Professional Documents

Culture Documents

Unprotected A3702003a 5

Unprotected A3702003a 5

Uploaded by

kaveh-bahiraeeCopyright:

Available Formats

You might also like

- C 174 .C 174M Test Method For Measuring Length of Drilled Concrete CoresDocument2 pagesC 174 .C 174M Test Method For Measuring Length of Drilled Concrete Coresjjaavenido100% (1)

- Aws B2.4-2012Document15 pagesAws B2.4-2012Vicky Gautam0% (1)

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Unprotected A3702003a 6Document1 pageUnprotected A3702003a 6kaveh-bahiraeeNo ratings yet

- Round Specimens: FIG. 5 Suggested Types of Ends For Standard Round Tension Test SpecimensDocument1 pageRound Specimens: FIG. 5 Suggested Types of Ends For Standard Round Tension Test Specimenskaveh-bahiraeeNo ratings yet

- FIG. 1 Rectangular Tension Test SpecimensDocument1 pageFIG. 1 Rectangular Tension Test SpecimensAlvaro Alexis Mendoza PradaNo ratings yet

- Tuft Height of Pile Floor Coverings: Standard Test Method ForDocument5 pagesTuft Height of Pile Floor Coverings: Standard Test Method ForJuanNo ratings yet

- Bending Stiffness of FiberboardDocument6 pagesBending Stiffness of FiberboardBobKatNo ratings yet

- Bending StiffnessDocument6 pagesBending StiffnessMark Samsel RohanNo ratings yet

- ASTM E436 Drop-Weight Tear Tests of Ferritic SteelsDocument5 pagesASTM E436 Drop-Weight Tear Tests of Ferritic SteelsledaswanNo ratings yet

- Astm C490Document5 pagesAstm C490Horacio ApolayoNo ratings yet

- 61.0 % of The: 6. Test SpecimensDocument2 pages61.0 % of The: 6. Test SpecimensluthfibomentNo ratings yet

- Tensile Calculation PDFDocument2 pagesTensile Calculation PDFWendimagen Meshesha FantaNo ratings yet

- B 565 - 94 R00 - Qju2ns05nfiwmaDocument3 pagesB 565 - 94 R00 - Qju2ns05nfiwmamalika_00No ratings yet

- D 2444 - 99 Rdi0ndqDocument8 pagesD 2444 - 99 Rdi0ndqHumberto GutierrezNo ratings yet

- Engineering Materials Exp. - 5Document10 pagesEngineering Materials Exp. - 5Nahid SultanNo ratings yet

- Astm D 1002Document5 pagesAstm D 1002Aisya IbrahimNo ratings yet

- ASTM D 2491 - Particulas Chatas y AlargadasDocument2 pagesASTM D 2491 - Particulas Chatas y AlargadasJuan Alex Alvarado RomeroNo ratings yet

- E190.29610 AstmDocument4 pagesE190.29610 AstmMassab JunaidNo ratings yet

- Press q3 Ass 2Document5 pagesPress q3 Ass 2Arslan RaoNo ratings yet

- Ensayo de Doblez GuiadoDocument4 pagesEnsayo de Doblez GuiadoJulio Alejandro GómezNo ratings yet

- Guided Bend Test For Ductility of WeldsDocument3 pagesGuided Bend Test For Ductility of WeldsErlinawati Bintu SupiyoNo ratings yet

- Wsdot Fop For Aashto T 23: 1. ScopeDocument10 pagesWsdot Fop For Aashto T 23: 1. ScopeEinstein JeboneNo ratings yet

- Astm d412 1968 PDFDocument13 pagesAstm d412 1968 PDFHassan Mehmood100% (1)

- D 2951 - 95 - Rdi5ntetukve PDFDocument4 pagesD 2951 - 95 - Rdi5ntetukve PDFsusanaNo ratings yet

