Professional Documents

Culture Documents

WF74PTG2 PDF

WF74PTG2 PDF

Uploaded by

Jessie Radaza TutorCopyright:

Available Formats

You might also like

- E-Ticket Itinerary/Receipt 12074713Document8 pagesE-Ticket Itinerary/Receipt 12074713Jessie Radaza Tutor100% (2)

- Manufacture Procedure of The Pressure VesselDocument45 pagesManufacture Procedure of The Pressure Vesselmallesh100% (1)

- Aa 036322 001Document1 pageAa 036322 001petronashscribdidNo ratings yet

- Roll Pass Design For BarsDocument20 pagesRoll Pass Design For BarsSøhaila Samy100% (4)

- 9-Flanges & Design of Non-Standard Flange PDFDocument35 pages9-Flanges & Design of Non-Standard Flange PDFUday Gokhale75% (4)

- W83PTG3 PDFDocument1 pageW83PTG3 PDFJessie Radaza TutorNo ratings yet

- Strand Debonding Detail: End 2 End 1Document1 pageStrand Debonding Detail: End 2 End 1Jessie Radaza TutorNo ratings yet

- Alternate Stirrup Detail Section ADocument1 pageAlternate Stirrup Detail Section AJessie Radaza TutorNo ratings yet

- 0602 - 2 - 012 Anchor Bolts PDFDocument2 pages0602 - 2 - 012 Anchor Bolts PDFthesobrevivienteNo ratings yet

- 3 FabricationDocument10 pages3 FabricationSergio CharcapeNo ratings yet

- Insert Shape ... : R S C T DDocument11 pagesInsert Shape ... : R S C T DskidamdnevnoNo ratings yet

- Indice Norma: Menú Principal Indice Manual Indice VolumenDocument1 pageIndice Norma: Menú Principal Indice Manual Indice Volumencmrn5No ratings yet

- Bunk House - PLANSDocument25 pagesBunk House - PLANSnikthomas24100% (4)

- Guppy 2 Paper Plan-1-2Document1 pageGuppy 2 Paper Plan-1-2Pablo D. RigoNo ratings yet

- Figures Girder Schedule: Negative Value Indicates Back From MidspanDocument1 pageFigures Girder Schedule: Negative Value Indicates Back From MidspangabemzamanNo ratings yet

- CuñaDocument20 pagesCuñaJulian Granados RicoNo ratings yet

- 1 - Dimensiones y Marcas PDFDocument2 pages1 - Dimensiones y Marcas PDFMiguelRagasNo ratings yet

- Critical Item Issue Note Page No. 1 of 1Document1 pageCritical Item Issue Note Page No. 1 of 1Erin JohnsonNo ratings yet

- VFA6 U (Assembly)Document2 pagesVFA6 U (Assembly)pacodmxNo ratings yet

- Is 2610Document8 pagesIs 2610kamalkraj4002No ratings yet

- Rotary Milling Head: e e e e 5Document11 pagesRotary Milling Head: e e e e 5gooolNo ratings yet

- r1Document3 pagesr1naseema1No ratings yet

- Grooved Pins Technical SpecsDocument8 pagesGrooved Pins Technical Specsjagan_san10No ratings yet

- StairDocument1 pageStairriz2010No ratings yet

- Granberg Precision Grinder G1012XT ManualDocument2 pagesGranberg Precision Grinder G1012XT ManualAnonymous GtkD9AEJqeNo ratings yet

- 3 BQDocument322 pages3 BQJia Jin100% (1)

- Zollern - Plain Bearing - Type ZDocument20 pagesZollern - Plain Bearing - Type ZYuri BachNo ratings yet

- Raise Boring Heads: User ManualDocument40 pagesRaise Boring Heads: User ManualMaykol Ken Hasaki MaselNo ratings yet

- E - Linear Slot Diffusers PDFDocument17 pagesE - Linear Slot Diffusers PDFabdullah khanNo ratings yet

- DETAIL DWG Sheet-16 PDFDocument1 pageDETAIL DWG Sheet-16 PDFbalotNo ratings yet

- COMPLETE - CE 20211125 Welding Guide 1.2Document10 pagesCOMPLETE - CE 20211125 Welding Guide 1.2rmrkp7sprmNo ratings yet

- 9 Riveted JointsDocument72 pages9 Riveted JointsROHAN PILLAI100% (1)

- F-117A Tiled With Borders (Rev4)Document20 pagesF-117A Tiled With Borders (Rev4)mtcfisioNo ratings yet

