Professional Documents

Culture Documents

Vacuum Pressure Impregnation: What Is It?

Vacuum Pressure Impregnation: What Is It?

Uploaded by

Praveen KumarCopyright:

Available Formats

You might also like

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- Degradation of Cellulose InsulationDocument70 pagesDegradation of Cellulose InsulationAmidou BetieNo ratings yet

- Filtros Sealkeen Emflon IIDocument2 pagesFiltros Sealkeen Emflon IItheflamebearerNo ratings yet

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- PresentationDocument36 pagesPresentationapi-3834081100% (1)

- Semi-Conductive Tape: Key Features & BenefitsDocument3 pagesSemi-Conductive Tape: Key Features & Benefitsammadbutt132No ratings yet

- Aircraft Tank RepairDocument31 pagesAircraft Tank RepairRoberto Carlos Subauste PérezNo ratings yet

- Resin ImpregnationDocument15 pagesResin Impregnationpc gamerNo ratings yet

- Cleaning Furnace CoilsDocument8 pagesCleaning Furnace CoilsMaruthiram100% (1)

- Final Mill Tariniggng ReportDocument53 pagesFinal Mill Tariniggng ReportPriyanka VishnoiNo ratings yet

- Applying Adiabatic and Steam Humidification Systems: Greg DrenskyDocument28 pagesApplying Adiabatic and Steam Humidification Systems: Greg Drenskydiagnoz7auto7carsvanNo ratings yet

- Sartorius Sartofluor Ptfe CartridgesDocument6 pagesSartorius Sartofluor Ptfe CartridgesMuhammad AkramNo ratings yet

- Aqua Cooling Adiabatic Cooling SystemDocument4 pagesAqua Cooling Adiabatic Cooling Systemcradha736No ratings yet

- 2005 Prevost PresentationDocument70 pages2005 Prevost Presentationtaufiqishak09No ratings yet

- Polyflow ExPERT Ecuador PresentationDocument29 pagesPolyflow ExPERT Ecuador PresentationRené Luis Perez MagneNo ratings yet

- Cooling Tower Presentation - Brandon Rees - 2012-10-03 PDFDocument67 pagesCooling Tower Presentation - Brandon Rees - 2012-10-03 PDFAhmad Zulkifli100% (1)

- Xenon Lamp Aging Test ChamberDocument6 pagesXenon Lamp Aging Test ChamberLisun GroupNo ratings yet

- Transformer CastingDocument10 pagesTransformer CastingJanmejaya MishraNo ratings yet

- Ball Tech EnergyDocument24 pagesBall Tech EnergySekar Sankar100% (1)

- C Series: Cage Design Control ValvesDocument6 pagesC Series: Cage Design Control Valvesdnageshm4n244No ratings yet

- The Definitive O Ring Design GuideDocument31 pagesThe Definitive O Ring Design GuideChezNo ratings yet

- Steam System 41Document41 pagesSteam System 41MadanKarkiNo ratings yet

- Impulse Cleaning SystemDocument18 pagesImpulse Cleaning SystemgjanklesariaNo ratings yet

- Buble Eliminator - QuicktronDocument2 pagesBuble Eliminator - Quicktronhpss77No ratings yet

- Air Pollution Prevention and ControlDocument48 pagesAir Pollution Prevention and Controlmuhammad usman HaiderNo ratings yet

- Considertion in On-Line ProcessingDocument13 pagesConsidertion in On-Line ProcessingsapholNo ratings yet

- Kitchen Exhaust Filtration Unit: The Revolution in Air FiltrationDocument12 pagesKitchen Exhaust Filtration Unit: The Revolution in Air FiltrationMohammad SadikNo ratings yet

- Case Study - Installation of Online Dryout System of Transformer - Tehri HPPDocument8 pagesCase Study - Installation of Online Dryout System of Transformer - Tehri HPPPraneeth ReddyNo ratings yet

- API Standard 622Document3 pagesAPI Standard 622Etienne Rocha50% (2)

