Professional Documents

Culture Documents

How To Read The Metric Vernier Caliper: MAIN (Stationary) BAR SCALE MM

How To Read The Metric Vernier Caliper: MAIN (Stationary) BAR SCALE MM

Uploaded by

Lighto LastoCopyright:

Available Formats

You might also like

- Lab Report 4 - Energy and MotionDocument6 pagesLab Report 4 - Energy and MotionDawood SulemanNo ratings yet

- The Digital Light Meter - hs1330-Hs1323-Hs1010-Instruction ManualDocument16 pagesThe Digital Light Meter - hs1330-Hs1323-Hs1010-Instruction Manualmtim36050% (2)

- Servomex 1440D ManualDocument24 pagesServomex 1440D ManualBill BrighamNo ratings yet

- Vernier CaliperDocument60 pagesVernier CalipervinayakcgmailNo ratings yet

- Mixing Coloured LightDocument2 pagesMixing Coloured LightPowerhouse MuseumNo ratings yet

- Byzantium Between The Ottomans and The LatinsDocument374 pagesByzantium Between The Ottomans and The Latinszgcabo100% (2)

- HART Transmitter Calibration From Cole-Parmer PDFDocument9 pagesHART Transmitter Calibration From Cole-Parmer PDFTuan TranNo ratings yet

- Sensor - Types of SensorDocument4 pagesSensor - Types of SensorAshish AgarwalNo ratings yet

- 3 - Sensor and ActuatorsDocument31 pages3 - Sensor and Actuatorsmehulprajapati1661No ratings yet

- Robotics SensorsDocument57 pagesRobotics Sensorsjoseph.morcoNo ratings yet

- Physics I Problems PDFDocument1 pagePhysics I Problems PDFbosschellenNo ratings yet

- Bio Physics - EquilibriumDocument9 pagesBio Physics - Equilibriumjeru2003No ratings yet

- How To Use A Dial Caliper: Activity Sheet 6Document5 pagesHow To Use A Dial Caliper: Activity Sheet 6Anoj pahathkumburaNo ratings yet

- Liquid Sensor Level TIDocument23 pagesLiquid Sensor Level TIDanielViasusNo ratings yet

- Instrumentation and Process Control-2Document15 pagesInstrumentation and Process Control-2Muhammad TalhaNo ratings yet

- Additive and Subtractive Colour Schemebuilding Services - 2sDocument5 pagesAdditive and Subtractive Colour Schemebuilding Services - 2sDharaniSKarthikNo ratings yet

- FR11 IntangibleNCA&Impairment (Stud)Document21 pagesFR11 IntangibleNCA&Impairment (Stud)duong duongNo ratings yet

- Laser FunDocument4 pagesLaser FunWarhammer13No ratings yet

- Kahoot TutorialsDocument20 pagesKahoot Tutorialsapi-217894426100% (2)

- ServiceDocument160 pagesServicemarian1_work100% (1)

- SCERT Kerala State Syllabus 6th Standard Maths Textbooks English Medium Part 2Document87 pagesSCERT Kerala State Syllabus 6th Standard Maths Textbooks English Medium Part 2Gowthamy SNo ratings yet

- Mathematics Stage 3A 3B Calc Free 2012Document16 pagesMathematics Stage 3A 3B Calc Free 2012gragon.07No ratings yet

- Digital SignaturesDocument35 pagesDigital SignaturesRamalingam ChandrasekharanNo ratings yet

- DombrowskiDocument446 pagesDombrowskiSheila DhengaleNo ratings yet

- Teacher's Starter Guide To Kahoot!Document11 pagesTeacher's Starter Guide To Kahoot!Dane CachiNo ratings yet

- Configuring Robot MovementDocument12 pagesConfiguring Robot MovementJlNo ratings yet

- 1080P Security: Electronics ComponentsDocument8 pages1080P Security: Electronics ComponentsRadio PartsNo ratings yet

