Professional Documents

Culture Documents

Shore Scleroscope Hardness Test

Shore Scleroscope Hardness Test

Uploaded by

Jay VoraCopyright:

Available Formats

You might also like

- Hardness Test Lab Report PDFDocument9 pagesHardness Test Lab Report PDFKalKatu MaLam76% (42)

- Impact Test Lab ReportDocument5 pagesImpact Test Lab Reportaisyah mohamad othman85% (72)

- Multi ModeDocument73 pagesMulti ModeShalinee KavadiyaNo ratings yet

- Tool and Material List-Girth Gear InstallDocument2 pagesTool and Material List-Girth Gear InstallPeter RoseNo ratings yet

- Hardness Lab ReportDocument6 pagesHardness Lab ReportRashmika Uluwatta100% (4)

- Engr: Temoor Abbas Larik: QUCEST Larkana Campus Mechanical Engineering DepartmentDocument42 pagesEngr: Temoor Abbas Larik: QUCEST Larkana Campus Mechanical Engineering DepartmentTemoor AbbasNo ratings yet

- TensileDocument5 pagesTensileTharinya SellathuraiNo ratings yet

- Low Coefficient of Thermal ExpansionDocument13 pagesLow Coefficient of Thermal ExpansionnileshsawNo ratings yet

- Scanning Probe MicroscopeDocument4 pagesScanning Probe MicroscopebabakNo ratings yet

- Micro Hardness Tester Manual Book HVD-1000AP MPDocument38 pagesMicro Hardness Tester Manual Book HVD-1000AP MPDaisy HeNo ratings yet

- 2168 - Jominy End Quench TestDocument6 pages2168 - Jominy End Quench TestNikhil Satbhai100% (1)

- Mechanical PropertiesDocument26 pagesMechanical PropertiesiqbalNo ratings yet

- HardnessDocument15 pagesHardnessAanand Rishabh DagaNo ratings yet

- Pin On Disc DryDocument8 pagesPin On Disc DryHrushikesh KhairnarNo ratings yet

- Charpy Impact Test: Experiment 2Document5 pagesCharpy Impact Test: Experiment 2Utkarsh KumarNo ratings yet

- Shore Scleresope NotesDocument1 pageShore Scleresope Noteslilianwakio2016No ratings yet

- Hardness Testing and Impact Testing of MaterialsDocument32 pagesHardness Testing and Impact Testing of MaterialsMUUTHUKRISHNAN100% (4)

- Shore ScleroscopeDocument6 pagesShore ScleroscopeAaliyahNo ratings yet

- Module No 2 Equipment and Apparatus For Construction Materials TestingDocument37 pagesModule No 2 Equipment and Apparatus For Construction Materials TestingjlssupanNo ratings yet

- Material ScienceDocument46 pagesMaterial Sciencealfa89pNo ratings yet

- Material TestingDocument7 pagesMaterial TestingkimsonNo ratings yet

- 14 Mattiullah Report WritingDocument15 pages14 Mattiullah Report WritingMattiullahNo ratings yet

- A Guide To Laboratory Testing of Metal ProductsDocument7 pagesA Guide To Laboratory Testing of Metal ProductsShemelsNo ratings yet

- Assignment 3 - POMDocument8 pagesAssignment 3 - POMMcDhanesh JiNo ratings yet

- Engineering Materials - Hardness TestingDocument5 pagesEngineering Materials - Hardness TestingrandomkillerNo ratings yet

- Rockwell Hardness TesterDocument5 pagesRockwell Hardness TesterShivansh PathakNo ratings yet

- Hardness Test A4Document9 pagesHardness Test A4aisyah mohamad othmanNo ratings yet

- Rockwell Hardness TestorDocument1 pageRockwell Hardness TestorAdnan MehmoodNo ratings yet

- JF 302 - Material Technology 1Document18 pagesJF 302 - Material Technology 1Arif AzizAnNo ratings yet

- (Useful) Unit 2 Mechanical Test of MaterialDocument57 pages(Useful) Unit 2 Mechanical Test of Materialbalajimeie100% (1)

- Q2-Materials TestingDocument58 pagesQ2-Materials Testingapi-348195110No ratings yet

- Destructive TestingDocument42 pagesDestructive TestingHyori AnapadaNo ratings yet

- Destructive Examination & TestingDocument33 pagesDestructive Examination & TestingMallesh KaruparthyNo ratings yet