- Accrolube SpecDocument3 pagesAccrolube SpecManuel GarniqueNo ratings yet

- SUCCESS STORY Pulse-Filter-House - Hazira - India - RE - 02-TM-621-May-2020-EN - LowDocument2 pagesSUCCESS STORY Pulse-Filter-House - Hazira - India - RE - 02-TM-621-May-2020-EN - LowdibNo ratings yet

- USP Presentation MunicipalDocument20 pagesUSP Presentation Municipalcoolvishal2003No ratings yet

- Prevention and Control of Air PollutionDocument48 pagesPrevention and Control of Air PollutionmikramNo ratings yet

- Prevention and Control of Air PollutionDocument48 pagesPrevention and Control of Air PollutionmikramNo ratings yet

- Rolon Dry Gas SealsDocument39 pagesRolon Dry Gas Sealsnarayan rajuNo ratings yet

- Solid Gas Separation1Document48 pagesSolid Gas Separation1krizel100% (1)

- API 622 Valve Packing For Fugitive EmissionsDocument2 pagesAPI 622 Valve Packing For Fugitive EmissionsHungphamphiNo ratings yet

- P128794 PDFDocument37 pagesP128794 PDFGustavo PalaciosNo ratings yet

- MCL Tongiani Press MPD 0Document2 pagesMCL Tongiani Press MPD 0baberoniNo ratings yet

- 70 e Deinking Laboratory Flotation Cell Delta25 VPR PB 07 0002 GB 02Document2 pages70 e Deinking Laboratory Flotation Cell Delta25 VPR PB 07 0002 GB 02cristianp55No ratings yet

- Basics of AutoclaveDocument53 pagesBasics of AutoclaveWallace GualandiNo ratings yet

- Seminar 1 - Cleanroom HVAC Design - KarachiDocument25 pagesSeminar 1 - Cleanroom HVAC Design - KarachituzlucayirNo ratings yet

- 3 LayerDocument4 pages3 LayerArya Raditya100% (1)

- Pehp7077 04Document4 pagesPehp7077 04Samille SousaNo ratings yet

- Air Intake Screen Installation: Case StudyDocument14 pagesAir Intake Screen Installation: Case Studyapi-223168153No ratings yet

- Atrium Smoke ManagementDocument33 pagesAtrium Smoke Managementmicaziv4786No ratings yet

- CTD-101K Datasheet 2003Document3 pagesCTD-101K Datasheet 2003tsram90No ratings yet

- What Is Vacuum: Vacuum Refers To The Degree of Emptiness of A Process SystemDocument38 pagesWhat Is Vacuum: Vacuum Refers To The Degree of Emptiness of A Process Systemrnsasikumar100% (1)

- Clean Rooms 101Document11 pagesClean Rooms 101gordoninklNo ratings yet

- GE Induction and Synchronous MotorsDocument8 pagesGE Induction and Synchronous MotorsidontlikeebooksNo ratings yet

- LN UK LabTecta 02b OptimisedDocument12 pagesLN UK LabTecta 02b OptimisedjbalageeNo ratings yet

- Industrial Air CleanersDocument4 pagesIndustrial Air CleanerssalgoraNo ratings yet

- Capsulas Limpias para ProduccionDocument12 pagesCapsulas Limpias para ProduccionluisrayvcNo ratings yet

- Ashish 123703 M.Tech. (AE)Document29 pagesAshish 123703 M.Tech. (AE)Ashish PariharNo ratings yet

- Cyclone FundamentalsDocument61 pagesCyclone Fundamentalsjayaram432No ratings yet

- Air CoolerDocument27 pagesAir CoolerEnriqueGDNo ratings yet

- Basic Application of PneumaticsDocument43 pagesBasic Application of PneumaticsMaheswaran MuthuNo ratings yet

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsFrom EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo ratings yet

- HT TP: //qpa Pe R.W But .Ac .In: Power System - IiiDocument7 pagesHT TP: //qpa Pe R.W But .Ac .In: Power System - IiiPraveen KumarNo ratings yet

