Professional Documents

Culture Documents

United States Patent (191: Seecamp

United States Patent (191: Seecamp

Uploaded by

9aszerfOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

United States Patent (191: Seecamp

United States Patent (191: Seecamp

Uploaded by

9aszerfCopyright:

Available Formats

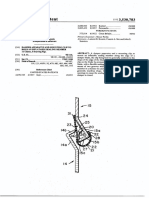

United States Patent [191

Seecamp

[541 CARTRIDGE MAGAZINE

4/1894 3/1968

In]

[451

3,711,981

Jan. 23, 1973

[76]

[22]

inventor: Louis W. Seecamp, 561 Whitney Avenue, New Haven, Conn. Filed: Oct. 29, 1970

Mannlicher ............................ ..42/50 Into ........................................ ..42/50

Primary Examiner~Benjamin A. lBorchelt

Assistant Examiner-C. T. Jordan

[2i] Appl. No.: 84,957

[52]

[51]

[57]

ABSTRACT

U.S. Cl ..................................................... ..42/50

Int. Cl . . . . . . . . . . . . . . . . . . . . . . ..F4lc 25/02

A box-magazine for cartridges in which the side walls are provided with integral knock-out fingers which have inwardly bent projections at their free ends for

engagement within the extractor grooves of the car

[58]

Field of Search ........................................ ..42/50

tridges, thereby preventing the cartridges from being

thrown forward in the magazine against the front wall.

[56]

References Cited

UNITED STATES PATENTS

7 Claims, 4 Drawing Figures

' 301213

YZITRVJWEIIiot".......

.......... ..142/50

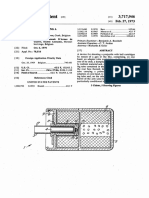

PATENTE?mzs I975

3.711.981

FIGZ

INVENTOR

[00/5 M1 seecmp

3,711,981

2

the cartridges 16 to slip easily backward so that the ?anges rest behind the projections 15, while at the

same time the rearward tilt serves to hold the cartridges

CARTRIDGE MAGAZINE The present invention relates to box-magazines for high-power ?rearms, and it relates more particularly to box~magazines in which the cartridges are protected

against damage resulting from impact with the front

wall of the magazine during recoil of the ?rearm.

l6 securely in that position once they have reached it.

Each ?nger 14 is rigidly connected at one end to the

Soft-nosed cartridges often are damaged by heavy

recoil as they lie in the magazine. Heavy recoil usually

propels a cartridge forward until it strikes the inner front wall of the magazine where damage is in?icted on

the soft-nosed portion of the cartridge. Repeated bat

tering of soft-nosed cartridges on the inner front wall of the magazine not infrequently causes a cartridge to become so deformed that it jams in the forearm when

being chambered. Occasionally a cartridge becomes so

mutilated that it may present a physical danger to the

shooter. Even mild deformation of a soft-nosed car

adjacent side wall 10 and extends longitudinally of the cartridges 16 with the projection 15 at its free end near, but spaced from, the rear end wall of the magazine by a distance not substantially greater than the width of the rim or ?ange of each cartridge 16. After loading the magazine in the customary way, the cartridges 16 can be rendered safe from recoil damage by striking the back outer surface 17 of the magazine against the hand or some other object. Inertia thus drives the cartridges 16 against the back inner wall of the magazine, where they are retained by the inward

projections 15 found on the resilient arms 14. As shown

tridge, however, it not without its consequences for the in FIG. 2, the inward projections 15 on the resilient shooter since deformation of the cartridge head adver arms 14 engage the grooves 18 of the cartridges l6 and 20 sely affects the accuracy of bullet ?ight. hold them against the back inner surface of the The present invention virtually eliminates those an magazine. Consequently, the cartridge tips are pro noying and often dangerous problems resulting from tected from recoil damage. recoil damage to soft-nosed cartridges. In addition, the

present invention does this in a way that is economi

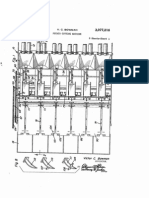

The box-magazine shown in the drawings is longitu

cally inexpensive from the manufacturing viewpoint. In

order to produce the device which prevents recoil>

25 dinally symmetrical with the exception of a follower 19

which is attached to the follower spring 20 (see FIGS.

damage to cartridge tips, the manufacturer need only

use a simple blanking operation when fabricating the magazine from sheet metal.

