Professional Documents

Culture Documents

MOSBrochure PDF

MOSBrochure PDF

Uploaded by

abisaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MOSBrochure PDF

MOSBrochure PDF

Uploaded by

abisaCopyright:

Available Formats

Bringing energy and the environment into harmony.

MOS COMPRESSORS

MOS

TM

compressors

The medium oilfield separable compressor for common jobs.

recovery, enhanced oil recovery, and many other applications. They are suited not only for sweet natural gas services, but can be built to handle sour natural gas, propane, carbon dioxide, air, nitrogen, and most other gases. As an alternative to more industry standard type units, the MOS compressor establishes itself by taking the best of previous Dresser-Rand designs, competing units and "voice of client" input. The lower cost, compact design and rapid delivery of packaged MOS compressors make it an ideal choice for the most common of gas field applications such as gas gathering and gas processing. With more than 30 years of experience in our closed-loop test facility using a variety of field gases, Dresser-Rand ensures the

integrity of the MOS compressor design and performance. Rated to 4,440 hp (3,310 kW) and 1,500 rpm with design pressures up to and exceeding 10,000 psig (690 bar), MOS compressors provide long life because of their heavy-duty construction. They are available in two-, four- or six-throw configurations and in cylinder sizes ranging from 3.75 (95.3 mm) to 20.50 (520.7 mm). The rigid, cast iron compressor frame is heavily ribbed and reinforced, with integrally cast crosshead extensions to handle almost any gas field requirement.

Dresser-Rand brings more than 60 years of separable compressor operating experience to the medium-duty MOS compressor line. These rugged compressors are engineered for high speed and high horsepower gas field applications, including gas lift, gas gathering, pipeline boosting, gas transmission, underground gas storage (injection and withdrawal), fuel gas boosting, landfill gas

A SINGLE SOURCE FOR ALL YOUR COMPRESSION NEEDS

MOS compressors offer many benefits to gas compressor users, whether used in a standard or customized package, in rental service or purchased outright. Dresser-Rand and its authorized distributors can provide singlesource responsibility, including engineering, manufacturing, packaging, installation, parts, and service. With MOS compressors on the job, you can expect less maintenance and less fuel consumption. Dresser-Rand and its distributors support the MOS compressor line with a network of computerized parts warehouses, and overhaul/revamp facilities located throughout the U.S. and Canada.

MOS compressor frame.

Rugged design for smooth operation, lo

Every MOS compressor includes components designed to enhance performance. The compressor frame and cylinders are matched to provide years of smooth, reliable, efficient compression service when operated within OEM recommendations.

Cylinder Basics

MOS compressor cylinders are gas-cooled for most applications. For special applications, the MOS compressor is available with water-cooled cylinders that provide additional protection in higher temperature and higher pressure services. Each system is designed and engineered to match your operating needs. Gas-cooled MOS cylinders use a solid bore cylinder barrel cast in nodular iron. Water-cooled MOS cylinders are HOS cylinders adapted to the MOS frame and are jacketed for circulating coolant. A full line-up of higher pressure, forged steel cylinders are available in sizes 3.75 (95.3 mm) to 6.5 (165.1 mm). The line-up also includes a pipeline cylinder for gas transmission and a storage cylinder for gas injection and withdrawal applications.

Cylinder per of valves w PF valve (m

pro

Frame Basics

The open top frame construction ensures rigidity while providing easy access to major running gear components from the top. Multiple covers and large access areas are provided for easy maintenance and inspection. Two-piece precision trimetal bronze main bearings ensure better heat dissipation, higher reliability and increased life. Thrust shoes are bronze. As an option, a full-length distance piece with oversized access doors are available. The unique thru-bolt distance piece is designed for improved load carrying ability.

High-strength, nodular iron crossheads feature a Babbitt overlay for enhanced lubrication. Surface-hardened crosshead pins are full floating for optimum reliability, and there are no crosshead pin bushings to contend with.

ong life and efficiency.

