Professional Documents

Culture Documents

Group 3 Tests and Adjustments Group 3 Tests and Adjustments: 1. Parking Brake Performance 1. Parking Brake Performance

Group 3 Tests and Adjustments Group 3 Tests and Adjustments: 1. Parking Brake Performance 1. Parking Brake Performance

Uploaded by

Sergey MovchanCopyright:

Available Formats

You might also like

- 12G, 130G & 140G Hydraulic System and Steering PRUBASDocument24 pages12G, 130G & 140G Hydraulic System and Steering PRUBASF Labio Alex100% (4)

- Steering System PDFDocument12 pagesSteering System PDFGeorge Guerrero100% (1)

- Testing and Adjusting: Troubleshooting The Transmission Hydraulic SystemDocument24 pagesTesting and Adjusting: Troubleshooting The Transmission Hydraulic SystemLeandro Sal91% (11)

- G Group 3 Tests and Adjustments: 1. Parking Brake PerformanceDocument2 pagesG Group 3 Tests and Adjustments: 1. Parking Brake PerformancePriscila RodriguesNo ratings yet

- Group 3 Tests and Adjustments Group 3 Tests and Adjustments: 1. Parking Brake Performance 1. Parking Brake PerformanceDocument2 pagesGroup 3 Tests and Adjustments Group 3 Tests and Adjustments: 1. Parking Brake Performance 1. Parking Brake PerformanceaimerNo ratings yet

- Group 3 Tests and Adjustments: 1. Parking Brake PerformanceDocument2 pagesGroup 3 Tests and Adjustments: 1. Parking Brake PerformanceSergey MovchanNo ratings yet

- G Group 3 Tests and Adjustments: 1. Parking Brake PerformanceDocument2 pagesG Group 3 Tests and Adjustments: 1. Parking Brake PerformanceSergey MovchanNo ratings yet

- Testing Adjusting Trans D8RDocument30 pagesTesting Adjusting Trans D8Rardan fadilah100% (1)

- Calibration Relief Valve ExcavatorDocument36 pagesCalibration Relief Valve Excavatorcriman4550% (2)

- Pruebas y Ajustes Trannmision 928gDocument23 pagesPruebas y Ajustes Trannmision 928gManuel RamosNo ratings yet

- Sis 631 PRTDocument15 pagesSis 631 PRTAshraf m aliNo ratings yet

- 938F 7SN Wheel Loader and It38f Integrated Toolcarrier Power TrainDocument23 pages938F 7SN Wheel Loader and It38f Integrated Toolcarrier Power Trainale aleNo ratings yet

- Testing and Adjusting: Troubleshooting The Transmission Hydraulic SystemDocument20 pagesTesting and Adjusting: Troubleshooting The Transmission Hydraulic SystemEdwin MelendezNo ratings yet

- Prueva y Ajuste Sist Hid. 950EDocument32 pagesPrueva y Ajuste Sist Hid. 950ESantiago FacundaNo ratings yet

- Operational ChecksDocument6 pagesOperational ChecksGuido Emanuel SteinbachNo ratings yet

- Automatic Transmission NAG1 - Fluid and FilterDocument4 pagesAutomatic Transmission NAG1 - Fluid and FilterKrivega88No ratings yet

- Testing and Adjusting: D6M Track-Type Tractor Hydraulic SystemDocument27 pagesTesting and Adjusting: D6M Track-Type Tractor Hydraulic SystemJUAN CARLOS PAZNo ratings yet

- AMWDocument14 pagesAMWSudeesh BabuNo ratings yet

- 322L EXCAVATOR 9RL00001-UP (MACHINE) POWERED BY 3116 ENGINE (SEBP2267 - 02) - DocumentaciónDocument60 pages322L EXCAVATOR 9RL00001-UP (MACHINE) POWERED BY 3116 ENGINE (SEBP2267 - 02) - DocumentaciónJose Corcega brito100% (2)

- Senr3193 Hydrostatic TransmissionDocument48 pagesSenr3193 Hydrostatic TransmissionMoicano P SánchezNo ratings yet

- Group 3 Tests and Adjustments: 1 1. Hydraulic Oil Clean Up Procedure Using Portable Filter CaddyDocument7 pagesGroup 3 Tests and Adjustments: 1 1. Hydraulic Oil Clean Up Procedure Using Portable Filter CaddyPriscila RodriguesNo ratings yet