- B 565 - 04 - Qju2nqDocument3 pagesB 565 - 04 - Qju2nqmalika_00No ratings yet

- FIG. 4-8 Charts For OVER 4 In. (100 MM) : (A) Random Rounded Indications (See Note (1) )Document10 pagesFIG. 4-8 Charts For OVER 4 In. (100 MM) : (A) Random Rounded Indications (See Note (1) )mahmoud_allam3No ratings yet

- IPC-TM-650 Test Methods ManualDocument3 pagesIPC-TM-650 Test Methods ManualRoman MiahNo ratings yet

- D 1052 - 85 R99 - RdewntiDocument4 pagesD 1052 - 85 R99 - RdewntimanthandevNo ratings yet

- Astm A370Document3 pagesAstm A370Kenny Wong50% (2)

- MTPPT6Document31 pagesMTPPT6EunnicePanaliganNo ratings yet

- Bolt ProcedureDocument19 pagesBolt ProcedureMurugan Raja50% (2)

- Is 1608 - 2005 - 10Document1 pageIs 1608 - 2005 - 10SvapneshNo ratings yet

- Wire Cloth and Sieves For Testing PurposesDocument5 pagesWire Cloth and Sieves For Testing Purposesvuqar0979No ratings yet

- Wsdot Fop For Aashto T 23: Making and Curing Concrete Test Specimens in The FieldDocument10 pagesWsdot Fop For Aashto T 23: Making and Curing Concrete Test Specimens in The FieldJefferson Fontanilla GanadoNo ratings yet

- Internal Tearing Resistance of Paper: Standard Test Method ForDocument7 pagesInternal Tearing Resistance of Paper: Standard Test Method ForAngel ValladaresNo ratings yet

- Asme Section II A-2 Sa-592 Sa-592mDocument4 pagesAsme Section II A-2 Sa-592 Sa-592mAnonymous GhPzn1xNo ratings yet

- E190 1044228-1Document4 pagesE190 1044228-1mantra2010No ratings yet

- Tension PlacaDocument1 pageTension PlacajoseNo ratings yet

- Aggregate: Testing EquipmentsDocument12 pagesAggregate: Testing EquipmentsMorched TounsiNo ratings yet

- C426 Contraccion Bloques 2010Document6 pagesC426 Contraccion Bloques 2010Javier MendezNo ratings yet

- Standard Test Method For Measuring Thickness of Concrete Elements Using Drilled Concrete Cores1Document3 pagesStandard Test Method For Measuring Thickness of Concrete Elements Using Drilled Concrete Cores1Lupita RamirezNo ratings yet

- Sieve Analysis of Aggregate C 136Document5 pagesSieve Analysis of Aggregate C 136Bisma Masood100% (2)

- An Introduction To IZOD IMPACT Testing of Plastics: Sample PreparationDocument4 pagesAn Introduction To IZOD IMPACT Testing of Plastics: Sample PreparationYago MendozaNo ratings yet

- Euronorm 2-80Document16 pagesEuronorm 2-80Phung Tuan AnhNo ratings yet

- ASME Sec VIII Div 1 Ed 2010 471 PDFDocument9 pagesASME Sec VIII Div 1 Ed 2010 471 PDFStephen Maloba100% (1)

- D 1632 - 96Document6 pagesD 1632 - 96realchicNo ratings yet

- C 559Document2 pagesC 559Asep TheaNo ratings yet

- Tensile TestingDocument4 pagesTensile Testingletter_ashish4444No ratings yet

- B769Document4 pagesB769wpwmhatNo ratings yet

- Astm C131Document4 pagesAstm C131Devi Suryono ArselorNo ratings yet

- Method For Determining The Unconfined Compressive Strength of Intact Rock Core Specimens SCT39Document4 pagesMethod For Determining The Unconfined Compressive Strength of Intact Rock Core Specimens SCT39Deepak Kumar MallickNo ratings yet

- Ductility of Oriented Electrical Steel: Standard Test Method ForDocument2 pagesDuctility of Oriented Electrical Steel: Standard Test Method Fornvh202148No ratings yet

- Transactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Tests of Creosoted Timber, Paper No. 1168From EverandTransactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Tests of Creosoted Timber, Paper No. 1168No ratings yet

- PNNL 14116Document78 pagesPNNL 14116mapasabcNo ratings yet

- OCTG Running and Pulling TpsDocument11 pagesOCTG Running and Pulling Tpskaveh-bahiraeeNo ratings yet

- List of Corrosion TestsDocument1 pageList of Corrosion Testskaveh-bahiraeeNo ratings yet

- High Chromium AlloyDocument3 pagesHigh Chromium Alloykaveh-bahiraeeNo ratings yet

- Aerospace Standards NewsletterDocument9 pagesAerospace Standards Newsletterkaveh-bahiraeeNo ratings yet

- Tubular Products From Special MetalsDocument26 pagesTubular Products From Special Metalskaveh-bahiraeeNo ratings yet

- Flange Calculation Results: CloseDocument2 pagesFlange Calculation Results: Closekaveh-bahiraeeNo ratings yet

- Circulating SwagesDocument1 pageCirculating Swageskaveh-bahiraee100% (1)

- The Effect of Helium On Welding Irradiated MaterialsDocument8 pagesThe Effect of Helium On Welding Irradiated Materialskaveh-bahiraeeNo ratings yet

- WSP HoldingsDocument164 pagesWSP Holdingskaveh-bahiraeeNo ratings yet

- Bridge PlugsDocument9 pagesBridge Plugskaveh-bahiraeeNo ratings yet

- Preliminary Design of A Stainless Steel Helium Tank and Its Associated Cold Tuning System For 700 MHZ SCRF Cavities For ProtonDocument5 pagesPreliminary Design of A Stainless Steel Helium Tank and Its Associated Cold Tuning System For 700 MHZ SCRF Cavities For Protonkaveh-bahiraeeNo ratings yet

- Factory Audit Sample ReportDocument20 pagesFactory Audit Sample Reportkaveh-bahiraee100% (1)

- Floating EquipmentDocument9 pagesFloating Equipmentkaveh-bahiraeeNo ratings yet

- BSI Standards GuideDocument33 pagesBSI Standards Guidekaveh-bahiraeeNo ratings yet

- Cameron Back Pressure ValveDocument1 pageCameron Back Pressure Valvekaveh-bahiraeeNo ratings yet

- Cladding TechnologyDocument59 pagesCladding TechnologycutefrenzyNo ratings yet

- Second Edition Note: Liane Smith Phil JackmanDocument1 pageSecond Edition Note: Liane Smith Phil Jackmankaveh-bahiraeeNo ratings yet

- API Valves: A. API Gate Valves B. Mud Gate Valves C. API Plug ValvesDocument15 pagesAPI Valves: A. API Gate Valves B. Mud Gate Valves C. API Plug Valveskaveh-bahiraeeNo ratings yet

- Tension in A CordDocument4 pagesTension in A Cordkaveh-bahiraeeNo ratings yet

- TPA List Approved by POGCDocument2 pagesTPA List Approved by POGCkaveh-bahiraeeNo ratings yet

Unprotected A3702003a 5

Unprotected A3702003a 5

Uploaded by

kaveh-bahiraeeCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Unprotected A3702003a 5

Unprotected A3702003a 5

Uploaded by

kaveh-bahiraeeCopyright:

Available Formats

A 370 03a

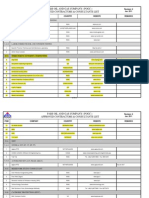

GGage length (Notes 1 and 2) WWidth (Notes 3, 5, and 6) TThickness (Note 7) RRadius of llet, min (Note 4) LOver-all length, min (Notes 2 and 8) ALength of reduced section, min BLength of grip section, min (Note 9) CWidth of grip section, approximate (Notes 4, 10, and 11)

