Professional Documents

Culture Documents

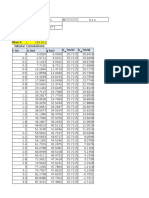

290 Table 19.11 Comprehensive Piping Estimating Units 3 16 SS

290 Table 19.11 Comprehensive Piping Estimating Units 3 16 SS

Uploaded by

sivavalaiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

290 Table 19.11 Comprehensive Piping Estimating Units 3 16 SS

290 Table 19.11 Comprehensive Piping Estimating Units 3 16 SS

Uploaded by

sivavalaiCopyright:

Available Formats

290 Table 19.

11 Comprehensive Piping Estimating Units - 3 16 SS

Piping - per foot

Chapter 19

i .(d;

d a,

r 0

Process areas Labor, hr. Matl,$

Interconnecting Labor, hr. Fab. Erect.

Valves - each Labor, hr. Matl,$

106.00 108.00 122.00 168.00 219.00 400.00 704.00

Fab. Erect. Matl, $

0.92 0.97 1.00 1.10 1.22 1.49 1.73 1.90 1.98 0.30 0.38 0.49 0.59 0.71 0.96 1.31

Fab. Erect.

2.0 2.3 3.2 4.1 5.0 7.2 9.4 1.5 1.8 2.4 3.1 3.8 4.8 6.8 9.4 11.0

u p to 1 40

1 1/2

30.60 31.30 35.10 44.30

-17.30

-0.14 0.16 0.19 0.22 0.28 0.36 0.43 0.51

-0.36 0.47 0.53 0.66 0.89 1.10

10 10 10 10 10 10 10 10

2 3 4 6 8 10 12

20.80

28.40 34.50 56.00 89.00

53.00

85.00 126.00 184.00 226.00

1.63 130.00 1.98 169.00

1.32 1,140.00 11.9 1.57 1,670.00 17.0

Material: Connections Service

316 SS Rating 150 Ib Up to 3/4 S.W. 1 in & over B.W. & L J flg. Process - Corrosive hydrocarbons & inorg. solutions.

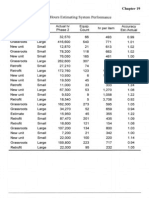

As shown in Tables 19.13 and 19.14, the fitting density varies with line size for the process area piping. The densities reflect actual experience on several projects and coincide with those used by others. In addition to preparing estimates, these units can be very useful for:

Checking estimates.

- Analyzing lump sum bids. - Discussing and evaluating field changes. - Monitoring field progress.

Note of caution: When checking estimates, it must be remembered that on sizes 2 1/2 in. and above, the process area pipe is usually prefabricated away from the field and some estimates would show pipe fabricated offsite as material cost. In that case, the cost will include:

You might also like

- Solution Manual Surveying PrinciplesDocument54 pagesSolution Manual Surveying PrinciplesRegina Lumbre100% (4)

- Bowles - Soil Spring Constant For Pile (Chapter 16)Document8 pagesBowles - Soil Spring Constant For Pile (Chapter 16)motiur basumNo ratings yet

- Piping Per Process Areas Interconnecting Valves Each: LaborDocument1 pagePiping Per Process Areas Interconnecting Valves Each: LaborsivavalaiNo ratings yet

- Piping Per Foot Process Areas Interconnecting Valves EachDocument1 pagePiping Per Foot Process Areas Interconnecting Valves EachsivavalaiNo ratings yet

- Ujian SOPDocument136 pagesUjian SOPsugendengalNo ratings yet

- Sieve Analysis of Fine and Coarse Aggregates Dsdasd: Name: Date Performed: Course/Year: InstructorDocument3 pagesSieve Analysis of Fine and Coarse Aggregates Dsdasd: Name: Date Performed: Course/Year: InstructorEinstein JeboneNo ratings yet

- Skedul 41Document61 pagesSkedul 41Andrie PrabowoNo ratings yet

- Volume CalculationDocument10 pagesVolume CalculationAdjei BaldanNo ratings yet

- Path of Projectile: dt θ g vDocument4 pagesPath of Projectile: dt θ g vMeghanNo ratings yet

- Anchor and Base Plate CalculationDocument6 pagesAnchor and Base Plate Calculationselahattin_erturk06No ratings yet

- Sieve Analysis of Fine & Coarse Aggregates: Cie 309 - Construction Materials Lab Lab Report 3 - Astm C136Document11 pagesSieve Analysis of Fine & Coarse Aggregates: Cie 309 - Construction Materials Lab Lab Report 3 - Astm C136Seyoung MyiouNo ratings yet

- Cotton in Central Asia: Curse' or Foundation For Development'?Document16 pagesCotton in Central Asia: Curse' or Foundation For Development'?Sachin KumarNo ratings yet

- Standard Costing For Fit Out Mechanical WorksDocument2 pagesStandard Costing For Fit Out Mechanical WorksAllan Pesimo BalgosNo ratings yet

