Professional Documents

Culture Documents

Daily Points To Recall (DAY 1) : Professional Training and Consultation

Daily Points To Recall (DAY 1) : Professional Training and Consultation

Uploaded by

raobabar210 ratings0% found this document useful (0 votes)

15 views3 pagesAPI 653 and API 650 provide codes for inspecting, repairing, and altering aboveground storage tanks. API 653 is used for tanks in service, while API 650 covers new tank construction. The codes apply to atmospheric tanks holding liquids below 90C. Tank plate thicknesses must be sufficient to prevent brittle failure and are calculated based on tank diameter, height, liquid density, and stress limits. Welds on tank shells and openings must meet standards for dimensions, plates, and non-destructive testing like radiography.

Original Description:

njhk

Original Title

API_653_PC_26Feb05_PTR_1_

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentAPI 653 and API 650 provide codes for inspecting, repairing, and altering aboveground storage tanks. API 653 is used for tanks in service, while API 650 covers new tank construction. The codes apply to atmospheric tanks holding liquids below 90C. Tank plate thicknesses must be sufficient to prevent brittle failure and are calculated based on tank diameter, height, liquid density, and stress limits. Welds on tank shells and openings must meet standards for dimensions, plates, and non-destructive testing like radiography.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

Download as doc, pdf, or txt

0 ratings0% found this document useful (0 votes)

15 views3 pagesDaily Points To Recall (DAY 1) : Professional Training and Consultation

Daily Points To Recall (DAY 1) : Professional Training and Consultation

Uploaded by

raobabar21API 653 and API 650 provide codes for inspecting, repairing, and altering aboveground storage tanks. API 653 is used for tanks in service, while API 650 covers new tank construction. The codes apply to atmospheric tanks holding liquids below 90C. Tank plate thicknesses must be sufficient to prevent brittle failure and are calculated based on tank diameter, height, liquid density, and stress limits. Welds on tank shells and openings must meet standards for dimensions, plates, and non-destructive testing like radiography.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

Download as doc, pdf, or txt

You are on page 1of 3

Professional Training and Consultation

API 653 Preparatory 26 Feb 3 Mar 2005 Page 1 of 3

DAILY POINTS TO RECALL (DAY 1)

1. API 653 is code used for inspection, repair, and alteration for the aboveground storage tanks which are placed in Service. API 650 is the basic construction code for making New Tanks. API 650 and API 653 are used for aboveground storage tanks at atmospheric pressure (maximum 2.5 psi above atmospheric) and temperatures not exceeding 90C. Design metal temperature of tank is assumed to be 8C (15 F) above the lowest one day mean temperature of tank site. Where necessary, as per Fig. 2-1 (API 650), the tank materials shall be checked against brittle failure by conducting impact testing. Acceptance criteria shall be as per Table 2-4. If average value of 3 specimen is < specified average value (SAV) reject. But if average value of 3 specimen SAV and, a. Value of one specimen is < SAV but 2/3 SAV accept b. Value of one specimen is < SAV and also < 2/3 SAV retest c. Value of two specimen is < SAV retest On retest for b and c all three specimen SAV accept 6. The required thickness of shell plates for tanks up to 60 m (200 feet) diameter shall be greater of td or tt:

2.

3. 4.

5.

4.9 D ( H 0.3) G +CA and Sd

t

=

4.9 D ( H 0.3) (metric) St

2.6 D ( H 1)G + C. A. and Sd

2.6 D ( H 1) St

(US units)

---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------/var/www/apps/conversion/tmp/scratch_2/166701507.doc 8/23/2013 / 21:24:23 a8/p8 / NCD

Professional Training and Consultation

API 653 Preparatory 26 Feb 3 Mar 2005 Page 2 of 3

DAILY POINTS TO RECALL (DAY 1)