NOTE 1For the 112-in. (40-mm) wide specimen, punch marks for measuring elongation after fracture shall be made on the at or on the edge of the specimen and within the reduced section. Either a set of nine or more punch marks 1 in. (25 mm) apart, or one or more pairs of punch marks 8 in. (200 mm) apart may be used. NOTE 2For the 12-in. (12.5-mm) wide specimen, gage marks for measuring the elongation after fracture shall be made on the 12-inch (12.5-mm) face or on the edge of the specimen and within the reduced section. Either a set of three or more marks 1.0 in. (25 mm) apart or one or more pairs of marks 2 in. (50 mm) apart may be used. NOTE 3For the three sizes of specimens, the ends of the reduced section shall not differ in width by more than 0.004, 0.002 or 0.001 in. (0.10, 0.05 or 0.025 mm), respectively. Also, there may be a gradual decrease in width from the ends to the center, but the width at either end shall not be more than 0.015 in., 0.005 in., or 0.003 in. (0.40, 0.10 or 0.08 mm), respectively, larger than the width at the center. NOTE 4For each specimen type, the radii of all llets shall be equal to each other with a tolerance of 0.05 in. (1.25 mm), and the centers of curvature of the two llets at a particular end shall be located across from each other (on a line perpendicular to the centerline) within a tolerance of 0.10 in. (2.5 mm). NOTE 5For each of the three sizes of specimens, narrower widths ( W and C) may be used when necessary. In such cases the width of the reduced section should be as large as the width of the material being tested permits; however, unless stated specically, the requirements for elongation in a product specication shall not apply when these narrower specimens are used. If the width of the material is less than W, the sides may be parallel throughout the length of the specimen. NOTE 6The specimen may be modied by making the sides parallel throughout the length of the specimen, the width and tolerances being the same as those specied above. When necessary a narrower specimen may be used, in which case the width should be as great as the width of the material being tested permits. If the width is 112 in. (38 mm) or less, the sides may be parallel throughout the length of the specimen. NOTE 7The dimension T is the thickness of the test specimen as provided for in the applicable material specications. Minimum nominal thickness of 112-in. (40-mm) wide specimens shall be 316 in. (5 mm), except as permitted by the product specication. Maximum nominal thickness of 12-in. (12.5-mm) and 14-in. (6-mm) wide specimens shall be 34 in. (19 mm) and 14 in. (6 mm), respectively. NOTE 8To aid in obtaining axial loading during testing of 14-in. (6-mm) wide specimens, the overall length should be as the material will permit. NOTE 9It is desirable, if possible, to make the length of the grip section large enough to allow the specimen to extend into the grips a distance equal to two thirds or more of the length of the grips. If the thickness of 12-in. (13-mm) wide specimens is over 38 in. (10 mm), longer grips and correspondingly longer grip sections of the specimen may be necessary to prevent failure in the grip section. NOTE 10For standard sheet-type specimens and subsize specimens the ends of the specimen shall be symmetrical with the center line of the reduced section within 0.01 and 0.005 in. (0.25 and 0.13 mm), respectively. However, for steel if the ends of the 12-in. (12.5-mm) wide specimen are symmetrical within 0.05 in. (1.0 mm) a specimen may be considered satisfactory for all but referee testing. NOTE 11For standard plate-type specimens the ends of the specimen shall be symmetrical with the center line of the reduced section within 0.25 in. (6.35 mm) except for referee testing in which case the ends of the specimen shall be symmetrical with the center line of the reduced section within 0.10 in. (2.5 mm).

