Professional Documents

Culture Documents

Test Certificate-Pressure Regulators

Test Certificate-Pressure Regulators

Uploaded by

Jonathan GriffinOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Test Certificate-Pressure Regulators

Test Certificate-Pressure Regulators

Uploaded by

Jonathan GriffinCopyright:

Available Formats

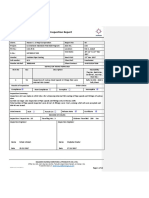

CERTIFICATE OF COMPLIANCE / TYPICAL MATERIAL CERTIFICATION (EN 10204:2004 3.1) TC No.

Date

CORRESPONDANCE DETAILS D.C./INVOICE NO. P.O. NO. MODEL NO. CHEMICAL TEST CERT. NO. FITTINGS DETAILS SAFETY RELIEF VALVE INLET PRESSURE GAUGE OUTLET PRESSURE GAUGE INLET CONNECTION QUALITY & TEST DETAILS HYDRAULIC TEST @ LEAK TEST PRESSURE TEST ON Kg/Cm2 REGULATOR NO. 0.5Kg LPM 1 Kg LPM 2 Kg LPM 3 Kg LPM 4 Kg LPM 6 Kg LPM 8 Kg LPM

ASSEMBLED BY TESTED BY Date

Note: Ex-Lok products referenced above are manufactured from material purchsed and certified as being in accordance with the specification (s). Typical mechanical and/or chemical analysis of the material used in the manufacture of the Ex-Lok products involved as per the attached test report. These values are average values determined from a sample of certified material test reports. Actual values for a material heat may vary from those indicated/mentioned. the relevant regulations are the responsibility of the system designer and the user. The products specified above were manufactured in accordance with Techman Systems quality assurance systems which are approved to ISO 9001. For Techman Systems,

The function of the regulator, the compatibility of the materials, correlating temperature ranges, correct installation, operation and maintenance in accordance w

Q.A. Engineer

This certificate was made by use of a computer system and is valid without signature.

L CERTIFICATION (EN 10204:2004 3.1)

DATE DATE SERIAL NO. DATE

SET PRESSURE MAX. INLET PRESSURE SET OUTLET PRESSURE OUTLET CONNECTION

CREEP LOCK TEST ALL PARTS TESTED MEDIA INLET GAUGE OUTLET GAUGE

being in accordance with the specification (s). x-Lok products involved as per the attached test report.

Actual values for a material heat may vary from those

ges, correct installation, operation and maintenance in accordance with

ity assurance systems which are approved to ISO 9001.

You might also like

- 1.high Voltage Discharge Rod PDFDocument1 page1.high Voltage Discharge Rod PDFsaptarshi Das100% (1)

- 2.6 List of Testing Equipments PDFDocument4 pages2.6 List of Testing Equipments PDFAmir BorhanipourNo ratings yet

- Product Manual 7098 1 CorrectedDocument10 pagesProduct Manual 7098 1 CorrectedIndravadan Vala100% (1)

- PM 9573 Part 2 cmd2Document6 pagesPM 9573 Part 2 cmd2Indranil SarkarNo ratings yet

- Temperature Sensors: Sensytemp Tsp311, Tsp321, Tsp331Document40 pagesTemperature Sensors: Sensytemp Tsp311, Tsp321, Tsp331Tin ThanNo ratings yet

- Inspection and Test Plan: Project NameDocument2 pagesInspection and Test Plan: Project NameehteshamNo ratings yet

- Earth Pit Test Report U2dnDocument1 pageEarth Pit Test Report U2dnMr. BijuNo ratings yet

- HT Panel QapDocument2 pagesHT Panel QapAlla Naveen KumarNo ratings yet

- Earth PitDocument2 pagesEarth PitJayam KondanNo ratings yet

- Asa-146 NSH Apco Ir 040Document10 pagesAsa-146 NSH Apco Ir 040Fahad AhmadNo ratings yet

