Professional Documents

Culture Documents

Ixys Igbt Basic I

Ixys Igbt Basic I

Uploaded by

shaharhr1Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ixys Igbt Basic I

Ixys Igbt Basic I

Uploaded by

shaharhr1Copyright:

Available Formats

Insulated Gate Bipolar Transistor (IGBT) Basics

Abdus Sattar, IXYS Corporation IXAN0063 high-blocking voltage rating is normally avoided. In contrast, for the IGBT, the drift region resistance is drastically reduced by the high concentration of injected minority carriers during on-state current conduction. The forward drop from the drift region becomes dependent upon its thickness and independent of its original resistivity. 2

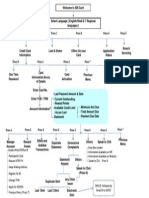

Basic Structure

The basic schematic of a typical N-channel IGBT based upon the DMOS process is shown in Figure 1. This is one of several structures possible for this device. It is evident that the silicon cross-section of an IGBT is almost identical to that of a vertical Power MOSFET except for the P+ injecting layer. It shares similar MOS gate structure and P wells with N+ source regions. The N+ layer at the top is the source or emitter and the P+ layer at the bottom is the drain or collector. It is also feasible to make P-channel IGBTs and for which the doping profile in each layer will be reversed. IGBT has a parasitic thyristor comprising the four-layer NPNP structure. Turn-on of this thyristor is undesirable.

Figure 1: Schematic view of a generic N-channel IGBT [2] Some IGBTs, manufactured without the N+ buffer layer, are called non-punch through (NPT) IGBTs whereas those with this layer are called punch-through (PT) IGBTs. The presence of this buffer layer can significantly improve the performance of the device if the doping level and thickness of this layer are chosen appropriately. Despite physical similarities, the operation of an IGBT is closer to that of a power BJT than a power MOSFET. It is due to the P+ drain layer (injecting layer) which is responsible for the minority carrier injection into the N--drift region and the resulting conductivity modulation.

You might also like

- IV R Flow of Sbi Bank For Queries of Customer Care, SBI FLOW, SBI IVR FLOWDocument1 pageIV R Flow of Sbi Bank For Queries of Customer Care, SBI FLOW, SBI IVR FLOWshaharhr1No ratings yet

- Insulated Gate Bipolar TransistorDocument4 pagesInsulated Gate Bipolar Transistor1balamanianNo ratings yet

- Power IgbtDocument17 pagesPower IgbtnandhakumarmeNo ratings yet

- IGBT CharacteristicsDocument16 pagesIGBT CharacteristicswrdlifeNo ratings yet

- IGBTDocument22 pagesIGBTzga5v5No ratings yet

- IGBT TutorialDocument15 pagesIGBT Tutorialtoybrain88No ratings yet

- I - G B T: Nsulated ATE Ipolar RansistorDocument59 pagesI - G B T: Nsulated ATE Ipolar RansistorsushilsemwalNo ratings yet

- IGBT - Basic - 1 EE TimeDocument11 pagesIGBT - Basic - 1 EE TimeRichard TsengNo ratings yet

- Analysis On IGBT DevelopmentsDocument6 pagesAnalysis On IGBT DevelopmentsGopal Chandra MahatoNo ratings yet

- IGBTDocument22 pagesIGBTumeshgangwar100% (1)

- 02 Lecture Transistors - 094618Document20 pages02 Lecture Transistors - 094618sudiptaNo ratings yet

- Instituto Tecnológico de La Costa GrandeDocument10 pagesInstituto Tecnológico de La Costa GrandeEver ContrerasNo ratings yet

- Application Note AN-983: IGBT CharacteristicsDocument16 pagesApplication Note AN-983: IGBT Characteristicswizardgrt1No ratings yet

- Project 1 FullDocument10 pagesProject 1 FullSaratul AkmaNo ratings yet

- Insulated Gate Bipolar TransistorDocument20 pagesInsulated Gate Bipolar TransistorUmashankar SubramaniamNo ratings yet

- Threshold Voltage Improvement Scheme For Highvoltage IGBTDocument4 pagesThreshold Voltage Improvement Scheme For Highvoltage IGBT張肇晏No ratings yet

- Presentation - Insulated Gate Bipolar Transistors IGBTDocument2 pagesPresentation - Insulated Gate Bipolar Transistors IGBTMimepNo ratings yet