- Digitalsignatures 100714211316 Phpapp02Document37 pagesDigitalsignatures 100714211316 Phpapp02Jahnavi BopudiNo ratings yet

- Moving StraightDocument15 pagesMoving StraightJlNo ratings yet

- Wiha Catalogue 2010 - 2012Document165 pagesWiha Catalogue 2010 - 2012Sasa Ristic100% (1)

- Respiratory Physiology PDFDocument4 pagesRespiratory Physiology PDFDiego AristizabalNo ratings yet

- Digital Signatures: CCA Controller of Certifying AuthoritiesDocument18 pagesDigital Signatures: CCA Controller of Certifying AuthoritieshemaNo ratings yet

- 10 USB Projects With The Leonardo - 30 Arduino Projects For The Evil Genius - Second EditionDocument8 pages10 USB Projects With The Leonardo - 30 Arduino Projects For The Evil Genius - Second EditionMihai BogdanNo ratings yet

- Welcome: at TheDocument32 pagesWelcome: at TheRob WillestoneNo ratings yet

- 001-Plumbing Tools PDFDocument26 pages001-Plumbing Tools PDFcha yokNo ratings yet

- Basic Voltmeter Use - Basic Electricity WorksheetsDocument10 pagesBasic Voltmeter Use - Basic Electricity WorksheetsMrsriyansyahNo ratings yet

- Natural FrequencyDocument4 pagesNatural FrequencyPRASANTH G KRISHNANNo ratings yet

- Rectilinear Motion PDFDocument16 pagesRectilinear Motion PDFcheng linNo ratings yet

- Riments 30 New ExpePlate Pages 94 FFDocument310 pagesRiments 30 New ExpePlate Pages 94 FFphywe0% (1)

- Rokkaku Jap Kite FightDocument1 pageRokkaku Jap Kite FighttononoinkNo ratings yet

- 570a PDFDocument61 pages570a PDFLyunlyunNo ratings yet

- Robotics in Space WorksheetDocument5 pagesRobotics in Space WorksheetCasper LuNo ratings yet

- Daisy 2021 Product CatalogDocument20 pagesDaisy 2021 Product Catalogwatch_sutNo ratings yet

- Experiment With Engineering Science With 30 Fun ProjectsDocument194 pagesExperiment With Engineering Science With 30 Fun ProjectsmatijahajekNo ratings yet

- Foundation Olympiad: Com - Bmatalent Sample)Document37 pagesFoundation Olympiad: Com - Bmatalent Sample)Rajesh mishraNo ratings yet

- MachinesAndMechanisms - Advancing With Simple and Powered Machines - 1.0 - en US PDFDocument186 pagesMachinesAndMechanisms - Advancing With Simple and Powered Machines - 1.0 - en US PDFTudor MinascurtaNo ratings yet

- Ventilator Basics NotesDocument6 pagesVentilator Basics Noteskgy5926No ratings yet

- Tinkercad Keyboard Shortcuts2Document1 pageTinkercad Keyboard Shortcuts2Daoui AchrafNo ratings yet

- Malerspace ToolsDocument34 pagesMalerspace ToolsEdson LMNo ratings yet

- DIY Squid HatDocument22 pagesDIY Squid Hatkailani_ishitaNo ratings yet

- Pt100 Temperature SensorDocument4 pagesPt100 Temperature SensorAreez MalikNo ratings yet

- Arduino Electronics 101Document12 pagesArduino Electronics 101swoneraNo ratings yet

- Department of Physics Laboratory Manual For Nuclear Physics (Phys2052)Document132 pagesDepartment of Physics Laboratory Manual For Nuclear Physics (Phys2052)Tadesse AbateNo ratings yet

- 570 Portable Oxygen Analyser: Instruction ManualDocument61 pages570 Portable Oxygen Analyser: Instruction ManualJennie CardozoNo ratings yet