FIG. 3 Rectangular Tension Test Specimens

8.4 Aging of Test SpecimensUnless otherwise specied, it shall be permissible to age tension test specimens. The timetemperature cycle employed must be such that the effects of previous processing will not be materially changed. It may be accomplished by aging at room temperature 24 to 48 h, or in

Copyright ASTM International Provided by IHS under license with ASTM No reproduction or networking permitted without license from IHS

--`-`-`,,`,,`,`,,`---

DIMENSIONS Standard Specimens Plate-Type, 112-in. Wide in. 8.00 6 0.01 112 + 18 14 18 9 3 2

12

Subsize Specimen Sheet-Type, 12-in. Wide

14

-in. Wide mm 25.0 6 0.08 6.25 6 0.05

mm 200 6 0.25 40 + 3 6 13 450 225 75 50

in. 2.000 6 0.005 0.500 6 0.010

mm 50.0 6 0.10 12.5 6 0.25

in. 1.000 6 0.003 0.250 6 0.002

8 214 2 34

12

Thickness of Material 13 200 60 50 20

4 114 114 38

14

6 100 32 32 10

shorter time at moderately elevated temperatures by boiling in water, heating in oil or in an oven. 8.5 Measurement of Dimensions of Test Specimens: 8.5.1 Standard Rectangular Tension Test SpecimensThese forms of specimens are shown in Fig. 3. To determine the

5

Not for Resale

You might also like

- C 174 .C 174M Test Method For Measuring Length of Drilled Concrete CoresDocument2 pagesC 174 .C 174M Test Method For Measuring Length of Drilled Concrete Coresjjaavenido100% (1)

- Aws B2.4-2012Document15 pagesAws B2.4-2012Vicky Gautam0% (1)

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Unprotected A3702003a 6Document1 pageUnprotected A3702003a 6kaveh-bahiraeeNo ratings yet

- Round Specimens: FIG. 5 Suggested Types of Ends For Standard Round Tension Test SpecimensDocument1 pageRound Specimens: FIG. 5 Suggested Types of Ends For Standard Round Tension Test Specimenskaveh-bahiraeeNo ratings yet

- FIG. 1 Rectangular Tension Test SpecimensDocument1 pageFIG. 1 Rectangular Tension Test SpecimensAlvaro Alexis Mendoza PradaNo ratings yet

- Tuft Height of Pile Floor Coverings: Standard Test Method ForDocument5 pagesTuft Height of Pile Floor Coverings: Standard Test Method ForJuanNo ratings yet

- Bending Stiffness of FiberboardDocument6 pagesBending Stiffness of FiberboardBobKatNo ratings yet

- Bending StiffnessDocument6 pagesBending StiffnessMark Samsel RohanNo ratings yet

- ASTM E436 Drop-Weight Tear Tests of Ferritic SteelsDocument5 pagesASTM E436 Drop-Weight Tear Tests of Ferritic SteelsledaswanNo ratings yet

- Astm C490Document5 pagesAstm C490Horacio ApolayoNo ratings yet

- 61.0 % of The: 6. Test SpecimensDocument2 pages61.0 % of The: 6. Test SpecimensluthfibomentNo ratings yet

- Tensile Calculation PDFDocument2 pagesTensile Calculation PDFWendimagen Meshesha FantaNo ratings yet

- B 565 - 94 R00 - Qju2ns05nfiwmaDocument3 pagesB 565 - 94 R00 - Qju2ns05nfiwmamalika_00No ratings yet

- D 2444 - 99 Rdi0ndqDocument8 pagesD 2444 - 99 Rdi0ndqHumberto GutierrezNo ratings yet

- Engineering Materials Exp. - 5Document10 pagesEngineering Materials Exp. - 5Nahid SultanNo ratings yet

- Astm D 1002Document5 pagesAstm D 1002Aisya IbrahimNo ratings yet

- ASTM D 2491 - Particulas Chatas y AlargadasDocument2 pagesASTM D 2491 - Particulas Chatas y AlargadasJuan Alex Alvarado RomeroNo ratings yet

- E190.29610 AstmDocument4 pagesE190.29610 AstmMassab JunaidNo ratings yet

- Press q3 Ass 2Document5 pagesPress q3 Ass 2Arslan RaoNo ratings yet

- Ensayo de Doblez GuiadoDocument4 pagesEnsayo de Doblez GuiadoJulio Alejandro GómezNo ratings yet

