Professional Documents

Culture Documents

Estimates of Cost of Production

Estimates of Cost of Production

Uploaded by

Bhuneshwar ChelakOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Estimates of Cost of Production

Estimates of Cost of Production

Uploaded by

Bhuneshwar ChelakCopyright:

Available Formats

16.

ESTIMATES OF COST OF PRODUCTION

The plant is operated for 330 days in one year.

1. Raw Materials Consumption Material -Picoline Oxygen Steam Sulfuric Acid kg per day 177.75 88.5 3 3 (Rs. / kg) 150 10 1 5 Cost Cost (lakhs/annum) 87.99 2.92 0.0099 0.050

Total Raw Materials Cost = Rs. 90.97 lakhs. 2. Utilities Consumption Material Steam Chilling water Cooling Water Dowtherm* Power kW-hr per year kg per day 11005.07 60001.24 37266.42 46737.02 175595.43 0.7 Rs/kg 20 Rs/m3 12 Rs/m3 100 Rs./kg 4 Rs/kW.hr Cost Cost (lakhs/annum) 25.42 3.96 1.48 0.23 7.02

Total Utilities Cost = Rs. 38.12 lakhs * Dowtherm is recycled. It is one time cost. Total life before replacement is assumed to be 1 years. 3. Catalyst Requirement Material V2O5 TiO2 kg 555.5 2530 3000 Rs/kg 250 Rs/kg Cost Cost (lakhs/annum) (Life = 3 years) 16.67 6.325

76

Total Catalyst Cost = 22.30 lakhs (Divided over 3 years) Catalyst cost = 7.7 lakhs/annum The various elements comprising the cost of production are as shown: Cost Component Variable Cost (V) 1. Raw Materials 2. 3. Utilities Catalyst Total V Fixed Cost (F) 1. Salaries and Wages 2. packaging 3. Factory Overheads 25.00 3.00 8.00 Cost in Rs. (lakhs)

90.97 38.12 7.70 136.8

Total F Cost of Production CP = (F + V) Gross Cost of Production, GP=(1.1xCP)

36.00 172.80 190.08

Gross Cost of Production, GP = Rs. 190.08 lakhs Annual Production of nicotinic acid = 66 Tons

Cost of Production per kg = GP / Annual Production Rate = 190.08 lakhs / 66 tons = Rs. 287.90 per kg

77

You might also like

- Bottle Production CostDocument6 pagesBottle Production CostHarun Or Rashid71% (7)

- Footprint Noodle Production SMEDocument4 pagesFootprint Noodle Production SMEIdo FongNo ratings yet

- 5 Economics of BiomassBoilersDocument20 pages5 Economics of BiomassBoilersmcalidonio5656No ratings yet

- Biomass Power Plant-Broercycle Green EnergyDocument29 pagesBiomass Power Plant-Broercycle Green EnergyChoirul Anwar100% (1)

- Ballarpur Industries Limited Unit - A.P.Rayons, Kamalapuram, Warangal, (AP)Document18 pagesBallarpur Industries Limited Unit - A.P.Rayons, Kamalapuram, Warangal, (AP)monish147852No ratings yet

- Energy Savings MeasuresDocument6 pagesEnergy Savings MeasuresRakesh KumarNo ratings yet

- Biogas EntrepreneurshipDocument5 pagesBiogas EntrepreneurshipRichard WorkbenchNo ratings yet

- Asian 9klkph DM OpexDocument2 pagesAsian 9klkph DM OpexUmang AgrawalNo ratings yet

- Cost AnalysisDocument1 pageCost AnalysisromeoyadavNo ratings yet

- Energy Conservation FrameworkDocument8 pagesEnergy Conservation FrameworkdiebymyswordNo ratings yet

- BatchDocument4 pagesBatchKareem AlselawyNo ratings yet

- Tasarım Soruları PDFDocument2 pagesTasarım Soruları PDFAkbey ApaydınNo ratings yet

- Steam System Audit: Vandana.Y Gajjar1, Omkar G.Ghodke, Krishna KumarDocument3 pagesSteam System Audit: Vandana.Y Gajjar1, Omkar G.Ghodke, Krishna KumarSarang BondeNo ratings yet

- Gujarat BOE 2015 Paper 1 SolutionDocument7 pagesGujarat BOE 2015 Paper 1 SolutionSaravana Prasad100% (1)

