Professional Documents

Culture Documents

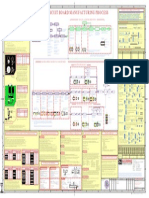

Installation Notes Notes For Manufacture and Inspection: Sleeve Pipe Size Dimension

Installation Notes Notes For Manufacture and Inspection: Sleeve Pipe Size Dimension

Uploaded by

narutothunderjet216Copyright:

Available Formats

You might also like

- VW Wiring DiagramDocument7 pagesVW Wiring Diagramdorcky100% (1)

- Tank DatasheetDocument4 pagesTank DatasheetAlvin Smith67% (6)

- Flange Type Pig SignallerDocument1 pageFlange Type Pig SignallerPrajwal ShettyNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Report of Lifting Beam DesignDocument5 pagesReport of Lifting Beam Designnarutothunderjet216100% (1)

- Lifting Lug Design ThuwalDocument80 pagesLifting Lug Design Thuwalnarutothunderjet216No ratings yet

- Disclosure To Promote The Right To Information: IS 5290 (1993) : Specification For Landing Valves (CED 22: Fire Fighting)Document20 pagesDisclosure To Promote The Right To Information: IS 5290 (1993) : Specification For Landing Valves (CED 22: Fire Fighting)Tanmoy Dutta100% (1)

- Wps Vosl-Pl-1 Pipeline Rev.2 XDocument11 pagesWps Vosl-Pl-1 Pipeline Rev.2 XVijo Jose100% (1)

- 1 1610 110Document4 pages1 1610 110MuhammedHafisNo ratings yet

- IS 2486 Part-2 (1989)Document28 pagesIS 2486 Part-2 (1989)tanto_deep_15No ratings yet

- Ac 036660 004Document1 pageAc 036660 004narutothunderjet216No ratings yet

- AC-036045-001 Vent, Drain and Sample ConnectionsDocument1 pageAC-036045-001 Vent, Drain and Sample Connectionsnarutothunderjet216No ratings yet

- Aa 036531 001Document1 pageAa 036531 001narutothunderjet2160% (1)

- Is 6848 1979Document31 pagesIs 6848 1979ShirishNo ratings yet

- MIL-DTL-17-133E - Cables, Radio Frequency, Coaxial, 0.0865 Diameter, Semi Rigid, 50 OhmsDocument11 pagesMIL-DTL-17-133E - Cables, Radio Frequency, Coaxial, 0.0865 Diameter, Semi Rigid, 50 OhmsgamillosNo ratings yet

- Modular Dual Line SystemDocument6 pagesModular Dual Line Systemangela_draguNo ratings yet

- BS 957-2008Document11 pagesBS 957-2008diegoNo ratings yet

- 2-01201-N-T-019 R05 Diseño de TuberiasDocument55 pages2-01201-N-T-019 R05 Diseño de TuberiasnarufredNo ratings yet

- RTDDocument68 pagesRTDMaria DenetNo ratings yet

- Nesstech 1Document24 pagesNesstech 1Brendys BuCaNo ratings yet

- Saej 1459Document6 pagesSaej 1459Nicole KeithNo ratings yet

- AB 036387 001 Tank GroundingDocument1 pageAB 036387 001 Tank Groundingnarutothunderjet216No ratings yet

- Bus Coupler Specs PDFDocument11 pagesBus Coupler Specs PDFRaj Chavan100% (1)

- 21-70-08 Socket Seat Weldind Details & TablesDocument63 pages21-70-08 Socket Seat Weldind Details & TablesJKKNo ratings yet

- Plant Design Ethanol (PRELIM)Document11 pagesPlant Design Ethanol (PRELIM)plyleNo ratings yet

- Pipe GuideDocument231 pagesPipe GuidegeorgD2010100% (2)

- Notes:: FORMERLY STD. DWG. AA-036072 SHT. 001 REV. 04Document1 pageNotes:: FORMERLY STD. DWG. AA-036072 SHT. 001 REV. 04aamirtec301No ratings yet

- INF 2887378 PCB Fab WallchartDocument1 pageINF 2887378 PCB Fab Wallchartnoman888100% (1)