- Submitted To:: Lab ManualDocument30 pagesSubmitted To:: Lab ManualAbdul Azeem50% (2)

- Destructive Examination & TestingDocument31 pagesDestructive Examination & TestingMau Atenas PerezNo ratings yet

- Material Science Module-2: Stress Strain Curve For Ductile MaterialDocument26 pagesMaterial Science Module-2: Stress Strain Curve For Ductile MaterialKushNo ratings yet

- Material TestingDocument59 pagesMaterial TestingWilliam Salazar100% (4)

- SVKM'S Nmims Mukesh Patel School Technology Management and Engineering Strength of Materials LabDocument4 pagesSVKM'S Nmims Mukesh Patel School Technology Management and Engineering Strength of Materials LabBender GamingNo ratings yet

- Destructive Test MethodsDocument33 pagesDestructive Test MethodsAvalcwiNo ratings yet

- Hardness of PolymerDocument10 pagesHardness of PolymerAadarsh BramhapurkarNo ratings yet

- Engineering Materials Lab ManualDocument14 pagesEngineering Materials Lab ManualHarood Nishat100% (1)

- Chapter4 150109005052 Conversion Gate02Document56 pagesChapter4 150109005052 Conversion Gate02زهديابوانسNo ratings yet

- Line Pipe InpectionDocument32 pagesLine Pipe InpectionRaza MehdiNo ratings yet

- PMT Sifat MaterialDocument67 pagesPMT Sifat MaterialFrislyNo ratings yet

- Hardness Testing of Metallic Materials: February 2021Document14 pagesHardness Testing of Metallic Materials: February 2021jvidal.salgadoNo ratings yet

- What Is Hardness?: (Type Text)Document5 pagesWhat Is Hardness?: (Type Text)akif222999No ratings yet

- Rockwell Hardness Test.... 1Document2 pagesRockwell Hardness Test.... 1rafai167% (3)

- Material TestingDocument58 pagesMaterial TestingChanoxismNo ratings yet

- MQA Technical ReportDocument8 pagesMQA Technical ReportShaffan AbbasiNo ratings yet

- Hardness ReportDocument6 pagesHardness ReportNawanshika MendisNo ratings yet

- Lab ReportDocument21 pagesLab ReportMuhammad YasirNo ratings yet

- Hardness Is The Resistance of A Material To Localized DeformationDocument17 pagesHardness Is The Resistance of A Material To Localized DeformationJonathan FloresNo ratings yet

- ME 2203 Engineering Materials: Dr. Kazi Md. ShorowordiDocument17 pagesME 2203 Engineering Materials: Dr. Kazi Md. ShorowordiTahmim AlamNo ratings yet

- Steel ApplicationDocument49 pagesSteel ApplicationRiben CaratingNo ratings yet

- Hardness TestDocument12 pagesHardness TestLola MeerazNo ratings yet

- Document (1) - 1Document28 pagesDocument (1) - 1Saad AliKhanNo ratings yet

- Tensile Test of Steel BarsDocument2 pagesTensile Test of Steel BarsCeddie PamintuanNo ratings yet

- UNIT-II Mechanical Property MeasurementDocument127 pagesUNIT-II Mechanical Property Measurementlol WANo ratings yet

- Fundamentals of Rockwell Hardness TestingDocument16 pagesFundamentals of Rockwell Hardness TestingAnonymous Wi2Pd2UgPINo ratings yet

- Hardness TestingDocument15 pagesHardness TestingSivakumar ChinnasamyNo ratings yet

- Chapter 7 - Destructive and Non Destructive Testing of MaterialDocument33 pagesChapter 7 - Destructive and Non Destructive Testing of MaterialzainonayraNo ratings yet

- AncientDocument172 pagesAncientJay VoraNo ratings yet

- Notice Period For FlatDocument1 pageNotice Period For FlatJay VoraNo ratings yet

- Aerodynamic Analysis For A Distributed Electric Propulsion AircraftDocument1 pageAerodynamic Analysis For A Distributed Electric Propulsion AircraftJay VoraNo ratings yet

- Co-Efficient of PressureDocument2 pagesCo-Efficient of PressureJay VoraNo ratings yet

- Examples of The Principle of Superposition: 1. Source Plus A Uniform FlowDocument6 pagesExamples of The Principle of Superposition: 1. Source Plus A Uniform FlowJay Vora100% (1)

