Professional Documents

Culture Documents

Electrode Classification by Aws A 5.1 PDF

Electrode Classification by Aws A 5.1 PDF

Uploaded by

Venkatesh NatlaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Electrode Classification by Aws A 5.1 PDF

Electrode Classification by Aws A 5.1 PDF

Uploaded by

Venkatesh NatlaCopyright:

Available Formats

ELECTRODE CLASSIFICATION BY AWS A 5.

1

The American Welding Society ( AWS) numbering system can tell a welder quite a bit about a specific stick electrode including what application it works best in and how it should be used to maximize performance. With that in mind ,lets take a look at the system and how it works.The prefix E designates an arc-welding electrode. The first two digits of a 4-digit number and the first three digits of 5 digit number indicate tensile strength. For example,E6010 is a 60,000 psi tensile strength electrode while E10018 designates a 100,000 psi tensile strength electrode. E 60 1 10 Type of Coating and current Electrode Tensile strength Position The next to last digit indicates position. The 1 designates an all position electrode, 2 is for flat and horizontal positions only; while 3 indicates an electrode that can be used for flat,horizontal, vertical down and overhead. The last 2 digits taken together indicate the type of coating and the correct polarity or current to use. See chart below:

Digit

10 11 12 13 14 15 16 27 18 20 22 24 28

Type of coating

Welding Current

High cellulose sodium Dc + High cellulose potassium Ac or Dc + or Dc High titania sodium Ac or DcHigh titania potassium Ac or Dc + Iron power titania Ac or Dc- or DC+ Low hydrogen sodium DC+ Low hydrogen potassium AC or DC+ Iron powder iron oxide AC or DC+or DCIron powder low hydrogen AC or DC+ High iron oxide AC or DC+or DCHigh iron oxid AC or DCIron powder titania AC or DC- or DC+ Low hydrogen potassium iron AC or DC+ powder As a welder,there are certain electrodes that you will most likely see and use time and time again as you go about your daily operations. A DC machine produces a smoother arc. DC rated electrodes will only run on a DC welding machin. Electrodes which are rated for AC welding are more forgiving and can also be used with a DC machin. Here are some of the most common electrodes and how they are typcally used:

You might also like

- Welding Electrode NomenclatureDocument3 pagesWelding Electrode NomenclaturedcevipinNo ratings yet

- Innovative In-Situ Repair of A High Temperature Steam Super Heater CoilDocument13 pagesInnovative In-Situ Repair of A High Temperature Steam Super Heater Coilvaratharajan g r100% (1)

- WSI Corrosion Control by Weld Overlay (Boilers)Document11 pagesWSI Corrosion Control by Weld Overlay (Boilers)Claudia Mms100% (1)

- Insp Checklist - Piping AlignmentDocument1 pageInsp Checklist - Piping AlignmentesutjiadiNo ratings yet

- A4-Jgs1ep-Epc1-Qp-014 Rev. B (Welding Repair Procedure Ag&p)Document12 pagesA4-Jgs1ep-Epc1-Qp-014 Rev. B (Welding Repair Procedure Ag&p)Darrel Espino AranasNo ratings yet

- AWS Electrode ClassificationsDocument3 pagesAWS Electrode ClassificationsUsamaIjazNo ratings yet

- How To Select Welding ElectrodesDocument6 pagesHow To Select Welding ElectrodesRobert DelafosseNo ratings yet

- Weld Fit Up Inspection Employee TrainingDocument10 pagesWeld Fit Up Inspection Employee TrainingviswamanojNo ratings yet

- Welding RodsDocument12 pagesWelding RodsDigital BusinessNo ratings yet

- Soldering & Brazing: Unit-IvDocument15 pagesSoldering & Brazing: Unit-IvRamu AmaraNo ratings yet

- Preheating and Post Weld Heat TreatmentsDocument3 pagesPreheating and Post Weld Heat TreatmentssubrataNo ratings yet

- Welding: Munther DiyabDocument113 pagesWelding: Munther DiyabMunther MohdNo ratings yet

- Arc Welding Arc Welding Electrode Electrode: CCCCC CCCCCDocument36 pagesArc Welding Arc Welding Electrode Electrode: CCCCC CCCCCSantanu SarmahNo ratings yet

- Jotamastic 87: Technical Data Sheet Application GuideDocument10 pagesJotamastic 87: Technical Data Sheet Application GuideMina RemonNo ratings yet

- Anodes in Cooling Water Exchangers PDFDocument12 pagesAnodes in Cooling Water Exchangers PDFcbrittaivNo ratings yet

- Heat Treatment: Dr. Mohamed Abd Elmonem DahaDocument23 pagesHeat Treatment: Dr. Mohamed Abd Elmonem DahashoroukNo ratings yet

- CRAHF Weld OverlayDocument2 pagesCRAHF Weld OverlayGogulu KumarNo ratings yet

- Section 2Document31 pagesSection 2Mohd Farid OsmanNo ratings yet

- PTFEDocument1 pagePTFEIkhsan LyNo ratings yet

- Brazing: Brazing Is A Metal-Joining Process in Which Two or More Metal Items Are JoinedDocument20 pagesBrazing: Brazing Is A Metal-Joining Process in Which Two or More Metal Items Are JoinedAaquil RaziNo ratings yet

- Floating Flange Rubber Expansion Joints: Series 980Document8 pagesFloating Flange Rubber Expansion Joints: Series 980Roland Bon IntudNo ratings yet

- Welding SGDocument76 pagesWelding SGPrasoon ChaturvediNo ratings yet

- Api 571 PDFDocument3 pagesApi 571 PDFumnartkhNo ratings yet

- 1434529014349-Welding DefectsDocument61 pages1434529014349-Welding DefectsJayaneela PrawinNo ratings yet