The MOS compressor uses either solid or two-piece cast iron or aluminum pistons depending upon service conditions, balance and inertia forces. Integral steel pistons and rods may be used in high-pressure applications. Each piston rod is made from a high-strength alloy steel and is wet-magnetic-particle inspected. Every piston rod thread form is inspected using Johnson gauging. Piston rods for a given stroke are identical, regardless of cylinder size.

rformance is optimized through the use of two types which are available on the MOS compressor, the (ported plate type) and the D-R Magnum valve mini-Poppet element). Both valves use exclusive Dresser-Rand Hi-Temp nonmetallic wear parts material. Each valve offers different advantages and is sized to optimize performance and reliability for a given application or client preference. Optional high-volume, manually operated variable volume clearance pockets ovide clearance for greater capacity control.

One packing case design is used, regardless of cylinder size or stroke. Packing cases use the emission control ring design to minimize leakage.

Crankpin and main bearings are two-piece precision tri-metal bronze and are identical, which reduces spare parts stocking. They are provided with a micro-babbitt overlay plate for added start-up protection and corrosion resistance.

Forged steel connecting rods are rifle-drilled for pressure lubrication of crossheads and feature high-strength bolts with rolled threads. Connecting rod pin bushings are centrifugally cast bronze with nickel plate barrier and topped with lead tin copper overlay on bore for reliable break-in.

The heavy-duty forged alloy crankshaft is rifle-drill balanced for connecting rod lubrication. The crankshaft is equipped with integral counterweights on the two- and four-throw units to reduce horizontal moments.

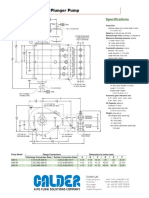

RatIngs

Model

5MOS2 5MOS4 5MOS6 6MOS2 6MOS4 6MOS6 7MOS2 7MOS4 7MOS6

Stroke in. (mm)

5 (127) 5 (127) 5 (127) 6 (152.4) 6 (152.4) 6 (152.4) 7 (177.8) 7 (177.8) 7 (177.8)

Number of Cylinders

2 4 6 2 4 6 2 4 6

Nominal Rated Power hp (kW)

1,950 (1,454) 3,900 (2,908) 4,200 (3,132) 1,800 (1,342) 3,600 (2,685) 4,320 (3,221) 1,700 (1,268) 3,400 (2,535) 4,440 (3,311)

Max. Allowable Operating Rod Load lbs. (kN)

45,000 (200) 45,000 (200) 45,000 (200) 45,000 (200) 45,000 (200) 45,000 (200) 45,000 (200) 45,000 (200) 45,000 (200)

Rated rpm

1,500 1,500 1,500 1,200 1,200 1,200 1,000 1,000 1,000

Standard Features

A chain-drive, positive displacement gear-type frame lube oil pump, with ship loose cooler and frame-mounted full-flow oil filter Drilled, tapped and plugged indicator holes on all cylinders Vented, full-floating, filled Teflon packing rings with cast iron back-up rings Filled Teflon, multi-piece combination rings perform double duty as both compression and rider rings Frame-fed block distribution system External frame oil relief valve

Optional Features

VVCP (Variable Volume Clearance Pocket) Dresser-Rand TC3 (HVOF) coated piston rods 17-4 PH stainless steel piston rods Purged packing and purged wiper case Single- or two-compartment distance piece Crankcase and lubricator oil heaters Crankcase explosion relief devices

118.4" (3,008 mm) (6 throw) 114.4" (2,906 mm) (4 throw) 42" 1,067 mm 42" 1,067 mm 26.375" 670 mm E

Main bearing RTDs Torsional studies Flywheel (if required) Dynamic valve analysis Pump-to-point cylinder lubrication Electric drive lubricator Dual oil filter Automatic unloading devices Manual frame pre-lube pump

