

Cost Saving Description:

Issue

Wire drawing roller tapered roller bearings

NSK Solution

No bearing change. Grease specification change & maintenance regime advice

Constant failure of bearings: 75 rolls changed per month

Vastly improved reliability: 45 rolls changed/month

Maintenance cost 1/2 hour per change @ $3,253 per 1/2 hour x 75 rolls x 12 months = $2,927,700

Maintenance costs 1/2 hour @ $3,253 per 1/2 hour x 45 rolls x 12 months = $1,756,620

Lost production $40 x 378 hours = $15,120

Lost production $53 x 108 hours = $5,724

Technical support & engineering time = $2,779

No longer required

Total Cost = $2,945,599

Total Cost = $1,762,344

Total Cost Savings = $1,183,255

4200 Goss Road, Ann Arbor, MI 48105 | 1.800.675.9930 | www.us.nsk.com

You might also like

- How to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsFrom EverandHow to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsRating: 5 out of 5 stars5/5 (5)

- Small Block Chevrolet: Stock and High-Performance RebuildsFrom EverandSmall Block Chevrolet: Stock and High-Performance RebuildsRating: 4 out of 5 stars4/5 (14)

- Automotive Machining: A Guide to Boring, Decking, Honing & MoreFrom EverandAutomotive Machining: A Guide to Boring, Decking, Honing & MoreRating: 4.5 out of 5 stars4.5/5 (11)

- SKF4560 - E Rolling Bearings in Industrial GearboxesDocument195 pagesSKF4560 - E Rolling Bearings in Industrial GearboxesVanessa Pajares Lanciato100% (6)

- Chevy Differentials: How to Rebuild the 10- and 12-BoltFrom EverandChevy Differentials: How to Rebuild the 10- and 12-BoltRating: 5 out of 5 stars5/5 (17)

- Case ReichardDocument23 pagesCase ReichardDesiSelviaNo ratings yet

- Bergerac System Case Analysis-Group 1Document11 pagesBergerac System Case Analysis-Group 1Karan Trivedi100% (1)

- Case Study: ChallengeDocument2 pagesCase Study: Challengeeng13No ratings yet

- Case Study: ChallengeDocument1 pageCase Study: ChallengeRicardo PeraltaNo ratings yet

- Case Study: ChallengeDocument1 pageCase Study: Challengeeng13No ratings yet

- Case Study: ChallengeDocument2 pagesCase Study: Challengeeng13No ratings yet

- Case Study: ChallengeDocument1 pageCase Study: Challengeeng13No ratings yet

- Case Study: $2.4 MillionDocument2 pagesCase Study: $2.4 Millioneng13No ratings yet

- Development of Fixture To Reduce The Cycle Time of C 8 Griding MachineDocument6 pagesDevelopment of Fixture To Reduce The Cycle Time of C 8 Griding Machinelaukik_rautNo ratings yet

- Bearings Split Roller SRB CatalogueDocument80 pagesBearings Split Roller SRB CatalogueStephen MurefuNo ratings yet

- Vrindavan 300 KVA Minigrid PRJ Nov23Document12 pagesVrindavan 300 KVA Minigrid PRJ Nov23Sandeep SharmaNo ratings yet

- Roller Press Hardfacing JobDocument2 pagesRoller Press Hardfacing Jobparthasfriends100% (2)

- Berlin Presentation RsDocument47 pagesBerlin Presentation RsH RahulNo ratings yet

- Yamaha PPT 2Document23 pagesYamaha PPT 2NitinChaudhary100% (1)

- Meritor Clutch (PB1624)Document38 pagesMeritor Clutch (PB1624)Eric LapierreNo ratings yet

- Sleeve Bearing Specification For MotorDocument45 pagesSleeve Bearing Specification For MotorThiMinhKhuyen100% (3)