- NXTway-GS Building InstructionsDocument17 pagesNXTway-GS Building InstructionsVinay SandeepNo ratings yet

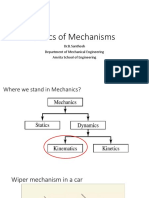

- Basics of Mechanisms: Dr.B.Santhosh Department of Mechanical Engineering Amrita School of EngineeringDocument34 pagesBasics of Mechanisms: Dr.B.Santhosh Department of Mechanical Engineering Amrita School of Engineeringkishore sNo ratings yet

- BIOMEDICALDocument21 pagesBIOMEDICALSyed Farhan ShahNo ratings yet

- How To Read The Metric Vernier Caliper: MAIN (Stationary) BAR SCALE MMDocument1 pageHow To Read The Metric Vernier Caliper: MAIN (Stationary) BAR SCALE MMTuhinVariaNo ratings yet

- 2.1.4. SievesDocument1 page2.1.4. SievesTrung Dương ĐứcNo ratings yet

- Cores 2Document20 pagesCores 2Mileta SindjelicNo ratings yet

- BMW Servisni IntervaliDocument3 pagesBMW Servisni IntervalizgcaboNo ratings yet

- Understanding Ottoman Heritage in BosniaDocument28 pagesUnderstanding Ottoman Heritage in BosniazgcaboNo ratings yet

- Fidic - Power Point PresentationDocument46 pagesFidic - Power Point PresentationDragan Gligorov100% (1)

- Art of The 20th CenturyDocument3 pagesArt of The 20th CenturyzgcaboNo ratings yet

- 中论Document112 pages中论张晓亮No ratings yet

- Scala AccesoriesDocument27 pagesScala AccesoriesZiggy BussyNo ratings yet

- The Aravind Eye Hospital, Madurai, India: in Service For SightDocument4 pagesThe Aravind Eye Hospital, Madurai, India: in Service For Sighttirth viraNo ratings yet

- Rational Expressions WorksheetDocument4 pagesRational Expressions WorksheetSishira PattanNo ratings yet

- Food Contact Surfaces 2Document27 pagesFood Contact Surfaces 2AliNo ratings yet

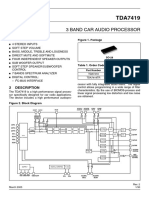

- Tda 7419Document30 pagesTda 7419heviandriasNo ratings yet

- Book Reviews: Supplemental Damping and Seismic Isolation by C. ChristopoulosDocument1 pageBook Reviews: Supplemental Damping and Seismic Isolation by C. ChristopoulosLuca AcetoNo ratings yet

- Interest InventoriesDocument7 pagesInterest Inventoriesandrewwilliampalileo@yahoocomNo ratings yet

- Progress in The Development of A Reynolds-Stress Turbulence ClosureDocument30 pagesProgress in The Development of A Reynolds-Stress Turbulence ClosureMutiaRezaNo ratings yet

- The Autism Diagnostic Observation Schedule, Module 4: Application of The Revised Algorithms in An Independent, Well-Defined, Dutch Sample (N 93)Document11 pagesThe Autism Diagnostic Observation Schedule, Module 4: Application of The Revised Algorithms in An Independent, Well-Defined, Dutch Sample (N 93)Laura CamusNo ratings yet

- Recruitment & Selection Reliance Jio Full Report - 100 Page MANU SHARMA MBA 3rd SEMDocument102 pagesRecruitment & Selection Reliance Jio Full Report - 100 Page MANU SHARMA MBA 3rd SEMImpression Graphics100% (4)

- Russound RS232 Hex Codes v1 - 00 - 7Document19 pagesRussound RS232 Hex Codes v1 - 00 - 7ceinstallerNo ratings yet

- Sccan Resourcemanual Allpages Update v2Document154 pagesSccan Resourcemanual Allpages Update v2SiangNo ratings yet

