Professional Documents

Culture Documents

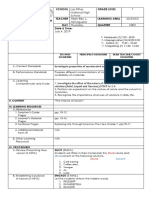

Ganan-V1,3 9

Ganan-V1,3 9

Uploaded by

juanescribdCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ganan-V1,3 9

Ganan-V1,3 9

Uploaded by

juanescribdCopyright:

Available Formats

fashion?

Following the ndings of nature itself, for which the liquid phase has been the essential ground for the emergence of chemical complexity and life, we focus on those processes involving manipulation of liquid phase on the microscale and, in particular, those oering homogeneous and reproducible yield. The last two decades have witnessed an explosive expansion in the understanding of capillary processes; this knowledge has served human creativity and the development of a number of technologies now considered forming a particular eld of uid mechanics: microuidics. In this eld, the intelligent combination of imposed geometries (devices) on small scales, surface tension and bulk forces tuned at precise intensities provides the tools to manipulate matter in an unprecedent way. Here, droplets, bubbles, microcapsules, microbers, etc. become basic building blocks of new functional materials, intelligent ingredients and APIs. While mass productivity pertains functional product manufacturing enough for current human demands, control of the microscopic scale directly inuences product delivery to an individual organism. This review aims to provide a gross mapping of current scientic and technological knowledge in the eld, in the quest for those current tools combining highest productivity with maximal control on the microscale and reproducibility. APIs can be present in many forms: solid dispersions (powders made up of solid particles), suspensions (powders in liquids) of any kind, emulsions (droplets of any size in immiscible liquids), solutions (APIs molecules dispersed in a solvent), etc. Nearly always, a fragmentation process is involved in these forms. The most controllable way to fragment a bulk material involves its reduction to liquid phase (melting or dissolution), fragmenting the liquid phase into droplets by the use of specic tools, and applying a further step to solidify it (freezing or desolvation), if necessary. In general, a high degree of care put into the liquid fragmentation step demands a careful subsequent solidifying step as well, to prevent undesired coalescence. Interestingly, some researchers have successfully proposed the use of electric charges to prevent such coalescence [38]. However, fragmentation involves manipulation tools adapted to the inherent nature of this process: rst, it always stores energy in the form of surface tension, and second, this storage should be as ordered as compatible with the functionality and control sought for, thus minimizing entropy. These demands go against Thermodynamics in many aspects. Therefore, the inventive steps involved in the design of liquid fragmentation tools are much taller than those demanded in subsequent solidifying steps. 9

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Chemistry Investigatory Project On The Topic: To Determine Percentage of Caffeine in Different Tea SamplesDocument16 pagesChemistry Investigatory Project On The Topic: To Determine Percentage of Caffeine in Different Tea SamplesJYOTI DOGRA77% (115)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Module 3Document16 pagesModule 3Stephen IpanNo ratings yet

- AP Chemistry Chapter 4 TestDocument3 pagesAP Chemistry Chapter 4 Testphysteach1216100% (2)

- Design of Wash Stage in Copper Solvent ExtractionDocument36 pagesDesign of Wash Stage in Copper Solvent Extractionjoseph kafumbila100% (2)

- Unit 24 (Unidad 24) : Prepositions Por and para (Las Preposiciones Por y Para)Document7 pagesUnit 24 (Unidad 24) : Prepositions Por and para (Las Preposiciones Por y Para)juanescribdNo ratings yet

- GE AmershamDocument32 pagesGE AmershamjuanescribdNo ratings yet

- KPL ELISA Technical GuideDocument44 pagesKPL ELISA Technical GuidejuanescribdNo ratings yet

- 5.2. Planar Microfluidic DevicesDocument1 page5.2. Planar Microfluidic DevicesjuanescribdNo ratings yet

- 2.3. Continuous Production of Droplets by Hydrodynamic MeansDocument1 page2.3. Continuous Production of Droplets by Hydrodynamic MeansjuanescribdNo ratings yet

- Sauter-Mean-Diameter: D D D .: I I I IDocument1 pageSauter-Mean-Diameter: D D D .: I I I IjuanescribdNo ratings yet

- 1.2. Functional Designs, Materials and Ingredients: Mechanics Versus Chem-IstryDocument1 page1.2. Functional Designs, Materials and Ingredients: Mechanics Versus Chem-IstryjuanescribdNo ratings yet

- Building Functional Materials For Health Care and Pharmacy From Microfluidic Principles and Flow FocusingDocument1 pageBuilding Functional Materials For Health Care and Pharmacy From Microfluidic Principles and Flow FocusingjuanescribdNo ratings yet