Where: D = Tank Diameter m (ft) H = Height shell course from top liquid level in m (ft) G = Specific Gravity of liquid to be stored Sd and St = Allowable stress for design and hydrostatic conditions in Mpa (psi) C.A. = Corrosion allowance in mm (in) 7. Shell thickness calculated above (point no. 6) shall not be less than that required by Diameter Thickness table in API 650. (3.6.1.1) Values of Sd and St are taken from Table 3-2 of API 650. For unlisted material: Sd = Lower of 2/3 (Y.S) or 2/5 (T.S.) and St = Lower of (Y.S) or 3/7 (T.S.) Minimum nominal thickness excluding corrosion allowance for roof plate shall be 5 mm (3/16) and for bottom plate shall be 6 mm (1/4). All nozzles, manholes and other openings shall have dimensions thickness, reinforcement plates and weld sizes as per tables 3-6 and 3-7 of API 650. Radiography inspection is required for all shell butt welds and annular plate butt welds and insert plates for manhole and nozzles. For shell plates the number of radiographs required depend on whether the plate thickness is up to 10 mm (3/8), or above 10 mm to 25 mm (3/8 1) or above 25 mm (1). (Fig. 6-1 of API 650).

8.

9.

10.

11.

12.

---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------/var/www/apps/conversion/tmp/scratch_2/166701507.doc 8/23/2013 / 21:24:23 a8/p8 / NCD

Professional Training and Consultation

API 653 Preparatory 26 Feb 3 Mar 2005 Page 3 of 3

DAILY POINTS TO RECALL (DAY 1)

13. Radiography is also required on: (i) 100% length of butt welds joining insert plate to shell, and (ii) Annular bottom plate radial joints (1 spot on 10% of radial welds if double butt welded and 1 spot on 50% of radial welds if single welded with backing strip.)

---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------/var/www/apps/conversion/tmp/scratch_2/166701507.doc 8/23/2013 / 21:24:23 a8/p8 / NCD

You might also like

- Aramco Interview Questions PRDocument11 pagesAramco Interview Questions PRhemant1284100% (3)

- Machine Design Elements and AssembliesFrom EverandMachine Design Elements and AssembliesRating: 3.5 out of 5 stars3.5/5 (2)

- TT Platform Rig Evaluation Matrix - FINALDocument9 pagesTT Platform Rig Evaluation Matrix - FINALrdos14100% (1)

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- TD-031 CFR Title 49 178.46 Specification 3AL Seamless Aluminum CylindersDocument11 pagesTD-031 CFR Title 49 178.46 Specification 3AL Seamless Aluminum CylindersswLuNo ratings yet

- Api650 Questionn°03 Open Book ResponseDocument2 pagesApi650 Questionn°03 Open Book Responsekorichi100% (1)

- ASME STS-1 Steel Stacks (Partial) - Edition 2000Document6 pagesASME STS-1 Steel Stacks (Partial) - Edition 2000Bui Chi TamNo ratings yet

- 1 API 653 Memories Sept 2012Document20 pages1 API 653 Memories Sept 2012majid100% (1)

- API 653 Questions-1Document4 pagesAPI 653 Questions-1gurdeepsarora873871% (7)

- API 653 QuestionsDocument4 pagesAPI 653 QuestionsRama Jeyam100% (6)

- Astm A 153M-05Document5 pagesAstm A 153M-05MritunjayNo ratings yet

- NBIC Part 2 PDFDocument12 pagesNBIC Part 2 PDFjhonjimenez87No ratings yet

- API Examination QuestionDocument4 pagesAPI Examination QuestionBalakumarNo ratings yet

- ChE 192 Handout 6a (Storage Tank)Document4 pagesChE 192 Handout 6a (Storage Tank)Aiza CabolesNo ratings yet

- SAIC-D-2002 Rev 2Document5 pagesSAIC-D-2002 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- 1750 22Document4 pages1750 22hogoyoNo ratings yet

- Sae Ams S 13165Document27 pagesSae Ams S 13165sabrunoNo ratings yet

- Exam July 2021Document16 pagesExam July 202101280724321 Helmy100% (1)

- Daily Points To Recall (Day 2) : Professional Training and ConsultationDocument4 pagesDaily Points To Recall (Day 2) : Professional Training and Consultationraobabar21No ratings yet

