Professional Documents

Culture Documents

Bimco Engineering Enterprise Bimco Engineering Enterprise Bimco Engineering Enterprise

Bimco Engineering Enterprise Bimco Engineering Enterprise Bimco Engineering Enterprise

Uploaded by

Tarun GuptaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bimco Engineering Enterprise Bimco Engineering Enterprise Bimco Engineering Enterprise

Bimco Engineering Enterprise Bimco Engineering Enterprise Bimco Engineering Enterprise

Uploaded by

Tarun GuptaCopyright:

Available Formats

BIMCO ENGINEERING ENTERPRISE

(MANUFACTURERS AND ENGINEERS)

AN ISO 2001-9008 CERTIFIED UNIT OFFICE: 40, RAMAN ENCLAVE EXTN. RISHI NAGAR, LUDHIANA - 141 001

WORKS: Jaspal Banger Road, Near Tyre Factory, Dhandari, LUDHIANA - 141 010

Phone: +91-161-2300479, 9417234191 Mobile: +91-9216134193 Fax: +91-161-2300479 E-mail: mail: tarungupta88@gmail.com

BRIGHT STEEL ROUND BAR 25 MM DIA LENGTH 1.5 MTRS. + 15MM/ MM/ - 0MM

5 M.T.

BRIGHT STEEL ROUND BAR 45 MM DIA - 39 M.T. LENGTH 3 MTRS. + 25MM/ - 0MM BRIGHT STEEL ROUND BAR 55.5 MM DIA - 99 M.T. LENGTH 3 MTRS. + 40MM/ - 0MM 4MM/ IN ONE MTR STRAIGHT TOLERANCE PLUS 4MM/-0MM DIMENSIONAL TOLERANCES AS PER IS 919 PT-2 PT LATEST REVISION GRADE AISI E8620 WITH RESTRICTED SULPHUR AND PHOSPHORUS The steel shall be made in electric arc furnance, fully killed and VAD treated with secondary refining. refining The bars shall be hot rolled, normalised, machine straightened, bright finish with sawn cut ends. The steel shall be 100% magnetic particle inspected. The bright steel bars shall be supplied under adequate coating of anti-rust compound. CHEMICAL COMPOSITION CARBON 0.18 0.23 SULPHUR 0.025 MAX SILICON 0.20 0.35 NICKEL 0.40 0.70

MANGANESE PHOSPHORUS CHROMIUM MOLYBDENUM

0.70 0.90 0.025 MAX 0.40 0.60 0.15 0.25

SURFACE DEFECTS: Total depth of surface defects (like seams, laps, scar marks, folds, total decarburization or any other harmful defect) shall be as per IS:9550 latest version, against the corresponding size. MACRO EXAMINATION Macro Examination of deep acid etched sections of bars (in as received condition) shall show no evidence of abnormalities like shrinkage-cavity, shrinkage blow-hole, hole, porosity, piping, pin-holes, pin hairline-cracks, seams or any other harmful defects. MICRO EXAMINATION Microstructure shall reveal uniform equiaxed grains of Ferrite and Pearlite. The grain size shall be of ASTM No 5 or finer. The microstructure shall be free from any banding, lamination, harmful segregation or any other detrimental defect. HARDNESS 140 200 BHN CLEANLINESS TYPE A B C D

Thin Series 1.5 1.5 1.5 1.5

Thick Series 1.0 1.0 1.0 1.0

You might also like

- Haresh Steel Centre: Copper-Nickel Pipe, Fittings & FlangesDocument16 pagesHaresh Steel Centre: Copper-Nickel Pipe, Fittings & FlangesHaresh Steel CentreNo ratings yet

- Specs For Station - and - Buildings - Construction - Spec PDFDocument1,688 pagesSpecs For Station - and - Buildings - Construction - Spec PDFahmadgce04No ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- 4320Document1 page4320Tarun GuptaNo ratings yet

- PCB CapabilitiesDocument2 pagesPCB Capabilitiesatsushi885No ratings yet

- Section-1000 (Materials For Structures)Document12 pagesSection-1000 (Materials For Structures)muralinaiduNo ratings yet

- Crom Plated BarsDocument24 pagesCrom Plated BarschonubobbyNo ratings yet

- Alambron CHQDocument4 pagesAlambron CHQJavier GranadosNo ratings yet

- Material Properties and Chemical CompositionDocument20 pagesMaterial Properties and Chemical CompositionMani Maran89% (9)

- HS90 CoiledTubeDocs101909Document12 pagesHS90 CoiledTubeDocs101909Yongqiang LiNo ratings yet