The nature of the present invention is well illustrated

3,4). The force exerted by the spring member 20 pushes the follower 19 upward. When the box magazine here illustrated is fully loaded, the asymmet

rical shape of the follower 19 causes the cartridges 16 to be arranged in the con?guration shown in FIGS. 3

and 4. In FIG. 3 where the bolt 21 is in the normal forward

by the box-magazine shown in the drawings; however,

it should be noted that the invention can be used as part

of other magazines not of the speci?c type which is here used to illustrate the principles of the invention. 35 position, the bottom longitudinal surface of the bolt 21 sets a limit on how far upward the follower spring 20 The box-magazine here shown is representative of the can push the cartridges 16. In FIG. 4 where the bolt 21 typical high-power ?rearm magazine and it can be used is in the retracted position and does not hold down the in conjunction with any standard high-power ?rearm. cartridges 16, a pair of feed lips 22 ful?lls this function. Of the drawings:

The feed lips 22 are best shown :in FIG. 2. They also hold down the follower 19 when the magazine is empty. By comparing FIGS. 3 and 4 it can be seen that the bot tom surface of the bolt 21 holds the cartridges 16 purposes. farther down in the magazine than the feed lips 22 do. FIG. 2 is a top view of the magazine as it would ap 45 As shown in FIG. 3, when the bolt 21 is in the forward or normal position, all cartridges 16 in the magazine pear when loaded, portions again being broken away. have some portion of their grooves 18 engaged by some FIG. 3 is a transverse section of the loaded magazine taken on the line 33 of FIG. 2 and showing it at portion of the inward projections 115. Each cartridge 16 tached to a firearm with the bolt in the normal position. is then protected from recoil damage. When the bolt 21 FIG. 4 is similar to FIG. 3, however the bolt section is is retracted, then the uppermost cartridge 16 moves to not shown since the bolt is in the retracted position as it the position shown in FIG. 4. It then no longer is would be when preparing to engage a cartridge. restrained by the inward projection 15 on the resilient The drawings show a box-magazine which consists of arm 14. When the bolt 21 is brought forward, the up a pair of parallel side walls 10, a pair of parallel end permost cartridge 16 is carried forward with it and walls 11 (see FIGS. 1, 2), and a floor plate 12 (see 55 chambered as the bolt 21 reaches battery position. FIGS. 3,4). The mechanism by which the magazine is In order to ensure that each cartridge 16 is restrained attached to the receiver 13 is not shown since this may by one or the other of the retaining ?ngers 14, the be any conventional latch means and has no bearing on upper end of each projection 15 is disposed from the the present invention. Each side wall 10 is in part made adjacent feed lip 22 by a distance only sufficient to up of a resilient arm or cartridge-retaining ?nger 14 allow the cartridge 16 to be fed longitudinally out of (see FIG. 1) which terminates in an inward projection the magazine when it is pressed against such feed lip 15, the cartridge-retaining ?ngers 14 being of sufficient 22. length to ensure enough resiliency so that the rims or What is claimed is: ?anges at the base of each cartridge 16 bend the ?ngers 1. A box-magazine for cartridges, each having a cir l4 outwardly when the cartridges 16 are forced to the 65 cumferential ?ange at its base forming an extractor back end of the magazine. The projections 15 are also shoulder, said box-magazine comprising a housing hav tilted rearwardly, as shown in FIG. 2, in order to allow ing opposite side walls, and front and rear end walls for