- FLOW SWITCH FS10-C SERIES Installation InstructionsDocument2 pagesFLOW SWITCH FS10-C SERIES Installation InstructionsWattsNo ratings yet

- 11c - Pile Cap Details - StructuralDocument2 pages11c - Pile Cap Details - StructuralAnthony FedericoNo ratings yet

- Bearing SNN Sadf 3 0Document32 pagesBearing SNN Sadf 3 0Budy AndikaNo ratings yet

- Pipe GuideDocument231 pagesPipe GuidegeorgD2010100% (2)

- Din 509Document14 pagesDin 509Bruno Menon0% (1)

- Spence StrainersDocument132 pagesSpence StrainersRahul LavandNo ratings yet

- AK31 TurretDocument34 pagesAK31 TurretVladimirAgeev100% (1)

- PBM Sanitary Ball ValvesDocument40 pagesPBM Sanitary Ball ValvesAnonymous bTvqZMftNo ratings yet

- RaiseBoringUsersManual PDFDocument40 pagesRaiseBoringUsersManual PDFJhonatanLiCuadradoNo ratings yet

- Concrete Blocking For Convex Vertical Bends Concrete Thrust Blocking (Horizontal)Document10 pagesConcrete Blocking For Convex Vertical Bends Concrete Thrust Blocking (Horizontal)chithirai10No ratings yet

- Dimensioning of TapersDocument2 pagesDimensioning of Tapers최승원No ratings yet

- WATTS TYPE NEMA 4X FS20 FLOW SWITCH Installation InstructionsDocument2 pagesWATTS TYPE NEMA 4X FS20 FLOW SWITCH Installation InstructionsWattsNo ratings yet

- Super Maxbit Hammer Bit BrochureDocument6 pagesSuper Maxbit Hammer Bit BrochurezapspazNo ratings yet

- Regulators Zero GovernorsDocument2 pagesRegulators Zero GovernorsraldavoodNo ratings yet

- Disclosure To Promote The Right To Information: IS 5290 (1993) : Specification For Landing Valves (CED 22: Fire Fighting)Document20 pagesDisclosure To Promote The Right To Information: IS 5290 (1993) : Specification For Landing Valves (CED 22: Fire Fighting)Tanmoy Dutta100% (1)

- Oem Gardner Denver Pz-11Document8 pagesOem Gardner Denver Pz-11caballero_tigre100% (1)

- GA Drawing of IR - 4 X 5Document1 pageGA Drawing of IR - 4 X 5Himanshu GuptaNo ratings yet

- 7 Riveted JointsDocument72 pages7 Riveted JointsanirudhNo ratings yet

- TANK Design DetailingDocument17 pagesTANK Design DetailingTiffany Vabiola100% (8)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- How to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideFrom EverandHow to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideNo ratings yet

- A Guide to Motor Boat Design and Construction - A Collection of Historical Articles Containing Information on the Methods and Equipment of the Boat BuilderFrom EverandA Guide to Motor Boat Design and Construction - A Collection of Historical Articles Containing Information on the Methods and Equipment of the Boat BuilderNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Album of Dated Latin Inscriptions, Part II, Plates: Rome and the Neighborhood, A.D. 100-199From EverandAlbum of Dated Latin Inscriptions, Part II, Plates: Rome and the Neighborhood, A.D. 100-199No ratings yet

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- ASPHALTDocument7 pagesASPHALTJessie Radaza TutorNo ratings yet

- TOEIC-style Error Recognition: 23130 Page 1 of 2Document2 pagesTOEIC-style Error Recognition: 23130 Page 1 of 2Jessie Radaza TutorNo ratings yet

- Generational Differences in Acute Care NursesDocument13 pagesGenerational Differences in Acute Care NursesJessie Radaza TutorNo ratings yet

- New Dicklumn Catchment Area Polygon 43 14.2203 27.9481: Name Shape Type of Points S) RS)Document3 pagesNew Dicklumn Catchment Area Polygon 43 14.2203 27.9481: Name Shape Type of Points S) RS)Jessie Radaza TutorNo ratings yet

- Balili River Polygon 177 56.5568 48.6741: Name Shape Type of Points S) RS)Document3 pagesBalili River Polygon 177 56.5568 48.6741: Name Shape Type of Points S) RS)Jessie Radaza TutorNo ratings yet

- Staad LectureDocument3 pagesStaad LectureJesus Ray M. Mansayon100% (3)