- CoatingDocument25 pagesCoatingjayavardhan_99No ratings yet

- Quality Assurance: Lab EquipmentDocument13 pagesQuality Assurance: Lab EquipmentchepurthiNo ratings yet

- Ans PresentationDocument34 pagesAns Presentationapi-3844707No ratings yet

- Monel K500 PDFDocument6 pagesMonel K500 PDFOZAIRTRADELINKNo ratings yet

- Steel Grade Indian StandardsDocument5 pagesSteel Grade Indian StandardsPriyanathan ThayalanNo ratings yet

- Aluminium SummaryDocument1 pageAluminium SummaryArvind ViswanathanNo ratings yet

- Product Catlogue Piping MaterialDocument25 pagesProduct Catlogue Piping Materialnedumaran.sNo ratings yet

- Chemical Composition of Carbon SteelDocument2 pagesChemical Composition of Carbon SteelAkilanNo ratings yet

- Welded Pipes - API 5L Grade X65 PSL 2Document2 pagesWelded Pipes - API 5L Grade X65 PSL 2Minh TrungNo ratings yet

- ARTY - Aubert Et Duval - Produits - Longs - GB PDFDocument6 pagesARTY - Aubert Et Duval - Produits - Longs - GB PDFScott_B4UNo ratings yet

- EN24 and EN24T SteelDocument3 pagesEN24 and EN24T Steelpatrik710No ratings yet

- TESTS ON STEEL (IS 1786 - 2008) : Concrete Cube Strength For R.C.C (Is 456 - 2000)Document4 pagesTESTS ON STEEL (IS 1786 - 2008) : Concrete Cube Strength For R.C.C (Is 456 - 2000)9rk9No ratings yet

- Urea 25 22 2 20030603Document4 pagesUrea 25 22 2 20030603Ghulam AhmadNo ratings yet

- Concrete LabDocument97 pagesConcrete LabSiva NatNo ratings yet

- Chemical DetailsDocument3 pagesChemical Detailsemmas18No ratings yet

- Carbon Steel CHQ CatalogueDocument1 pageCarbon Steel CHQ CatalogueSundarNo ratings yet

- Chemical CompositionDocument13 pagesChemical Compositionssharma3474No ratings yet

- Chemistry: Above Grade Chemistry Can Be Changed As Per The Customer's RequirmentDocument1 pageChemistry: Above Grade Chemistry Can Be Changed As Per The Customer's RequirmentDilshadJamilNo ratings yet

- Amardeep Steel - Corten Steel Products Corten Steel Tube IntroductionDocument3 pagesAmardeep Steel - Corten Steel Products Corten Steel Tube IntroductionAmardeep Steel SalesNo ratings yet

- Vircap Profile NewDocument12 pagesVircap Profile Newtgohiakri2006No ratings yet

- Salem Product CatalogueDocument6 pagesSalem Product Cataloguedramilt0% (1)

- Cold Drawn Seamless Steel Tubes For Hydraulic CylindersDocument8 pagesCold Drawn Seamless Steel Tubes For Hydraulic Cylindersvijayasarathy2013No ratings yet

- DEsign, Cons and Maintenance RP) PDFDocument215 pagesDEsign, Cons and Maintenance RP) PDFShiba Shankar Satapathy100% (1)

- Assab MM40 140331Document8 pagesAssab MM40 140331underscore1992No ratings yet

- Cilindros e Servo CilindrosDocument16 pagesCilindros e Servo CilindrosluisbottonNo ratings yet

- LL HS Data SheetDocument1 pageLL HS Data SheetSantii CampitelliNo ratings yet

- Kaiser Aluminum Soft Alloy Tube PDFDocument31 pagesKaiser Aluminum Soft Alloy Tube PDFgerrzen64No ratings yet

- PS 8956 NDocument7 pagesPS 8956 N林坤緯No ratings yet

- Peeled Round Steel BarsDocument9 pagesPeeled Round Steel BarsaxgasaNo ratings yet

- Catalogo Er70s3Document3 pagesCatalogo Er70s3upedro26No ratings yet

- BPE Technical DataDocument5 pagesBPE Technical Datasmtamaskar2277No ratings yet

- 270 SorDocument9 pages270 SorNitesh SrivastavaNo ratings yet

- Procedure WrappingDocument6 pagesProcedure Wrappingyogacruise100% (1)

- Duplex Stainless Steel WeldingDocument25 pagesDuplex Stainless Steel Weldingkdsenipah6667No ratings yet

- ASTM A108 TolerancesDocument9 pagesASTM A108 TolerancesJosh ByronNo ratings yet

