Professional Documents

Culture Documents

Qcf305 Ut Report

Qcf305 Ut Report

Uploaded by

minhnn0 ratings0% found this document useful (0 votes)

67 views1 pageThis ultrasonic testing report summarizes an inspection of welds on the Dung Quat Refinery project in Vietnam. It provides details on calibration blocks, welding and material specifications, probes and flaw detectors used, and inspection results including locations and dimensions of any defects found. The report found some welds acceptable and some requiring rejection or repair based on the acceptance standards for the project.

Original Description:

form

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis ultrasonic testing report summarizes an inspection of welds on the Dung Quat Refinery project in Vietnam. It provides details on calibration blocks, welding and material specifications, probes and flaw detectors used, and inspection results including locations and dimensions of any defects found. The report found some welds acceptable and some requiring rejection or repair based on the acceptance standards for the project.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

Download as doc, pdf, or txt

0 ratings0% found this document useful (0 votes)

67 views1 pageQcf305 Ut Report

Qcf305 Ut Report

Uploaded by

minhnnThis ultrasonic testing report summarizes an inspection of welds on the Dung Quat Refinery project in Vietnam. It provides details on calibration blocks, welding and material specifications, probes and flaw detectors used, and inspection results including locations and dimensions of any defects found. The report found some welds acceptable and some requiring rejection or repair based on the acceptance standards for the project.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

Download as doc, pdf, or txt

You are on page 1of 1

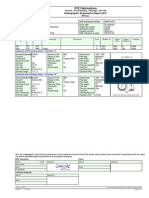

ULTRASONIC TESTING REPORT

Project: DUNG QUAT REFINERY (DQR) PROJECT Client: VIETNAM OIL AND GAS CORPORATION (PETROVIETNAM)

Project No.: 8474L

Subcontractor Logo

Quality Control Form: QCF 305

Report No.: Date:

Page: Calibration blocks: DAC block: Weld Preparation: Welding Process: Material spec.: Surface condition: Parent Metal Examined:

Drawing No./Line No.:

Acceptance Standard: Produce No.: Probes 0o Type Serial No.: Size (mm) Frequency (mHz) Range (mm) Sensitivity (dB) Transfer (dB) Couplant: Stage of Examination: No.: Weld No.: Size/ Length 45o Flaw detector : Serial No.: 60o 70o

Date of inspection: As Welded Thick. (mm) /Sch After P.W.H.T Welder No. Defect Location Defect Length Defect Width

Request No.: After Hydrotest Defect Depth Other Type of Defect Result Acc./Rej.

REMARKS: Acc: Accept Material Identification for lamination check Detect Type: PL; Planar defect CL: Cylindrical defect SP: Spherical defect

TOTAL LENGTH: (meters) Rej:

Reject

SUBCONTRACTOR Company: Name: Sign Date:

CONTRACTOR

CLIENT

You might also like

- QCF304 Magnetic Particle Testing ReportDocument2 pagesQCF304 Magnetic Particle Testing Reportminhnn100% (1)

- ACI 304R-00 Guide For Measuring, Mixing, Transporting, and Placing ConcreteDocument41 pagesACI 304R-00 Guide For Measuring, Mixing, Transporting, and Placing Concretebonnico75% (4)

- QCF108 Grouting Inspection ReportDocument1 pageQCF108 Grouting Inspection Reportminhnn100% (3)

- Inspection Report Radiographic TestingDocument1 pageInspection Report Radiographic TestingJindarat Kasemsooksakul0% (1)

- Ultrasonic Testing Report For PipingDocument54 pagesUltrasonic Testing Report For Pipingeldobie3No ratings yet

- AWS QC 10-95 Spec 4 Qualification Certification Entry Level WelderDocument25 pagesAWS QC 10-95 Spec 4 Qualification Certification Entry Level WelderminhnnNo ratings yet