- Final Exam (Open) : InstructionsDocument8 pagesFinal Exam (Open) : InstructionssujadevNo ratings yet

- API 653 - Data SheetsDocument12 pagesAPI 653 - Data SheetsJunderhill100% (4)

- 11Document5 pages11MOHAMEDNo ratings yet

- ASME Code Section 8Document9 pagesASME Code Section 8snehal.deshmukhNo ratings yet

- 1876 3Document4 pages1876 3hogoyoNo ratings yet

- Dot FRP-1Document21 pagesDot FRP-1gohary18047No ratings yet

- API 653 - Section 650 Flash Card - 36 QuestionsDocument5 pagesAPI 653 - Section 650 Flash Card - 36 QuestionsdanielbellaNo ratings yet

- API 653 Fig and Table ProblemsDocument5 pagesAPI 653 Fig and Table ProblemsBashu Poudel100% (2)

- Temp StrainersDocument12 pagesTemp StrainersRahul Lavand100% (1)

- Tender SpecificationDocument19 pagesTender SpecificationManoj RanaNo ratings yet

- Minimum Threads Exposed at Each NutDocument11 pagesMinimum Threads Exposed at Each NutSingaravel GanesanNo ratings yet

- MIL-H-19886, 1988 Helmet, Ground Troops, Parachutists, Steel, M-1Document23 pagesMIL-H-19886, 1988 Helmet, Ground Troops, Parachutists, Steel, M-1cjnjr1No ratings yet

- Api 653 QuestionsDocument28 pagesApi 653 Questionskorichi100% (2)

- Section 6 - Manholes, Frames, Covers and Cleanouts 6-01. General RequirementsDocument3 pagesSection 6 - Manholes, Frames, Covers and Cleanouts 6-01. General RequirementsThupten Gedun Kelvin Ong100% (1)

- PCSE-100-ET-C-024:: Perú Camisea Second Expansion (Pcse)Document6 pagesPCSE-100-ET-C-024:: Perú Camisea Second Expansion (Pcse)Moises Alvarez LeandroNo ratings yet

- 510 Open ExamDocument17 pages510 Open Examariyamanjula2914100% (1)

- Merge 13 to 18Document6 pagesMerge 13 to 18irvansyahNo ratings yet

- Saej 1459Document6 pagesSaej 1459Nicole KeithNo ratings yet

- ASME Code Section 8 ContentDocument6 pagesASME Code Section 8 ContenttasingenieriaNo ratings yet

- Jacobs (HPCL) Standard On Pressure Vessel & He PDFDocument52 pagesJacobs (HPCL) Standard On Pressure Vessel & He PDFAnit100% (2)

- Appendix 27 Alternative Requirements For Glass-Lined VesselsDocument2 pagesAppendix 27 Alternative Requirements For Glass-Lined VesselsBinay K SrivastawaNo ratings yet

- Sample Question & AnswersDocument9 pagesSample Question & Answersabhi_mohit2005No ratings yet

- It Re 500-SDDocument40 pagesIt Re 500-SDmarighergutNo ratings yet

- COADE's Application of Welding Research Council Bulletins 107, 297 and 368Document3 pagesCOADE's Application of Welding Research Council Bulletins 107, 297 and 368shivabtowin3301100% (3)

- Understanding API ICP653 Reading 12-Worksheet-8Document290 pagesUnderstanding API ICP653 Reading 12-Worksheet-8Charlie Chong100% (1)

- Api 653 Daily Points To Recall (Day 1)Document2 pagesApi 653 Daily Points To Recall (Day 1)Naveed AhmedNo ratings yet

- Index PHP PDFDocument9 pagesIndex PHP PDFEloise CamposNo ratings yet

- BS 812-Part 113-90Document10 pagesBS 812-Part 113-90anish_am2005No ratings yet

- API 653 - 650 Flash Cards - 40 QuestionsDocument5 pagesAPI 653 - 650 Flash Cards - 40 QuestionsSERFORTEC CIA. LTDA.No ratings yet