- 938FDocument21 pages938Fمحمد يونسNo ratings yet

- Testing and Adjusting: Visual ChecksDocument10 pagesTesting and Adjusting: Visual CheckscacafaruqNo ratings yet

- 12H Frein TestDocument13 pages12H Frein TestaniriNo ratings yet

- Testing and Adjusting: Troubleshooting The Transmission Hydraulic SystemDocument21 pagesTesting and Adjusting: Troubleshooting The Transmission Hydraulic Systemlin koNo ratings yet

- Pruebas y Ajustes 416bDocument30 pagesPruebas y Ajustes 416bVictor NunezNo ratings yet

- Title Minyak EnjinDocument8 pagesTitle Minyak EnjinKhairul SyahreelNo ratings yet

- Pruebas Dumper S250EDocument18 pagesPruebas Dumper S250EUilmerKrdenasNo ratings yet

- D8r Hydraulic SystemDocument69 pagesD8r Hydraulic SystemKibrom hilufNo ratings yet

- Testing and Adjusting: Cerrar SISDocument35 pagesTesting and Adjusting: Cerrar SISWilliams ArayaNo ratings yet

- TESTE e AJUSTE - Sistema de Ar e FreiosDocument4 pagesTESTE e AJUSTE - Sistema de Ar e FreiosSebastiao GoncalvesNo ratings yet

- SpectDocument23 pagesSpectSteven Y.MNo ratings yet

- Steering Pilot System Pressure - Test - Command Control SteeringDocument4 pagesSteering Pilot System Pressure - Test - Command Control SteeringWilliams ArayaNo ratings yet

- 446 PresionesDocument30 pages446 PresionesJose Cruz Martinez MedinaNo ratings yet

- Gravel Road Maintenance: Problems Associated With Gravel RoadsDocument56 pagesGravel Road Maintenance: Problems Associated With Gravel RoadsBlen tesfayeNo ratings yet

- Steering System PDFDocument49 pagesSteering System PDFErkki IsokangasNo ratings yet

- Forklift MaintenanceDocument11 pagesForklift MaintenanceTrường NguyenNo ratings yet

- D8R TRACK-TYPE TRACTOR 9EM00001-UP (MACHINE) POWERED BY 3406C Engine (SEBP2536 - 130) - DocumentationDocument29 pagesD8R TRACK-TYPE TRACTOR 9EM00001-UP (MACHINE) POWERED BY 3406C Engine (SEBP2536 - 130) - Documentationdedy imranNo ratings yet

- 924F Pruebas y AjustesDocument26 pages924F Pruebas y AjustesSan Gabriel Representaciones100% (1)

- GM 3.0L EngineDocument100 pagesGM 3.0L EngineAndre AlexandreNo ratings yet

- 48-22 Steering Fluid Check & BleedingDocument5 pages48-22 Steering Fluid Check & Bleedingmefisto06cNo ratings yet

- Elevador de AutosDocument11 pagesElevador de AutoschcorreaNo ratings yet

- ManualDocument64 pagesManualCoco Samuel-Furlonge100% (2)

- Cheuqeo Cilindros Hidraulicos Del Cargador 988KDocument5 pagesCheuqeo Cilindros Hidraulicos Del Cargador 988KRAMON CALDERONNo ratings yet

- Ajustes de Transmision CaterpillarDocument23 pagesAjustes de Transmision CaterpillarPlstina RamsNo ratings yet

- 722.9 Tranny Oil Line FlushDocument3 pages722.9 Tranny Oil Line FlushAntonio da LuzNo ratings yet

- V8051 335 Instruction Manual 88aceDocument7 pagesV8051 335 Instruction Manual 88acecarlNo ratings yet

- Crankcase PressureDocument12 pagesCrankcase PressureMuhammad SyaqirinNo ratings yet

- Practical TH460-1 023826Document6 pagesPractical TH460-1 023826eskully92No ratings yet

- Evalucion de Transmision r1600gDocument38 pagesEvalucion de Transmision r1600gmijael1393No ratings yet

- 8SG 021508Document18 pages8SG 021508ronald enrique gareca ruedaNo ratings yet

- 777D Testing and Adjusting - Brake System Air - PurgeDocument7 pages777D Testing and Adjusting - Brake System Air - Purgezawmoe aungNo ratings yet

- Hydraulic Bottle Jack ManualDocument8 pagesHydraulic Bottle Jack ManualAlex Lake100% (1)