- Costo de EquiposDocument9 pagesCosto de EquiposninoronaldNo ratings yet

- Weekly Water Consumption CostDocument1 pageWeekly Water Consumption CostCitizen MattersNo ratings yet

- Capacity Planning BriquettesDocument8 pagesCapacity Planning Briquettesmichael odiemboNo ratings yet

- Case Study-Sri Ravishankar Ashram-Biogas PlantDocument3 pagesCase Study-Sri Ravishankar Ashram-Biogas PlantJaya NarulaNo ratings yet

- Chapter D (Hyundai)Document3 pagesChapter D (Hyundai)Mavrix AgustinNo ratings yet

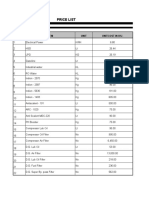

- Price List: S.No Item Unit Unitcost in RSDocument7 pagesPrice List: S.No Item Unit Unitcost in RSamitans2003No ratings yet

- Home Exercises - AllDocument6 pagesHome Exercises - AllRajithaSomathilakeNo ratings yet

- 2.3 Cost Estimation of Operating Labour: NP Ol NP 0.5Document2 pages2.3 Cost Estimation of Operating Labour: NP Ol NP 0.5Vineeth GoudNo ratings yet

- 04-2007!08!04-Comparison-500MW SC & SubC Plants in IndiaDocument4 pages04-2007!08!04-Comparison-500MW SC & SubC Plants in IndiaSovan NandyNo ratings yet

- Internship Presentation 19PE10026Document14 pagesInternship Presentation 19PE10026SAURABH KUMARNo ratings yet

- BOILER DossierDocument18 pagesBOILER DossierKiran DasNo ratings yet

- Manufacturing Cost EstimationDocument7 pagesManufacturing Cost EstimationMadiha ZaimuriNo ratings yet

- Renewable Energy Resources: Introduction & Economic Analysis of A Gasification PlantDocument36 pagesRenewable Energy Resources: Introduction & Economic Analysis of A Gasification PlantfaizanNo ratings yet

- Jindal Steel and Power Limited: First Prize Integrated Steel PlantsDocument11 pagesJindal Steel and Power Limited: First Prize Integrated Steel PlantsPrasenjit DeyNo ratings yet

- Waste ManagementDocument22 pagesWaste ManagementAisyah GhazaliNo ratings yet

- Comparison Biogas Vs OWC (500 & 1000 KG)Document4 pagesComparison Biogas Vs OWC (500 & 1000 KG)krayNo ratings yet

- Aqua Refinery LTD.: LPG Consumption of Six Heaters Per DayDocument1 pageAqua Refinery LTD.: LPG Consumption of Six Heaters Per DayAnwar SadatNo ratings yet

- Utilization of Solar Energy For Drying Paddy in Par Boiled Rice Mill by Using Flat Plate Solar Air HeaterDocument3 pagesUtilization of Solar Energy For Drying Paddy in Par Boiled Rice Mill by Using Flat Plate Solar Air HeaterInternational Journal of Innovations in Engineering and ScienceNo ratings yet

- 1 PBDocument4 pages1 PBmituNo ratings yet

- Equipment Tutorial-2015Document47 pagesEquipment Tutorial-2015Naty GriffinNo ratings yet

- Module 1 - Lecture 5Document4 pagesModule 1 - Lecture 5jbb_sitNo ratings yet

- Units ConvFactors - Mit Energy Club Factsheet.v8Document2 pagesUnits ConvFactors - Mit Energy Club Factsheet.v8sanjeet4friendsNo ratings yet

- Combustion1 PDFDocument515 pagesCombustion1 PDFcynaidu100% (1)

- Design of Biogas DigestersDocument22 pagesDesign of Biogas DigestersSharath Chandra100% (5)

- Financial Return of Investment - Crystaline V11Document5 pagesFinancial Return of Investment - Crystaline V11Nishikant GuptaNo ratings yet

- Anaerobic Digester - QasimDocument35 pagesAnaerobic Digester - Qasimawaluddin nurmiyantoNo ratings yet

- QB. PPDocument15 pagesQB. PPRajib MandalNo ratings yet

- Mycelium Composite-Construction Insulating PanelDocument21 pagesMycelium Composite-Construction Insulating PanelATITHEE NANDANWARNo ratings yet

- Modul 2b Analisis Biaya PeralatanDocument17 pagesModul 2b Analisis Biaya PeralatananonNo ratings yet