- Pipe Reinforcing at SupportDocument12 pagesPipe Reinforcing at SupportSeungmin Paek100% (3)

- Technical DetailsDocument3 pagesTechnical DetailsRushikesh ChikteNo ratings yet

- A Proposed Mixed-Use Development: I. Structural Design CriteriaDocument28 pagesA Proposed Mixed-Use Development: I. Structural Design CriteriaAnonymous sOSxA7SNo ratings yet

- Socket Weld & Screwed FittingsDocument31 pagesSocket Weld & Screwed FittingsJavier GarcíaNo ratings yet

- Steel Pipes and FittingsDocument14 pagesSteel Pipes and FittingsMohammed ShallabyNo ratings yet

- Is-909 Underground Fire HydrantDocument9 pagesIs-909 Underground Fire HydrantCharls JamesNo ratings yet

- KV-27XBR51 KV-27XBR55Document81 pagesKV-27XBR51 KV-27XBR55David RoldanNo ratings yet

- BSJ Jakarta (Site B) : For ConstructionDocument1 pageBSJ Jakarta (Site B) : For ConstructionIskandar HasibuanNo ratings yet

- 66 KV CT PTDocument11 pages66 KV CT PTSharafat AliNo ratings yet

- HeliCoil NPT Inserts 8UNDocument4 pagesHeliCoil NPT Inserts 8UNAce Industrial SuppliesNo ratings yet

- Pdvsa: Engineering Design ManualDocument5 pagesPdvsa: Engineering Design ManualnoxleekNo ratings yet

- For Tender: Beca Philippines LTD Pacifictech Solutions IncDocument1 pageFor Tender: Beca Philippines LTD Pacifictech Solutions Incchristian reyesNo ratings yet

- Syabas Standard Drawing 02Document20 pagesSyabas Standard Drawing 02Jpmega Civil StructuralNo ratings yet

- HeliCoil NPT Inserts 8UN 2Document2 pagesHeliCoil NPT Inserts 8UN 2Ace Industrial SuppliesNo ratings yet

- Elect Manhole Handhole MetricDocument7 pagesElect Manhole Handhole MetricRom GuarenNo ratings yet

- HP 739A Manual EarlyDocument12 pagesHP 739A Manual Earlyfred_m_48601No ratings yet

- 72.5-420kV Current TransformerDocument4 pages72.5-420kV Current TransformerPaulo CardosoNo ratings yet

- Alpema Standards Rev1 2000Document8 pagesAlpema Standards Rev1 2000anonimppNo ratings yet

- Is 13095 1991Document15 pagesIs 13095 1991Surendra MalasaneNo ratings yet

- Specification For Ducting of Ac PlantDocument7 pagesSpecification For Ducting of Ac PlantSubbarayan SaravanakumarNo ratings yet

- ASME Code Calculations For Companion FlangesDocument9 pagesASME Code Calculations For Companion FlangesKamlesh DalavadiNo ratings yet

- FLOW SWITCH FS10-C SERIES Installation InstructionsDocument2 pagesFLOW SWITCH FS10-C SERIES Installation InstructionsWattsNo ratings yet

- Kabelindo NYY CableDocument11 pagesKabelindo NYY CableReza Putra PamungkasNo ratings yet

- Kabelindo NYY CableDocument11 pagesKabelindo NYY CableAvan Setyo PratamaNo ratings yet

- Sirio 827Document2 pagesSirio 82710sd156No ratings yet

- Inspection and Tests: Instrument Air Receiver TWO Code Stamp: Not RequiredDocument2 pagesInspection and Tests: Instrument Air Receiver TWO Code Stamp: Not RequiredSean DavisNo ratings yet

- Hookup LibraryDocument221 pagesHookup Librarykapilarora123100% (6)

- Specification of 11KV MUDocument16 pagesSpecification of 11KV MUPaatala Raagamlo Jeevitha SaagaramNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Linotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeFrom EverandLinotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Echnical Ulletin: Cmnsi P S CrmoDocument1 pageEchnical Ulletin: Cmnsi P S Crmonarutothunderjet216No ratings yet