- 950H WHEEL LOADER J5J00001-UP (MACHINE) POWERED BY C7 ENGINE (XEBP8563 - 00) - DocumentationDocument12 pages950H WHEEL LOADER J5J00001-UP (MACHINE) POWERED BY C7 ENGINE (XEBP8563 - 00) - DocumentationMohamed ZohierNo ratings yet

- Pruebas y Ajustes DIRECCION 428BDocument19 pagesPruebas y Ajustes DIRECCION 428BRamiro MillazNo ratings yet

- Presiones 988bDocument24 pagesPresiones 988bMarielisa Zertuche FloresNo ratings yet

- Pruebas Ajust Transmision 416C, 426C, 428C, 436C & 438CDocument22 pagesPruebas Ajust Transmision 416C, 426C, 428C, 436C & 438CFerreira Anibal ParedesNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Section 7 Disassembly and AssemblyDocument4 pagesSection 7 Disassembly and AssemblySergey MovchanNo ratings yet

- Group 4 Disassembly and Assembly: 1. Electro-Hydraulic Control UnitDocument210 pagesGroup 4 Disassembly and Assembly: 1. Electro-Hydraulic Control UnitSergey MovchanNo ratings yet

- Group 2 Tightening Torque: 1. Major ComponentsDocument3 pagesGroup 2 Tightening Torque: 1. Major ComponentsSergey MovchanNo ratings yet

- Group 2 Major ComponentDocument11 pagesGroup 2 Major ComponentSergey MovchanNo ratings yet

- Group 2 Major ComponentDocument11 pagesGroup 2 Major ComponentSergey MovchanNo ratings yet

- Group 2 Major Component: 1. Main PumpDocument11 pagesGroup 2 Major Component: 1. Main PumpSergey MovchanNo ratings yet

- Group 2 Tightening Torque: 1. Major ComponentsDocument3 pagesGroup 2 Tightening Torque: 1. Major ComponentsSergey MovchanNo ratings yet

- G Group 3 Tests and Adjustments: 1. Parking Brake PerformanceDocument2 pagesG Group 3 Tests and Adjustments: 1. Parking Brake PerformanceSergey MovchanNo ratings yet

- Group 2 Tightening TorqueDocument3 pagesGroup 2 Tightening TorqueSergey MovchanNo ratings yet

- Group 3 Tests and Adjustments: 1. Parking Brake PerformanceDocument2 pagesGroup 3 Tests and Adjustments: 1. Parking Brake PerformanceSergey MovchanNo ratings yet

- Group 5 Travel Speed Control SystemDocument1 pageGroup 5 Travel Speed Control SystemSergey MovchanNo ratings yet

- Group 2 Operational Checks and TroubleshootingDocument11 pagesGroup 2 Operational Checks and TroubleshootingSergey MovchanNo ratings yet

- Group 3 Pump Device: 1. Removal and InstallDocument22 pagesGroup 3 Pump Device: 1. Removal and InstallSergey MovchanNo ratings yet

- Group 4 Main Control Valve Group 4 Main Control Valve: 1. Removal and Install of MotorDocument14 pagesGroup 4 Main Control Valve Group 4 Main Control Valve: 1. Removal and Install of MotorSergey MovchanNo ratings yet

Group 3 Tests and Adjustments Group 3 Tests and Adjustments: 1. Parking Brake Performance 1. Parking Brake Performance

Group 3 Tests and Adjustments Group 3 Tests and Adjustments: 1. Parking Brake Performance 1. Parking Brake Performance

Uploaded by

Sergey MovchanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Group 3 Tests and Adjustments Group 3 Tests and Adjustments: 1. Parking Brake Performance 1. Parking Brake Performance

Group 3 Tests and Adjustments Group 3 Tests and Adjustments: 1. Parking Brake Performance 1. Parking Brake Performance

Uploaded by

Sergey MovchanCopyright:

Available Formats

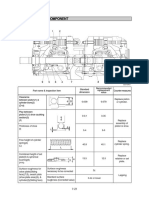

GROUP 3 TESTS AND ADJUSTMENTS

1. PARKING BRAKE PERFORMANCE

EASUREMENT CONDITION 1) MEASUREMENT (1) Tire inflation pressure : Specified pressure (2) Road surface : Flat, dry, paved surface with 1/5 (1120') gradient. (3) Machine : In operating condition

Item Parking brake performance Standard valve Keep machine on 20% (1120') gradient

20% gradient 11 20'

75794BS17

2) MEASURING PROCEDURE (1) Start the engine and drive the machine straight up a 1/5 gradient with the bucket unloaded. (2) Depress the service brake, place the gear selector lever in neutral, then stop the engine. (3) Turn the parking brake switch ON, then slowly release the service brake pedal and the machine must be kept stopped. The measurement must be made with the machine facing either up or down the slope.