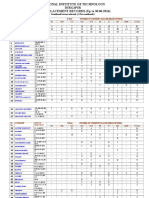

- National Institute of Technology: DurgapurDocument1 pageNational Institute of Technology: DurgapurPraveen KumarNo ratings yet

- Earthing PracticesDocument16 pagesEarthing PracticesPraveen KumarNo ratings yet

- Durgapur: (0-Considered But Not Selected, (-) Not Considered.)Document4 pagesDurgapur: (0-Considered But Not Selected, (-) Not Considered.)Praveen KumarNo ratings yet

- Live Line TransmissionDocument8 pagesLive Line TransmissionPraveen KumarNo ratings yet

- Re: What Is An Exciter and How Does It Work? Answer Ramesh GaurDocument1 pageRe: What Is An Exciter and How Does It Work? Answer Ramesh GaurPraveen KumarNo ratings yet

- Basic Principles and Functions of ElectricalDocument18 pagesBasic Principles and Functions of ElectricalPraveen KumarNo ratings yet

- Importance of Earthing & PracticesDocument26 pagesImportance of Earthing & PracticesPraveen KumarNo ratings yet

- Electrical Fault Level CalculationDocument11 pagesElectrical Fault Level CalculationPraveen KumarNo ratings yet

- Nuclear Power PlantDocument8 pagesNuclear Power PlantPraveen KumarNo ratings yet

- Schema Theory: Suggested Reading: D. E. Goldberg, Genetic Algorithm inDocument21 pagesSchema Theory: Suggested Reading: D. E. Goldberg, Genetic Algorithm inPraveen KumarNo ratings yet

- AnnexDocument1 pageAnnexPraveen KumarNo ratings yet

- Veac Ja ReportDocument99 pagesVeac Ja ReportPraveen KumarNo ratings yet

- Iostream.h Conio.h String.h Stdio.h Dos.h Stdlib.h Process.h Fstream.hDocument1 pageIostream.h Conio.h String.h Stdio.h Dos.h Stdlib.h Process.h Fstream.hPraveen KumarNo ratings yet

- Instantaneous Reactive Power SystemDocument16 pagesInstantaneous Reactive Power SystemPraveen KumarNo ratings yet

- Village TourDocument3 pagesVillage TourPraveen KumarNo ratings yet

- National Institute of Technology Durgapur Department of Physical TrainingDocument1 pageNational Institute of Technology Durgapur Department of Physical TrainingPraveen KumarNo ratings yet

- (WWW - Entrance-Exam - Net) - Exclusive Aptitude Test For L&TDocument3 pages(WWW - Entrance-Exam - Net) - Exclusive Aptitude Test For L&TPraveen KumarNo ratings yet

- Natura FinalDocument1 pageNatura FinalPraveen KumarNo ratings yet

- GSM Invoice April BSNLDocument1 pageGSM Invoice April BSNLPraveen KumarNo ratings yet

- Synchronous Generator Capability Limitt: 1.MVA or Armature Current Limit of GeneratorDocument2 pagesSynchronous Generator Capability Limitt: 1.MVA or Armature Current Limit of GeneratorPraveen Kumar100% (1)

- Prakriti: Official Environmental ClubDocument2 pagesPrakriti: Official Environmental ClubPraveen KumarNo ratings yet

- A Thing of BeautyDocument6 pagesA Thing of BeautyPraveen KumarNo ratings yet

- PhysicsDocument1 pagePhysicsPraveen KumarNo ratings yet

Vacuum Pressure Impregnation: What Is It?

Vacuum Pressure Impregnation: What Is It?

Uploaded by

Praveen KumarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Vacuum Pressure Impregnation: What Is It?

Vacuum Pressure Impregnation: What Is It?

Uploaded by

Praveen KumarCopyright:

Available Formats

Vacuum Pressure Impregnation

What is it?

Removes Air, Gas & Moisture from the System Complete Penetration of Turns, Coils, Slots & Insulation Coil Preparation Evacuation Saturation Pressure Cure Better Heat Dissipation Longer Insulation Life Less Susceptible to Cracking and Corona Improved Resistance to Moisture and Chemicals Reduction of Coil Movement Improved Quality Lower Cost

How does it Work?