FIG. 1 is a right-side perspective view of the

magazine, the follower spring, cartridge follower and ?oor plate being removed and portions of the walls of the magazine being shown broken away for illustrative

3,711,981

4

the reception of a plurality of cartridges, feed lips

3 disposed on the upper edges of said side walls for

cartridge~retaining ?nger.

an elongated cartridge-retaining ?nger disposed lon

3. A box-magazine as de?ned in claim 2, wherein said cartridge-retaining fingers are blanked out of the into the chamber of a ?rearm, a follower spring for urg material forming said side walls. ing the cartridges upwardly within said housing against 5 4. A box-magazine as defined in claim 2, wherein the said feed lips and at least one of said side walls having upper edge of each of said projections on said car

retaining the cartridges and guiding them individually

gitudinally of the cartridges and having one end rigidly

connected to said side wall and a free end spaced from said rear end wall by a distance not substantially

tridge-retaining ?ngers is spaced from the said feed lip

on the corresponding side wall a distance only suf?

greater than the thickness of the circumferential ?ange

on each of the cartridges, the free end of said retaining

cient to allow the cartridge being urged by said follower spring against the said feed lip to be fed longitudinally

out of said magazine.

5. A box-magazine as de?ned in claim 4 for a ?rearm having a reciprocable branch both, wherein the car jacent ones of said cartridges, the length of said retain 15 tridges are held out of engagement with said feed lips by a longitudinal surface of the bolt of the ?rearm when ing finger being sufficient to ensure adequate resiliency said magazine is assembled in a ?rearm in which the of said ?nger, thereby permitting the ?anges of the car bolt is closed, such that all of the cartridges in said tridges to be forced rearwardly of said projection by

?nger having a projection directed inwardly of said side

walls for engagement with the extractor shoulder of ad

resiliently bending said retaining ?nger outwardly while

being rigid enough to prevent the ?anges of the car

tridges from moving forward of said projection during

recoil of the ?rearm, the front end wall of said housing being spaced from the nose of each of the cartridges when their extractor shoulders are engaged by said pro

jection.

2. A box-magazine as de?ned in claim 1, wherein each of said side walls is provided with a said elongated

magazine are retained by said cartridge-retaining ?n gers against forward movement in said magazine. 6. A box-magazine as de?ned in claim I, wherein said cartridge-retaining ?nger is blanked out of the material forming said side wall. 7. A box-magazine as de?ned in claim 1, wherein 25 said projection is slightly tilted toward the rear end wall

of said housing.

30

35

40

45

55

65

You might also like

- "A1.h.. May,: June 4, 1929. A. B. Kerr 1,715,929Document7 pages"A1.h.. May,: June 4, 1929. A. B. Kerr 1,715,929Guillermo Avila RiveraNo ratings yet

- SL / y Tºš W: Feb. 2, 1965 H. R. Cowley 3,168,296Document7 pagesSL / y Tºš W: Feb. 2, 1965 H. R. Cowley 3,168,296lucasmosnaNo ratings yet

- US2126921Document5 pagesUS2126921Jhonnatan E Avendaño Florez100% (1)

- United States Patent (191: Sullivan Et A1Document21 pagesUnited States Patent (191: Sullivan Et A1fghdfjerNo ratings yet

- Unlted States Patent (191 1111 3,736,693: Koch 1451 June 5, 1973Document4 pagesUnlted States Patent (191 1111 3,736,693: Koch 1451 June 5, 1973fgrt45No ratings yet

- Err-Easels - / ' Ma. Ma @&?7hii?%: March 3, 1936. G, Gimera Et Al 2,032,695Document3 pagesErr-Easels - / ' Ma. Ma @&?7hii?%: March 3, 1936. G, Gimera Et Al 2,032,695RakeshNo ratings yet

- Us 4676137Document6 pagesUs 4676137fghdfjerNo ratings yet

- Us 4207797Document7 pagesUs 4207797fghdfjerNo ratings yet

- ??????zzzzzzzzzzzzzzzzzzzzzz!é:1: Patented Sept. 24, 1901Document7 pages??????zzzzzzzzzzzzzzzzzzzzzz!é:1: Patented Sept. 24, 1901Слэйтер Строительная компания100% (1)