11 20' 20% gradient

75794BS18

2. ADJUSTMENT OF PARKING BRAKE

(1) External brake inspection Inspect for wear of brake pad (2) Refer to the PARKING BRAKE SYSTEM on the page 4-21.

Adjust nut

75794BS22

4-36

3. HYDRAULIC BRAKE BLEEDING PROCEDURE

Escaping fluid under pressure can penetrate the skin causing serious injury. Avoid the hazard by relieving pressure before disconnecting hydraulic or other lines. Tighten all connections before applying pressure. Search for leaks with a piece of cardboard. Protect hands and body from high pressure fluids. If an accident occurs, see a doctor immediately. Any fluid injected into the skin must be surgically removed within a few hours or gangrene may result. Doctors unfamiliar with this type of injury should reference a knowledgeable medical source. Two people are required to bleed brake system oil, one to operate brake valve and other to open and close bleed screws. 1) Install frame locking bar. Engage parking brake. 2) Put a clear plastic tube on bleed screw to route low to hydraulic oil tank filler tube or container (A). 3) Start engine and run at low idle. 4) Push and hold brake pedal down until brake bleeding procedure is complete. If bubbles continue for more than 2 minutes, stop bleeding procedure. Check for and correct problem, then continue. 5) Open on bleed screw on differential and axle assembly until hydraulic oil starts to flow. Close bleed screw when oil is free of air. Release brake pedal. 6) Repeat steps 1)~5) for each bleed screw. 7) Push either brake pedal and hold down. 8) Check hydraulic oil level.

75794BS19

Breather vent Air breather Breather vent

Safety lock bar

4-37

You might also like

- 12G, 130G & 140G Hydraulic System and Steering PRUBASDocument24 pages12G, 130G & 140G Hydraulic System and Steering PRUBASF Labio Alex100% (4)

- Steering System PDFDocument12 pagesSteering System PDFGeorge Guerrero100% (1)

- Testing and Adjusting: Troubleshooting The Transmission Hydraulic SystemDocument24 pagesTesting and Adjusting: Troubleshooting The Transmission Hydraulic SystemLeandro Sal91% (11)

- G Group 3 Tests and Adjustments: 1. Parking Brake PerformanceDocument2 pagesG Group 3 Tests and Adjustments: 1. Parking Brake PerformancePriscila RodriguesNo ratings yet

- Group 3 Tests and Adjustments Group 3 Tests and Adjustments: 1. Parking Brake Performance 1. Parking Brake PerformanceDocument2 pagesGroup 3 Tests and Adjustments Group 3 Tests and Adjustments: 1. Parking Brake Performance 1. Parking Brake PerformanceaimerNo ratings yet

- Group 3 Tests and Adjustments: 1. Parking Brake PerformanceDocument2 pagesGroup 3 Tests and Adjustments: 1. Parking Brake PerformanceSergey MovchanNo ratings yet

- G Group 3 Tests and Adjustments: 1. Parking Brake PerformanceDocument2 pagesG Group 3 Tests and Adjustments: 1. Parking Brake PerformanceSergey MovchanNo ratings yet

- Testing Adjusting Trans D8RDocument30 pagesTesting Adjusting Trans D8Rardan fadilah100% (1)

- Calibration Relief Valve ExcavatorDocument36 pagesCalibration Relief Valve Excavatorcriman4550% (2)

- Pruebas y Ajustes Trannmision 928gDocument23 pagesPruebas y Ajustes Trannmision 928gManuel RamosNo ratings yet

- Sis 631 PRTDocument15 pagesSis 631 PRTAshraf m aliNo ratings yet

- 938F 7SN Wheel Loader and It38f Integrated Toolcarrier Power TrainDocument23 pages938F 7SN Wheel Loader and It38f Integrated Toolcarrier Power Trainale aleNo ratings yet

- Testing and Adjusting: Troubleshooting The Transmission Hydraulic SystemDocument20 pagesTesting and Adjusting: Troubleshooting The Transmission Hydraulic SystemEdwin MelendezNo ratings yet

- Prueva y Ajuste Sist Hid. 950EDocument32 pagesPrueva y Ajuste Sist Hid. 950ESantiago FacundaNo ratings yet

- Operational ChecksDocument6 pagesOperational ChecksGuido Emanuel SteinbachNo ratings yet