What are the Advantages of a fully Impregnated System?

Typical Treatment Cycle for Vacuum Pressure Impregnation

1. 2. 3. 4. 5. 6. 7. 8. 9. Preheat for 3 Hours at 250 degrees F. De-aerate Resin in Reservoir: 1mm. Cool Stator: 70-100 degrees F. Place Stator in Chamber and pull Vacuum: 1mm. Impregnate and hold Vacuum: 1 hour. Pressure Chamber: 80-100 psi for 1 hour. Depressurize and drain. Cure: 5 hours at 300 degrees F. Repeat Process

One of the high longevity contributors to the electric motor is the method of encapsulation. The highest industry standards for electric motor encapsulation is through a process called VPI; (Vacuum Pressure Impregnation) This state of the art method is only used in less than 10% of worlds standard electric motor production and is primarily applied on extreme heavy duty applications. Van der Graaf has adopted the VPI method as standard to all of our products. This process has helped the end user to reduce electric motor failures substantially.

You might also like

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- Degradation of Cellulose InsulationDocument70 pagesDegradation of Cellulose InsulationAmidou BetieNo ratings yet

- Filtros Sealkeen Emflon IIDocument2 pagesFiltros Sealkeen Emflon IItheflamebearerNo ratings yet

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- PresentationDocument36 pagesPresentationapi-3834081100% (1)

- Semi-Conductive Tape: Key Features & BenefitsDocument3 pagesSemi-Conductive Tape: Key Features & Benefitsammadbutt132No ratings yet

- Aircraft Tank RepairDocument31 pagesAircraft Tank RepairRoberto Carlos Subauste PérezNo ratings yet

- Resin ImpregnationDocument15 pagesResin Impregnationpc gamerNo ratings yet

- Cleaning Furnace CoilsDocument8 pagesCleaning Furnace CoilsMaruthiram100% (1)

- Final Mill Tariniggng ReportDocument53 pagesFinal Mill Tariniggng ReportPriyanka VishnoiNo ratings yet

- Applying Adiabatic and Steam Humidification Systems: Greg DrenskyDocument28 pagesApplying Adiabatic and Steam Humidification Systems: Greg Drenskydiagnoz7auto7carsvanNo ratings yet

- Sartorius Sartofluor Ptfe CartridgesDocument6 pagesSartorius Sartofluor Ptfe CartridgesMuhammad AkramNo ratings yet

- Aqua Cooling Adiabatic Cooling SystemDocument4 pagesAqua Cooling Adiabatic Cooling Systemcradha736No ratings yet

- 2005 Prevost PresentationDocument70 pages2005 Prevost Presentationtaufiqishak09No ratings yet

- Polyflow ExPERT Ecuador PresentationDocument29 pagesPolyflow ExPERT Ecuador PresentationRené Luis Perez MagneNo ratings yet

- Cooling Tower Presentation - Brandon Rees - 2012-10-03 PDFDocument67 pagesCooling Tower Presentation - Brandon Rees - 2012-10-03 PDFAhmad Zulkifli100% (1)

- Xenon Lamp Aging Test ChamberDocument6 pagesXenon Lamp Aging Test ChamberLisun GroupNo ratings yet

- Transformer CastingDocument10 pagesTransformer CastingJanmejaya MishraNo ratings yet

- Ball Tech EnergyDocument24 pagesBall Tech EnergySekar Sankar100% (1)

- C Series: Cage Design Control ValvesDocument6 pagesC Series: Cage Design Control Valvesdnageshm4n244No ratings yet

- The Definitive O Ring Design GuideDocument31 pagesThe Definitive O Ring Design GuideChezNo ratings yet

- Steam System 41Document41 pagesSteam System 41MadanKarkiNo ratings yet

- Impulse Cleaning SystemDocument18 pagesImpulse Cleaning SystemgjanklesariaNo ratings yet

- Buble Eliminator - QuicktronDocument2 pagesBuble Eliminator - Quicktronhpss77No ratings yet