- BOΤTLE LABELING MACHINEDocument4 pagesBOΤTLE LABELING MACHINEq12wertyNo ratings yet

- Jan. 4, L 1966 T. W. Spack 3,227,148Document6 pagesJan. 4, L 1966 T. W. Spack 3,227,148MainAvelNo ratings yet

- M © JG) - B) John Garlic/9r.: Sept-3, 1959 J. Gallo, SR 2,902,815Document3 pagesM © JG) - B) John Garlic/9r.: Sept-3, 1959 J. Gallo, SR 2,902,815James LindonNo ratings yet

- 1,322,227. L - Y Patented Nov. 18, Í919.: F. F. BurtonDocument7 pages1,322,227. L - Y Patented Nov. 18, Í919.: F. F. BurtonJin SongNo ratings yet

- Us1517483 PDFDocument10 pagesUs1517483 PDFJin SongNo ratings yet

- Foldable Boat FlierDocument5 pagesFoldable Boat FlierRakeshNo ratings yet

- No. 640,627. Patented Jan. 2, 1900Document5 pagesNo. 640,627. Patented Jan. 2, 1900Слэйтер Строительная компанияNo ratings yet

- Limited States Patent: LngramDocument7 pagesLimited States Patent: LngramJin SongNo ratings yet

- Mannlicher Us1008162Document6 pagesMannlicher Us1008162cll1968No ratings yet

- Us1223254 PDFDocument7 pagesUs1223254 PDFRodrigoPomaNo ratings yet

- United States PatentDocument5 pagesUnited States PatentJagannathan ArumugamNo ratings yet

- ZZ? ??/?? ???P?c222/Z: Filed April 20, 1945Document5 pagesZZ? ??/?? ???P?c222/Z: Filed April 20, 1945Edikan AkpanNo ratings yet

- Dec. 24, 1963 A. K. Kline 3,115,186: Gln/I301. '6 Bym Fda LDocument5 pagesDec. 24, 1963 A. K. Kline 3,115,186: Gln/I301. '6 Bym Fda LcheesewizzNo ratings yet

- April 5, 1966 B. Weiser 3,243,910: Filed Feb. 2, 1965Document4 pagesApril 5, 1966 B. Weiser 3,243,910: Filed Feb. 2, 1965fgrt490No ratings yet

- Data Originating From Sources Other Than The EPO May Not Be Accurate, Complete, or Up To DateDocument3 pagesData Originating From Sources Other Than The EPO May Not Be Accurate, Complete, or Up To DateJaymar ManualNo ratings yet

- Viewfinder ProjectDocument4 pagesViewfinder ProjectAndrei PoseaNo ratings yet

- Dau TomDocument6 pagesDau TomPham LoiNo ratings yet

- Us 3960084Document3 pagesUs 3960084rte678No ratings yet

- US4893426Document7 pagesUS4893426Jean DelaronciereNo ratings yet

- MMM-@U: H. M. SpragueDocument4 pagesMMM-@U: H. M. SpraguedjsfNo ratings yet

- Sept. 2, 1958 R, J, KQPF: 6 Sheets-Sheet 1 Filed Feb. 3. 1955Document16 pagesSept. 2, 1958 R, J, KQPF: 6 Sheets-Sheet 1 Filed Feb. 3. 1955Jin SongNo ratings yet

- Patented Oct. 27, 1896.: Gas Operated Magazine GunDocument14 pagesPatented Oct. 27, 1896.: Gas Operated Magazine GunСлэйтер Строительная компанияNo ratings yet

- Filed Oct. 22, 1951: P. C. HuttonDocument5 pagesFiled Oct. 22, 1951: P. C. HuttonGalo YambayNo ratings yet