- Compression Spring Design (Static Loads) : Music WireDocument2 pagesCompression Spring Design (Static Loads) : Music Wiresaiful anwarNo ratings yet

- Semi-Detailed Estimating System: M LabDocument1 pageSemi-Detailed Estimating System: M LabsivavalaiNo ratings yet

- Sieve Analysis of Fine and Coarse Aggregates: Name: Date Performed: Course/Year: InstructorDocument3 pagesSieve Analysis of Fine and Coarse Aggregates: Name: Date Performed: Course/Year: InstructorJebone Stein Web JuarbalNo ratings yet

- Estimates Ibuild1Document3 pagesEstimates Ibuild1Geraldine BermundoNo ratings yet

- Lab Report 1 & 2Document10 pagesLab Report 1 & 219MME-S1-323 Usman Ul Hassan PirzadaNo ratings yet

- 5.0 Itemized Cost of RevisionDocument9 pages5.0 Itemized Cost of Revisiondexter guanzon serotNo ratings yet

- KAPOY2 (1) SCDSDDocument9 pagesKAPOY2 (1) SCDSDEmanoAceNo ratings yet

- Aashto T-99-10Document12 pagesAashto T-99-10Roberto VasquezNo ratings yet

- AssignmentDocument4 pagesAssignmentEjigayehu Desalegn60% (5)

- Tubeline Circular Hollow Sections GRADE C250L0 (AS 1163) : Dimensions and Properties ® ® ® ® ®Document6 pagesTubeline Circular Hollow Sections GRADE C250L0 (AS 1163) : Dimensions and Properties ® ® ® ® ®Adrian CallusNo ratings yet

- Lab 1:site Investigation and Water Content in Soil: ObjectiveDocument10 pagesLab 1:site Investigation and Water Content in Soil: ObjectiveEf TahNo ratings yet

- 22.0 Pile Capacity (A2) : (IS:2911 (Part I Sec 2) - 2010 Case 1: Pile in Soil (Cohesive + Cohesionless) 1.2 25.00Document6 pages22.0 Pile Capacity (A2) : (IS:2911 (Part I Sec 2) - 2010 Case 1: Pile in Soil (Cohesive + Cohesionless) 1.2 25.00Anonymous jLLjBdrNo ratings yet

- Amiel A. Cabatchete Bsce-4B Group No. 1 SEPTEMBER 19, 2017: Activity # 3Document10 pagesAmiel A. Cabatchete Bsce-4B Group No. 1 SEPTEMBER 19, 2017: Activity # 3EmanoAceNo ratings yet

- Load Computations For Beams and Girders (Version 5)Document4 pagesLoad Computations For Beams and Girders (Version 5)Reuben James BangaoilNo ratings yet

- Eastwest Astake 2020 QuantityDocument1 pageEastwest Astake 2020 QuantityDorothy LeonardoNo ratings yet

- Columnas AcademicoDocument8 pagesColumnas AcademicoGonzalo AlcazarNo ratings yet

- Canal Hydraulics DesignDocument1,541 pagesCanal Hydraulics DesignSamarakoon Banda100% (2)

- Bernoulli's TheoremDocument12 pagesBernoulli's TheoremNur Falini Mohd Sukkri100% (3)

- Experiment 4: Sedimentation: Group No.: 6 Date: 6 September 2011Document13 pagesExperiment 4: Sedimentation: Group No.: 6 Date: 6 September 2011Ankur GargNo ratings yet

- Sprinkler Irrigation Application Rates and DepthsDocument2 pagesSprinkler Irrigation Application Rates and DepthsKhurram SherazNo ratings yet

- Assignment 1 (2017) NMP 700: Wynand - Roux@up - Ac.zaDocument3 pagesAssignment 1 (2017) NMP 700: Wynand - Roux@up - Ac.zaJodi MackenzieNo ratings yet

- My FianancailDocument48 pagesMy FianancailAshok_sthNo ratings yet

- Lab Report 5-Engineering StaticsDocument10 pagesLab Report 5-Engineering StaticsAndhika UtamaNo ratings yet

- Technical Conversions - HANDBOOKDocument88 pagesTechnical Conversions - HANDBOOKShishir KoyareNo ratings yet

- September 2022 Rev.2Document283 pagesSeptember 2022 Rev.2IsalNo ratings yet

- Calculo Informe BernulliDocument18 pagesCalculo Informe BernullibbustillosiriarteNo ratings yet

- Accutron SpecificationsDocument1 pageAccutron SpecificationsZxNo ratings yet

- Moisture-Density Relations of Soils Using A 2.5-kg (5.5-lb) Rammer and A 305-mm (12-In.) DropDocument13 pagesMoisture-Density Relations of Soils Using A 2.5-kg (5.5-lb) Rammer and A 305-mm (12-In.) DropJulio César ChávezNo ratings yet