- AWS Exam - Modules 01-10Document335 pagesAWS Exam - Modules 01-10minhnnNo ratings yet

- Aci 117 - 90 Concrete Construction PDFDocument16 pagesAci 117 - 90 Concrete Construction PDFcessare08100% (4)

- QCF101 Compaction Test ReportDocument1 pageQCF101 Compaction Test ReportminhnnNo ratings yet

- Ultrasonic Examination Report: The Royal Utilisation Services Pvt. LTDDocument9 pagesUltrasonic Examination Report: The Royal Utilisation Services Pvt. LTDNazmul HasanNo ratings yet

- Magnetic Particle Testing ReporDocument2 pagesMagnetic Particle Testing ReporGabriela MotaNo ratings yet

- REPORT-MT 21.10.2022 (Test)Document2 pagesREPORT-MT 21.10.2022 (Test)Nhien ManNo ratings yet

- International Limited: Certificate of Visual Examination and MpiDocument2 pagesInternational Limited: Certificate of Visual Examination and MpiMichael OkwuwaNo ratings yet

- Defect / Non Compliance ReportDocument12 pagesDefect / Non Compliance ReportMichael OkwuwaNo ratings yet

- Vac Box Bubble Leak Testing AcessoriesDocument4 pagesVac Box Bubble Leak Testing AcessoriessbmmlaNo ratings yet

- DP Test Tank 1Document2 pagesDP Test Tank 1sushant sanjay jadhav0% (1)

- Ut Report-1 PDFDocument1 pageUt Report-1 PDFsureshrathod2No ratings yet

- Magnetic Particle TestDocument4 pagesMagnetic Particle TestHarry Doble100% (1)

- 002 DPB PT Asme 2012 PT AsmeDocument43 pages002 DPB PT Asme 2012 PT AsmeAozoraLazoraNo ratings yet

- Welder Qualification ReportDocument2 pagesWelder Qualification ReportSyed Mahmud Habibur RahmanNo ratings yet

- CV of Engineer MD Sazid Alam1Document8 pagesCV of Engineer MD Sazid Alam1Alam MD SazidNo ratings yet

- UT Report FormDocument1 pageUT Report FormElisha NguyenNo ratings yet

- Thickness GaugingDocument3 pagesThickness GaugingAmit HasanNo ratings yet

- ResumeDocument5 pagesResumeHemant ChaudharyNo ratings yet

- CAST MT 001, Rev.0 Pressure VesselDocument10 pagesCAST MT 001, Rev.0 Pressure VesselFendi100% (1)

- International Limited: Magnetic Particle Inspection ReportDocument43 pagesInternational Limited: Magnetic Particle Inspection ReportMichael OkwuwaNo ratings yet

- Ultrasonic Test Report: Probe: Frequency: Type: Size: Angle: Reference Sensitivity (DB) ScanDocument1 pageUltrasonic Test Report: Probe: Frequency: Type: Size: Angle: Reference Sensitivity (DB) ScanZafar BhiwandiwalaNo ratings yet

- Trinity Transformer PVT LTD: Liquidpenetrant Examination ReportDocument2 pagesTrinity Transformer PVT LTD: Liquidpenetrant Examination ReportipraoNo ratings yet

- Ultrasonic Wall Thickness Report Feb.27-28,20062 - 2Document32 pagesUltrasonic Wall Thickness Report Feb.27-28,20062 - 2Endickk Screamo PoreperrNo ratings yet

- Dimensional Check-Form 3TDocument3 pagesDimensional Check-Form 3Tlempeng durianNo ratings yet

- Ut PQRDocument10 pagesUt PQRArvind Sahani100% (1)

- Wall Thickness - ReportDocument1 pageWall Thickness - ReportPetro100% (1)

- Liquid Penetrant Test Report.Document2 pagesLiquid Penetrant Test Report.mani kandan100% (1)