- Mlliambn/Ef?Ey: M As A?Document4 pagesMlliambn/Ef?Ey: M As A?scibduser001No ratings yet

- US1024739Document3 pagesUS1024739AndrewNo ratings yet

- United States Patent (191: OuelletteDocument7 pagesUnited States Patent (191: OuellettecxzczxNo ratings yet

- US1507881Document3 pagesUS1507881Lawrence RyperNo ratings yet

- Aug-15, 1967 I P. R. Southall 3,336,042: Filed Aug. 17, 19.64 2 Sheets-Sheet 1Document4 pagesAug-15, 1967 I P. R. Southall 3,336,042: Filed Aug. 17, 19.64 2 Sheets-Sheet 1raseks1No ratings yet

- Us 3717946Document4 pagesUs 3717946ererNo ratings yet

- ?é4%.276 /4.7 Easter: RT - A2 (Alw'celeteDocument8 pages?é4%.276 /4.7 Easter: RT - A2 (Alw'celeteСлэйтер Строительная компанияNo ratings yet

- United States Patent (19) : (75) Inventor: Nahemia Sirkis, King County, WashDocument7 pagesUnited States Patent (19) : (75) Inventor: Nahemia Sirkis, King County, WashSandeep SNo ratings yet

- Us 2543888Document5 pagesUs 2543888Juan Sebastian PrietoNo ratings yet

- Berthier Us1446635Document12 pagesBerthier Us1446635cll19680% (1)

- Us965386 PDFDocument6 pagesUs965386 PDFJin SongNo ratings yet

- Tube Saport PDFDocument4 pagesTube Saport PDFjr110livecomNo ratings yet

- O/65ézá / /zzáez: Ozzezz67Document4 pagesO/65ézá / /zzáez: Ozzezz67TECUMCE GOMEZ PEREZNo ratings yet

- Us 1908930Document9 pagesUs 1908930Gerisovaldo SilvaNo ratings yet

- Us1955360 PDFDocument8 pagesUs1955360 PDFRodrigoPomaNo ratings yet

- A Single ShontgunDocument3 pagesA Single ShontgunyuehanNo ratings yet

- WWW VMQ, I07: Feb. 12, 1963 v. C. BOWMANDocument6 pagesWWW VMQ, I07: Feb. 12, 1963 v. C. BOWMANRodrigoPomaNo ratings yet

- Us4540334 PDFDocument9 pagesUs4540334 PDFJigar SutharNo ratings yet

- Us4522105 PDFDocument10 pagesUs4522105 PDFJin SongNo ratings yet

- 06.damper Apparatus and Mounting Clip ToDocument4 pages06.damper Apparatus and Mounting Clip ToRohit BirajdarNo ratings yet

- Umted States Patent (191 (11) 4,173,936: Secord Et Al. (45) Nov. 13, 1979Document8 pagesUmted States Patent (191 (11) 4,173,936: Secord Et Al. (45) Nov. 13, 1979venkatrangan2003No ratings yet

- United States "Patents PDFDocument17 pagesUnited States "Patents PDFTien Nguyen VanNo ratings yet

- Nov. 9, 1965 G. C. Molotzak 3,216,390Document5 pagesNov. 9, 1965 G. C. Molotzak 3,216,390احمد عبدالكريمNo ratings yet

- United States Patent (19) : Wood (45) Date of Patent: Jan. 8, 1985Document5 pagesUnited States Patent (19) : Wood (45) Date of Patent: Jan. 8, 1985mohammadreza91No ratings yet

- 1,138,232. Patented May 4, 1915,: 0, J, McgannDocument3 pages1,138,232. Patented May 4, 1915,: 0, J, McgannVyacheslavNo ratings yet

- A Guide to Motor Boat Design and Construction - A Collection of Historical Articles Containing Information on the Methods and Equipment of the Boat BuilderFrom EverandA Guide to Motor Boat Design and Construction - A Collection of Historical Articles Containing Information on the Methods and Equipment of the Boat BuilderNo ratings yet