- Recent Trends in IGBT TechnologyDocument3 pagesRecent Trends in IGBT TechnologyRichard TsengNo ratings yet

- Structure and Features: PrefaceDocument7 pagesStructure and Features: PrefacedhruvNo ratings yet

- What Is IGBT?: IgbtsDocument14 pagesWhat Is IGBT?: IgbtsShahzaid AhmadNo ratings yet

- REH984b A 81r2c4zg6yDocument131 pagesREH984b A 81r2c4zg6ymahesh1shrimali-1No ratings yet

- IgbtDocument10 pagesIgbtNayeem HossainNo ratings yet

- Power IGBTDocument42 pagesPower IGBTNishant SaxenaNo ratings yet

- Latest Technology PT Igbts vs. Power Mosfets: Application Note Apt0302 Rev. A April 4, 2003Document6 pagesLatest Technology PT Igbts vs. Power Mosfets: Application Note Apt0302 Rev. A April 4, 2003Jyothsna VayyalaNo ratings yet

- 3rd Module IGBT NotesDocument5 pages3rd Module IGBT NotesPranathi GNo ratings yet

- IgbtDocument22 pagesIgbtmohammad2110959No ratings yet

- Igbt Notes 2Document22 pagesIgbt Notes 2gomathyNo ratings yet

- IGBTs BasicsDocument10 pagesIGBTs BasicsTomas HuerdoNo ratings yet

- Constructional Features of A GTO: Lesson 4 (Chapter One) Gate Turn Off Thyristor (GTO)Document3 pagesConstructional Features of A GTO: Lesson 4 (Chapter One) Gate Turn Off Thyristor (GTO)Sarmad KhanNo ratings yet

- 17 - L-7 (DK) (Pe) ( (Ee) Nptel)Document1 page17 - L-7 (DK) (Pe) ( (Ee) Nptel)GagneNo ratings yet

- 05961633Document9 pages05961633dabalejoNo ratings yet

- Bourns Understanding Igbt Data Sheet Parameters White PaperDocument12 pagesBourns Understanding Igbt Data Sheet Parameters White PaperPablo CuevasNo ratings yet

- How To Design An R Resistor For A Vishay Trench PT IGBT: RectifiersDocument12 pagesHow To Design An R Resistor For A Vishay Trench PT IGBT: RectifiersHoangNo ratings yet

- Igpt 0.02Document8 pagesIgpt 0.02Šämęh ËšśämNo ratings yet

- Practical Macromodel For The IGBTDocument5 pagesPractical Macromodel For The IGBTAris Sid AhmedNo ratings yet

- Modeling The Turn-Off of IGBT's in Hard-And Soft-Switching ApplicationsDocument7 pagesModeling The Turn-Off of IGBT's in Hard-And Soft-Switching ApplicationsJeevananthan SeenithangamNo ratings yet

- Study Material On IgbtDocument13 pagesStudy Material On IgbtSandipan DebNo ratings yet

- IGBTDocument12 pagesIGBT304920 ktr.eee.17100% (1)

- 01 Schreiber SemikronDocument57 pages01 Schreiber SemikronAbdallah BelabbesNo ratings yet

- Insulated-Gate Bipolar TransistorDocument6 pagesInsulated-Gate Bipolar TransistorVinay SinghNo ratings yet

- Igbt Spice ModelingDocument43 pagesIgbt Spice ModelingBrian WillardNo ratings yet

- Mofet - IGBT - SCR - Traic - Snubber CKTDocument17 pagesMofet - IGBT - SCR - Traic - Snubber CKTTejas krishnakanthNo ratings yet

- Igbt BasicsDocument16 pagesIgbt BasicsRahul SoniNo ratings yet

- Exploring The Silicon Design Limits of Thin Wafer IGBT TechnologyDocument5 pagesExploring The Silicon Design Limits of Thin Wafer IGBT TechnologyRichard TsengNo ratings yet

- Power TransistorDocument37 pagesPower Transistorsaikarthick023No ratings yet

- 08 Lecture Power Transistors (IGBT)Document22 pages08 Lecture Power Transistors (IGBT)Abid Hasan HimelNo ratings yet

- IGBT NoteDocument3 pagesIGBT NoteBheshNo ratings yet

- Siemens IGBT CaractDocument13 pagesSiemens IGBT CaractJie RongNo ratings yet

- Power Electronics - Chapter 2 - Power Switching DevicesDocument31 pagesPower Electronics - Chapter 2 - Power Switching Deviceskennedy kipsangNo ratings yet