- Pipe Pressure Drope ASEREHDocument3 pagesPipe Pressure Drope ASEREHSenghou MeasNo ratings yet

- 1000mm BOPP Tape Coating Machine Two Color Printing 40 Speed TangerangDocument6 pages1000mm BOPP Tape Coating Machine Two Color Printing 40 Speed TangerangJaja JamaludinNo ratings yet

- Mini Capstone Final Project Implementation and AssessmentDocument8 pagesMini Capstone Final Project Implementation and AssessmentSodium ChlorideNo ratings yet

- TCS AIP Take Home AssignmentDocument16 pagesTCS AIP Take Home AssignmentShruthiSAthreyaNo ratings yet

- The EI SLP Therapy BundleDocument14 pagesThe EI SLP Therapy BundlelevyNo ratings yet

- 5 6Document3 pages5 6Giorgi VasadzeNo ratings yet

- Chapter 04Document37 pagesChapter 04BLESSEDNo ratings yet

- CH 12Document31 pagesCH 12asin12336No ratings yet

- PHOTOCOPIABLE Gateway B1 Workbook AnswerDocument2 pagesPHOTOCOPIABLE Gateway B1 Workbook Answerhaler kolokNo ratings yet

- OrangeHRM FRS NewDocument171 pagesOrangeHRM FRS NewAmar DeoNo ratings yet

- PDF Sermon Notes - The Temptation of Christ (Luke 4.1-13)Document5 pagesPDF Sermon Notes - The Temptation of Christ (Luke 4.1-13)fergie45315No ratings yet

- Stamens PDFDocument10 pagesStamens PDFAmeya KannamwarNo ratings yet

- Israel's Agriculture BookletDocument58 pagesIsrael's Agriculture BookletShrikant KajaleNo ratings yet

- Week 17 2nd Bondy SchoolDocument4 pagesWeek 17 2nd Bondy SchoolOswaldo Coronel UlloaNo ratings yet

- Gr11 Mock Exam Schedule 2024Document13 pagesGr11 Mock Exam Schedule 2024potrillo0330No ratings yet

- Healthy Pregnancy Meals:: LAMB Doula and Birthing CenterDocument16 pagesHealthy Pregnancy Meals:: LAMB Doula and Birthing Centerapi-44273750No ratings yet

- Temario Final Ingles 5°b PrimariaDocument1 pageTemario Final Ingles 5°b PrimariainstitutovalladolidNo ratings yet

How To Read The Metric Vernier Caliper: MAIN (Stationary) BAR SCALE MM

How To Read The Metric Vernier Caliper: MAIN (Stationary) BAR SCALE MM

Uploaded by

Lighto LastoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

How To Read The Metric Vernier Caliper: MAIN (Stationary) BAR SCALE MM

How To Read The Metric Vernier Caliper: MAIN (Stationary) BAR SCALE MM

Uploaded by

Lighto LastoCopyright:

Available Formats

HOW TO READ THE METRIC VERNIER CALIPER

1. READ THE VALUE OF THE MAIN (stationary) BAR SCALE WHICH IS JUST TO THE LEFT AND ABOVE THE '0' ZERO READING ON THE VERNIER (moveable) SCALE. VALUES WILL BE IN mm 2. THEN ADD THE VALUE ON THE VERNIER (moveable) SCALE WHICH EXACTLY COINCIDES WITH A LINE ON THE MAIN (stationary) BAR SCALE. VALUES WILL BE IN 0.1 OR 0.15 mm

Internal measurement, or if threads = minor diameter Depth measurement

0 10 20 30 40

50

60

70

80

90

100

110

120

130

140

150

0.05 mm

0 1 2 3 4 5 6 7 8 9 10

Value on main bar scale = 12 + Value on vernier scale = 0.3 + Total = 12.3 mm

0

MAIN (stationary) BAR SCALE

10 20 30

mm

40

External measurement, or if threads = major diameter value reading from main bar scale