- Engr. Jessie Radaza Tutor: Personal InformationDocument4 pagesEngr. Jessie Radaza Tutor: Personal InformationJessie Radaza TutorNo ratings yet

- New Dicklumn Catchment Area Polygon 43 3,513.9229 17.3662: Name Shape Type of Points (Acres) (Miles)Document3 pagesNew Dicklumn Catchment Area Polygon 43 3,513.9229 17.3662: Name Shape Type of Points (Acres) (Miles)Jessie Radaza TutorNo ratings yet

- Origin and Theoretical Basis of The New Public Management (NPM)Document35 pagesOrigin and Theoretical Basis of The New Public Management (NPM)Jessie Radaza TutorNo ratings yet

- JDS Math2013 SolutionDocument5 pagesJDS Math2013 SolutionJessie Radaza Tutor100% (3)

- Syllabus Public Management ReformsDocument3 pagesSyllabus Public Management ReformsJessie Radaza TutorNo ratings yet

- Structural Analysis ExamDocument3 pagesStructural Analysis ExamJessie Radaza TutorNo ratings yet

- Philippine Journal of Public AdministrationDocument18 pagesPhilippine Journal of Public AdministrationJessie Radaza Tutor0% (1)

- President of The Philippines: QualificationsDocument20 pagesPresident of The Philippines: QualificationsJessie Radaza TutorNo ratings yet

- BureaucracyDocument23 pagesBureaucracyAbdillah Abdul-rahmanNo ratings yet

- REvised - Assignment of Topic Presentation For Quantitative Approaches in ManagementDocument1 pageREvised - Assignment of Topic Presentation For Quantitative Approaches in ManagementJessie Radaza TutorNo ratings yet

- Table of ContentsDocument1 pageTable of ContentsJessie Radaza TutorNo ratings yet

- ReservoirsDocument2 pagesReservoirsJay R SVNo ratings yet

- Inspection of Crane Wire RopesDocument14 pagesInspection of Crane Wire RopesP Venkata Suresh100% (3)

- How To Build Your Own Acoustic PanelsDocument47 pagesHow To Build Your Own Acoustic Panelspampaboy100% (1)

- 2 LM30Document2 pages2 LM30EfrainAquinoMezaNo ratings yet

- Lec6w Processintegration Ee143 CTNDocument15 pagesLec6w Processintegration Ee143 CTNstansilawNo ratings yet

- Ecss e HB 32 20 - Part 5a PDFDocument435 pagesEcss e HB 32 20 - Part 5a PDFNasos MasourasNo ratings yet

- 7-Empirical Formula For MgODocument6 pages7-Empirical Formula For MgOairiel_hamkaNo ratings yet

- SV10-20 Poppet, 2-Way, Normally Closed: Solenoid ValvesDocument2 pagesSV10-20 Poppet, 2-Way, Normally Closed: Solenoid ValvesMartin Andrew TugadeNo ratings yet

- Design Basis: M/S Space Combine Kind Attn: Mr. Arun VishwakarmaDocument6 pagesDesign Basis: M/S Space Combine Kind Attn: Mr. Arun Vishwakarmabyajaytyagi2266No ratings yet

- GMW15520Document10 pagesGMW15520Ed RiNo ratings yet

- 51 100Document50 pages51 100Anonymous GGc8FbNo ratings yet

- Ldpe L2100TN00Document4 pagesLdpe L2100TN00mohamad mostafaviNo ratings yet

- 01 BIO4600 BioMEMS IntroductionDocument55 pages01 BIO4600 BioMEMS IntroductionMd Ehtashamul HaqueNo ratings yet

- ML12045A005Document98 pagesML12045A005atanu1820dasNo ratings yet

- V80Service Manual 3 Powertrain Right VI CD Y Y 02Document86 pagesV80Service Manual 3 Powertrain Right VI CD Y Y 02Henry Yogaswara100% (2)

- Bismuth Film Electrodes For Heavy Metals Determination: &) I. Hotovy M. Vojs F. MikaDocument8 pagesBismuth Film Electrodes For Heavy Metals Determination: &) I. Hotovy M. Vojs F. MikaErico JuneNo ratings yet

- Engine Technical Data Sheet G3616 3100-3400 KW 900 RPMDocument2 pagesEngine Technical Data Sheet G3616 3100-3400 KW 900 RPMNavdeep GoyalNo ratings yet

- Tutorial 5 Phase EquilibriumDocument3 pagesTutorial 5 Phase EquilibriumezanaNo ratings yet