- Comparison of Pathline and StreamlineDocument1 pageComparison of Pathline and StreamlineJay VoraNo ratings yet

- For For: %uniform Stream %grid %gridDocument2 pagesFor For: %uniform Stream %grid %gridJay VoraNo ratings yet

- CFDDocument6 pagesCFDJay VoraNo ratings yet

- LORDocument1 pageLORJay VoraNo ratings yet

- Precipitation HardeningDocument3 pagesPrecipitation HardeningJay Vora100% (1)

- Research Statement: Language As A Mode and A Model of InteractionDocument2 pagesResearch Statement: Language As A Mode and A Model of InteractionJay VoraNo ratings yet

- Flow CalculationsDocument22 pagesFlow CalculationsJay VoraNo ratings yet

- TLV 320 Adc Stereo Evaluation Audio AmplifierDocument85 pagesTLV 320 Adc Stereo Evaluation Audio AmplifierJay VoraNo ratings yet

- Adaptive Compliant Wing (Morphing Concept) SynopsisDocument18 pagesAdaptive Compliant Wing (Morphing Concept) SynopsisJay VoraNo ratings yet

- 12 Tips For Better E-Mail EtiquetteDocument2 pages12 Tips For Better E-Mail EtiquetteJay VoraNo ratings yet

- Abstract FastenersDocument2 pagesAbstract FastenersJay VoraNo ratings yet

- Laser-Driven Micro-Rocket: Applied Physics ADocument9 pagesLaser-Driven Micro-Rocket: Applied Physics AJay VoraNo ratings yet

- Precipitation HardeningDocument3 pagesPrecipitation HardeningJay Vora100% (1)

- Tu RCV 27MHz PCB AssembledDocument7 pagesTu RCV 27MHz PCB AssembledJay VoraNo ratings yet

- Tu RCV 27MHz PCB AssembledDocument7 pagesTu RCV 27MHz PCB AssembledJay VoraNo ratings yet

- Flat Band PotentialDocument7 pagesFlat Band PotentialAshish KumarNo ratings yet

- Overcoming Paint Film DefectsDocument7 pagesOvercoming Paint Film DefectsMahmood H NaqviNo ratings yet

- I.C EngineDocument154 pagesI.C EngineShafiq AhmadNo ratings yet

- 706 Aed 831676438Document27 pages706 Aed 831676438Online JobNo ratings yet

- Engg Mechanics Question Bank UNIT-1Document10 pagesEngg Mechanics Question Bank UNIT-1Thiyagarajan GurusamyNo ratings yet

- 4th Quarter-Second QuizDocument13 pages4th Quarter-Second QuizMICHELLE ALVAREZ100% (1)

- Circular Steel Tank Design CalculationDocument9 pagesCircular Steel Tank Design CalculationRathika100% (1)

- Bakelite PropertiesDocument6 pagesBakelite PropertiesAlexander PrasetyaNo ratings yet

- LC-LMD Laser Modules OverviewDocument2 pagesLC-LMD Laser Modules OverviewSAPA FirstNo ratings yet

- Final Technical Seminar Report PDFDocument30 pagesFinal Technical Seminar Report PDFKumarNo ratings yet

- NPSHDocument5 pagesNPSHmbakhshi2No ratings yet

- Geotechnical Earthquake Engineering: Prof. Deepankar ChoudhuryDocument49 pagesGeotechnical Earthquake Engineering: Prof. Deepankar ChoudhuryadssadasdsadNo ratings yet

- Fluidized Bed Reactor DesignDocument22 pagesFluidized Bed Reactor Designs barmanNo ratings yet

- Syllabus For B.TECH PDFDocument117 pagesSyllabus For B.TECH PDFsachin varmaNo ratings yet

- Chemical KineticsDocument116 pagesChemical KineticsSai Vishnu GainiNo ratings yet

- SCJ-MA3700-A2-Loads - (Weeks 1&2)Document28 pagesSCJ-MA3700-A2-Loads - (Weeks 1&2)crtveNo ratings yet

- AAPM - RPT - 76 - TG61 - 40-300kV X-Ray Dosimetry in Radiotherapy and Radiobiology PDFDocument26 pagesAAPM - RPT - 76 - TG61 - 40-300kV X-Ray Dosimetry in Radiotherapy and Radiobiology PDFClaudia Morales UlloaNo ratings yet

- Maths TUT 7Document1 pageMaths TUT 7Rahul SehgalNo ratings yet

- Influence of Diaphragm Wall InstallDocument11 pagesInfluence of Diaphragm Wall InstallMaruda8382No ratings yet