0 1 2 3 4 5 6 7 8 9 10

VERNIER (moveable) SCALE

value from vernier scale which EXACTLY COINCIDES with a line on the main bar scale

1. SELECT THE INDIVIDUAL THREAD GAGE FROM THE SET WHICH EXACTLY MATCHES THE PITCH OR NUMBER OF THREADS PER INCH ON THE ITEM TO BE MEASURED. 2. NOTE THE MARKING ON THE INDIVIDUAL GAGE. IT MAY BE IN METRIC PITCH (P) OR IN THREADS PER INCH (TPI) Example: If the major 1.25 mm READING ON 1.25 diameter value is 8 mm LEAF FROM PITCH and the pitch is 1.25 mm GAGE SET then the thread is: M8 x 1.25 P

METRIC PITCH (P) IS THE DISTANCE IN mm FROM THE CENTER POINT OF ONE THREAD TO THE CORRESPONDING POINT ON THE NEXT THREAD.

HOW TO USE A THREAD PITCH GAGE

A helpful formula is: 25.4 TPI = P

READ THE VALUES FROM THE VERNIER CALIPER, AND THE DATA FROM THE THREAD PITCH GAGE. THEN DETERMINE THE SIZE AND IDENTITY OF THE THREAD (metric, USA, or British) FROM THE THREAD IDENTIFICATION CHART DATA.

Note: If you are measuring an internal (female) thread; then this yields the minor diameter of the item. The necessary (external male) major diameter (OD) value will have to be calculated. See the instructions below. 1. Multiply the factor value (F) of 1.0825 by the pitch (P) which yields result (R). (F x P = R) Example: 1.0825(F) x 1.75(P) = 1.8944(R) 2. Add the carefully measured value for the internal diameter (ID) to the result (R) which yields the nominal major diameter (OD) of the internal thread. (ID + R = OD) Example: measured value 10.036 (ID) + result (R) 1.8944 = approximate nominal major diameter (OD) 12.

copyright 1997 md metrics

filnam: calipuse.cdr/gif

You might also like

- Lab Report 4 - Energy and MotionDocument6 pagesLab Report 4 - Energy and MotionDawood SulemanNo ratings yet

- The Digital Light Meter - hs1330-Hs1323-Hs1010-Instruction ManualDocument16 pagesThe Digital Light Meter - hs1330-Hs1323-Hs1010-Instruction Manualmtim36050% (2)

- Servomex 1440D ManualDocument24 pagesServomex 1440D ManualBill BrighamNo ratings yet

- Vernier CaliperDocument60 pagesVernier CalipervinayakcgmailNo ratings yet

- Mixing Coloured LightDocument2 pagesMixing Coloured LightPowerhouse MuseumNo ratings yet

- Byzantium Between The Ottomans and The LatinsDocument374 pagesByzantium Between The Ottomans and The Latinszgcabo100% (2)

- HART Transmitter Calibration From Cole-Parmer PDFDocument9 pagesHART Transmitter Calibration From Cole-Parmer PDFTuan TranNo ratings yet

- Sensor - Types of SensorDocument4 pagesSensor - Types of SensorAshish AgarwalNo ratings yet

- 3 - Sensor and ActuatorsDocument31 pages3 - Sensor and Actuatorsmehulprajapati1661No ratings yet

- Robotics SensorsDocument57 pagesRobotics Sensorsjoseph.morcoNo ratings yet

- Physics I Problems PDFDocument1 pagePhysics I Problems PDFbosschellenNo ratings yet

- Bio Physics - EquilibriumDocument9 pagesBio Physics - Equilibriumjeru2003No ratings yet

- How To Use A Dial Caliper: Activity Sheet 6Document5 pagesHow To Use A Dial Caliper: Activity Sheet 6Anoj pahathkumburaNo ratings yet

- Liquid Sensor Level TIDocument23 pagesLiquid Sensor Level TIDanielViasusNo ratings yet