- Anak 'Child',作者:Freddie Aguilar, 1978 ANAK (Original song & lyrics in Filipino)Document1 pageAnak 'Child',作者:Freddie Aguilar, 1978 ANAK (Original song & lyrics in Filipino)narutothunderjet216No ratings yet

- Summary ISO TR 15608 Metallic Materials Grouping SystemDocument4 pagesSummary ISO TR 15608 Metallic Materials Grouping SystemV SwamiNo ratings yet

- Orbital Tube Welding PDFDocument7 pagesOrbital Tube Welding PDFnarutothunderjet216100% (1)

- ,mhlfp765 8t76jye 34t3rbtshd 65trhs6wDocument1 page,mhlfp765 8t76jye 34t3rbtshd 65trhs6wnarutothunderjet216No ratings yet

- Piping Class Summary - OSBL PDFDocument2 pagesPiping Class Summary - OSBL PDFnarutothunderjet216100% (1)

- QM-CBI Tank Specification 4-28-10Document24 pagesQM-CBI Tank Specification 4-28-10narutothunderjet216No ratings yet

- Welder Qualification (ALL CODES)Document3 pagesWelder Qualification (ALL CODES)narutothunderjet216No ratings yet

- EquationcscxDocument1 pageEquationcscxnarutothunderjet216No ratings yet

- Piping Class Summary - CM2Document1 pagePiping Class Summary - CM2narutothunderjet216100% (1)

- Storage Tank DesignDocument19 pagesStorage Tank DesignSellappan Muthusamy100% (3)

- API 650 Basic FactsDocument4 pagesAPI 650 Basic Factsnarutothunderjet216No ratings yet

- Forms - Fab of Separator VesselDocument1 pageForms - Fab of Separator Vesselnarutothunderjet216No ratings yet

Installation Notes Notes For Manufacture and Inspection: Sleeve Pipe Size Dimension

Installation Notes Notes For Manufacture and Inspection: Sleeve Pipe Size Dimension

Uploaded by

narutothunderjet216Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Installation Notes Notes For Manufacture and Inspection: Sleeve Pipe Size Dimension

Installation Notes Notes For Manufacture and Inspection: Sleeve Pipe Size Dimension

Uploaded by

narutothunderjet216Copyright:

Available Formats

1.

25

1.5 x 25mm STEEL BACKING STRIP FULL LENGTH. TACK WELD IN PLACE AS NECESSARY. FIELD SUPPLIED

DETAIL-BUTT WELD FOR SEAM

DRILL & TAP 1/2 " NPT W/STEEL BAR STOCK PLUG SEE NOTE-2 2 A

R-PER MFR. STD. T

19

SEE NOTE-2 2 BACKING STRIP FOR SEAM SEE BUTT WELD DETAIL

C

PLANT NO.

990

37^

C

INDEX

AC-036279

DRAWING NO.

SHT. NO.

001

REV. NO.

04

NOTES FOR MANUFACTURE AND INSPECTION

INSTALLATION NOTES

+0 -2

1. USE SLEEVES OF GRADE TO MATCH PIPE. 1. TOLERANCES: T -0 T OF SLEEVE TO BE AT LEAST 1.25 TIMES + 1.5mm, A + - 3mm PIPE THICKNESS. DIAMETER-SLEEVE TO BE FORMED SO THAT 1 2 IS THE THE INTERNAL DIAMETER MEASURED WITH AN 2. WELDS MARKED THUS NORMAL WELDING SEQUENCE (SEQUENCE MAY I.D. TAPE WITH WELD BEVELS ABUTTING WILL BE VARIED ACCORDING TO CIRCUMSTANCES). NOT BE LESS THAN THE TABULATED PIPE DIAMETER MINUS 3mm MAX. I.D. TO EQUAL 3. WELDING PER (G.I.M.) GENERAL INSTRUCTION PIPE DIAMETER. MANUAL 434.001. 2. MATERIAL IS TO BE APPRORIATE FOR THE PIPE GRADE SPECIFIED IN THE PURCHASE ORDER, USING MATERIAL SPECIFICATIONS OF MSS-SP-75 AS FOLLOWS:FOR GRADE B OR X42 PIPE USE CLASS WPHY-42. FOR GRADE X52 PIPE USE CLASS WPHY-52. FOR GRADE X60 PIPE USE CLASS WPHY-60. 3. CARBON EQUIVALENT (C.E.) BASED ON PRODUCT ANALYSIS BE DETERMINED PER MSS-SP-75. 4. MARKINGS TO BE PER MSS-SP-75 PLUS THE FOLLOWING STENCILS ON EACH HALF:C.E. FOLLOWED BY THE C.E. VALUE TO 2 FIGURES.