- ASTM C1147-14 CodeDocument4 pagesASTM C1147-14 CodeGene DiJoseph100% (1)

- GE Power & Water P8A-AG3: Ge Class Ii (Internal Non-Critical)Document50 pagesGE Power & Water P8A-AG3: Ge Class Ii (Internal Non-Critical)Manzar Khan0% (1)

- Bend Testing: Job Knowledge 73Document3 pagesBend Testing: Job Knowledge 73kevin herryNo ratings yet

- Tips Tack WeldingDocument1 pageTips Tack WeldingPemburu JablayNo ratings yet

- Welding Rod Selection PDFDocument1 pageWelding Rod Selection PDFBalasubramanian RasuNo ratings yet

- Prorox WM 960 Sa PDFDocument1 pageProrox WM 960 Sa PDFr afriantoNo ratings yet

- EsscDocument56 pagesEsscMakwana Mehul100% (1)

- ASME L&D B31.8 Natural Gas Pipelines GuideDocument12 pagesASME L&D B31.8 Natural Gas Pipelines GuideCalin NeagoieNo ratings yet

- Asme 9Document11 pagesAsme 9H_DEBIANENo ratings yet

- Welding Processes: EN358 - Ship StructuresDocument27 pagesWelding Processes: EN358 - Ship Structuressuri345No ratings yet

- Transformer-WPS OfficeDocument19 pagesTransformer-WPS OfficeVinaya kumar BGNo ratings yet

- UG-100 Pneumatic TestDocument2 pagesUG-100 Pneumatic TestInaamNo ratings yet

- Astm A 335Document8 pagesAstm A 335Ruben Dario Espinoza Vasquez100% (1)

- Specification For Nickel and Nickel-Alloy Bare Welding Electrodes and RodsDocument19 pagesSpecification For Nickel and Nickel-Alloy Bare Welding Electrodes and RodsT arekiNo ratings yet

- Weldability of MaterialsDocument5 pagesWeldability of MaterialsclnNo ratings yet

- Dish Head TypesDocument6 pagesDish Head TypesJohn MaldonadoNo ratings yet

- Heat Treatment DefectsDocument13 pagesHeat Treatment DefectsAbu HurairaNo ratings yet

- 03 - GtawDocument20 pages03 - GtawEnache DaniNo ratings yet

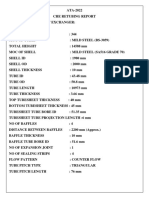

- CHE Retubing ReportDocument29 pagesCHE Retubing ReportRajesh KtrNo ratings yet

- Variables For Welding 11-3-2016 - 264B1DF6 PDFDocument2 pagesVariables For Welding 11-3-2016 - 264B1DF6 PDFSameh AminNo ratings yet

- Basic Points of P91Document4 pagesBasic Points of P91Asad Bin Ala Qatari100% (1)

- Flange Face Surface FinishDocument2 pagesFlange Face Surface FinishJoel Ashley D'SouzaNo ratings yet

- Corrosion Resistant Type CF8M (UNS J92900) and CF12MDocument4 pagesCorrosion Resistant Type CF8M (UNS J92900) and CF12MAnonymous kU3uh2dZ5INo ratings yet

- What Is The Difference Between Welding TransformerDocument33 pagesWhat Is The Difference Between Welding TransformerAkhilesh KumarNo ratings yet

- ASTM A283 Grade C: General Product DescriptionDocument1 pageASTM A283 Grade C: General Product DescriptionPratyas SarahNo ratings yet

- American Welding Soceity 5.9Document33 pagesAmerican Welding Soceity 5.9Hư VôNo ratings yet

- Iron Carbon Phase DiagramDocument4 pagesIron Carbon Phase DiagramnaveedNo ratings yet

- Arc Welding of Copper Alloys: Technical UpdateDocument35 pagesArc Welding of Copper Alloys: Technical UpdateKamal ThummarNo ratings yet

- Welding ConsumablesDocument1 pageWelding ConsumablesBalakumarNo ratings yet

- Duplex Stainless Steel WeldingDocument25 pagesDuplex Stainless Steel WeldingcfcshakerNo ratings yet

- Heat ExchangerDocument36 pagesHeat ExchangerUsman MansuriNo ratings yet

- Mechanical Testing Requirement As Per ASME BPVC Section IXDocument6 pagesMechanical Testing Requirement As Per ASME BPVC Section IXHary adiNo ratings yet

- AWS ClassificationsDocument6 pagesAWS ClassificationsSubbarayan SaravanakumarNo ratings yet

- Arc WeldingDocument48 pagesArc WeldingSumma ThanNo ratings yet

- Welders Hand BookDocument23 pagesWelders Hand Booksamyqatar100% (2)

- A Basic Guide of Arc Welding Electrodes: by Bruce BauerleinDocument4 pagesA Basic Guide of Arc Welding Electrodes: by Bruce BauerleinRajeev KhantwalNo ratings yet

- Pipe Expansion and Support - International Site For Spirax SarcoDocument8 pagesPipe Expansion and Support - International Site For Spirax SarcoVenkatesh NatlaNo ratings yet

- Oisd RP 233 DraftDocument66 pagesOisd RP 233 DraftVenkatesh NatlaNo ratings yet

- Gas Tungsten Arc WeldingDocument2 pagesGas Tungsten Arc WeldingVenkatesh NatlaNo ratings yet

- Heat Exchanger Tube Bundle InspectionDocument3 pagesHeat Exchanger Tube Bundle InspectionVenkatesh Natla100% (4)