- Instrumentation and Process Control-2Document15 pagesInstrumentation and Process Control-2Muhammad TalhaNo ratings yet

- Additive and Subtractive Colour Schemebuilding Services - 2sDocument5 pagesAdditive and Subtractive Colour Schemebuilding Services - 2sDharaniSKarthikNo ratings yet

- FR11 IntangibleNCA&Impairment (Stud)Document21 pagesFR11 IntangibleNCA&Impairment (Stud)duong duongNo ratings yet

- Laser FunDocument4 pagesLaser FunWarhammer13No ratings yet

- Kahoot TutorialsDocument20 pagesKahoot Tutorialsapi-217894426100% (2)

- ServiceDocument160 pagesServicemarian1_work100% (1)

- SCERT Kerala State Syllabus 6th Standard Maths Textbooks English Medium Part 2Document87 pagesSCERT Kerala State Syllabus 6th Standard Maths Textbooks English Medium Part 2Gowthamy SNo ratings yet

- Mathematics Stage 3A 3B Calc Free 2012Document16 pagesMathematics Stage 3A 3B Calc Free 2012gragon.07No ratings yet

- Digital SignaturesDocument35 pagesDigital SignaturesRamalingam ChandrasekharanNo ratings yet

- DombrowskiDocument446 pagesDombrowskiSheila DhengaleNo ratings yet

- Teacher's Starter Guide To Kahoot!Document11 pagesTeacher's Starter Guide To Kahoot!Dane CachiNo ratings yet

- Configuring Robot MovementDocument12 pagesConfiguring Robot MovementJlNo ratings yet

- 1080P Security: Electronics ComponentsDocument8 pages1080P Security: Electronics ComponentsRadio PartsNo ratings yet

- Digitalsignatures 100714211316 Phpapp02Document37 pagesDigitalsignatures 100714211316 Phpapp02Jahnavi BopudiNo ratings yet

- Moving StraightDocument15 pagesMoving StraightJlNo ratings yet

- Wiha Catalogue 2010 - 2012Document165 pagesWiha Catalogue 2010 - 2012Sasa Ristic100% (1)

- Respiratory Physiology PDFDocument4 pagesRespiratory Physiology PDFDiego AristizabalNo ratings yet

- Digital Signatures: CCA Controller of Certifying AuthoritiesDocument18 pagesDigital Signatures: CCA Controller of Certifying AuthoritieshemaNo ratings yet

- 10 USB Projects With The Leonardo - 30 Arduino Projects For The Evil Genius - Second EditionDocument8 pages10 USB Projects With The Leonardo - 30 Arduino Projects For The Evil Genius - Second EditionMihai BogdanNo ratings yet

- Welcome: at TheDocument32 pagesWelcome: at TheRob WillestoneNo ratings yet

- 001-Plumbing Tools PDFDocument26 pages001-Plumbing Tools PDFcha yokNo ratings yet

- Basic Voltmeter Use - Basic Electricity WorksheetsDocument10 pagesBasic Voltmeter Use - Basic Electricity WorksheetsMrsriyansyahNo ratings yet

- Natural FrequencyDocument4 pagesNatural FrequencyPRASANTH G KRISHNANNo ratings yet

- Rectilinear Motion PDFDocument16 pagesRectilinear Motion PDFcheng linNo ratings yet

- Riments 30 New ExpePlate Pages 94 FFDocument310 pagesRiments 30 New ExpePlate Pages 94 FFphywe0% (1)

- Rokkaku Jap Kite FightDocument1 pageRokkaku Jap Kite FighttononoinkNo ratings yet

- 570a PDFDocument61 pages570a PDFLyunlyunNo ratings yet

- Robotics in Space WorksheetDocument5 pagesRobotics in Space WorksheetCasper LuNo ratings yet

- Daisy 2021 Product CatalogDocument20 pagesDaisy 2021 Product Catalogwatch_sutNo ratings yet