- Air Pollution Prevention and ControlDocument48 pagesAir Pollution Prevention and Controlmuhammad usman HaiderNo ratings yet

- Considertion in On-Line ProcessingDocument13 pagesConsidertion in On-Line ProcessingsapholNo ratings yet

- Kitchen Exhaust Filtration Unit: The Revolution in Air FiltrationDocument12 pagesKitchen Exhaust Filtration Unit: The Revolution in Air FiltrationMohammad SadikNo ratings yet

- Case Study - Installation of Online Dryout System of Transformer - Tehri HPPDocument8 pagesCase Study - Installation of Online Dryout System of Transformer - Tehri HPPPraneeth ReddyNo ratings yet

- API Standard 622Document3 pagesAPI Standard 622Etienne Rocha50% (2)

- Accrolube SpecDocument3 pagesAccrolube SpecManuel GarniqueNo ratings yet

- SUCCESS STORY Pulse-Filter-House - Hazira - India - RE - 02-TM-621-May-2020-EN - LowDocument2 pagesSUCCESS STORY Pulse-Filter-House - Hazira - India - RE - 02-TM-621-May-2020-EN - LowdibNo ratings yet

- USP Presentation MunicipalDocument20 pagesUSP Presentation Municipalcoolvishal2003No ratings yet

- Prevention and Control of Air PollutionDocument48 pagesPrevention and Control of Air PollutionmikramNo ratings yet

- Prevention and Control of Air PollutionDocument48 pagesPrevention and Control of Air PollutionmikramNo ratings yet

- Rolon Dry Gas SealsDocument39 pagesRolon Dry Gas Sealsnarayan rajuNo ratings yet

- Solid Gas Separation1Document48 pagesSolid Gas Separation1krizel100% (1)

- API 622 Valve Packing For Fugitive EmissionsDocument2 pagesAPI 622 Valve Packing For Fugitive EmissionsHungphamphiNo ratings yet

- P128794 PDFDocument37 pagesP128794 PDFGustavo PalaciosNo ratings yet

- MCL Tongiani Press MPD 0Document2 pagesMCL Tongiani Press MPD 0baberoniNo ratings yet

- 70 e Deinking Laboratory Flotation Cell Delta25 VPR PB 07 0002 GB 02Document2 pages70 e Deinking Laboratory Flotation Cell Delta25 VPR PB 07 0002 GB 02cristianp55No ratings yet

- Basics of AutoclaveDocument53 pagesBasics of AutoclaveWallace GualandiNo ratings yet

- Seminar 1 - Cleanroom HVAC Design - KarachiDocument25 pagesSeminar 1 - Cleanroom HVAC Design - KarachituzlucayirNo ratings yet

- 3 LayerDocument4 pages3 LayerArya Raditya100% (1)

- Pehp7077 04Document4 pagesPehp7077 04Samille SousaNo ratings yet

- Air Intake Screen Installation: Case StudyDocument14 pagesAir Intake Screen Installation: Case Studyapi-223168153No ratings yet

- Atrium Smoke ManagementDocument33 pagesAtrium Smoke Managementmicaziv4786No ratings yet

- CTD-101K Datasheet 2003Document3 pagesCTD-101K Datasheet 2003tsram90No ratings yet

- What Is Vacuum: Vacuum Refers To The Degree of Emptiness of A Process SystemDocument38 pagesWhat Is Vacuum: Vacuum Refers To The Degree of Emptiness of A Process Systemrnsasikumar100% (1)

- Clean Rooms 101Document11 pagesClean Rooms 101gordoninklNo ratings yet

- GE Induction and Synchronous MotorsDocument8 pagesGE Induction and Synchronous MotorsidontlikeebooksNo ratings yet

- LN UK LabTecta 02b OptimisedDocument12 pagesLN UK LabTecta 02b OptimisedjbalageeNo ratings yet

- Industrial Air CleanersDocument4 pagesIndustrial Air CleanerssalgoraNo ratings yet

- Capsulas Limpias para ProduccionDocument12 pagesCapsulas Limpias para ProduccionluisrayvcNo ratings yet