- Technical Specification - G.I. Wire & Stay Wire PDFDocument9 pagesTechnical Specification - G.I. Wire & Stay Wire PDFsingaravelan narayanasamyNo ratings yet

- PFI Panel Erection ChecklistDocument2 pagesPFI Panel Erection ChecklistMohammad NasarNo ratings yet

- Digital Micro-Ohm MeterDocument2 pagesDigital Micro-Ohm MeterjamilNo ratings yet

- Section 2 QAP, Cable TrayDocument3 pagesSection 2 QAP, Cable TrayveerendraNo ratings yet

- 003-Megger - Insulation TesterDocument4 pages003-Megger - Insulation TesterAjlan Khan100% (1)

- Certificate of Motor Solo RunDocument1 pageCertificate of Motor Solo RuntalhaNo ratings yet

- Flocat LB45A Manual Version 1 4Document48 pagesFlocat LB45A Manual Version 1 4JimBoringNo ratings yet

- LP Gloster Pricelist Aug14 PDFDocument5 pagesLP Gloster Pricelist Aug14 PDFvjtheeeNo ratings yet

- Illumination Test ReportDocument1 pageIllumination Test ReportSói XámNo ratings yet

- Interplant Standard - Steel Industry: Specification For Control Transformers (First Revision) IPSS:1-04-013-02Document6 pagesInterplant Standard - Steel Industry: Specification For Control Transformers (First Revision) IPSS:1-04-013-02GopalMahantaNo ratings yet

- Saudi Aramco Pre-Commissioning Form: Instrument and Control CablesDocument2 pagesSaudi Aramco Pre-Commissioning Form: Instrument and Control Cableszahid1078No ratings yet

- Laser Cleaning Machine ManualDocument17 pagesLaser Cleaning Machine ManualForfi RithNo ratings yet

- Pressure Test Sample Form R2Document1 pagePressure Test Sample Form R2Ruel fernandezNo ratings yet

- QC-151 Motor Inspection TestDocument1 pageQC-151 Motor Inspection TestcisyabNo ratings yet

- Dokumen - Tips - Project Packing and Preservation ProcedureDocument27 pagesDokumen - Tips - Project Packing and Preservation ProceduremohdfaridabubakarNo ratings yet

- Motor InstallationDocument4 pagesMotor InstallationAj100% (1)

- ConduitsDocument10 pagesConduitsSiddiqui Abdul KhaliqNo ratings yet

- Check List For Erection of Switch Gear-FieldDocument3 pagesCheck List For Erection of Switch Gear-Fieldsantoshkumar100% (1)

- 2022-07-14 - D - Approved Tunnel Earthing Plan For Package-3 - MRTDocument25 pages2022-07-14 - D - Approved Tunnel Earthing Plan For Package-3 - MRTBhawani NayakNo ratings yet

- OCEFDocument2 pagesOCEFmmsaNo ratings yet

- QAP CI Flsnged PipesDocument11 pagesQAP CI Flsnged PipesNaveen NagisettiNo ratings yet

- Miniature Circuit Breaker IEC 60898 Is 8828 Test BenchDocument8 pagesMiniature Circuit Breaker IEC 60898 Is 8828 Test BenchFares NehaouaNo ratings yet

- Inward Material Inspection Report: Project Name: Job Code: LocationDocument2 pagesInward Material Inspection Report: Project Name: Job Code: LocationTarun GodiyalNo ratings yet

- PRIMER COAT-Zinc Anode 304 MZV - PDSDocument2 pagesPRIMER COAT-Zinc Anode 304 MZV - PDSMANIMARAN QCNo ratings yet

- Agreement With KSEBDocument3 pagesAgreement With KSEBhafizrahimmitNo ratings yet

- Rishabh Instruments Pvt. LTD.: Test CertificateDocument1 pageRishabh Instruments Pvt. LTD.: Test CertificateSufiyan KhedekarNo ratings yet