- Experiment With Engineering Science With 30 Fun ProjectsDocument194 pagesExperiment With Engineering Science With 30 Fun ProjectsmatijahajekNo ratings yet

- Foundation Olympiad: Com - Bmatalent Sample)Document37 pagesFoundation Olympiad: Com - Bmatalent Sample)Rajesh mishraNo ratings yet

- MachinesAndMechanisms - Advancing With Simple and Powered Machines - 1.0 - en US PDFDocument186 pagesMachinesAndMechanisms - Advancing With Simple and Powered Machines - 1.0 - en US PDFTudor MinascurtaNo ratings yet

- Ventilator Basics NotesDocument6 pagesVentilator Basics Noteskgy5926No ratings yet

- Tinkercad Keyboard Shortcuts2Document1 pageTinkercad Keyboard Shortcuts2Daoui AchrafNo ratings yet

- Malerspace ToolsDocument34 pagesMalerspace ToolsEdson LMNo ratings yet

- DIY Squid HatDocument22 pagesDIY Squid Hatkailani_ishitaNo ratings yet

- Pt100 Temperature SensorDocument4 pagesPt100 Temperature SensorAreez MalikNo ratings yet

- Arduino Electronics 101Document12 pagesArduino Electronics 101swoneraNo ratings yet

- Department of Physics Laboratory Manual For Nuclear Physics (Phys2052)Document132 pagesDepartment of Physics Laboratory Manual For Nuclear Physics (Phys2052)Tadesse AbateNo ratings yet

- 570 Portable Oxygen Analyser: Instruction ManualDocument61 pages570 Portable Oxygen Analyser: Instruction ManualJennie CardozoNo ratings yet

- NXTway-GS Building InstructionsDocument17 pagesNXTway-GS Building InstructionsVinay SandeepNo ratings yet

- Basics of Mechanisms: Dr.B.Santhosh Department of Mechanical Engineering Amrita School of EngineeringDocument34 pagesBasics of Mechanisms: Dr.B.Santhosh Department of Mechanical Engineering Amrita School of Engineeringkishore sNo ratings yet

- BIOMEDICALDocument21 pagesBIOMEDICALSyed Farhan ShahNo ratings yet

- How To Read The Metric Vernier Caliper: MAIN (Stationary) BAR SCALE MMDocument1 pageHow To Read The Metric Vernier Caliper: MAIN (Stationary) BAR SCALE MMTuhinVariaNo ratings yet

- 2.1.4. SievesDocument1 page2.1.4. SievesTrung Dương ĐứcNo ratings yet

- Cores 2Document20 pagesCores 2Mileta SindjelicNo ratings yet

- BMW Servisni IntervaliDocument3 pagesBMW Servisni IntervalizgcaboNo ratings yet

- Understanding Ottoman Heritage in BosniaDocument28 pagesUnderstanding Ottoman Heritage in BosniazgcaboNo ratings yet

- Fidic - Power Point PresentationDocument46 pagesFidic - Power Point PresentationDragan Gligorov100% (1)

- Art of The 20th CenturyDocument3 pagesArt of The 20th CenturyzgcaboNo ratings yet

- 中论Document112 pages中论张晓亮No ratings yet

- Scala AccesoriesDocument27 pagesScala AccesoriesZiggy BussyNo ratings yet

- The Aravind Eye Hospital, Madurai, India: in Service For SightDocument4 pagesThe Aravind Eye Hospital, Madurai, India: in Service For Sighttirth viraNo ratings yet

- Rational Expressions WorksheetDocument4 pagesRational Expressions WorksheetSishira PattanNo ratings yet

- Food Contact Surfaces 2Document27 pagesFood Contact Surfaces 2AliNo ratings yet