- Ampacities and Mechanical Properties of Rectangular Copper BusbarsDocument4 pagesAmpacities and Mechanical Properties of Rectangular Copper BusbarsSofia Rincon GomezNo ratings yet

- Perbandingan Grafik Spektrum Dengan Variasi GDocument23 pagesPerbandingan Grafik Spektrum Dengan Variasi GRizki KresnaNo ratings yet

- Plate Load Test ReportDocument9 pagesPlate Load Test ReportAtul Kumar Engineer100% (8)

- Lab 5 - CDocument8 pagesLab 5 - Cnoor shyahdaNo ratings yet

- Unit Hydrograph DerivationDocument7 pagesUnit Hydrograph DerivationSudharsananPRSNo ratings yet

- Sieve Analysis IntroductionDocument8 pagesSieve Analysis IntroductionJam GaholNo ratings yet

- Suelos CohesivosDocument13 pagesSuelos CohesivosDennis Apaza DymNo ratings yet

- Lab 1 Seive AnalysisDocument9 pagesLab 1 Seive AnalysisElvis KarayigaNo ratings yet

- Post Liquefaction Ground DeformationsDocument6 pagesPost Liquefaction Ground DeformationsbatuaydoganNo ratings yet

- asset-v1-CornellX+ENGR2000X+2T2016+type@asset+block@F-1 Engine Model Calculations Non-Proprietyary Non-ITAR Rev2Document42 pagesasset-v1-CornellX+ENGR2000X+2T2016+type@asset+block@F-1 Engine Model Calculations Non-Proprietyary Non-ITAR Rev2Axel DominiqueNo ratings yet

- Hydrology PDFDocument10 pagesHydrology PDFYau Wen JaeNo ratings yet

- Cladiri Inalte ModelDocument42 pagesCladiri Inalte ModelBogdan BîngăNo ratings yet

- Conversion Tables & Useful FormulasDocument37 pagesConversion Tables & Useful FormulasJose Luis Atalaya ChumanNo ratings yet

- Johannes Final Laboratory #3 - Earthworks (Area and Volume)Document7 pagesJohannes Final Laboratory #3 - Earthworks (Area and Volume)BLESSA TORRESNo ratings yet

- General Data: Design of AbutmentDocument18 pagesGeneral Data: Design of AbutmentsurangaNo ratings yet

- Enhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsFrom EverandEnhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsRating: 5 out of 5 stars5/5 (1)

- Hours: Table 19.25 Engineering Estimating System PerformanceDocument1 pageHours: Table 19.25 Engineering Estimating System PerformancesivavalaiNo ratings yet

- Semi-Detailed Estimating System: M LabDocument1 pageSemi-Detailed Estimating System: M LabsivavalaiNo ratings yet

- 3 - Shakedown Areas.: Construction ManagementDocument1 page3 - Shakedown Areas.: Construction ManagementsivavalaiNo ratings yet

- Cost Estimate Summary Case: Estimating 119Document1 pageCost Estimate Summary Case: Estimating 119sivavalaiNo ratings yet

- Communications 241: 17.2 Documentation ChecklistDocument1 pageCommunications 241: 17.2 Documentation ChecklistsivavalaiNo ratings yet

- Phases The Startup: of An For ofDocument1 pagePhases The Startup: of An For ofsivavalaiNo ratings yet

- Project Control: Plant LayoutDocument1 pageProject Control: Plant LayoutsivavalaiNo ratings yet

- 00055Document1 page00055sivavalaiNo ratings yet

- This Page Intentionally Left BlankDocument1 pageThis Page Intentionally Left BlanksivavalaiNo ratings yet

- 15.5 Control During Construction: 80% of Bulk Materials Normally SuppliedDocument1 page15.5 Control During Construction: 80% of Bulk Materials Normally SuppliedsivavalaiNo ratings yet

- Project Control Problem Correction: During ConstructionDocument1 pageProject Control Problem Correction: During ConstructionsivavalaiNo ratings yet

- 14.3 Construction Management ActivitiesDocument1 page14.3 Construction Management ActivitiessivavalaiNo ratings yet

- Speclfic To Project: 2 - Depth and BreadthDocument1 pageSpeclfic To Project: 2 - Depth and BreadthsivavalaiNo ratings yet

- Process Design Phaseolphasel: Phase 1 SpecificationsDocument1 pageProcess Design Phaseolphasel: Phase 1 SpecificationssivavalaiNo ratings yet

- Agreement: ContractingDocument1 pageAgreement: ContractingsivavalaiNo ratings yet

- 2 - Drawings.: 3 - SpecificationsDocument1 page2 - Drawings.: 3 - SpecificationssivavalaiNo ratings yet

- Estimating Methods: Engineering EstimatesDocument1 pageEstimating Methods: Engineering EstimatessivavalaiNo ratings yet

- All Equipment Should Be Accessible by Either Crane or Lift TruckDocument1 pageAll Equipment Should Be Accessible by Either Crane or Lift TrucksivavalaiNo ratings yet