Professional Documents

Culture Documents

Takt PDF

Takt PDF

Uploaded by

Hariharan GanesanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Takt PDF

Takt PDF

Uploaded by

Hariharan GanesanCopyright:

Available Formats

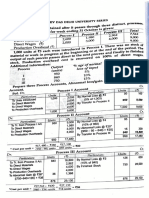

The Lean Lexicon published by the Lean Enterprise Institute defines Takt Time as : Takt Time is the time

interval between parts being produced to meet customer demand This simple example shows how Takt time can be calculated from customer demand and the available production time.

C10

Customer

Customer Demand

Flywheel Demand

1000

Per Day

A10

A20

A30

Make

Inspect

Ship

P10

Plant Data

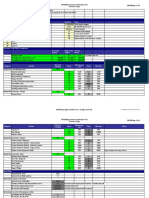

Takt Days 2 Shfts Shfts 7.5 Hrs Hrs 60 Mins Mins 60 Secs 0.90 Mins

Unit Converters Takt Time to be calculated

The eVSM calculator transfers map data to an Excel spreadsheet. It also transfers the results of calculations in Excel back onto the map for display

B 1

Tag

C

Operation

D

Data flywheel demand

E

Data

2 3 4 5 6 7 8 9 10

per day A010 A020 A030 C010 P010 Make Inspect Ship Customer Plant Data

mins

1000.00 0.90

Takt Time

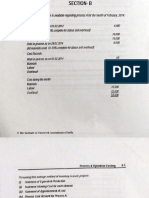

= Production Time Per Day / Daily Demand = No of Minutes Per Day / Daily Demand = eVUnit_Page_1_days_mins / D8 = 900/1000 = 0.9 minutes

Note : In the formula above the variable eVUnit_Page_1_days_mins is used to convert from days to minutes : Conversion variables are automatically generated in the excel spreadsheet based on the unit converters defined on the map

takt

You might also like

- Hotel Audit Program RR FixedDocument6 pagesHotel Audit Program RR FixedPulkit Mathur75% (4)

- KT Factor CalculationDocument1 pageKT Factor CalculationDEADMANNo ratings yet

- IE3120 Manufacturing Logistics: Tutorial 2Document27 pagesIE3120 Manufacturing Logistics: Tutorial 2Joli SmithNo ratings yet

- MAS - 1410 Inventory ManagementDocument25 pagesMAS - 1410 Inventory ManagementAzureBlazeNo ratings yet

- Beer GameDocument8 pagesBeer Gamelay fengNo ratings yet

- Revit BIM Manual - Procedures Version 4.0 PDFDocument49 pagesRevit BIM Manual - Procedures Version 4.0 PDFClifford Santos100% (1)

- Takt Calc PDFDocument2 pagesTakt Calc PDFHariharan GanesanNo ratings yet

- LP Eoq2021lf2Document209 pagesLP Eoq2021lf2sahilvaddoriyaNo ratings yet

- Paper - 3: Cost Accounting and Financial Management Part-I: Cost Accounting Questions MaterialDocument43 pagesPaper - 3: Cost Accounting and Financial Management Part-I: Cost Accounting Questions MaterialSuriya KakaniNo ratings yet

- MGT Info (KL-PS) Question BankDocument14 pagesMGT Info (KL-PS) Question BankPrabir Kumer RoyNo ratings yet

- Contract Agreement Uu Library Aug 8, 2019Document8 pagesContract Agreement Uu Library Aug 8, 2019Jemila MurshidNo ratings yet

- WK4 Abc Ii HMWRK QDocument1 pageWK4 Abc Ii HMWRK QFungaiNo ratings yet

- Group / Parameter Name IED Value PC Value Unit Min Max FormatDocument1 pageGroup / Parameter Name IED Value PC Value Unit Min Max FormatElenildo Oliveira da SilvaNo ratings yet

- Project Operation ManagementDocument73 pagesProject Operation ManagementAbrar Jahin SresthaNo ratings yet

- Input Quantity Items Quantity ItemsDocument10 pagesInput Quantity Items Quantity ItemsRavi RangariNo ratings yet

- Requirements Estimation ToolDocument9 pagesRequirements Estimation Toolshwetank sharmaNo ratings yet

- Overhead Question Bank B.com - (H) Sem IV Paper Bch4.1 Cost Accounting Module 8Document6 pagesOverhead Question Bank B.com - (H) Sem IV Paper Bch4.1 Cost Accounting Module 8Utkarsh VermaNo ratings yet

- Activity Based Costing Review QuestionsDocument3 pagesActivity Based Costing Review Questionshome labNo ratings yet

- Acc271215 OhdDocument4 pagesAcc271215 Ohdbasilimagambo22No ratings yet

- RTP May-2020Document29 pagesRTP May-2020mehtastha5454No ratings yet

- Term 1 Test 27 June 2013 Deferred Marking KeyDocument5 pagesTerm 1 Test 27 June 2013 Deferred Marking KeyPETERNo ratings yet