- Cond MonitorDocument5 pagesCond MonitorANo ratings yet

- Improving Solar Tracking Performance and Reliability With The SKF Solar HubDocument2 pagesImproving Solar Tracking Performance and Reliability With The SKF Solar HubEmilianoSimonNo ratings yet

- Case Study: ChallengeDocument2 pagesCase Study: ChallengeRicardo PeraltaNo ratings yet

- Design of Valve Lapping Machine For Ic EngineDocument35 pagesDesign of Valve Lapping Machine For Ic EngineIfa75% (4)

- Case Study: ChallengeDocument1 pageCase Study: Challengeeng13No ratings yet

- Overhaul of Raw Material Mill Gearbox Saves More Than 300,000 EurosDocument5 pagesOverhaul of Raw Material Mill Gearbox Saves More Than 300,000 Eurosjesus rodriguezNo ratings yet

- Industrial Training Presentation NBCDocument31 pagesIndustrial Training Presentation NBCSuraj Singh Mehta100% (2)

- SxsDocument12 pagesSxsArvin BabuNo ratings yet

- Understanding Key Welding Business Issues and Turning Them Into OpportunitiesDocument7 pagesUnderstanding Key Welding Business Issues and Turning Them Into OpportunitiessanjibkrjanaNo ratings yet

- Bearing RemanufacturingDocument8 pagesBearing RemanufacturingvsarrNo ratings yet

- Cooper Bearing Catalog RudUK5Kv4Document74 pagesCooper Bearing Catalog RudUK5Kv4a04204100% (2)

- Gearbox Maintenance Tips: Keep Your Gearbox Humming AlongDocument8 pagesGearbox Maintenance Tips: Keep Your Gearbox Humming AlongRaju ChaudharyNo ratings yet

- SKF Rolling Bearings InformationDocument117 pagesSKF Rolling Bearings InformationchoongzjNo ratings yet

- SKF Bearing CatalogueDocument66 pagesSKF Bearing Cataloguefarchipmm58No ratings yet

- Rulmenti Role CilindriceDocument66 pagesRulmenti Role CilindriceSara HeartNo ratings yet

- Design of High-Speed Ball Screw Drives: Juan José Zulaika, Jokin Lekunberri, José GorrotxategiDocument8 pagesDesign of High-Speed Ball Screw Drives: Juan José Zulaika, Jokin Lekunberri, José GorrotxategiMrdao ThieuNo ratings yet

- Catalog For Bearing DesignDocument70 pagesCatalog For Bearing DesignHameer ReddyNo ratings yet

- 07 Frameless Motors & GearmotorsDocument46 pages07 Frameless Motors & GearmotorsHassan IrshadNo ratings yet

- Spherical Roller Bearing SKF CatlougeDocument72 pagesSpherical Roller Bearing SKF Catlougemrkadu_61No ratings yet

- Magnetic Bearing Oil Free Technology MN Ashrae PDFDocument27 pagesMagnetic Bearing Oil Free Technology MN Ashrae PDFtpqnhat100% (1)

- Welcome: Bestek Engineering PVT LTDDocument39 pagesWelcome: Bestek Engineering PVT LTDankush kokitkarNo ratings yet

- Lecture 5, Part2Document17 pagesLecture 5, Part2jaradatNo ratings yet

- Prognosis of Repair and Maintenance of Perkins Engine 1100 SeriesDocument11 pagesPrognosis of Repair and Maintenance of Perkins Engine 1100 Seriesafofu osNo ratings yet

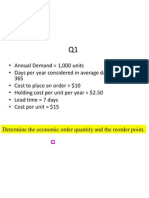

- EOQ QuestionsDocument3 pagesEOQ QuestionsmalingapereraNo ratings yet

- OM Final Project Group 10Document14 pagesOM Final Project Group 10Ravi GoyalNo ratings yet

- E2 Bearing Electric - MotorsDocument2 pagesE2 Bearing Electric - MotorsJurun_BidanshiNo ratings yet