- GRP - PM.QA.02A - Prosedur Magnetic Test (AWS) - Rev.01Document14 pagesGRP - PM.QA.02A - Prosedur Magnetic Test (AWS) - Rev.01Riyan to100% (1)

- DPI Test ReportDocument1 pageDPI Test Reportengsam777100% (1)

- VT ReportDocument1 pageVT ReportAbhishek SharmaNo ratings yet

- Ultrasonic Thickness ReportDocument1 pageUltrasonic Thickness ReportengmuhmudNo ratings yet

- F-Liquid Penetran Exam ReportDocument24 pagesF-Liquid Penetran Exam Reportzat572000No ratings yet

- Inspection Report Magnetic Particle Examination (Tupi STR)Document1 pageInspection Report Magnetic Particle Examination (Tupi STR)Jindarat Kasemsooksakul100% (1)

- ET NDT Sample Test Report FormatDocument1 pageET NDT Sample Test Report Formatanas dwiNo ratings yet

- Pt. Saferad Servis Indonesia: Ultrasonic Inspection ReportDocument3 pagesPt. Saferad Servis Indonesia: Ultrasonic Inspection Reportkucing_batam0% (1)

- Summary TER of 13 Unit 20FT ISO Dry ContainerDocument219 pagesSummary TER of 13 Unit 20FT ISO Dry ContainerGhilman0529No ratings yet

- Magnetic Particle Examination: DateDocument2 pagesMagnetic Particle Examination: DateAbhishek SharmaNo ratings yet

- Pt. Sispum Sarana GrahaDocument2 pagesPt. Sispum Sarana GrahaMochammad AriefNo ratings yet

- Ultrasonic Report: Probe Details and Position (Fig 1)Document2 pagesUltrasonic Report: Probe Details and Position (Fig 1)BALA GANESH100% (1)

- Prequalified Welding Procedure Spesification (WPSS) : (Semiautomatics, Mechanized, Etc)Document2 pagesPrequalified Welding Procedure Spesification (WPSS) : (Semiautomatics, Mechanized, Etc)Nuril VS theWorldNo ratings yet

- NDT TestDocument109 pagesNDT TestAnonymous uXdS9Y7No ratings yet

- Nondestructive Material Testing With Ult PDFDocument41 pagesNondestructive Material Testing With Ult PDFdanielsanchezcalNo ratings yet

- Visible Penetrant Examination Using The Water-Washable ProcessDocument6 pagesVisible Penetrant Examination Using The Water-Washable ProcessERNESTO ENRIQUE FERNANDEZ BAPTISTANo ratings yet

- Pws Convention PresentationDocument93 pagesPws Convention Presentationbenj100% (1)

- Daily Welding Report PLD LogoDocument1 pageDaily Welding Report PLD Logonike_y2kNo ratings yet

- International Limited: Certificate of Visual Examination and MpiDocument2 pagesInternational Limited: Certificate of Visual Examination and MpiMichael OkwuwaNo ratings yet

- PT-Liquid Penetrant Testing Procedure R01 - 2 2Document12 pagesPT-Liquid Penetrant Testing Procedure R01 - 2 2George Ogbeche100% (1)

- Procedure For Liquid Penetrant ExaminationDocument12 pagesProcedure For Liquid Penetrant ExaminationShashank ParmarNo ratings yet

- RNS - NDT - PT - 001 Rev.0Document8 pagesRNS - NDT - PT - 001 Rev.0Goutam Kumar Deb100% (1)

- Ndtspec Radiographic Nde ReportDocument1 pageNdtspec Radiographic Nde ReportcarlosNo ratings yet

- SSIS Visual Examination Report FormatDocument1 pageSSIS Visual Examination Report FormatSalman KhanNo ratings yet

- WPQ Certificates Klis14Document8 pagesWPQ Certificates Klis14AdhicharanNo ratings yet