67.25" 1,708 mm 26.375" 670 mm E

Frame Specifications and Dimensions

Frame. . . . . . . . . . . . . . . . . . . . . . . . . . . One piece, cast iron, high-strength Crosshead pins . . . . . . . . . . . . . . . . . . . . Alloy-steel, hardened, super-finished Main bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Tri-metal Crosshead pin bushings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Bronze Crankshaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Forged steel Piston rods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Alloy steel, rolled threads Crankpin bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Tri-metal Connecting rods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Forged steel Oil pump. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Gear-type, chain-drive Connecting rod bolts . . . . . . . . . . . . . . . . . . . . . . . . Alloy steel, rolled threads Oil filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Full-flow, 10 micron Connecting rod bushings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Tri-metal Oil cooler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Shell-and-tube Crossheads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Nodular iron, babbit Lubricator . . . . . . . . . . . . . . . . . . . . . . . . . . . . Flange mounted, chain-drive Standard Cylinder offering and dimensions

B C A D

B C A D

C D

C D

B E 33.38" 848 mm

42" 1,067 mm

42" 1,067 mm

33.38" 848 mm

Note: E dimension is the piston and rod removal distance.

Cylinder Size in. (mm)

20.50 (520.7) 19.00 (482.6) 17.50 (444.5) 16.25 (412.7) 15.00 (381.0) 14.00 (355.6) 13.00 (330.2) 12.25 (311.1) 11.50 (292.1) 10.50 (266.7) 9.50 (241.3) 9.00 (228.6) 8.50 (215.9) 8.00 (203.2) 7.50 (190.5) 7.00 (177.8) 6.50 (165.1) 6.00 (152.4) 5.75 (146.0) 4.75 (120.7) 3.75 to 7.00 (95.3 to 177.8)

MAWP psig (kg/cm2) No Jacket

265 (18.6) 265 (18.6) 385 (27.1) 385 (27.1) 385 (27.1) 385 (27.1) 550 (38.7) 550 (38.7) 660 (46.6) 660 (46.6) 750 (52.7) 750 (52.7) 1,150 (80.8) 1,150 (80.8) 1,650 (116.0) 1,650 (116.0) 1,925 (135.3) 1,925 (135.3) 1,925 (135.3) 1,925 (135.3) 6,000 (421.8)

A in. (mm)

43.5 (1,105) 43.5 (1,105) 43.5 (1,105) 43.5 (1,105) 43.5 (1,105) 43.5 (1,105) 43.5 (1,105) 43.5 (1,105) 43.5 (1,105) 43.5 (1,105) 43.5 (1,105) 43.5 (1,105) 43.5 (1,105) 43.5 (1,105) 43.5 (1,105) 43.5 (1,105) 43.5 (1,105) 43.5 (1,105) 43.5 (1,105) 43.5 (1,105)

B in. (mm)

15.0 (381) 15.0 (381) 15.0 (381) 15.0 (381) 15.0 (381) 15.0 (381) 15.0 (381) 15.0 (381) 15.0 (381) 15.0 (381) 15.0 (381) 15.0 (381) 15.0 (381) 15.0 (381) 15.0 (381) 15.0 (381) 15.0 (381) 15.0 (381) 15.0 (381) 15.0 (381)

C in. (mm)

58.5 (1,486) 58.5 (1,486) 58.5 (1,486) 58.5 (1,486) 58.5 (1,486) 58.5 (1,486) 58.5 (1,486) 58.5 (1,486) 58.5 (1,486) 58.5 (1,486) 58.5 (1,486) 58.5 (1,486) 58.5 (1,486) 58.5 (1,486) 58.5 (1,486) 58.5 (1,486) 58.5 (1,486) 58.5 (1,486) 58.5 (1,486) 58.5 (1,486)

D in. (mm)

102.0 (2,591) 102.0 (2,591) 102.0 (2,591) 102.0 (2,591) 102.0 (2,591) 102.0 (2,591) 102.0 (2,591) 102.0 (2,591) 102.0 (2,591) 102.0 (2,591) 102.0 (2,591) 102.0 (2,591) 102.0 (2,591) 102.0 (2,591) 102.0 (2,591) 102.0 (2,591) 102.0 (2,591) 102.0 (2,591) 102.0 (2,591) 102.0 (2,591)