- Internal Test ReportDocument4 pagesInternal Test ReportAvishek ChowdhuryNo ratings yet

- TKR 21 - Calibration Record For O2 Meter (Revised)Document1 pageTKR 21 - Calibration Record For O2 Meter (Revised)Mohammed MufarisNo ratings yet

- SCI - Modular Home Testing Comparison Advantages and Disadvantages of AC and DC Hipot PDFDocument1 pageSCI - Modular Home Testing Comparison Advantages and Disadvantages of AC and DC Hipot PDFTTaanNo ratings yet

- Generator Polarization Index (Pi) Test: 1 10/10/2014 Generators Automated Example Plant Example OwnerDocument17 pagesGenerator Polarization Index (Pi) Test: 1 10/10/2014 Generators Automated Example Plant Example OwnerJUAN CARLOS BERNAL MEJIANo ratings yet

- Appendix-2 (POWER PANEL Test Report)Document2 pagesAppendix-2 (POWER PANEL Test Report)hafed baccoucheNo ratings yet

- QC Form TestDocument18 pagesQC Form TestAnton SujarwoNo ratings yet

- Test Procedure TXDocument4 pagesTest Procedure TXVasu100% (1)

- Q A P (Qap) - PV C: Uality Ssurance LAN ELLDocument5 pagesQ A P (Qap) - PV C: Uality Ssurance LAN ELLsasikumarNo ratings yet

- Holiday PipelineDocument4 pagesHoliday PipelineJose Manuel Castro100% (1)

- Xyz Company: PurposeDocument5 pagesXyz Company: PurposeAnonymous 3eHGEDbxNo ratings yet

- ECS 06-0024 Earthing Testing and Measurements PDFDocument43 pagesECS 06-0024 Earthing Testing and Measurements PDFRajendra Prasad ShuklaNo ratings yet

- Earth Switch Contact Resistance Test ReportDocument1 pageEarth Switch Contact Resistance Test ReportGajendran SriramNo ratings yet

- IS 16018 Product ManualDocument12 pagesIS 16018 Product ManualsaikiranNo ratings yet

- Thickness MeasurementDocument6 pagesThickness MeasurementHarish Gupta (JSHL)No ratings yet

- Factory Acceptance Test Procedure For DCS - Part 6Document1 pageFactory Acceptance Test Procedure For DCS - Part 6kapsarcNo ratings yet

- CL-NG-6460-002-020 Checklist For Surge Arrester Rev00Document2 pagesCL-NG-6460-002-020 Checklist For Surge Arrester Rev00WajahatNo ratings yet

- Safety Understand The Requirement Calibration Documentation Calibration Procedure For Various InstrumentDocument6 pagesSafety Understand The Requirement Calibration Documentation Calibration Procedure For Various Instrumentkrishna kumarNo ratings yet

- Transformer: Quality Assurance PlanDocument9 pagesTransformer: Quality Assurance PlanRadhakrishnan VNo ratings yet

- Test Report: Measurement of Turns RatioDocument2 pagesTest Report: Measurement of Turns RatioJRC TestingNo ratings yet

- Best Practices in Quality Assurance & Inspection IN NTPCDocument39 pagesBest Practices in Quality Assurance & Inspection IN NTPCPrincy SinghNo ratings yet

- 13 Fan Coil Unit: Location: - No.Document1 page13 Fan Coil Unit: Location: - No.JIJUNo ratings yet

- P 54 Holiday Testing Procedure R1Document43 pagesP 54 Holiday Testing Procedure R1rahul reyashNo ratings yet

- Fire Protection Test ProcedureDocument7 pagesFire Protection Test Procedurekunalji_jainNo ratings yet

- JFTOT Analysis ASTM D1655, D7566 and Def Stan 91-91Document10 pagesJFTOT Analysis ASTM D1655, D7566 and Def Stan 91-91am4rNo ratings yet