- Basic Reservoir EngineeringDocument74 pagesBasic Reservoir EngineeringRizaldiSaputraNo ratings yet

- Presentation On SprinklerDocument45 pagesPresentation On SprinklerAdoni SetsofiaNo ratings yet

- ChemistryDocument6 pagesChemistryDivij VermaNo ratings yet

- 1 Operational Characteristics of The Co-Rotating Twin-Screw ExtruderDocument37 pages1 Operational Characteristics of The Co-Rotating Twin-Screw ExtruderMadhumitha katreddyNo ratings yet

- Effect of Addition of Multimodal YSZ and PDFDocument19 pagesEffect of Addition of Multimodal YSZ and PDFMahmoud ElemamNo ratings yet

- Abaqus For Oil & Gas Geomechanics: Stephen King - SIMULIADocument28 pagesAbaqus For Oil & Gas Geomechanics: Stephen King - SIMULIAalistugui100% (1)

- Syn Converter NitridingDocument10 pagesSyn Converter NitridingGaurav GuptaNo ratings yet

- ArChine AC-9907-68 (E)Document2 pagesArChine AC-9907-68 (E)Siti MustanirohNo ratings yet

- Chapter 5 Work and EnergyDocument68 pagesChapter 5 Work and EnergyDylan HNo ratings yet

- Microfisura, GranularDocument22 pagesMicrofisura, GranularDardo OdelloNo ratings yet

Shore Scleroscope Hardness Test

Shore Scleroscope Hardness Test

Uploaded by

Jay VoraOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Shore Scleroscope Hardness Test

Shore Scleroscope Hardness Test

Uploaded by

Jay VoraCopyright:

Available Formats

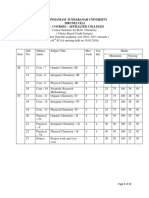

Shore Scleroscope Hardness Test The Shore Scleroscope hardness is associated with the elasticity of the material.

The appliance consists of a diamond-tipped hammer, falling in a graduated glass tube from a definite height. The tube is divided into 140 equal parts. The height of the first rebound is the hardness index of the material. The harder the material, the higher the rebound. The Shore method is widely used for measuring hardness of large machine components like rolls, gears, dies, etc. The Shore scleroscope is not only small and mobile, it also leaves no impressions on the tested surface.\

The Scleroscope test consists of dropping a diamond tipped hammer, which falls inside a glass tube under the force of its own weight from a fixed height, onto the test specimen. The height of the rebound travel of the hammer is measured on a graduated scale. The scale of the rebound is arbitrarily chosen and consists on Shore units, divided into 100 parts, which represent the average rebound from pure hardened high-carbon steel. The scale is continued higher than 100 to include metals having greater hardness. In normal use the shore scleroscope test does not mark the material under test. The Shore Scleroscope measures hardness in terms of the elasticity of the material and the hardness number depends on the height to which the hammer rebounds, the harder the material, the higher the rebound. Advantages of this method are portability and non-marking of the test surface

You might also like

- Hardness Test Lab Report PDFDocument9 pagesHardness Test Lab Report PDFKalKatu MaLam76% (42)

- Impact Test Lab ReportDocument5 pagesImpact Test Lab Reportaisyah mohamad othman85% (72)

- Multi ModeDocument73 pagesMulti ModeShalinee KavadiyaNo ratings yet

- Tool and Material List-Girth Gear InstallDocument2 pagesTool and Material List-Girth Gear InstallPeter RoseNo ratings yet

- Hardness Lab ReportDocument6 pagesHardness Lab ReportRashmika Uluwatta100% (4)

- Engr: Temoor Abbas Larik: QUCEST Larkana Campus Mechanical Engineering DepartmentDocument42 pagesEngr: Temoor Abbas Larik: QUCEST Larkana Campus Mechanical Engineering DepartmentTemoor AbbasNo ratings yet

- TensileDocument5 pagesTensileTharinya SellathuraiNo ratings yet

- Low Coefficient of Thermal ExpansionDocument13 pagesLow Coefficient of Thermal ExpansionnileshsawNo ratings yet

- Scanning Probe MicroscopeDocument4 pagesScanning Probe MicroscopebabakNo ratings yet

- Micro Hardness Tester Manual Book HVD-1000AP MPDocument38 pagesMicro Hardness Tester Manual Book HVD-1000AP MPDaisy HeNo ratings yet