- CV Hotrungtinh QC-NDT PDFDocument6 pagesCV Hotrungtinh QC-NDT PDFTrung Tinh HoNo ratings yet

- 75914199-2 - Fu-10-Pad - Eyes-Mpi, 20-May-2024Document1 page75914199-2 - Fu-10-Pad - Eyes-Mpi, 20-May-2024Mohamed El-SawahNo ratings yet

- Sathik NDT ResumeDocument7 pagesSathik NDT ResumeulocksystemNo ratings yet

- Laser Cleaning Machine ManualDocument17 pagesLaser Cleaning Machine ManualForfi RithNo ratings yet

- Techno NDT Services: Ultrasonic Flaw Detection ReportDocument1 pageTechno NDT Services: Ultrasonic Flaw Detection Reportram dreamsNo ratings yet

- Drawing No./Line No.:: DateDocument2 pagesDrawing No./Line No.:: DatesuparnaNo ratings yet

- Welder Qualification Report FormDocument1 pageWelder Qualification Report FormNanaba Nanayaw DwomohNo ratings yet

- QCF312 WPQRDocument2 pagesQCF312 WPQRminhnnNo ratings yet

- AWS QC 11-96 Spec 4 Qualification Certification Advanced Level WelderDocument38 pagesAWS QC 11-96 Spec 4 Qualification Certification Advanced Level Welderminhnn50% (2)

- Aci 304.6R-91Document14 pagesAci 304.6R-91minhnnNo ratings yet

- Welding EngineerDocument10 pagesWelding EngineerNnamdi Celestine NnamdiNo ratings yet

- Batching, Mixing and Job-Control of Lightweight ConcreteDocument9 pagesBatching, Mixing and Job-Control of Lightweight ConcreteRonaldo HertezNo ratings yet

- QCF011 Asphalt Concrete Site ControlDocument3 pagesQCF011 Asphalt Concrete Site ControlminhnnNo ratings yet

- 126 3R-99 PDFDocument50 pages126 3R-99 PDFfarhadamNo ratings yet

- QCF007 Post Pour Inspection and Concrete RepairDocument1 pageQCF007 Post Pour Inspection and Concrete Repairminhnn100% (1)

- Aci 304.2R-96Document25 pagesAci 304.2R-96minhnnNo ratings yet

- Aci 304.3R-96Document8 pagesAci 304.3R-96minhnnNo ratings yet

- QCF008 Concrete Mixing Order No.Document1 pageQCF008 Concrete Mixing Order No.minhnnNo ratings yet

- Dung Quat Refinery Project: Works Inspection ReportDocument1 pageDung Quat Refinery Project: Works Inspection ReportminhnnNo ratings yet

- QCF010 Works Inspection Report GeotextileDocument1 pageQCF010 Works Inspection Report GeotextileminhnnNo ratings yet

- QCF110 Instrument Cable Trench Inspection SheetDocument1 pageQCF110 Instrument Cable Trench Inspection SheetminhnnNo ratings yet

- QCF009 Insp Report-Precast ConcreteDocument1 pageQCF009 Insp Report-Precast ConcreteminhnnNo ratings yet

- QCF013 Inspection Check SheetDocument1 pageQCF013 Inspection Check SheetminhnnNo ratings yet

- QCF102 Concrete Pouring RecordDocument1 pageQCF102 Concrete Pouring RecordminhnnNo ratings yet

- QCF113 Structural Steel Pre-Fabrication CertificateDocument1 pageQCF113 Structural Steel Pre-Fabrication CertificateminhnnNo ratings yet

- QCF106 Surveying Record - FoundationDocument1 pageQCF106 Surveying Record - FoundationminhnnNo ratings yet

- QCF111 Cement Concrete Paving ReportDocument2 pagesQCF111 Cement Concrete Paving ReportminhnnNo ratings yet

- QCF113 Insert Rebar InspectionDocument1 pageQCF113 Insert Rebar InspectionminhnnNo ratings yet