- Guided Bend Test For Ductility of WeldsDocument3 pagesGuided Bend Test For Ductility of WeldsErlinawati Bintu SupiyoNo ratings yet

- Wsdot Fop For Aashto T 23: 1. ScopeDocument10 pagesWsdot Fop For Aashto T 23: 1. ScopeEinstein JeboneNo ratings yet

- Astm d412 1968 PDFDocument13 pagesAstm d412 1968 PDFHassan Mehmood100% (1)

- D 2951 - 95 - Rdi5ntetukve PDFDocument4 pagesD 2951 - 95 - Rdi5ntetukve PDFsusanaNo ratings yet

- B 565 - 04 - Qju2nqDocument3 pagesB 565 - 04 - Qju2nqmalika_00No ratings yet

- FIG. 4-8 Charts For OVER 4 In. (100 MM) : (A) Random Rounded Indications (See Note (1) )Document10 pagesFIG. 4-8 Charts For OVER 4 In. (100 MM) : (A) Random Rounded Indications (See Note (1) )mahmoud_allam3No ratings yet

- IPC-TM-650 Test Methods ManualDocument3 pagesIPC-TM-650 Test Methods ManualRoman MiahNo ratings yet

- D 1052 - 85 R99 - RdewntiDocument4 pagesD 1052 - 85 R99 - RdewntimanthandevNo ratings yet

- Astm A370Document3 pagesAstm A370Kenny Wong50% (2)

- MTPPT6Document31 pagesMTPPT6EunnicePanaliganNo ratings yet

- Bolt ProcedureDocument19 pagesBolt ProcedureMurugan Raja50% (2)

- Is 1608 - 2005 - 10Document1 pageIs 1608 - 2005 - 10SvapneshNo ratings yet

- Wire Cloth and Sieves For Testing PurposesDocument5 pagesWire Cloth and Sieves For Testing Purposesvuqar0979No ratings yet

- Wsdot Fop For Aashto T 23: Making and Curing Concrete Test Specimens in The FieldDocument10 pagesWsdot Fop For Aashto T 23: Making and Curing Concrete Test Specimens in The FieldJefferson Fontanilla GanadoNo ratings yet

- Internal Tearing Resistance of Paper: Standard Test Method ForDocument7 pagesInternal Tearing Resistance of Paper: Standard Test Method ForAngel ValladaresNo ratings yet

- Asme Section II A-2 Sa-592 Sa-592mDocument4 pagesAsme Section II A-2 Sa-592 Sa-592mAnonymous GhPzn1xNo ratings yet

- E190 1044228-1Document4 pagesE190 1044228-1mantra2010No ratings yet

- Tension PlacaDocument1 pageTension PlacajoseNo ratings yet

- Aggregate: Testing EquipmentsDocument12 pagesAggregate: Testing EquipmentsMorched TounsiNo ratings yet

- C426 Contraccion Bloques 2010Document6 pagesC426 Contraccion Bloques 2010Javier MendezNo ratings yet

- Standard Test Method For Measuring Thickness of Concrete Elements Using Drilled Concrete Cores1Document3 pagesStandard Test Method For Measuring Thickness of Concrete Elements Using Drilled Concrete Cores1Lupita RamirezNo ratings yet

- Sieve Analysis of Aggregate C 136Document5 pagesSieve Analysis of Aggregate C 136Bisma Masood100% (2)

- An Introduction To IZOD IMPACT Testing of Plastics: Sample PreparationDocument4 pagesAn Introduction To IZOD IMPACT Testing of Plastics: Sample PreparationYago MendozaNo ratings yet

- Euronorm 2-80Document16 pagesEuronorm 2-80Phung Tuan AnhNo ratings yet

- ASME Sec VIII Div 1 Ed 2010 471 PDFDocument9 pagesASME Sec VIII Div 1 Ed 2010 471 PDFStephen Maloba100% (1)