- 2168 - Jominy End Quench TestDocument6 pages2168 - Jominy End Quench TestNikhil Satbhai100% (1)

- Mechanical PropertiesDocument26 pagesMechanical PropertiesiqbalNo ratings yet

- HardnessDocument15 pagesHardnessAanand Rishabh DagaNo ratings yet

- Pin On Disc DryDocument8 pagesPin On Disc DryHrushikesh KhairnarNo ratings yet

- Charpy Impact Test: Experiment 2Document5 pagesCharpy Impact Test: Experiment 2Utkarsh KumarNo ratings yet

- Shore Scleresope NotesDocument1 pageShore Scleresope Noteslilianwakio2016No ratings yet

- Hardness Testing and Impact Testing of MaterialsDocument32 pagesHardness Testing and Impact Testing of MaterialsMUUTHUKRISHNAN100% (4)

- Shore ScleroscopeDocument6 pagesShore ScleroscopeAaliyahNo ratings yet

- Module No 2 Equipment and Apparatus For Construction Materials TestingDocument37 pagesModule No 2 Equipment and Apparatus For Construction Materials TestingjlssupanNo ratings yet

- Material ScienceDocument46 pagesMaterial Sciencealfa89pNo ratings yet

- Material TestingDocument7 pagesMaterial TestingkimsonNo ratings yet

- 14 Mattiullah Report WritingDocument15 pages14 Mattiullah Report WritingMattiullahNo ratings yet

- A Guide To Laboratory Testing of Metal ProductsDocument7 pagesA Guide To Laboratory Testing of Metal ProductsShemelsNo ratings yet

- Assignment 3 - POMDocument8 pagesAssignment 3 - POMMcDhanesh JiNo ratings yet

- Engineering Materials - Hardness TestingDocument5 pagesEngineering Materials - Hardness TestingrandomkillerNo ratings yet

- Rockwell Hardness TesterDocument5 pagesRockwell Hardness TesterShivansh PathakNo ratings yet

- Hardness Test A4Document9 pagesHardness Test A4aisyah mohamad othmanNo ratings yet

- Rockwell Hardness TestorDocument1 pageRockwell Hardness TestorAdnan MehmoodNo ratings yet

- JF 302 - Material Technology 1Document18 pagesJF 302 - Material Technology 1Arif AzizAnNo ratings yet

- (Useful) Unit 2 Mechanical Test of MaterialDocument57 pages(Useful) Unit 2 Mechanical Test of Materialbalajimeie100% (1)

- Q2-Materials TestingDocument58 pagesQ2-Materials Testingapi-348195110No ratings yet

- Destructive TestingDocument42 pagesDestructive TestingHyori AnapadaNo ratings yet

- Destructive Examination & TestingDocument33 pagesDestructive Examination & TestingMallesh KaruparthyNo ratings yet

- Submitted To:: Lab ManualDocument30 pagesSubmitted To:: Lab ManualAbdul Azeem50% (2)

- Destructive Examination & TestingDocument31 pagesDestructive Examination & TestingMau Atenas PerezNo ratings yet

- Material Science Module-2: Stress Strain Curve For Ductile MaterialDocument26 pagesMaterial Science Module-2: Stress Strain Curve For Ductile MaterialKushNo ratings yet

- Material TestingDocument59 pagesMaterial TestingWilliam Salazar100% (4)

- SVKM'S Nmims Mukesh Patel School Technology Management and Engineering Strength of Materials LabDocument4 pagesSVKM'S Nmims Mukesh Patel School Technology Management and Engineering Strength of Materials LabBender GamingNo ratings yet

- Destructive Test MethodsDocument33 pagesDestructive Test MethodsAvalcwiNo ratings yet

- Hardness of PolymerDocument10 pagesHardness of PolymerAadarsh BramhapurkarNo ratings yet

- Engineering Materials Lab ManualDocument14 pagesEngineering Materials Lab ManualHarood Nishat100% (1)

- Chapter4 150109005052 Conversion Gate02Document56 pagesChapter4 150109005052 Conversion Gate02زهديابوانسNo ratings yet

- Line Pipe InpectionDocument32 pagesLine Pipe InpectionRaza MehdiNo ratings yet

- PMT Sifat MaterialDocument67 pagesPMT Sifat MaterialFrislyNo ratings yet

- Hardness Testing of Metallic Materials: February 2021Document14 pagesHardness Testing of Metallic Materials: February 2021jvidal.salgadoNo ratings yet