E in. (mm)

26.0 (660) 26.0 (660) 26.0 (660) 26.0 (660) 26.0 (660) 26.0 (660) 26.0 (660) 26.0 (660) 26.0 (660) 26.0 (660) 26.0 (660) 26.0 (660) 26.0 (660) 26.0 (660) 26.0 (660) 26.0 (660) 26.0 (660) 27.0 (686) 27.0 (686) 27.0 (686)

VA RY D E P E N D IN G ON P IP IN G N E E D S

HOS (higher pressure and/or water cooled) cylinders are available for the MOS compressor as well as cylinder liners. Additionally, specialty cylinders for storage or pipeline applications can be applied to the MOS compressor.

For more information on the MOS Compressor, visit www.dresser-rand.com/gfc or contact us at:

Dresser-Rand Gas Field Compressors 1354 South Sheridan Road Tulsa, Oklahoma 74112-5416 USA Tel: (Intl +1) 918-254-4099 Fax: (Intl +1) 918-252-9055 E-mail: GFC@dresser-rand.com

Dresser-Rand Reciprocating Operations 100 Chemung Street Painted Post, NY 14870 USA Tel: (Intl +1) 607-937-2011 Fax: (Intl +1) 607-937-2905

For a complete list of products and services, visit www.dresser-rand.com or contact the following:

CORPORATE HeaDQUarterS Dresser-Rand West8 Tower, Suite 1000 10205 Westheimer Road Houston, Texas 77042 Tel: (Int'l +1) 713-354-6100 Fax: (Int'l +1) 713-354-6110 Dresser-Rand 112, Avenue Kleber Cedex 16 Paris 75784 France Tel: (Intl +33) 156 26 71 71 Fax: (Intl +33) 156 26 71 72 Email: info@dresser-rand.com ReGIoNaL HeaDQUarterS The Americas West8 Tower, Suite 1000 10205 Westheimer Road Houston, Texas 77042 Tel: (Intl +1) 713-354-6100 Fax: (Intl +1) 713-354-6110 EMEA

(Europe, Middle East & Africa)

Dresser-Rand S.A. 31 Boulevard Winston Churchill Cedex 7013 Le Havre 76080, France Tel: (Int'l +33) 2-35-25-5225 Fax: (Int'l +33) 2-35-25-5366/5367

Asia-Pacific Dresser-Rand Asia Pacific Sdn Bhd Unit 9-4, 9th Floor Bangunan Malaysian Re 17 Lorong Dungun Damansara Heights 50490 Kuala Lumpur, Malaysia Tel: (Int'l +60) 3-2093-6633 Fax: (Int'l +60) 3-2093-2622

FPO

2012 Dresser-Rand. DRESSER-RAND is a registered trademark of Dresser-Rand Company. Printed in U.S.A. This brochure comprises a general overview of the Dresser-Rand products described herein. It is solely for informational purposes, does not represent a warranty or guarantee of the information contained herein, and is not to be construed as an offer to sell or solicitation to buy. Contact Dresser-Rand for detailed design and engineering information suitable to your specific applications. Dresser-Rand reserves the right to modify its products and related product information at any time without prior notice.

Form 85246

Bringing energy and the environment into harmony.

You might also like

- Hose Hanger Installation Operating Procedures Rev.1Document9 pagesHose Hanger Installation Operating Procedures Rev.1HSE PULAI ANo ratings yet

- KCDocument3 pagesKCSandheepKumarNo ratings yet

- Flyer DBS SeriesDocument2 pagesFlyer DBS SeriesddadaraNo ratings yet

- ALTRONIC DD Series Annunciator Installation InstructionsDocument14 pagesALTRONIC DD Series Annunciator Installation InstructionsCNorris505No ratings yet

- Varat Pump and Machinery Pvt. Ltd.Document59 pagesVarat Pump and Machinery Pvt. Ltd.Kaushik ChakrabortyNo ratings yet