REVISION NOTE:-

4. USE LOW HYDROGEN ELECTRODES E-7018, ALL CIRCUMFERENTIAL WELD PASSES TO BE UPHILL. 5. GRIND BEVELS BACK AS NECESSARY TO GET GOOD FITUP. 6. OPEN SLEEVE WITH HYDRAULIC JACK AS NECESSARY TO CLEAR BACK-UP STRIP. 7. SLEEVES SHALL BE SUPPLIED UNPAINTED. 8. ALL DIMENSIONS ARE IN MILLIMETERS UNLESS NOTED OTHERWISE.

FIELD WELD WITH E-7018 ELECTRODE. PREHEAT. PER STD. DWG. AE-036451

SLEEVE PIPE SIZE

PIPE SIZE IN. 6" 8" 10" 12" PIPE O.D. mm 168 219 273 324

DIMENSION

A mm 150 200 250 290 290

1. REDRAWN AND CONSOLIDATED SH. 1 & 2 INTO SH. 1 METRIC VERSION ONLY. ADDED TYPICAL INSTALL. DWG.

14" & ABOVE

TYPICAL INSTALLATION DRAWING

04

REV. NO.

08-13-86

DATE

RLO

BY

SEE REVISION NOTE-1

DESCRIPTION CHKD CERT. APPD.

FOR ARABIAN AMERICAN OIL COMPANY

DRAWN BY ULFAT/RASHID CHECKED BY DATE STARTED OPRG. DEPT.

THIS DRAWING IS NOT TO BE USED FOR CONSTRUCTION OR FOR ORDERING MATERIAL UNTIL CERTIFIED AND DATED

FUB

SCALE:

NONE

DATE COMPLETED ENG. DEPT. CERTIFIED DATE

01-23-78

02-20-78

CORRUGATED WELD REPAIR SLEEVE

1 SEE NOTE-2 STD. CORRUGATED STEEL SLEEVE

PIPE SIZE 6" THROUGH 48"

STD. DWG.

PLANT NO. INDEX DRAWING NO. SHT. NO.

METRIC

REV. NO.

990

CopyrightSaudi Aramco 2009. All rights reserved.

AC-036279

001

04

You might also like

- VW Wiring DiagramDocument7 pagesVW Wiring Diagramdorcky100% (1)

- Tank DatasheetDocument4 pagesTank DatasheetAlvin Smith67% (6)

- Flange Type Pig SignallerDocument1 pageFlange Type Pig SignallerPrajwal ShettyNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Report of Lifting Beam DesignDocument5 pagesReport of Lifting Beam Designnarutothunderjet216100% (1)

- Lifting Lug Design ThuwalDocument80 pagesLifting Lug Design Thuwalnarutothunderjet216No ratings yet

- Disclosure To Promote The Right To Information: IS 5290 (1993) : Specification For Landing Valves (CED 22: Fire Fighting)Document20 pagesDisclosure To Promote The Right To Information: IS 5290 (1993) : Specification For Landing Valves (CED 22: Fire Fighting)Tanmoy Dutta100% (1)

- Wps Vosl-Pl-1 Pipeline Rev.2 XDocument11 pagesWps Vosl-Pl-1 Pipeline Rev.2 XVijo Jose100% (1)

- 1 1610 110Document4 pages1 1610 110MuhammedHafisNo ratings yet

- IS 2486 Part-2 (1989)Document28 pagesIS 2486 Part-2 (1989)tanto_deep_15No ratings yet