- Tda 7419Document30 pagesTda 7419heviandriasNo ratings yet

- Book Reviews: Supplemental Damping and Seismic Isolation by C. ChristopoulosDocument1 pageBook Reviews: Supplemental Damping and Seismic Isolation by C. ChristopoulosLuca AcetoNo ratings yet

- Interest InventoriesDocument7 pagesInterest Inventoriesandrewwilliampalileo@yahoocomNo ratings yet

- Progress in The Development of A Reynolds-Stress Turbulence ClosureDocument30 pagesProgress in The Development of A Reynolds-Stress Turbulence ClosureMutiaRezaNo ratings yet

- The Autism Diagnostic Observation Schedule, Module 4: Application of The Revised Algorithms in An Independent, Well-Defined, Dutch Sample (N 93)Document11 pagesThe Autism Diagnostic Observation Schedule, Module 4: Application of The Revised Algorithms in An Independent, Well-Defined, Dutch Sample (N 93)Laura CamusNo ratings yet

- Recruitment & Selection Reliance Jio Full Report - 100 Page MANU SHARMA MBA 3rd SEMDocument102 pagesRecruitment & Selection Reliance Jio Full Report - 100 Page MANU SHARMA MBA 3rd SEMImpression Graphics100% (4)

- Russound RS232 Hex Codes v1 - 00 - 7Document19 pagesRussound RS232 Hex Codes v1 - 00 - 7ceinstallerNo ratings yet

- Sccan Resourcemanual Allpages Update v2Document154 pagesSccan Resourcemanual Allpages Update v2SiangNo ratings yet

- Pipe Pressure Drope ASEREHDocument3 pagesPipe Pressure Drope ASEREHSenghou MeasNo ratings yet

- 1000mm BOPP Tape Coating Machine Two Color Printing 40 Speed TangerangDocument6 pages1000mm BOPP Tape Coating Machine Two Color Printing 40 Speed TangerangJaja JamaludinNo ratings yet

- Mini Capstone Final Project Implementation and AssessmentDocument8 pagesMini Capstone Final Project Implementation and AssessmentSodium ChlorideNo ratings yet

- TCS AIP Take Home AssignmentDocument16 pagesTCS AIP Take Home AssignmentShruthiSAthreyaNo ratings yet

- The EI SLP Therapy BundleDocument14 pagesThe EI SLP Therapy BundlelevyNo ratings yet

- 5 6Document3 pages5 6Giorgi VasadzeNo ratings yet

- Chapter 04Document37 pagesChapter 04BLESSEDNo ratings yet

- CH 12Document31 pagesCH 12asin12336No ratings yet

- PHOTOCOPIABLE Gateway B1 Workbook AnswerDocument2 pagesPHOTOCOPIABLE Gateway B1 Workbook Answerhaler kolokNo ratings yet

- OrangeHRM FRS NewDocument171 pagesOrangeHRM FRS NewAmar DeoNo ratings yet

- PDF Sermon Notes - The Temptation of Christ (Luke 4.1-13)Document5 pagesPDF Sermon Notes - The Temptation of Christ (Luke 4.1-13)fergie45315No ratings yet

- Stamens PDFDocument10 pagesStamens PDFAmeya KannamwarNo ratings yet

- Israel's Agriculture BookletDocument58 pagesIsrael's Agriculture BookletShrikant KajaleNo ratings yet

- Week 17 2nd Bondy SchoolDocument4 pagesWeek 17 2nd Bondy SchoolOswaldo Coronel UlloaNo ratings yet

- Gr11 Mock Exam Schedule 2024Document13 pagesGr11 Mock Exam Schedule 2024potrillo0330No ratings yet

- Healthy Pregnancy Meals:: LAMB Doula and Birthing CenterDocument16 pagesHealthy Pregnancy Meals:: LAMB Doula and Birthing Centerapi-44273750No ratings yet

- Temario Final Ingles 5°b PrimariaDocument1 pageTemario Final Ingles 5°b PrimariainstitutovalladolidNo ratings yet