- 100, 101, 200 and 201 - DatasheetDocument4 pages100, 101, 200 and 201 - DatasheetJoão Paulo Giacomello67% (3)

- GGHJKDocument8 pagesGGHJKnopibotakNo ratings yet

- A 0000209 TechDocument36 pagesA 0000209 Techjose antonioNo ratings yet

- Scope: CautionDocument13 pagesScope: CautionYudi PermanaNo ratings yet

- OA 3961 Zinc Phosphate Primer Product Data: (Exterior / Interior)Document1 pageOA 3961 Zinc Phosphate Primer Product Data: (Exterior / Interior)tshawkyNo ratings yet

- Sludge Oil Liquefying System (Sols) Using Paralax®Document72 pagesSludge Oil Liquefying System (Sols) Using Paralax®Agung RakhmadiNo ratings yet

- Yellow Jacket HosesDocument10 pagesYellow Jacket HosesdBfreakNo ratings yet

- MSC Thesis Stephen GrechDocument198 pagesMSC Thesis Stephen GrechJamesFarrugiaNo ratings yet

- Gun Drill PriceDocument15 pagesGun Drill Price1mmahoneyNo ratings yet

- WPS 1-1-GT-SM-6 Rev. 0Document8 pagesWPS 1-1-GT-SM-6 Rev. 0Melby de la rosaNo ratings yet

- ASU SIte Management PlanDocument20 pagesASU SIte Management PlanPRIYABRATA SANTANU RANJAN AichNo ratings yet

- 1104C-44T IOPU Technical Data Sheet PDFDocument8 pages1104C-44T IOPU Technical Data Sheet PDFBob100% (2)

WF74PTG2 PDF

WF74PTG2 PDF

Uploaded by

Jessie Radaza TutorOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WF74PTG2 PDF

WF74PTG2 PDF

Uploaded by

Jessie Radaza TutorCopyright:

Available Formats

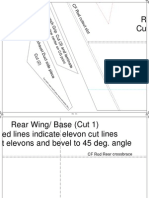

LIFTING BARS ~ H.S. THREADED BARS WITH ANCHOR PLATES AND NUTS AT BOTTOM. POSITION TO AVOID P.T.

DUCTS - SEE NOTE 5. FIELD BENDING REQUIRED TO OBTAIN 1" CONCRETE COVER AT PAVEMENT SEAT.

E

PICKUP FORCE 90 10

PRE-TENSIONING NOTES

1. PLAN LENGTH SHALL BE INCREASED AS NECESSARY TO COMPENSATE FOR SHORTENING DUE TO PRESTRESS AND SHRINKAGE. 2. ALL PRETENSIONED AND TEMPORARY STRANDS SHALL BE [" OR 0.6"] LOW RELAXATION STRANDS (AASHTO M203 GRADE 270.) 3. FOR END TYPES A, C, D AND E CUT ALL STRANDS FLUSH WITH THE GIRDER ENDS AND PAINT WITH AN APPROVED EPOXY RESIN, EXCEPT FOR EXTENDED STRANDS AS SHOWN. FOR END TYPE B CUT ALL STRANDS 1" BELOW CONCRETE SURFACE AND GROUT WITH AN APPROVED EPOXY GROUT. 4. THE TOP SURFACE OF THE GIRDER FLANGE SHALL BE ROUGHENED IN ACCORDANCE WITH SECTION 6-02.3(25)H OF THE STANDARD SPECIFICATIONS.

2 G5 #5 ADJUST LOCATION TO CLEAR P.T. DUCTS

B

6"

PICKUP FORCE X (TYP.)

6 G4 #5

2 G5 #5 & 2 G9 #5 ADJUST LOCATION TO CLEAR P.T. DUCTS

SAWTEETH

SAWTEETH

5. LIFTING EMBEDMENTS SHALL BE INSTALLED IN ACCORDANCE WITH SECTION 6-02.3(25)L OF THE STANDARD SPECIFICATIONS. CONTRACTOR TO DESIGN OTHER LIFTING MECHANISM IF THE GIRDER SECTION WEIGHT EXCEEDS 200 KIPS. 6. CAUTION SHALL BE EXERCISED IN HANDLING AND PLACING GIRDERS. ALL GIRDERS SHALL BE CHECKED BY THE CONTRACTOR TO ENSURE THAT THEY ARE BRACED ADEQUATELY TO PREVENT TIPPING AND TO CONTROL LATERAL BENDING DURING SHIPPING. ONCE ERECTED, ALL GIRDERS SHALL BE BRACED LATERALLY TO PREVENT TIPPING UNTIL THE DIAPHRAGMS ARE CAST AND CURED. 7. FORMS FOR BEARING PAD RECESSES SHALL BE CONSTRUCTED AND FASTENED IN SUCH A MANNER AS TO NOT CAUSE DAMAGE TO THE GIRDER DURING THE STRAND RELEASE OPERATION.