- What Is Hardness?: (Type Text)Document5 pagesWhat Is Hardness?: (Type Text)akif222999No ratings yet

- Rockwell Hardness Test.... 1Document2 pagesRockwell Hardness Test.... 1rafai167% (3)

- Material TestingDocument58 pagesMaterial TestingChanoxismNo ratings yet

- MQA Technical ReportDocument8 pagesMQA Technical ReportShaffan AbbasiNo ratings yet

- Hardness ReportDocument6 pagesHardness ReportNawanshika MendisNo ratings yet

- Lab ReportDocument21 pagesLab ReportMuhammad YasirNo ratings yet

- Hardness Is The Resistance of A Material To Localized DeformationDocument17 pagesHardness Is The Resistance of A Material To Localized DeformationJonathan FloresNo ratings yet

- ME 2203 Engineering Materials: Dr. Kazi Md. ShorowordiDocument17 pagesME 2203 Engineering Materials: Dr. Kazi Md. ShorowordiTahmim AlamNo ratings yet

- Steel ApplicationDocument49 pagesSteel ApplicationRiben CaratingNo ratings yet

- Hardness TestDocument12 pagesHardness TestLola MeerazNo ratings yet

- Document (1) - 1Document28 pagesDocument (1) - 1Saad AliKhanNo ratings yet

- Tensile Test of Steel BarsDocument2 pagesTensile Test of Steel BarsCeddie PamintuanNo ratings yet

- UNIT-II Mechanical Property MeasurementDocument127 pagesUNIT-II Mechanical Property Measurementlol WANo ratings yet

- Fundamentals of Rockwell Hardness TestingDocument16 pagesFundamentals of Rockwell Hardness TestingAnonymous Wi2Pd2UgPINo ratings yet

- Hardness TestingDocument15 pagesHardness TestingSivakumar ChinnasamyNo ratings yet

- Chapter 7 - Destructive and Non Destructive Testing of MaterialDocument33 pagesChapter 7 - Destructive and Non Destructive Testing of MaterialzainonayraNo ratings yet

- AncientDocument172 pagesAncientJay VoraNo ratings yet

- Notice Period For FlatDocument1 pageNotice Period For FlatJay VoraNo ratings yet

- Aerodynamic Analysis For A Distributed Electric Propulsion AircraftDocument1 pageAerodynamic Analysis For A Distributed Electric Propulsion AircraftJay VoraNo ratings yet

- Co-Efficient of PressureDocument2 pagesCo-Efficient of PressureJay VoraNo ratings yet

- Examples of The Principle of Superposition: 1. Source Plus A Uniform FlowDocument6 pagesExamples of The Principle of Superposition: 1. Source Plus A Uniform FlowJay Vora100% (1)

- Comparison of Pathline and StreamlineDocument1 pageComparison of Pathline and StreamlineJay VoraNo ratings yet

- For For: %uniform Stream %grid %gridDocument2 pagesFor For: %uniform Stream %grid %gridJay VoraNo ratings yet

- CFDDocument6 pagesCFDJay VoraNo ratings yet

- LORDocument1 pageLORJay VoraNo ratings yet

- Precipitation HardeningDocument3 pagesPrecipitation HardeningJay Vora100% (1)

- Research Statement: Language As A Mode and A Model of InteractionDocument2 pagesResearch Statement: Language As A Mode and A Model of InteractionJay VoraNo ratings yet

- Flow CalculationsDocument22 pagesFlow CalculationsJay VoraNo ratings yet

- TLV 320 Adc Stereo Evaluation Audio AmplifierDocument85 pagesTLV 320 Adc Stereo Evaluation Audio AmplifierJay VoraNo ratings yet

- Adaptive Compliant Wing (Morphing Concept) SynopsisDocument18 pagesAdaptive Compliant Wing (Morphing Concept) SynopsisJay VoraNo ratings yet

- 12 Tips For Better E-Mail EtiquetteDocument2 pages12 Tips For Better E-Mail EtiquetteJay VoraNo ratings yet

- Abstract FastenersDocument2 pagesAbstract FastenersJay VoraNo ratings yet

- Laser-Driven Micro-Rocket: Applied Physics ADocument9 pagesLaser-Driven Micro-Rocket: Applied Physics AJay VoraNo ratings yet