- Ashish 123703 M.Tech. (AE)Document29 pagesAshish 123703 M.Tech. (AE)Ashish PariharNo ratings yet

- Cyclone FundamentalsDocument61 pagesCyclone Fundamentalsjayaram432No ratings yet

- Air CoolerDocument27 pagesAir CoolerEnriqueGDNo ratings yet

- Basic Application of PneumaticsDocument43 pagesBasic Application of PneumaticsMaheswaran MuthuNo ratings yet

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsFrom EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo ratings yet

- HT TP: //qpa Pe R.W But .Ac .In: Power System - IiiDocument7 pagesHT TP: //qpa Pe R.W But .Ac .In: Power System - IiiPraveen KumarNo ratings yet

- National Institute of Technology: DurgapurDocument1 pageNational Institute of Technology: DurgapurPraveen KumarNo ratings yet

- Earthing PracticesDocument16 pagesEarthing PracticesPraveen KumarNo ratings yet

- Durgapur: (0-Considered But Not Selected, (-) Not Considered.)Document4 pagesDurgapur: (0-Considered But Not Selected, (-) Not Considered.)Praveen KumarNo ratings yet

- Live Line TransmissionDocument8 pagesLive Line TransmissionPraveen KumarNo ratings yet

- Re: What Is An Exciter and How Does It Work? Answer Ramesh GaurDocument1 pageRe: What Is An Exciter and How Does It Work? Answer Ramesh GaurPraveen KumarNo ratings yet

- Basic Principles and Functions of ElectricalDocument18 pagesBasic Principles and Functions of ElectricalPraveen KumarNo ratings yet

- Importance of Earthing & PracticesDocument26 pagesImportance of Earthing & PracticesPraveen KumarNo ratings yet

- Electrical Fault Level CalculationDocument11 pagesElectrical Fault Level CalculationPraveen KumarNo ratings yet

- Nuclear Power PlantDocument8 pagesNuclear Power PlantPraveen KumarNo ratings yet

- Schema Theory: Suggested Reading: D. E. Goldberg, Genetic Algorithm inDocument21 pagesSchema Theory: Suggested Reading: D. E. Goldberg, Genetic Algorithm inPraveen KumarNo ratings yet

- AnnexDocument1 pageAnnexPraveen KumarNo ratings yet

- Veac Ja ReportDocument99 pagesVeac Ja ReportPraveen KumarNo ratings yet

- Iostream.h Conio.h String.h Stdio.h Dos.h Stdlib.h Process.h Fstream.hDocument1 pageIostream.h Conio.h String.h Stdio.h Dos.h Stdlib.h Process.h Fstream.hPraveen KumarNo ratings yet

- Instantaneous Reactive Power SystemDocument16 pagesInstantaneous Reactive Power SystemPraveen KumarNo ratings yet

- Village TourDocument3 pagesVillage TourPraveen KumarNo ratings yet

- National Institute of Technology Durgapur Department of Physical TrainingDocument1 pageNational Institute of Technology Durgapur Department of Physical TrainingPraveen KumarNo ratings yet

- (WWW - Entrance-Exam - Net) - Exclusive Aptitude Test For L&TDocument3 pages(WWW - Entrance-Exam - Net) - Exclusive Aptitude Test For L&TPraveen KumarNo ratings yet

- Natura FinalDocument1 pageNatura FinalPraveen KumarNo ratings yet

- GSM Invoice April BSNLDocument1 pageGSM Invoice April BSNLPraveen KumarNo ratings yet

- Synchronous Generator Capability Limitt: 1.MVA or Armature Current Limit of GeneratorDocument2 pagesSynchronous Generator Capability Limitt: 1.MVA or Armature Current Limit of GeneratorPraveen Kumar100% (1)

- Prakriti: Official Environmental ClubDocument2 pagesPrakriti: Official Environmental ClubPraveen KumarNo ratings yet

- A Thing of BeautyDocument6 pagesA Thing of BeautyPraveen KumarNo ratings yet

- PhysicsDocument1 pagePhysicsPraveen KumarNo ratings yet