- Insulated-Gate Bipolar TransistorDocument12 pagesInsulated-Gate Bipolar TransistorMustafa ErcümenNo ratings yet

- 4.) - General - Using - of - IGBT - Modules GOOD PDFDocument26 pages4.) - General - Using - of - IGBT - Modules GOOD PDFDoDuyBacNo ratings yet

- Power Semiconductors: The BJT, Mosfet, and Igbt: Reid L. Sprite, Member, IEEEDocument3 pagesPower Semiconductors: The BJT, Mosfet, and Igbt: Reid L. Sprite, Member, IEEEFazreen ZainalNo ratings yet

- Group 6Document21 pagesGroup 6cj gamatNo ratings yet

- Heterojunction Bipolar Transistors for Circuit Design: Microwave Modeling and Parameter ExtractionFrom EverandHeterojunction Bipolar Transistors for Circuit Design: Microwave Modeling and Parameter ExtractionNo ratings yet

- Fundamentals of Electronics 1: Electronic Components and Elementary FunctionsFrom EverandFundamentals of Electronics 1: Electronic Components and Elementary FunctionsNo ratings yet

- Organic Light-Emitting Transistors: Towards the Next Generation Display TechnologyFrom EverandOrganic Light-Emitting Transistors: Towards the Next Generation Display TechnologyNo ratings yet

- Physics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to LSIFrom EverandPhysics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to LSINo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Physics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to DisplaysFrom EverandPhysics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to DisplaysNo ratings yet

- Automated Optical Inspection: Advancements in Computer Vision TechnologyFrom EverandAutomated Optical Inspection: Advancements in Computer Vision TechnologyNo ratings yet

- Upgrade Exact To A Newer VersionDocument2 pagesUpgrade Exact To A Newer Versionshaharhr1No ratings yet

- Here Are A Few Different Methods.: Method 1Document2 pagesHere Are A Few Different Methods.: Method 1shaharhr1No ratings yet

- SOP - Adding A Clients To Automated CSA and DSADocument4 pagesSOP - Adding A Clients To Automated CSA and DSAshaharhr1No ratings yet

- Principles of Accounting I: Jackson Community College ACCOUNTING 231-02 Winter 2013Document8 pagesPrinciples of Accounting I: Jackson Community College ACCOUNTING 231-02 Winter 2013shaharhr1No ratings yet

- Recall A Tendered Order - Reprint A Receipt:: Kumnandi Food CompanyDocument5 pagesRecall A Tendered Order - Reprint A Receipt:: Kumnandi Food Companyshaharhr1No ratings yet

- Fastnet Radiopad SetupDocument5 pagesFastnet Radiopad Setupshaharhr1No ratings yet

- Evolution Manual - Fixed Assets PDFDocument44 pagesEvolution Manual - Fixed Assets PDFshaharhr1No ratings yet

- Business Analytics For Pastel EvolutionDocument4 pagesBusiness Analytics For Pastel Evolutionshaharhr1No ratings yet

- Call Centre Manual 04052007Document27 pagesCall Centre Manual 04052007shaharhr1No ratings yet

- Spectroscopy I (1a)Document6 pagesSpectroscopy I (1a)shaharhr1No ratings yet

- Yahoo! Sports: Baseball Chicago CubsDocument3 pagesYahoo! Sports: Baseball Chicago Cubsshaharhr1No ratings yet

- Regression With Dummy Variables Econ420 1Document47 pagesRegression With Dummy Variables Econ420 1shaharhr1No ratings yet

- Advertisements - The CBSE Way: Format and Marking SchemeDocument5 pagesAdvertisements - The CBSE Way: Format and Marking Schemeshaharhr1No ratings yet

- Business Associations Uber OutlineDocument131 pagesBusiness Associations Uber Outlineshaharhr1No ratings yet

- English Japanese Chinese French Russian Learn All These Languages For The TourDocument1 pageEnglish Japanese Chinese French Russian Learn All These Languages For The Tourshaharhr1No ratings yet

- ERISA Class Notes (Spring 2011) - 1Document107 pagesERISA Class Notes (Spring 2011) - 1shaharhr1100% (1)

- Barbri Corp OutlineDocument12 pagesBarbri Corp Outlineshaharhr1100% (3)