- Is Matter Around Us PureDocument24 pagesIs Matter Around Us PureNisha SinghNo ratings yet

- Serologia Forense de 1910 PDFDocument212 pagesSerologia Forense de 1910 PDFPancho PanteraNo ratings yet

- Ferrous Sulfate Solubility in WaterDocument19 pagesFerrous Sulfate Solubility in WaterElmuntaser EltayebNo ratings yet

- Compressed Sheet & GasketDocument13 pagesCompressed Sheet & GaskettruongNo ratings yet

- J. Phys. Chem. B 2013, 117, 9980 9995Document16 pagesJ. Phys. Chem. B 2013, 117, 9980 9995AristidesNo ratings yet

- Reactions P-Hydroxybenzyl Alcohol Derivatives and Their Methyl Ethers With Molecular Chlorine'Document6 pagesReactions P-Hydroxybenzyl Alcohol Derivatives and Their Methyl Ethers With Molecular Chlorine'Sandipan SahaNo ratings yet

- STP Neomycin Sulfate RMA015Document5 pagesSTP Neomycin Sulfate RMA015Bejoy KarimNo ratings yet

- SCHOOL Las Piñas Grade Level: Daily Learning PlanDocument3 pagesSCHOOL Las Piñas Grade Level: Daily Learning Planallan rey l. almogueraNo ratings yet

- Grade 7 Q1 MELCs Unpacked InventoryDocument8 pagesGrade 7 Q1 MELCs Unpacked InventoryHonleth Jheney Mamaril50% (2)

- Experiment 7Document7 pagesExperiment 7enieynaz80% (5)

- Appendix XIV A - BP Microbiological Assay MethodsDocument6 pagesAppendix XIV A - BP Microbiological Assay MethodsSantosh Kumar TataNo ratings yet

- Liquid Liquid Phase Separation in PolysulfoneDocument11 pagesLiquid Liquid Phase Separation in PolysulfoneJamilly Ribeiro LopesNo ratings yet

- Hafta PDFDocument38 pagesHafta PDFAdu GilbertNo ratings yet

- Introduction To Experimental TechniquesDocument25 pagesIntroduction To Experimental TechniquesRana Hassan TariqNo ratings yet

- Lidocaine - British PharmacopoeiaDocument4 pagesLidocaine - British PharmacopoeiaAinul HudaNo ratings yet

- Artemether and Lumefantrine Tablets (Artemetheri Et Lumefantrini Compressi)Document3 pagesArtemether and Lumefantrine Tablets (Artemetheri Et Lumefantrini Compressi)daizhussain004No ratings yet

- United States Patent Office: Benzylideneacetone-CH-CH CH-CO-CH3Document4 pagesUnited States Patent Office: Benzylideneacetone-CH-CH CH-CO-CH3danyNo ratings yet

- ETEA GuideDocument30 pagesETEA Guideshoaibkhaliq0% (1)

- Extraction FAQDocument18 pagesExtraction FAQDaria SchkaNo ratings yet

- CIE - AS - and - A-Level - Chemistry - Coursebook - 2nd-Edition (1) - 99-114Document16 pagesCIE - AS - and - A-Level - Chemistry - Coursebook - 2nd-Edition (1) - 99-114An Trương Nguyễn HoàngNo ratings yet

- 1 2 2 5 2 PDFDocument16 pages1 2 2 5 2 PDFSrinivas VenkataramanNo ratings yet

- Kimiko Yauri 01/03/2021 Science Experiment Separa NG Mixture Ms. MeasuryDocument3 pagesKimiko Yauri 01/03/2021 Science Experiment Separa NG Mixture Ms. MeasuryKimiko YauriNo ratings yet

- Polymerization and Characterization of N-VinylcaprolactamDocument89 pagesPolymerization and Characterization of N-VinylcaprolactamEmre Saka100% (1)

- 2008local ExamDocument8 pages2008local ExamshengzhoumiNo ratings yet

- How To Make Liposomal Vitamin C at Home (Homemade Lipo-Spheric Sodium Ascorbate Recipe)Document3 pagesHow To Make Liposomal Vitamin C at Home (Homemade Lipo-Spheric Sodium Ascorbate Recipe)liz knight100% (2)

- Characteristics of Polyglycerol Ester and Its Different FractionsDocument10 pagesCharacteristics of Polyglycerol Ester and Its Different FractionsliliNo ratings yet