- Energy Management Tutorial SolutionsDocument9 pagesEnergy Management Tutorial SolutionsLucas LentzNo ratings yet

- How Much Coal Required To Produce 1 MW Power?: What Is The TPH of A Boiler?Document5 pagesHow Much Coal Required To Produce 1 MW Power?: What Is The TPH of A Boiler?coconut borneoNo ratings yet

- Modul 2b Analisis Biaya PeralatanDocument17 pagesModul 2b Analisis Biaya PeralatanSanjika IlhamNo ratings yet

- Tutorial #6&7Document3 pagesTutorial #6&7Sohini RoyNo ratings yet

- Soda Ash and Energy EfficiencyDocument7 pagesSoda Ash and Energy Efficiencyanandrings100% (1)

- Energy Savings of Cement Industry Sir Usman SBDocument6 pagesEnergy Savings of Cement Industry Sir Usman SBMuhammad ImranNo ratings yet

- Assignment 1Document11 pagesAssignment 1Mahmoud MansourNo ratings yet

- Excess Air OptimizationDocument9 pagesExcess Air OptimizationJunaid MazharNo ratings yet

- Operating Cost Calculation For EvaporatorDocument1 pageOperating Cost Calculation For EvaporatorAtul WaghNo ratings yet

- Boiler Dengan Safety FactorDocument8 pagesBoiler Dengan Safety FactorFarah HafizhahNo ratings yet

- 9717-Article Text-35845-1-10-20221109Document10 pages9717-Article Text-35845-1-10-20221109anthony puyatNo ratings yet

- INONESIA POWER - Suralaya Coal Power PlantDocument31 pagesINONESIA POWER - Suralaya Coal Power PlantEko Tjahjantoko100% (1)

- 10 35378-Gujs 1052416-2171116Document14 pages10 35378-Gujs 1052416-2171116dasde87No ratings yet

- Clean Ironmaking and Steelmaking Processes: Efficient Technologies for Greenhouse Emissions AbatementFrom EverandClean Ironmaking and Steelmaking Processes: Efficient Technologies for Greenhouse Emissions AbatementNo ratings yet

- Synthetic Natural Gas: From Coal, Dry Biomass, and Power-to-Gas ApplicationsFrom EverandSynthetic Natural Gas: From Coal, Dry Biomass, and Power-to-Gas ApplicationsTilman J. SchildhauerNo ratings yet

- Packed Bed TheoryDocument6 pagesPacked Bed TheoryBhuneshwar ChelakNo ratings yet

- Pressure Drop CorrelationDocument2 pagesPressure Drop CorrelationBhuneshwar ChelakNo ratings yet

- Friction Factor: Fig. Effect of Liquid and Gas Velocity On Friction FactorDocument2 pagesFriction Factor: Fig. Effect of Liquid and Gas Velocity On Friction FactorBhuneshwar ChelakNo ratings yet

- Recipro. CompressorDocument3 pagesRecipro. CompressorBhuneshwar ChelakNo ratings yet

- OxygenDocument2 pagesOxygenBhuneshwar Chelak0% (1)

- ΔP L D φ ε 3 Dpφ ε 3: Pressure Drop, Kpa/mDocument2 pagesΔP L D φ ε 3 Dpφ ε 3: Pressure Drop, Kpa/mBhuneshwar ChelakNo ratings yet

- CoefficientDocument3 pagesCoefficientBhuneshwar ChelakNo ratings yet

- Urface Finish ChartsSDocument4 pagesUrface Finish ChartsSBhuneshwar ChelakNo ratings yet

- Process Reactor Phase Temperature Pressure Catalyst Metal Conversion Per Pass (%) Yield By-ProductsDocument2 pagesProcess Reactor Phase Temperature Pressure Catalyst Metal Conversion Per Pass (%) Yield By-ProductsBhuneshwar ChelakNo ratings yet

- Table C.1: Tube Counts For 5/8-In. OD Tubes On 13/16-In. Square PitchDocument2 pagesTable C.1: Tube Counts For 5/8-In. OD Tubes On 13/16-In. Square PitchBhuneshwar ChelakNo ratings yet

- WR Pump 2-1 & 2-2Document1 pageWR Pump 2-1 & 2-2Bhuneshwar ChelakNo ratings yet

- Constituency Candidate PartyDocument4 pagesConstituency Candidate PartyBhuneshwar ChelakNo ratings yet