- Superbolt Nut TorqueDocument2 pagesSuperbolt Nut TorquechematchesomNo ratings yet

- Friction Loss On SuctionDocument2 pagesFriction Loss On SuctionSathish LingamNo ratings yet

- Highlighted Must Change ItemsDocument62 pagesHighlighted Must Change Itemsraju sankarNo ratings yet

- Manual Cat Pump Model 45Document4 pagesManual Cat Pump Model 45Jhon Jairo Maestre UribeNo ratings yet

- Assembling Procedure For Framo Pump Sd200Document4 pagesAssembling Procedure For Framo Pump Sd200Gonçalo CruzeiroNo ratings yet

- IK-525-DM3 IK-525-DM4 Dual Media Air Heater CleanersDocument135 pagesIK-525-DM3 IK-525-DM4 Dual Media Air Heater CleanersPhạm Hưng100% (1)

- D VipDocument6 pagesD VipClemente Rafael Marval EscalonaNo ratings yet

- WarrenDocument28 pagesWarrennolispe6No ratings yet

- SB 530 CH240A Product Improvement 6-1999Document1 pageSB 530 CH240A Product Improvement 6-1999salmonsilalahiNo ratings yet

- 3620 10th Lores 2Document8 pages3620 10th Lores 2Dinh Quang NhamNo ratings yet

- RS W446 PUMP OperationManualDocument29 pagesRS W446 PUMP OperationManualADM MTCNo ratings yet

- Properties of Ss410Document5 pagesProperties of Ss410gregkilatonNo ratings yet

- BPCL Training ReportDocument34 pagesBPCL Training ReportVishalVaishNo ratings yet

- Xq114-6yx Manual PDFDocument55 pagesXq114-6yx Manual PDFFredy NavasNo ratings yet

- Model 3201 Liquid Level Controller: FeaturesDocument8 pagesModel 3201 Liquid Level Controller: Featuresio1_roNo ratings yet

- EZ Torque: Hydraulic Cathead User's ManualDocument35 pagesEZ Torque: Hydraulic Cathead User's ManualJuan Garcia100% (1)

- 600ws Plunger OmegaDocument37 pages600ws Plunger Omegaariel feNo ratings yet

- 231,241,271 SchematicDocument4 pages231,241,271 Schematicab5951No ratings yet

- Inoxihp Quintuplex Catalog 2005Document4 pagesInoxihp Quintuplex Catalog 2005Lisa Zielinski50% (2)

- 使用说明书Operation ManualDocument84 pages使用说明书Operation ManualMohamed el attarNo ratings yet

- B+V General Catalog 2010Document32 pagesB+V General Catalog 2010Leonardo Faria Bueno100% (1)

- Emsco F 350 Pump PartsDocument2 pagesEmsco F 350 Pump Partschymax3mNo ratings yet

- Grove g4n Gate Valve BrochureDocument24 pagesGrove g4n Gate Valve BrochureFrancis Almia100% (1)

- Fso pm3 CaaDocument2 pagesFso pm3 CaaskisascribdNo ratings yet

- CatalogueDocument429 pagesCatalogueHarkamal SinghNo ratings yet

- NuFlo EZ-In User Manual - PEDDocument32 pagesNuFlo EZ-In User Manual - PEDsarkaft100% (1)

- Bombas MultietapaDocument60 pagesBombas MultietapaManuel Jumbo RamírezNo ratings yet

- Compressor FS604 Data SheetDocument4 pagesCompressor FS604 Data SheetprimmughalNo ratings yet

- Mongoose Mud Cleaner Spare Parts List-1Document3 pagesMongoose Mud Cleaner Spare Parts List-1bouteraaNo ratings yet

- TECHNICAL DATA SHEET CelatomDocument1 pageTECHNICAL DATA SHEET CelatomAntonNo ratings yet

- 100T Pump Parts List PDFDocument30 pages100T Pump Parts List PDFGabriel Andres ValenciaNo ratings yet