2 G8 #6

EXTEND STRAIGHT STRANDS (1) THROUGH (8) L (TYP.)

2 G9 #5

EXTEND STRAIGHT STRANDS (1) THROUGH (8) GIRDER

Y (TYP.)

TYPICAL ELEVATION AT END SEGMENT

END TYPE A SHOWN, OTHER END TYPES SIMILAR 3'-0" 4'-6" SPLAY G3 AND 2 G7

TYPICAL END ELEVATION AT CLOSURE

GIRDER 4" 4" 4" 1'-4" 1'-2" 4" 3" 2"+B1 1'-3" 6" G3 #5 1" CLR. (TYP.) G3 #5 3" 4'-2" GIRDER G4 #5 (TYP.)

Stirrup spacing shall be determined by the designer. 3'-0" 3" 3" 3" 4'-6"

TRANSVERSE REINFORCING AT SKEWED ENDS

ONLY TRANSVERSE REINFORCING SHOWN

G4 #5 (TYP.) TEMPORARY STRANDS (TYP.) G2 #5 (TYP.)

3" 3"

G1 #5 G6 W12 TIES (TYP.) G9 #5 (TYP.) 6'-2" G5 #5 (TYP.)

2 G1 #5, G3 #5 & 2 G7 #3 2 G1 #5, 2 G2 #5, G3 #5 & 2 G7 #3 9 SPA. @ 3" 6" 8 SPA. @ 6" 9" 2 G2 #5, G3 #5 & 2 G7 #3 SPA. @ 1'-0" 10 SPA. @ 6" = 5'-0" 6 SPA. @ 3"= 1'-6" 3" 4'-0"

6" MIN. 3" G2 #5 FORM HANGERS G5 #5 (TYP.) 1'-4" 3" 7" G7 #3 (TYP.) G8 #6 (TYP.)

6"+B1 GIR. 1'-0" 6" RECESS

1'-3"

6"

2'-0"

1'-0"

G8 #6 (TYP.) 5"

4" 3"

G7 #3 (TYP.)

G6 W12 TIES (TYP.)

G9 #5 End block may be eliminated if PT anchorages are placed in the cast-in-place diaphragm.

G5 #5

SECTION

VIEW

SAWTEETH SHOWN BY HATCHED AREA.

SECTION C

FOR "B1" SEE GIRDER DETAILS 3 OF 5

1" CHAMFER (TYP.)

3'-4"

SECTION

D

4

SAWTEETH SHOWN BY HATCHED AREA

VIEW

E

4

M:\Standards\Girders\PT Wide Flange\WF74PTG2.MAN

5.9-A1-4

Tue Apr 29 13:46:51 2008

You might also like

- E-Ticket Itinerary/Receipt 12074713Document8 pagesE-Ticket Itinerary/Receipt 12074713Jessie Radaza Tutor100% (2)

- Manufacture Procedure of The Pressure VesselDocument45 pagesManufacture Procedure of The Pressure Vesselmallesh100% (1)

- Aa 036322 001Document1 pageAa 036322 001petronashscribdidNo ratings yet

- Roll Pass Design For BarsDocument20 pagesRoll Pass Design For BarsSøhaila Samy100% (4)

- 9-Flanges & Design of Non-Standard Flange PDFDocument35 pages9-Flanges & Design of Non-Standard Flange PDFUday Gokhale75% (4)

- W83PTG3 PDFDocument1 pageW83PTG3 PDFJessie Radaza TutorNo ratings yet

- Strand Debonding Detail: End 2 End 1Document1 pageStrand Debonding Detail: End 2 End 1Jessie Radaza TutorNo ratings yet

- Alternate Stirrup Detail Section ADocument1 pageAlternate Stirrup Detail Section AJessie Radaza TutorNo ratings yet

- 0602 - 2 - 012 Anchor Bolts PDFDocument2 pages0602 - 2 - 012 Anchor Bolts PDFthesobrevivienteNo ratings yet

- 3 FabricationDocument10 pages3 FabricationSergio CharcapeNo ratings yet

- Insert Shape ... : R S C T DDocument11 pagesInsert Shape ... : R S C T DskidamdnevnoNo ratings yet