- Coremax H43Document1 pageCoremax H43LIM hoon boonNo ratings yet

- Free Cutting Cold Drawn 11SMnPb30 Calibrated AUSADocument2 pagesFree Cutting Cold Drawn 11SMnPb30 Calibrated AUSAsobheysaidNo ratings yet

- Carbon Hollow BarDocument3 pagesCarbon Hollow Barscrane@No ratings yet

- RPG Cable GlandsDocument6 pagesRPG Cable GlandsAhamed AshithNo ratings yet

- Weldability of Cr-Mo SteelsDocument20 pagesWeldability of Cr-Mo SteelsNitin Bajpai100% (2)

- Machining For Rubber Lining (MRL) : Rubber or Urethane Lined PipeDocument1 pageMachining For Rubber Lining (MRL) : Rubber or Urethane Lined PipeAnthony RamosNo ratings yet

- Advanced and Refractory Ceramics for Energy Conservation and EfficiencyFrom EverandAdvanced and Refractory Ceramics for Energy Conservation and EfficiencyHua-Tay LinNo ratings yet

- Mechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandMechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesDileep SinghNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Advances in Solid Oxide Fuel Cells and Electronic CeramicsFrom EverandAdvances in Solid Oxide Fuel Cells and Electronic CeramicsNo ratings yet

- Processing, Properties, and Design of Advanced Ceramics and CompositesFrom EverandProcessing, Properties, and Design of Advanced Ceramics and CompositesGurpreet SinghNo ratings yet

- Metal Matrix Composites: A Modern Approach to ManufacturingFrom EverandMetal Matrix Composites: A Modern Approach to ManufacturingNo ratings yet

- SWR Bill FormatDocument3 pagesSWR Bill FormatTarun GuptaNo ratings yet

- Notes On Circuits Prepared by Dr. SrivastavaDocument17 pagesNotes On Circuits Prepared by Dr. SrivastavaTarun GuptaNo ratings yet

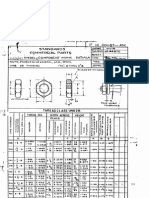

- N 1-Metric Equivalent: 1 In. 25.4 MMDocument1 pageN 1-Metric Equivalent: 1 In. 25.4 MMTarun GuptaNo ratings yet

- D7130A11Document1 pageD7130A11Tarun GuptaNo ratings yet

- Is.1573.1986 ED Coating StandardDocument24 pagesIs.1573.1986 ED Coating StandardUlhas Kavathekar100% (1)

- Phys Notes ElecDocument10 pagesPhys Notes ElecHakim DahouNo ratings yet

- Menges CrowningDocument8 pagesMenges CrowningTarun Gupta100% (1)

- Annex UreaDocument1 pageAnnex UreaTarun GuptaNo ratings yet

- Electricity NotesDocument24 pagesElectricity NotesTarun GuptaNo ratings yet

- NABL103Document93 pagesNABL103ajaylamba1980No ratings yet

- 2P79000XDocument1 page2P79000XTarun GuptaNo ratings yet

- Digitally Signed by Jyoti 903807 Date: 2011.10.04 11:21:08 PDTDocument1 pageDigitally Signed by Jyoti 903807 Date: 2011.10.04 11:21:08 PDTTarun GuptaNo ratings yet

- Digitally Signed by Bharat Bhushan 904633 Diesel Loco Modernisation Works Date: 2012.01.07 12:11:59 ISTDocument5 pagesDigitally Signed by Bharat Bhushan 904633 Diesel Loco Modernisation Works Date: 2012.01.07 12:11:59 ISTTarun GuptaNo ratings yet

- EMS0058EDocument1 pageEMS0058ETarun GuptaNo ratings yet

- SK0130NILDocument1 pageSK0130NILTarun GuptaNo ratings yet

- Kit06 10272860Document1 pageKit06 10272860Tarun GuptaNo ratings yet

- Digitally Signed by Jyoti 903807 Date: 2011.06.07 14:09:59 ISTDocument1 pageDigitally Signed by Jyoti 903807 Date: 2011.06.07 14:09:59 ISTTarun GuptaNo ratings yet

- 1P62870 NilDocument1 page1P62870 NilTarun GuptaNo ratings yet

- Digitally Signed by Jyoti 903807 Date: 2011.09.14 10:54:12 PDTDocument1 pageDigitally Signed by Jyoti 903807 Date: 2011.09.14 10:54:12 PDTTarun GuptaNo ratings yet

- Table of Electron NegDocument2 pagesTable of Electron NegTarun GuptaNo ratings yet

- 4320Document1 page4320Tarun GuptaNo ratings yet

- Test Bansal Coordinationcompounds PDFDocument10 pagesTest Bansal Coordinationcompounds PDFTarun Gupta100% (2)