- Industrial Training Presentation NBCDocument31 pagesIndustrial Training Presentation NBCsarvesh50% (2)

- Anti Friction Bearings For PumpsDocument165 pagesAnti Friction Bearings For PumpsJaime Berry100% (1)

- NSK Cat E1267Document9 pagesNSK Cat E1267Anonymous 5RUnMVLMPNo ratings yet

- Vlvna SB 237 060 04Document31 pagesVlvna SB 237 060 04Jonah RagleNo ratings yet

- Water Pump ReportDocument15 pagesWater Pump ReportMohammed BashierNo ratings yet

- Auto-Roll Cutting Machine (Using Geneva Mechanism) : Northern India Engineering College, NEW DELHI-110053Document18 pagesAuto-Roll Cutting Machine (Using Geneva Mechanism) : Northern India Engineering College, NEW DELHI-110053Vaishali GautamNo ratings yet

- Project On Tool Consumption in Hero Cycles in Rim PlantDocument14 pagesProject On Tool Consumption in Hero Cycles in Rim Plantsharanjeet4uNo ratings yet

- SKF Ball Bearing Failure Analysis ISO 15243Document24 pagesSKF Ball Bearing Failure Analysis ISO 15243VILLANUEVA_DANIEL2064100% (1)

- Valve Seat Installation InstructionsDocument10 pagesValve Seat Installation InstructionscpaolinodNo ratings yet

- 5 Product SpecifiactionDocument43 pages5 Product SpecifiactionAMIT SOLANKINo ratings yet

- Aerodinamic Noise PDFDocument8 pagesAerodinamic Noise PDFeng13No ratings yet

- Complex Modulus Estimation PDFDocument8 pagesComplex Modulus Estimation PDFeng13No ratings yet

- Webtrak - : My NeighbourhoodDocument2 pagesWebtrak - : My Neighbourhoodeng13No ratings yet

- Indoor Passby SystemDocument6 pagesIndoor Passby Systemeng13No ratings yet

- Reliable Packaging Equipment Design Should Not Be Kept Under WrapsDocument2 pagesReliable Packaging Equipment Design Should Not Be Kept Under Wrapseng13No ratings yet

- Food Processing BearingsDocument2 pagesFood Processing Bearingseng13No ratings yet

- Food Designed BearingsDocument2 pagesFood Designed Bearingseng13No ratings yet

- Bearing For GearboxDocument32 pagesBearing For Gearboxeng13100% (1)

- Precision Machine Tool BearingDocument4 pagesPrecision Machine Tool Bearingeng13No ratings yet

- Advanced Bearing Technologies & Value-Added ServicesDocument5 pagesAdvanced Bearing Technologies & Value-Added Serviceseng13No ratings yet

- Industrial Electrical HandbookDocument122 pagesIndustrial Electrical Handbookeng13100% (3)

- Bearings For Food and BeverageDocument7 pagesBearings For Food and Beverageeng13No ratings yet

- Cesna 172Document7 pagesCesna 172eng13No ratings yet

- Sound Power Determination With or Without IS09614-1: by Erik Cletus Petersen, Bruei&Kjser, DenmarkDocument2 pagesSound Power Determination With or Without IS09614-1: by Erik Cletus Petersen, Bruei&Kjser, Denmarkeng13No ratings yet

- Quality-Control of Bearings Using Vibration Monitoring: Application NotesDocument2 pagesQuality-Control of Bearings Using Vibration Monitoring: Application Noteseng13No ratings yet

- Bo 0409Document8 pagesBo 0409eng13No ratings yet

- G. Polt, T. Sebesty, A. Pauschitz and F. Franek: Investigations of Stick-Slip Effects in Wet Friction Drive ElementsDocument6 pagesG. Polt, T. Sebesty, A. Pauschitz and F. Franek: Investigations of Stick-Slip Effects in Wet Friction Drive Elementseng13No ratings yet