- Indice Norma: Menú Principal Indice Manual Indice VolumenDocument1 pageIndice Norma: Menú Principal Indice Manual Indice Volumencmrn5No ratings yet

- Bunk House - PLANSDocument25 pagesBunk House - PLANSnikthomas24100% (4)

- Guppy 2 Paper Plan-1-2Document1 pageGuppy 2 Paper Plan-1-2Pablo D. RigoNo ratings yet

- Figures Girder Schedule: Negative Value Indicates Back From MidspanDocument1 pageFigures Girder Schedule: Negative Value Indicates Back From MidspangabemzamanNo ratings yet

- CuñaDocument20 pagesCuñaJulian Granados RicoNo ratings yet

- 1 - Dimensiones y Marcas PDFDocument2 pages1 - Dimensiones y Marcas PDFMiguelRagasNo ratings yet

- Critical Item Issue Note Page No. 1 of 1Document1 pageCritical Item Issue Note Page No. 1 of 1Erin JohnsonNo ratings yet

- VFA6 U (Assembly)Document2 pagesVFA6 U (Assembly)pacodmxNo ratings yet

- Is 2610Document8 pagesIs 2610kamalkraj4002No ratings yet

- Rotary Milling Head: e e e e 5Document11 pagesRotary Milling Head: e e e e 5gooolNo ratings yet

- r1Document3 pagesr1naseema1No ratings yet

- Grooved Pins Technical SpecsDocument8 pagesGrooved Pins Technical Specsjagan_san10No ratings yet

- StairDocument1 pageStairriz2010No ratings yet

- Granberg Precision Grinder G1012XT ManualDocument2 pagesGranberg Precision Grinder G1012XT ManualAnonymous GtkD9AEJqeNo ratings yet

- 3 BQDocument322 pages3 BQJia Jin100% (1)

- Zollern - Plain Bearing - Type ZDocument20 pagesZollern - Plain Bearing - Type ZYuri BachNo ratings yet

- Raise Boring Heads: User ManualDocument40 pagesRaise Boring Heads: User ManualMaykol Ken Hasaki MaselNo ratings yet

- E - Linear Slot Diffusers PDFDocument17 pagesE - Linear Slot Diffusers PDFabdullah khanNo ratings yet

- DETAIL DWG Sheet-16 PDFDocument1 pageDETAIL DWG Sheet-16 PDFbalotNo ratings yet

- COMPLETE - CE 20211125 Welding Guide 1.2Document10 pagesCOMPLETE - CE 20211125 Welding Guide 1.2rmrkp7sprmNo ratings yet

- 9 Riveted JointsDocument72 pages9 Riveted JointsROHAN PILLAI100% (1)

- F-117A Tiled With Borders (Rev4)Document20 pagesF-117A Tiled With Borders (Rev4)mtcfisioNo ratings yet

- FLOW SWITCH FS10-C SERIES Installation InstructionsDocument2 pagesFLOW SWITCH FS10-C SERIES Installation InstructionsWattsNo ratings yet

- 11c - Pile Cap Details - StructuralDocument2 pages11c - Pile Cap Details - StructuralAnthony FedericoNo ratings yet

- Bearing SNN Sadf 3 0Document32 pagesBearing SNN Sadf 3 0Budy AndikaNo ratings yet

- Pipe GuideDocument231 pagesPipe GuidegeorgD2010100% (2)

- Din 509Document14 pagesDin 509Bruno Menon0% (1)

- Spence StrainersDocument132 pagesSpence StrainersRahul LavandNo ratings yet

- AK31 TurretDocument34 pagesAK31 TurretVladimirAgeev100% (1)

- PBM Sanitary Ball ValvesDocument40 pagesPBM Sanitary Ball ValvesAnonymous bTvqZMftNo ratings yet

- RaiseBoringUsersManual PDFDocument40 pagesRaiseBoringUsersManual PDFJhonatanLiCuadradoNo ratings yet

- Concrete Blocking For Convex Vertical Bends Concrete Thrust Blocking (Horizontal)Document10 pagesConcrete Blocking For Convex Vertical Bends Concrete Thrust Blocking (Horizontal)chithirai10No ratings yet

- Dimensioning of TapersDocument2 pagesDimensioning of Tapers최승원No ratings yet

- WATTS TYPE NEMA 4X FS20 FLOW SWITCH Installation InstructionsDocument2 pagesWATTS TYPE NEMA 4X FS20 FLOW SWITCH Installation InstructionsWattsNo ratings yet