- D 1632 - 96Document6 pagesD 1632 - 96realchicNo ratings yet

- C 559Document2 pagesC 559Asep TheaNo ratings yet

- Tensile TestingDocument4 pagesTensile Testingletter_ashish4444No ratings yet

- B769Document4 pagesB769wpwmhatNo ratings yet

- Astm C131Document4 pagesAstm C131Devi Suryono ArselorNo ratings yet

- Method For Determining The Unconfined Compressive Strength of Intact Rock Core Specimens SCT39Document4 pagesMethod For Determining The Unconfined Compressive Strength of Intact Rock Core Specimens SCT39Deepak Kumar MallickNo ratings yet

- Ductility of Oriented Electrical Steel: Standard Test Method ForDocument2 pagesDuctility of Oriented Electrical Steel: Standard Test Method Fornvh202148No ratings yet

- Transactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Tests of Creosoted Timber, Paper No. 1168From EverandTransactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Tests of Creosoted Timber, Paper No. 1168No ratings yet

- PNNL 14116Document78 pagesPNNL 14116mapasabcNo ratings yet

- OCTG Running and Pulling TpsDocument11 pagesOCTG Running and Pulling Tpskaveh-bahiraeeNo ratings yet

- List of Corrosion TestsDocument1 pageList of Corrosion Testskaveh-bahiraeeNo ratings yet

- High Chromium AlloyDocument3 pagesHigh Chromium Alloykaveh-bahiraeeNo ratings yet

- Aerospace Standards NewsletterDocument9 pagesAerospace Standards Newsletterkaveh-bahiraeeNo ratings yet

- Tubular Products From Special MetalsDocument26 pagesTubular Products From Special Metalskaveh-bahiraeeNo ratings yet

- Flange Calculation Results: CloseDocument2 pagesFlange Calculation Results: Closekaveh-bahiraeeNo ratings yet

- Circulating SwagesDocument1 pageCirculating Swageskaveh-bahiraee100% (1)

- The Effect of Helium On Welding Irradiated MaterialsDocument8 pagesThe Effect of Helium On Welding Irradiated Materialskaveh-bahiraeeNo ratings yet

- WSP HoldingsDocument164 pagesWSP Holdingskaveh-bahiraeeNo ratings yet

- Bridge PlugsDocument9 pagesBridge Plugskaveh-bahiraeeNo ratings yet

- Preliminary Design of A Stainless Steel Helium Tank and Its Associated Cold Tuning System For 700 MHZ SCRF Cavities For ProtonDocument5 pagesPreliminary Design of A Stainless Steel Helium Tank and Its Associated Cold Tuning System For 700 MHZ SCRF Cavities For Protonkaveh-bahiraeeNo ratings yet

- Factory Audit Sample ReportDocument20 pagesFactory Audit Sample Reportkaveh-bahiraee100% (1)

- Floating EquipmentDocument9 pagesFloating Equipmentkaveh-bahiraeeNo ratings yet

- BSI Standards GuideDocument33 pagesBSI Standards Guidekaveh-bahiraeeNo ratings yet

- Cameron Back Pressure ValveDocument1 pageCameron Back Pressure Valvekaveh-bahiraeeNo ratings yet

- Cladding TechnologyDocument59 pagesCladding TechnologycutefrenzyNo ratings yet

- Second Edition Note: Liane Smith Phil JackmanDocument1 pageSecond Edition Note: Liane Smith Phil Jackmankaveh-bahiraeeNo ratings yet

- API Valves: A. API Gate Valves B. Mud Gate Valves C. API Plug ValvesDocument15 pagesAPI Valves: A. API Gate Valves B. Mud Gate Valves C. API Plug Valveskaveh-bahiraeeNo ratings yet

- Tension in A CordDocument4 pagesTension in A Cordkaveh-bahiraeeNo ratings yet

- TPA List Approved by POGCDocument2 pagesTPA List Approved by POGCkaveh-bahiraeeNo ratings yet