- Precipitation HardeningDocument3 pagesPrecipitation HardeningJay Vora100% (1)

- Tu RCV 27MHz PCB AssembledDocument7 pagesTu RCV 27MHz PCB AssembledJay VoraNo ratings yet

- Tu RCV 27MHz PCB AssembledDocument7 pagesTu RCV 27MHz PCB AssembledJay VoraNo ratings yet

- Flat Band PotentialDocument7 pagesFlat Band PotentialAshish KumarNo ratings yet

- Overcoming Paint Film DefectsDocument7 pagesOvercoming Paint Film DefectsMahmood H NaqviNo ratings yet

- I.C EngineDocument154 pagesI.C EngineShafiq AhmadNo ratings yet

- 706 Aed 831676438Document27 pages706 Aed 831676438Online JobNo ratings yet

- Engg Mechanics Question Bank UNIT-1Document10 pagesEngg Mechanics Question Bank UNIT-1Thiyagarajan GurusamyNo ratings yet

- 4th Quarter-Second QuizDocument13 pages4th Quarter-Second QuizMICHELLE ALVAREZ100% (1)

- Circular Steel Tank Design CalculationDocument9 pagesCircular Steel Tank Design CalculationRathika100% (1)

- Bakelite PropertiesDocument6 pagesBakelite PropertiesAlexander PrasetyaNo ratings yet

- LC-LMD Laser Modules OverviewDocument2 pagesLC-LMD Laser Modules OverviewSAPA FirstNo ratings yet

- Final Technical Seminar Report PDFDocument30 pagesFinal Technical Seminar Report PDFKumarNo ratings yet

- NPSHDocument5 pagesNPSHmbakhshi2No ratings yet

- Geotechnical Earthquake Engineering: Prof. Deepankar ChoudhuryDocument49 pagesGeotechnical Earthquake Engineering: Prof. Deepankar ChoudhuryadssadasdsadNo ratings yet

- Fluidized Bed Reactor DesignDocument22 pagesFluidized Bed Reactor Designs barmanNo ratings yet

- Syllabus For B.TECH PDFDocument117 pagesSyllabus For B.TECH PDFsachin varmaNo ratings yet

- Chemical KineticsDocument116 pagesChemical KineticsSai Vishnu GainiNo ratings yet

- SCJ-MA3700-A2-Loads - (Weeks 1&2)Document28 pagesSCJ-MA3700-A2-Loads - (Weeks 1&2)crtveNo ratings yet

- AAPM - RPT - 76 - TG61 - 40-300kV X-Ray Dosimetry in Radiotherapy and Radiobiology PDFDocument26 pagesAAPM - RPT - 76 - TG61 - 40-300kV X-Ray Dosimetry in Radiotherapy and Radiobiology PDFClaudia Morales UlloaNo ratings yet

- Maths TUT 7Document1 pageMaths TUT 7Rahul SehgalNo ratings yet

- Influence of Diaphragm Wall InstallDocument11 pagesInfluence of Diaphragm Wall InstallMaruda8382No ratings yet

- Basic Reservoir EngineeringDocument74 pagesBasic Reservoir EngineeringRizaldiSaputraNo ratings yet

- Presentation On SprinklerDocument45 pagesPresentation On SprinklerAdoni SetsofiaNo ratings yet

- ChemistryDocument6 pagesChemistryDivij VermaNo ratings yet

- 1 Operational Characteristics of The Co-Rotating Twin-Screw ExtruderDocument37 pages1 Operational Characteristics of The Co-Rotating Twin-Screw ExtruderMadhumitha katreddyNo ratings yet

- Effect of Addition of Multimodal YSZ and PDFDocument19 pagesEffect of Addition of Multimodal YSZ and PDFMahmoud ElemamNo ratings yet

- Abaqus For Oil & Gas Geomechanics: Stephen King - SIMULIADocument28 pagesAbaqus For Oil & Gas Geomechanics: Stephen King - SIMULIAalistugui100% (1)

- Syn Converter NitridingDocument10 pagesSyn Converter NitridingGaurav GuptaNo ratings yet

- ArChine AC-9907-68 (E)Document2 pagesArChine AC-9907-68 (E)Siti MustanirohNo ratings yet

- Chapter 5 Work and EnergyDocument68 pagesChapter 5 Work and EnergyDylan HNo ratings yet

- Microfisura, GranularDocument22 pagesMicrofisura, GranularDardo OdelloNo ratings yet