- Ac 036660 004Document1 pageAc 036660 004narutothunderjet216No ratings yet

- AC-036045-001 Vent, Drain and Sample ConnectionsDocument1 pageAC-036045-001 Vent, Drain and Sample Connectionsnarutothunderjet216No ratings yet

- Aa 036531 001Document1 pageAa 036531 001narutothunderjet2160% (1)

- Is 6848 1979Document31 pagesIs 6848 1979ShirishNo ratings yet

- MIL-DTL-17-133E - Cables, Radio Frequency, Coaxial, 0.0865 Diameter, Semi Rigid, 50 OhmsDocument11 pagesMIL-DTL-17-133E - Cables, Radio Frequency, Coaxial, 0.0865 Diameter, Semi Rigid, 50 OhmsgamillosNo ratings yet

- Modular Dual Line SystemDocument6 pagesModular Dual Line Systemangela_draguNo ratings yet

- BS 957-2008Document11 pagesBS 957-2008diegoNo ratings yet

- 2-01201-N-T-019 R05 Diseño de TuberiasDocument55 pages2-01201-N-T-019 R05 Diseño de TuberiasnarufredNo ratings yet

- RTDDocument68 pagesRTDMaria DenetNo ratings yet

- Nesstech 1Document24 pagesNesstech 1Brendys BuCaNo ratings yet

- Saej 1459Document6 pagesSaej 1459Nicole KeithNo ratings yet

- AB 036387 001 Tank GroundingDocument1 pageAB 036387 001 Tank Groundingnarutothunderjet216No ratings yet

- Bus Coupler Specs PDFDocument11 pagesBus Coupler Specs PDFRaj Chavan100% (1)

- 21-70-08 Socket Seat Weldind Details & TablesDocument63 pages21-70-08 Socket Seat Weldind Details & TablesJKKNo ratings yet

- Plant Design Ethanol (PRELIM)Document11 pagesPlant Design Ethanol (PRELIM)plyleNo ratings yet

- Pipe GuideDocument231 pagesPipe GuidegeorgD2010100% (2)

- Notes:: FORMERLY STD. DWG. AA-036072 SHT. 001 REV. 04Document1 pageNotes:: FORMERLY STD. DWG. AA-036072 SHT. 001 REV. 04aamirtec301No ratings yet

- INF 2887378 PCB Fab WallchartDocument1 pageINF 2887378 PCB Fab Wallchartnoman888100% (1)

- Pipe Reinforcing at SupportDocument12 pagesPipe Reinforcing at SupportSeungmin Paek100% (3)

- Technical DetailsDocument3 pagesTechnical DetailsRushikesh ChikteNo ratings yet

- A Proposed Mixed-Use Development: I. Structural Design CriteriaDocument28 pagesA Proposed Mixed-Use Development: I. Structural Design CriteriaAnonymous sOSxA7SNo ratings yet

- Socket Weld & Screwed FittingsDocument31 pagesSocket Weld & Screwed FittingsJavier GarcíaNo ratings yet

- Steel Pipes and FittingsDocument14 pagesSteel Pipes and FittingsMohammed ShallabyNo ratings yet

- Is-909 Underground Fire HydrantDocument9 pagesIs-909 Underground Fire HydrantCharls JamesNo ratings yet

- KV-27XBR51 KV-27XBR55Document81 pagesKV-27XBR51 KV-27XBR55David RoldanNo ratings yet

- BSJ Jakarta (Site B) : For ConstructionDocument1 pageBSJ Jakarta (Site B) : For ConstructionIskandar HasibuanNo ratings yet

- 66 KV CT PTDocument11 pages66 KV CT PTSharafat AliNo ratings yet

- HeliCoil NPT Inserts 8UNDocument4 pagesHeliCoil NPT Inserts 8UNAce Industrial SuppliesNo ratings yet

- Pdvsa: Engineering Design ManualDocument5 pagesPdvsa: Engineering Design ManualnoxleekNo ratings yet

- For Tender: Beca Philippines LTD Pacifictech Solutions IncDocument1 pageFor Tender: Beca Philippines LTD Pacifictech Solutions Incchristian reyesNo ratings yet