- Automatic Transmission NAG1 - Fluid and FilterDocument4 pagesAutomatic Transmission NAG1 - Fluid and FilterKrivega88No ratings yet

- Testing and Adjusting: D6M Track-Type Tractor Hydraulic SystemDocument27 pagesTesting and Adjusting: D6M Track-Type Tractor Hydraulic SystemJUAN CARLOS PAZNo ratings yet

- AMWDocument14 pagesAMWSudeesh BabuNo ratings yet

- 322L EXCAVATOR 9RL00001-UP (MACHINE) POWERED BY 3116 ENGINE (SEBP2267 - 02) - DocumentaciónDocument60 pages322L EXCAVATOR 9RL00001-UP (MACHINE) POWERED BY 3116 ENGINE (SEBP2267 - 02) - DocumentaciónJose Corcega brito100% (2)

- Senr3193 Hydrostatic TransmissionDocument48 pagesSenr3193 Hydrostatic TransmissionMoicano P SánchezNo ratings yet

- Group 3 Tests and Adjustments: 1 1. Hydraulic Oil Clean Up Procedure Using Portable Filter CaddyDocument7 pagesGroup 3 Tests and Adjustments: 1 1. Hydraulic Oil Clean Up Procedure Using Portable Filter CaddyPriscila RodriguesNo ratings yet

- 938FDocument21 pages938Fمحمد يونسNo ratings yet

- Testing and Adjusting: Visual ChecksDocument10 pagesTesting and Adjusting: Visual CheckscacafaruqNo ratings yet

- 12H Frein TestDocument13 pages12H Frein TestaniriNo ratings yet

- Testing and Adjusting: Troubleshooting The Transmission Hydraulic SystemDocument21 pagesTesting and Adjusting: Troubleshooting The Transmission Hydraulic Systemlin koNo ratings yet

- Pruebas y Ajustes 416bDocument30 pagesPruebas y Ajustes 416bVictor NunezNo ratings yet

- Title Minyak EnjinDocument8 pagesTitle Minyak EnjinKhairul SyahreelNo ratings yet

- Pruebas Dumper S250EDocument18 pagesPruebas Dumper S250EUilmerKrdenasNo ratings yet

- D8r Hydraulic SystemDocument69 pagesD8r Hydraulic SystemKibrom hilufNo ratings yet

- Testing and Adjusting: Cerrar SISDocument35 pagesTesting and Adjusting: Cerrar SISWilliams ArayaNo ratings yet

- TESTE e AJUSTE - Sistema de Ar e FreiosDocument4 pagesTESTE e AJUSTE - Sistema de Ar e FreiosSebastiao GoncalvesNo ratings yet

- SpectDocument23 pagesSpectSteven Y.MNo ratings yet

- Steering Pilot System Pressure - Test - Command Control SteeringDocument4 pagesSteering Pilot System Pressure - Test - Command Control SteeringWilliams ArayaNo ratings yet

- 446 PresionesDocument30 pages446 PresionesJose Cruz Martinez MedinaNo ratings yet

- Gravel Road Maintenance: Problems Associated With Gravel RoadsDocument56 pagesGravel Road Maintenance: Problems Associated With Gravel RoadsBlen tesfayeNo ratings yet

- Steering System PDFDocument49 pagesSteering System PDFErkki IsokangasNo ratings yet

- Forklift MaintenanceDocument11 pagesForklift MaintenanceTrường NguyenNo ratings yet

- D8R TRACK-TYPE TRACTOR 9EM00001-UP (MACHINE) POWERED BY 3406C Engine (SEBP2536 - 130) - DocumentationDocument29 pagesD8R TRACK-TYPE TRACTOR 9EM00001-UP (MACHINE) POWERED BY 3406C Engine (SEBP2536 - 130) - Documentationdedy imranNo ratings yet

- 924F Pruebas y AjustesDocument26 pages924F Pruebas y AjustesSan Gabriel Representaciones100% (1)

- GM 3.0L EngineDocument100 pagesGM 3.0L EngineAndre AlexandreNo ratings yet

- 48-22 Steering Fluid Check & BleedingDocument5 pages48-22 Steering Fluid Check & Bleedingmefisto06cNo ratings yet

- Elevador de AutosDocument11 pagesElevador de AutoschcorreaNo ratings yet

- ManualDocument64 pagesManualCoco Samuel-Furlonge100% (2)

- Cheuqeo Cilindros Hidraulicos Del Cargador 988KDocument5 pagesCheuqeo Cilindros Hidraulicos Del Cargador 988KRAMON CALDERONNo ratings yet