- Closing Entries AssignmentDocument4 pagesClosing Entries AssignmentDrippy SnowflakeNo ratings yet

- Axios Systems: West Lothian Council ITSM Case StudyDocument2 pagesAxios Systems: West Lothian Council ITSM Case StudyAxiosSystemsNo ratings yet

- Procedure For Contract ReviewDocument7 pagesProcedure For Contract ReviewAmine ChahiNo ratings yet

- Adobe Scan 19 May 2022Document10 pagesAdobe Scan 19 May 2022Mary CharlesNo ratings yet

- Case For Overhead and DistributionDocument2 pagesCase For Overhead and DistributionBhargav D.S.No ratings yet

- Bacc232 .309 Management Accounting Assignment 1Document13 pagesBacc232 .309 Management Accounting Assignment 1TarusengaNo ratings yet

- Process and Operating CostingDocument20 pagesProcess and Operating CostingBHANU PRATAP SINGHNo ratings yet

- CE-MI-TEST V3PM012-Change Code of Functional LocationDocument8 pagesCE-MI-TEST V3PM012-Change Code of Functional LocationNeeraj GuptaNo ratings yet

- 66088bos53351inter p3Document34 pages66088bos53351inter p3Asfarin ShaikhNo ratings yet

- Price BidDocument1 pagePrice BidСергей ВельдяксовNo ratings yet

- Monte Carlo Simulation Tutorial v2.0Document50 pagesMonte Carlo Simulation Tutorial v2.0moepoeNo ratings yet

- 01 Traffic Engineering - Traffic Parameters PDFDocument24 pages01 Traffic Engineering - Traffic Parameters PDFLestor NaribNo ratings yet

- Mytimeandexpenses Time ReportDocument3 pagesMytimeandexpenses Time ReportGrim AzelNo ratings yet

- 3acc0809 Introduction To Management Accounting Tutorial 7: (ACCA, F5, BPP)Document2 pages3acc0809 Introduction To Management Accounting Tutorial 7: (ACCA, F5, BPP)Sarah RanduNo ratings yet

- F5 Practice Questions 1-7Document22 pagesF5 Practice Questions 1-7Dilli Ram Pokhrel100% (2)

- 5 Adodotnet by Example m5 SlidesDocument13 pages5 Adodotnet by Example m5 Slidesamitfegade121No ratings yet

- 102.COA PL I Solution CMA Special Examination 2021novemberDocument7 pages102.COA PL I Solution CMA Special Examination 2021novemberSky WalkerNo ratings yet

- Tutorial Question Overheads 2Document2 pagesTutorial Question Overheads 2tawanaishe shoniwaNo ratings yet

- People Soft Bundle Release Note 9 Bundle12Document23 pagesPeople Soft Bundle Release Note 9 Bundle12rajiv_xguysNo ratings yet

- Pet. ATOS 41693. SE - IBE - BDS - Cyber - STM - McAfee ProfileDocument3 pagesPet. ATOS 41693. SE - IBE - BDS - Cyber - STM - McAfee ProfileSalatiel NavaNo ratings yet

- IT Systems Acquistion Budget TemplateDocument6 pagesIT Systems Acquistion Budget TemplateAkram M. AlmotaaNo ratings yet

- 2024 02 15 Fe Webinar Disruption WebsiteDocument26 pages2024 02 15 Fe Webinar Disruption WebsiteKrishan RodrigoNo ratings yet

- Emily-1 Project Fuel Terminal and Jetty Compaction Inspection ReportDocument9 pagesEmily-1 Project Fuel Terminal and Jetty Compaction Inspection Reportmuhammad sauqiNo ratings yet

- Shipping Intelligence Network TimeseriesDocument17 pagesShipping Intelligence Network TimeseriesLuis Enrique LavayenNo ratings yet

- OVERHEAD Control ProblemDocument7 pagesOVERHEAD Control Problemmuttakin106No ratings yet

- Pwa Application Winter 2020Document3 pagesPwa Application Winter 2020ArifNo ratings yet

- Homework/Assignment: Full Name of submitter: Nguyễn Ngọc Hân Student ID: IEIEIU18152Document8 pagesHomework/Assignment: Full Name of submitter: Nguyễn Ngọc Hân Student ID: IEIEIU18152Quynh Chau TranNo ratings yet

- Ridj Offset PrintingDocument9 pagesRidj Offset Printingsanjit laishramNo ratings yet

- ASSESMENT 3 ASSETdocx 2310Document4 pagesASSESMENT 3 ASSETdocx 2310Content PediaNo ratings yet

- OM Final Revision 2022-2023Document26 pagesOM Final Revision 2022-2023Abdel JuniorNo ratings yet

- 9 A. Factory - CostDocument4 pages9 A. Factory - CostDÃljït SīñghNo ratings yet