- Advanced and Refractory Ceramics for Energy Conservation and EfficiencyFrom EverandAdvanced and Refractory Ceramics for Energy Conservation and EfficiencyHua-Tay LinNo ratings yet

- Mechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandMechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesDileep SinghNo ratings yet

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášNo ratings yet

- Advances in Solid Oxide Fuel Cells and Electronic Ceramics IIFrom EverandAdvances in Solid Oxide Fuel Cells and Electronic Ceramics IIMihails KusnezoffNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Advances in Ceramic Armor XIFrom EverandAdvances in Ceramic Armor XIJerry C. LaSalviaNo ratings yet

- Southern Marine Engineering Desk Reference: Second Edition Volume IFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume INo ratings yet

- Ceramic Materials for Energy Applications IV: A Collection of Papers Presented at the 38th International Conference on Advanced Ceramics and Composites, January 27-31, 2014, Daytona Beach, FLFrom EverandCeramic Materials for Energy Applications IV: A Collection of Papers Presented at the 38th International Conference on Advanced Ceramics and Composites, January 27-31, 2014, Daytona Beach, FLHua-Tay LinNo ratings yet

- Linotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeFrom EverandLinotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeNo ratings yet

- Refractory Solution FDocument5 pagesRefractory Solution Fraobabar21No ratings yet

- Pavingexpert - Formwork and ShutteringDocument6 pagesPavingexpert - Formwork and Shutteringraobabar21No ratings yet

- China Coreless IntermediateDocument21 pagesChina Coreless Intermediateraobabar21No ratings yet

- Financial AnalysisDocument16 pagesFinancial Analysisraobabar21No ratings yet

- Bangla Steel Mill RollDocument29 pagesBangla Steel Mill Rollraobabar21No ratings yet

- Compressor ChecklistDocument5 pagesCompressor ChecklistJuanPabloAlvarezNo ratings yet

- Geart Failure LubricationDocument17 pagesGeart Failure Lubricationraobabar21No ratings yet

- Usrcontrol3 Plant Svcs Tcm9 12753Document8 pagesUsrcontrol3 Plant Svcs Tcm9 12753raobabar21No ratings yet

- Texas Commission On Environmental Quality Table 11 InstructionsDocument2 pagesTexas Commission On Environmental Quality Table 11 Instructionsraobabar21No ratings yet

- Capital Asset and Supply Inventory Control: Management Manual Revised August 7, 2009 Title 24 Chapter HDocument14 pagesCapital Asset and Supply Inventory Control: Management Manual Revised August 7, 2009 Title 24 Chapter Hraobabar21No ratings yet

- MSS SP-115 (1999)Document11 pagesMSS SP-115 (1999)raobabar21No ratings yet

- Agma 9002-A86 Inch Bore and Ansi b17.1Document6 pagesAgma 9002-A86 Inch Bore and Ansi b17.1k21p81100% (2)

- Trainer API NDT Welding Qaqc Aws Asme Sixsigma Iso Softskill Profile Vedagiri Umashankar Chennai India 9600162099Document2 pagesTrainer API NDT Welding Qaqc Aws Asme Sixsigma Iso Softskill Profile Vedagiri Umashankar Chennai India 9600162099raobabar21No ratings yet

- 95000401Document1 page95000401raobabar21No ratings yet

- Rad 1/2 D: 001 C/D M88 DB-950006 00Document1 pageRad 1/2 D: 001 C/D M88 DB-950006 00raobabar21No ratings yet

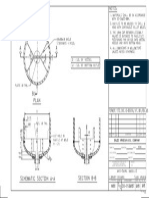

- Notes:: D I.D. of Vessel D I.D. of Bottom OutletDocument1 pageNotes:: D I.D. of Vessel D I.D. of Bottom Outletraobabar21No ratings yet

- Design Notes: 001 D M88 DB-950009 00Document1 pageDesign Notes: 001 D M88 DB-950009 00raobabar21No ratings yet