- Syabas Standard Drawing 02Document20 pagesSyabas Standard Drawing 02Jpmega Civil StructuralNo ratings yet

- HeliCoil NPT Inserts 8UN 2Document2 pagesHeliCoil NPT Inserts 8UN 2Ace Industrial SuppliesNo ratings yet

- Elect Manhole Handhole MetricDocument7 pagesElect Manhole Handhole MetricRom GuarenNo ratings yet

- HP 739A Manual EarlyDocument12 pagesHP 739A Manual Earlyfred_m_48601No ratings yet

- 72.5-420kV Current TransformerDocument4 pages72.5-420kV Current TransformerPaulo CardosoNo ratings yet

- Alpema Standards Rev1 2000Document8 pagesAlpema Standards Rev1 2000anonimppNo ratings yet

- Is 13095 1991Document15 pagesIs 13095 1991Surendra MalasaneNo ratings yet

- Specification For Ducting of Ac PlantDocument7 pagesSpecification For Ducting of Ac PlantSubbarayan SaravanakumarNo ratings yet

- ASME Code Calculations For Companion FlangesDocument9 pagesASME Code Calculations For Companion FlangesKamlesh DalavadiNo ratings yet

- FLOW SWITCH FS10-C SERIES Installation InstructionsDocument2 pagesFLOW SWITCH FS10-C SERIES Installation InstructionsWattsNo ratings yet

- Kabelindo NYY CableDocument11 pagesKabelindo NYY CableReza Putra PamungkasNo ratings yet

- Kabelindo NYY CableDocument11 pagesKabelindo NYY CableAvan Setyo PratamaNo ratings yet

- Sirio 827Document2 pagesSirio 82710sd156No ratings yet

- Inspection and Tests: Instrument Air Receiver TWO Code Stamp: Not RequiredDocument2 pagesInspection and Tests: Instrument Air Receiver TWO Code Stamp: Not RequiredSean DavisNo ratings yet

- Hookup LibraryDocument221 pagesHookup Librarykapilarora123100% (6)

- Specification of 11KV MUDocument16 pagesSpecification of 11KV MUPaatala Raagamlo Jeevitha SaagaramNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Linotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeFrom EverandLinotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Echnical Ulletin: Cmnsi P S CrmoDocument1 pageEchnical Ulletin: Cmnsi P S Crmonarutothunderjet216No ratings yet

- Anak 'Child',作者:Freddie Aguilar, 1978 ANAK (Original song & lyrics in Filipino)Document1 pageAnak 'Child',作者:Freddie Aguilar, 1978 ANAK (Original song & lyrics in Filipino)narutothunderjet216No ratings yet

- Summary ISO TR 15608 Metallic Materials Grouping SystemDocument4 pagesSummary ISO TR 15608 Metallic Materials Grouping SystemV SwamiNo ratings yet

- Orbital Tube Welding PDFDocument7 pagesOrbital Tube Welding PDFnarutothunderjet216100% (1)

- ,mhlfp765 8t76jye 34t3rbtshd 65trhs6wDocument1 page,mhlfp765 8t76jye 34t3rbtshd 65trhs6wnarutothunderjet216No ratings yet

- Piping Class Summary - OSBL PDFDocument2 pagesPiping Class Summary - OSBL PDFnarutothunderjet216100% (1)

- QM-CBI Tank Specification 4-28-10Document24 pagesQM-CBI Tank Specification 4-28-10narutothunderjet216No ratings yet

- Welder Qualification (ALL CODES)Document3 pagesWelder Qualification (ALL CODES)narutothunderjet216No ratings yet

- EquationcscxDocument1 pageEquationcscxnarutothunderjet216No ratings yet

- Piping Class Summary - CM2Document1 pagePiping Class Summary - CM2narutothunderjet216100% (1)

- Storage Tank DesignDocument19 pagesStorage Tank DesignSellappan Muthusamy100% (3)

- API 650 Basic FactsDocument4 pagesAPI 650 Basic Factsnarutothunderjet216No ratings yet

- Forms - Fab of Separator VesselDocument1 pageForms - Fab of Separator Vesselnarutothunderjet216No ratings yet