- Paper - 3: Cost Accounting and Financial Management Part I: Cost Accounting Questions Short Answer Type Questions From Misc ChaptersDocument44 pagesPaper - 3: Cost Accounting and Financial Management Part I: Cost Accounting Questions Short Answer Type Questions From Misc ChaptersVarinder AnandNo ratings yet

- 63edbface4b06000ece81962 OriginalDocument49 pages63edbface4b06000ece81962 OriginalTM GamingNo ratings yet

- PM - SDD - Master Data - V1.0Document13 pagesPM - SDD - Master Data - V1.0Dhanush S TNo ratings yet

- 03 Overhead CostingDocument16 pages03 Overhead CostingBharatbhusan RoutNo ratings yet

- Design Report Naveen Ji ChoudharyDocument836 pagesDesign Report Naveen Ji ChoudharyMUKESH RAJENDRANo ratings yet

- Assignment 01Document2 pagesAssignment 01Rae Jeniña E.MerelosNo ratings yet

- Truss 1Document9 pagesTruss 1Avnish raiNo ratings yet

- Ex3 Accounting For FOHDocument7 pagesEx3 Accounting For FOHLemuel ReñaNo ratings yet

- FM Sep04 ClelandDocument4 pagesFM Sep04 ClelandkhengmaiNo ratings yet

- 03 Overhead CostingDocument9 pages03 Overhead CostingPappu LalNo ratings yet

- Placement Test CSBDocument11 pagesPlacement Test CSBPashaeva TachiNo ratings yet

- 031 Calanza v. PICOPDocument3 pages031 Calanza v. PICOPthornapple25No ratings yet

- Employee Hand Book GTZDocument105 pagesEmployee Hand Book GTZAabha GaurNo ratings yet

- Computer Vision: Models, Learning and InferenceDocument59 pagesComputer Vision: Models, Learning and InferencePREM KUMAR MNo ratings yet

- Distance and SizeDocument2 pagesDistance and SizeLịch PhạmNo ratings yet

- Work Immersion Training Plan 1Document2 pagesWork Immersion Training Plan 1c6358179No ratings yet

- Empress Bass Compressor Manuel Utilisateur en 81366Document12 pagesEmpress Bass Compressor Manuel Utilisateur en 81366MURPHYNo ratings yet

- 5 BrakeDocument69 pages5 BrakeAtalelew ZeruNo ratings yet

- Democracy Beyond The Nation State PracticingDocument342 pagesDemocracy Beyond The Nation State PracticingSergio Hoffman CartesNo ratings yet

- Chapter - III Financial System and Non-Banking Financial Companies - The Structure and Status ProfileDocument55 pagesChapter - III Financial System and Non-Banking Financial Companies - The Structure and Status Profilechirag10pnNo ratings yet

- EN 1090 White Paper tcm17-119019Document24 pagesEN 1090 White Paper tcm17-119019Gerard BorstNo ratings yet

- Activity Based Costing HCCDocument8 pagesActivity Based Costing HCCIhsan danishNo ratings yet

- Normal 5f5fc792e6de4Document66 pagesNormal 5f5fc792e6de4AbdulmalekNo ratings yet

- Luật Thương Mại Quốc Tế- Song Ngữ-2017Document571 pagesLuật Thương Mại Quốc Tế- Song Ngữ-2017Ngoc VõNo ratings yet

- CB Assignment IIIDocument12 pagesCB Assignment IIIJaya BharneNo ratings yet

- Technical Data: Aluminium Composite PanelsDocument2 pagesTechnical Data: Aluminium Composite PanelsSushil dixitNo ratings yet

- Draft - Schedule MBA Orientation 21-25 August 2023Document5 pagesDraft - Schedule MBA Orientation 21-25 August 2023Anmol TiwariNo ratings yet

- ETCE MICRO (Group 2)Document19 pagesETCE MICRO (Group 2)19IF001 Chaitali AkhareNo ratings yet

- Coca Cola Co.Document19 pagesCoca Cola Co.ParvShuklaNo ratings yet

- NT71710MFG 000 PDFDocument1 pageNT71710MFG 000 PDFFadiNo ratings yet

- AsdfDocument5 pagesAsdfOmar FarukNo ratings yet

- STE-Elective Biotech Q4 W1-8 Learning-Activity-SheetsDocument10 pagesSTE-Elective Biotech Q4 W1-8 Learning-Activity-SheetsFriah Mae Delgado0% (1)

- The Theory of StrategyDocument12 pagesThe Theory of StrategyLumbardh BajramiNo ratings yet

- Nova Fórmula de Gessagem Caires e GuimaraesDocument9 pagesNova Fórmula de Gessagem Caires e GuimaraesJefrejan Souza RezendeNo ratings yet

- Group3 SafeliteDocument11 pagesGroup3 SafeliteVeeranjaneyulu KacherlaNo ratings yet

- Zenon Manual: RuntimeDocument78 pagesZenon Manual: RuntimeRachid MoussaouiNo ratings yet

- India's Stalled RiseDocument12 pagesIndia's Stalled RiseSiddharth AroraNo ratings yet