- Super Maxbit Hammer Bit BrochureDocument6 pagesSuper Maxbit Hammer Bit BrochurezapspazNo ratings yet

- Regulators Zero GovernorsDocument2 pagesRegulators Zero GovernorsraldavoodNo ratings yet

- Disclosure To Promote The Right To Information: IS 5290 (1993) : Specification For Landing Valves (CED 22: Fire Fighting)Document20 pagesDisclosure To Promote The Right To Information: IS 5290 (1993) : Specification For Landing Valves (CED 22: Fire Fighting)Tanmoy Dutta100% (1)

- Oem Gardner Denver Pz-11Document8 pagesOem Gardner Denver Pz-11caballero_tigre100% (1)

- GA Drawing of IR - 4 X 5Document1 pageGA Drawing of IR - 4 X 5Himanshu GuptaNo ratings yet

- 7 Riveted JointsDocument72 pages7 Riveted JointsanirudhNo ratings yet

- TANK Design DetailingDocument17 pagesTANK Design DetailingTiffany Vabiola100% (8)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- How to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideFrom EverandHow to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideNo ratings yet

- A Guide to Motor Boat Design and Construction - A Collection of Historical Articles Containing Information on the Methods and Equipment of the Boat BuilderFrom EverandA Guide to Motor Boat Design and Construction - A Collection of Historical Articles Containing Information on the Methods and Equipment of the Boat BuilderNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Album of Dated Latin Inscriptions, Part II, Plates: Rome and the Neighborhood, A.D. 100-199From EverandAlbum of Dated Latin Inscriptions, Part II, Plates: Rome and the Neighborhood, A.D. 100-199No ratings yet

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- ASPHALTDocument7 pagesASPHALTJessie Radaza TutorNo ratings yet

- TOEIC-style Error Recognition: 23130 Page 1 of 2Document2 pagesTOEIC-style Error Recognition: 23130 Page 1 of 2Jessie Radaza TutorNo ratings yet

- Generational Differences in Acute Care NursesDocument13 pagesGenerational Differences in Acute Care NursesJessie Radaza TutorNo ratings yet

- New Dicklumn Catchment Area Polygon 43 14.2203 27.9481: Name Shape Type of Points S) RS)Document3 pagesNew Dicklumn Catchment Area Polygon 43 14.2203 27.9481: Name Shape Type of Points S) RS)Jessie Radaza TutorNo ratings yet

- Balili River Polygon 177 56.5568 48.6741: Name Shape Type of Points S) RS)Document3 pagesBalili River Polygon 177 56.5568 48.6741: Name Shape Type of Points S) RS)Jessie Radaza TutorNo ratings yet

- Staad LectureDocument3 pagesStaad LectureJesus Ray M. Mansayon100% (3)

- Engr. Jessie Radaza Tutor: Personal InformationDocument4 pagesEngr. Jessie Radaza Tutor: Personal InformationJessie Radaza TutorNo ratings yet

- New Dicklumn Catchment Area Polygon 43 3,513.9229 17.3662: Name Shape Type of Points (Acres) (Miles)Document3 pagesNew Dicklumn Catchment Area Polygon 43 3,513.9229 17.3662: Name Shape Type of Points (Acres) (Miles)Jessie Radaza TutorNo ratings yet

- Origin and Theoretical Basis of The New Public Management (NPM)Document35 pagesOrigin and Theoretical Basis of The New Public Management (NPM)Jessie Radaza TutorNo ratings yet

- JDS Math2013 SolutionDocument5 pagesJDS Math2013 SolutionJessie Radaza Tutor100% (3)

- Syllabus Public Management ReformsDocument3 pagesSyllabus Public Management ReformsJessie Radaza TutorNo ratings yet

- Structural Analysis ExamDocument3 pagesStructural Analysis ExamJessie Radaza TutorNo ratings yet

- Philippine Journal of Public AdministrationDocument18 pagesPhilippine Journal of Public AdministrationJessie Radaza Tutor0% (1)

- President of The Philippines: QualificationsDocument20 pagesPresident of The Philippines: QualificationsJessie Radaza TutorNo ratings yet

- BureaucracyDocument23 pagesBureaucracyAbdillah Abdul-rahmanNo ratings yet

- REvised - Assignment of Topic Presentation For Quantitative Approaches in ManagementDocument1 pageREvised - Assignment of Topic Presentation For Quantitative Approaches in ManagementJessie Radaza TutorNo ratings yet