- Ajustes de Transmision CaterpillarDocument23 pagesAjustes de Transmision CaterpillarPlstina RamsNo ratings yet

- 722.9 Tranny Oil Line FlushDocument3 pages722.9 Tranny Oil Line FlushAntonio da LuzNo ratings yet

- V8051 335 Instruction Manual 88aceDocument7 pagesV8051 335 Instruction Manual 88acecarlNo ratings yet

- Crankcase PressureDocument12 pagesCrankcase PressureMuhammad SyaqirinNo ratings yet

- Practical TH460-1 023826Document6 pagesPractical TH460-1 023826eskully92No ratings yet

- Evalucion de Transmision r1600gDocument38 pagesEvalucion de Transmision r1600gmijael1393No ratings yet

- 8SG 021508Document18 pages8SG 021508ronald enrique gareca ruedaNo ratings yet

- 777D Testing and Adjusting - Brake System Air - PurgeDocument7 pages777D Testing and Adjusting - Brake System Air - Purgezawmoe aungNo ratings yet

- Hydraulic Bottle Jack ManualDocument8 pagesHydraulic Bottle Jack ManualAlex Lake100% (1)

- 950H WHEEL LOADER J5J00001-UP (MACHINE) POWERED BY C7 ENGINE (XEBP8563 - 00) - DocumentationDocument12 pages950H WHEEL LOADER J5J00001-UP (MACHINE) POWERED BY C7 ENGINE (XEBP8563 - 00) - DocumentationMohamed ZohierNo ratings yet

- Pruebas y Ajustes DIRECCION 428BDocument19 pagesPruebas y Ajustes DIRECCION 428BRamiro MillazNo ratings yet

- Presiones 988bDocument24 pagesPresiones 988bMarielisa Zertuche FloresNo ratings yet

- Pruebas Ajust Transmision 416C, 426C, 428C, 436C & 438CDocument22 pagesPruebas Ajust Transmision 416C, 426C, 428C, 436C & 438CFerreira Anibal ParedesNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Section 7 Disassembly and AssemblyDocument4 pagesSection 7 Disassembly and AssemblySergey MovchanNo ratings yet

- Group 4 Disassembly and Assembly: 1. Electro-Hydraulic Control UnitDocument210 pagesGroup 4 Disassembly and Assembly: 1. Electro-Hydraulic Control UnitSergey MovchanNo ratings yet

- Group 2 Tightening Torque: 1. Major ComponentsDocument3 pagesGroup 2 Tightening Torque: 1. Major ComponentsSergey MovchanNo ratings yet

- Group 2 Major ComponentDocument11 pagesGroup 2 Major ComponentSergey MovchanNo ratings yet

- Group 2 Major ComponentDocument11 pagesGroup 2 Major ComponentSergey MovchanNo ratings yet

- Group 2 Major Component: 1. Main PumpDocument11 pagesGroup 2 Major Component: 1. Main PumpSergey MovchanNo ratings yet

- Group 2 Tightening Torque: 1. Major ComponentsDocument3 pagesGroup 2 Tightening Torque: 1. Major ComponentsSergey MovchanNo ratings yet

- G Group 3 Tests and Adjustments: 1. Parking Brake PerformanceDocument2 pagesG Group 3 Tests and Adjustments: 1. Parking Brake PerformanceSergey MovchanNo ratings yet

- Group 2 Tightening TorqueDocument3 pagesGroup 2 Tightening TorqueSergey MovchanNo ratings yet

- Group 3 Tests and Adjustments: 1. Parking Brake PerformanceDocument2 pagesGroup 3 Tests and Adjustments: 1. Parking Brake PerformanceSergey MovchanNo ratings yet

- Group 5 Travel Speed Control SystemDocument1 pageGroup 5 Travel Speed Control SystemSergey MovchanNo ratings yet

- Group 2 Operational Checks and TroubleshootingDocument11 pagesGroup 2 Operational Checks and TroubleshootingSergey MovchanNo ratings yet

- Group 3 Pump Device: 1. Removal and InstallDocument22 pagesGroup 3 Pump Device: 1. Removal and InstallSergey MovchanNo ratings yet

- Group 4 Main Control Valve Group 4 Main Control Valve: 1. Removal and Install of MotorDocument14 pagesGroup 4 Main Control Valve Group 4 Main Control Valve: 1. Removal and Install of MotorSergey MovchanNo ratings yet