- Oc-10-Triplex Pump: 20 TO 25 HP - 3,000 PSI VOLTAGE: 230, 460, 380 & 575Document2 pagesOc-10-Triplex Pump: 20 TO 25 HP - 3,000 PSI VOLTAGE: 230, 460, 380 & 575logistica 902100% (1)

- Sundyne LMC-347: Compressor and Gearbox Cross Section Single Seal ArrangementDocument1 pageSundyne LMC-347: Compressor and Gearbox Cross Section Single Seal ArrangementmohammadNo ratings yet

- A08012200E D en TPH400Document85 pagesA08012200E D en TPH400Doni Kurniawan100% (1)

- IPU Spring Starter PDFDocument6 pagesIPU Spring Starter PDFHumberto Mateus Becerra100% (1)

- Triplex Pump: TPH 400 Main SpecificationsDocument2 pagesTriplex Pump: TPH 400 Main SpecificationsAttou Housseyn100% (1)

- Gate Valve Parts CatalogueDocument12 pagesGate Valve Parts CatalogueLeandroNo ratings yet

- C Tuthill PDFDocument37 pagesC Tuthill PDFRaulEfrainCharrezCastilloNo ratings yet

- DHV 6a Catalogue-FinalDocument16 pagesDHV 6a Catalogue-FinalJohn UrdanetaNo ratings yet

- Viscosimetro OfiteDocument20 pagesViscosimetro OfitejomarlucaNo ratings yet

- INFA3227 Esquema 01-MAR-2021Document9 pagesINFA3227 Esquema 01-MAR-2021sasgarisNo ratings yet

- 1026 FC FXX Duplex Power Pump PDFDocument2 pages1026 FC FXX Duplex Power Pump PDFMaria Julieta Calderon OrtizNo ratings yet

- NOV Gill Services Handling Tools BrochureDocument8 pagesNOV Gill Services Handling Tools BrochureAnonymous VNu3ODGavNo ratings yet

- 9 5in Modular Motor - MMTR 70 01 003Document2 pages9 5in Modular Motor - MMTR 70 01 003Qiang ZhangNo ratings yet

- TGH 400 Data SheetDocument2 pagesTGH 400 Data SheetMiriam SalazarNo ratings yet

- Drillmax Gate Valve Product Bro PDFDocument12 pagesDrillmax Gate Valve Product Bro PDFMónica Fraile de ManterolaNo ratings yet

- KB 4696 CC - Drawing PDFDocument1 pageKB 4696 CC - Drawing PDFhugoheloNo ratings yet

- Peppers Catalogue PDFDocument64 pagesPeppers Catalogue PDFStone123456789No ratings yet

- B-2372-S Drawing ARIELDocument1 pageB-2372-S Drawing ARIELhugoheloNo ratings yet

- 300Q-5 Quintuplex Plunger PumpDocument2 pages300Q-5 Quintuplex Plunger PumpJuanNo ratings yet

- Vacuum DehydratorDocument12 pagesVacuum DehydratorAntonne E. PhillipNo ratings yet

- Product Overview - LeuschDocument32 pagesProduct Overview - Leuschprihartono_diasNo ratings yet

- HOS (Heavy Oilfield Separable Compressor) BrochureDocument6 pagesHOS (Heavy Oilfield Separable Compressor) BrochureakamalapuriNo ratings yet

- Aurora 340 DsDocument4 pagesAurora 340 DsdesuyaNo ratings yet

- Cylinder Catalog HydraulicDocument130 pagesCylinder Catalog HydraulicArmando Alvarado AraujoNo ratings yet

- Data Sheet API 610Document20 pagesData Sheet API 610abisaNo ratings yet

- Data Sheet API 610Document20 pagesData Sheet API 610abisaNo ratings yet

- Shell Morlina OilDocument2 pagesShell Morlina OilabisaNo ratings yet

- Gevisa QM eDocument57 pagesGevisa QM eabisaNo ratings yet

- 2133 Rla RlvaDocument2 pages2133 Rla RlvaAgung SubangunNo ratings yet