- Table of ContentsDocument1 pageTable of ContentsJessie Radaza TutorNo ratings yet

- ReservoirsDocument2 pagesReservoirsJay R SVNo ratings yet

- Inspection of Crane Wire RopesDocument14 pagesInspection of Crane Wire RopesP Venkata Suresh100% (3)

- How To Build Your Own Acoustic PanelsDocument47 pagesHow To Build Your Own Acoustic Panelspampaboy100% (1)

- 2 LM30Document2 pages2 LM30EfrainAquinoMezaNo ratings yet

- Lec6w Processintegration Ee143 CTNDocument15 pagesLec6w Processintegration Ee143 CTNstansilawNo ratings yet

- Ecss e HB 32 20 - Part 5a PDFDocument435 pagesEcss e HB 32 20 - Part 5a PDFNasos MasourasNo ratings yet

- 7-Empirical Formula For MgODocument6 pages7-Empirical Formula For MgOairiel_hamkaNo ratings yet

- SV10-20 Poppet, 2-Way, Normally Closed: Solenoid ValvesDocument2 pagesSV10-20 Poppet, 2-Way, Normally Closed: Solenoid ValvesMartin Andrew TugadeNo ratings yet

- Design Basis: M/S Space Combine Kind Attn: Mr. Arun VishwakarmaDocument6 pagesDesign Basis: M/S Space Combine Kind Attn: Mr. Arun Vishwakarmabyajaytyagi2266No ratings yet

- GMW15520Document10 pagesGMW15520Ed RiNo ratings yet

- 51 100Document50 pages51 100Anonymous GGc8FbNo ratings yet

- Ldpe L2100TN00Document4 pagesLdpe L2100TN00mohamad mostafaviNo ratings yet

- 01 BIO4600 BioMEMS IntroductionDocument55 pages01 BIO4600 BioMEMS IntroductionMd Ehtashamul HaqueNo ratings yet

- ML12045A005Document98 pagesML12045A005atanu1820dasNo ratings yet

- V80Service Manual 3 Powertrain Right VI CD Y Y 02Document86 pagesV80Service Manual 3 Powertrain Right VI CD Y Y 02Henry Yogaswara100% (2)

- Bismuth Film Electrodes For Heavy Metals Determination: &) I. Hotovy M. Vojs F. MikaDocument8 pagesBismuth Film Electrodes For Heavy Metals Determination: &) I. Hotovy M. Vojs F. MikaErico JuneNo ratings yet

- Engine Technical Data Sheet G3616 3100-3400 KW 900 RPMDocument2 pagesEngine Technical Data Sheet G3616 3100-3400 KW 900 RPMNavdeep GoyalNo ratings yet

- Tutorial 5 Phase EquilibriumDocument3 pagesTutorial 5 Phase EquilibriumezanaNo ratings yet

- 100, 101, 200 and 201 - DatasheetDocument4 pages100, 101, 200 and 201 - DatasheetJoão Paulo Giacomello67% (3)

- GGHJKDocument8 pagesGGHJKnopibotakNo ratings yet

- A 0000209 TechDocument36 pagesA 0000209 Techjose antonioNo ratings yet

- Scope: CautionDocument13 pagesScope: CautionYudi PermanaNo ratings yet

- OA 3961 Zinc Phosphate Primer Product Data: (Exterior / Interior)Document1 pageOA 3961 Zinc Phosphate Primer Product Data: (Exterior / Interior)tshawkyNo ratings yet

- Sludge Oil Liquefying System (Sols) Using Paralax®Document72 pagesSludge Oil Liquefying System (Sols) Using Paralax®Agung RakhmadiNo ratings yet

- Yellow Jacket HosesDocument10 pagesYellow Jacket HosesdBfreakNo ratings yet

- MSC Thesis Stephen GrechDocument198 pagesMSC Thesis Stephen GrechJamesFarrugiaNo ratings yet

- Gun Drill PriceDocument15 pagesGun Drill Price1mmahoneyNo ratings yet

- WPS 1-1-GT-SM-6 Rev. 0Document8 pagesWPS 1-1-GT-SM-6 Rev. 0Melby de la rosaNo ratings yet

- ASU SIte Management PlanDocument20 pagesASU SIte Management PlanPRIYABRATA SANTANU RANJAN AichNo ratings yet

- 1104C-44T IOPU Technical Data Sheet PDFDocument8 pages1104C-44T IOPU Technical Data Sheet PDFBob100% (2)