Professional Documents

Culture Documents

PDF

Uploaded by

sivavalaiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PDF

Uploaded by

sivavalaiCopyright:

Available Formats

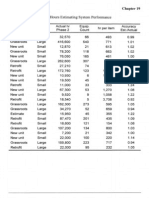

346

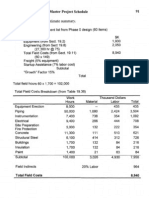

Table 1 9 . 3 6 Field Costs Factor Breakdown

Chapter 19

- " Total

Field Activity c Equipment erection Piping Instrumentation Electrical Site Preparation Fire Protection Concrete Structural Steel Buildings Insulation Painting Total Directs Field lndirects 20% Labor

Thousand $ Mat'l

Labor

Hours Work $MIH

W-H

Total

7,250 58,400 18,200 1 1,800 2,200 3,700 10,350 12,100 3,600 3,600 1,400 1703 132,600 48.30 82,200 50,400 16.400 149.000

0 18,000 12,300 4,400 350 1,850 1,850 6,900 2,200 2,200 350

1,250 40,400 5,900 7,400 1,850 1,850 8,500 5,200 1,400 1,400 1,050

54.00 48.50 47.50 47.50 45.00 45.00 45.00 51 .OO 45.00 48.50 45.00

134 833 124 156 4 1 4 1 189 102 31 29 23

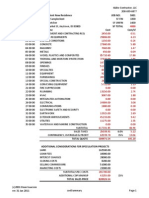

Interconnecting Pipe and Utility Distribution Estimate based on either flowsheet and plot plans take-offs, or use 50% of the process areas' piping.

Equipment-Related Costs

Instrumentation Account

Based on the Table19.34 historical data, $20,000 per equipment itemis more than adequate.

Electrical Account

An allowance of$2 1,000 per motor and feeders is usually adequate to cover:

- Unit substation and switchgear. - Power and control wiring. - Process area lighting. - Grounding.

You might also like

- Project Execution Planmaster Project Schedule Table 9.1 Conceptual Estimate Summary. 0Document1 pageProject Execution Planmaster Project Schedule Table 9.1 Conceptual Estimate Summary. 0sivavalaiNo ratings yet

- Outline Level Quantity Unit Rate Amount Item No - Service No. Service DescriptionDocument8 pagesOutline Level Quantity Unit Rate Amount Item No - Service No. Service DescriptionWillip Desert KingNo ratings yet

- Example PROGRESS Report of A High Rise BuildDocument3 pagesExample PROGRESS Report of A High Rise BuildMehmet Akif Cirit100% (1)

- UPA-BOQ Alveo HQ Rev July 26Document15 pagesUPA-BOQ Alveo HQ Rev July 26Shai DelfinNo ratings yet

- WorksheetDocument44 pagesWorksheetMathurathipan RajendraseelanNo ratings yet

- Worksheet Cost Takeoff MF 04Document45 pagesWorksheet Cost Takeoff MF 04Mathurathipan RajendraseelanNo ratings yet

- ExamplesDocument21 pagesExamplespapeliapenNo ratings yet

- Advance Payment of Materials - Percentage BreakdownDocument4 pagesAdvance Payment of Materials - Percentage BreakdownRohitNo ratings yet

- Typical Bill For A 2x15MVA Transformer Substation ConstructionDocument6 pagesTypical Bill For A 2x15MVA Transformer Substation ConstructionRajeshYadav100% (1)

- CostingDocument12 pagesCostingKarthik SelvarajNo ratings yet

- Rcc95 Continuous Beams (Tables)Document8 pagesRcc95 Continuous Beams (Tables)Steve JsobNo ratings yet

- CE IndexDocument1 pageCE IndexPablo JavierNo ratings yet

- Cost Estimate of Hydro Plant 11MW and 16.5MWDocument33 pagesCost Estimate of Hydro Plant 11MW and 16.5MWwalitedison100% (1)

- Kandukuru Mutton Market 20.2.2016Document3,205 pagesKandukuru Mutton Market 20.2.2016Patan Abdul Mehmood KhanNo ratings yet

- Descripcion Red Primaria Total S/. Obras Civiles 86,372.47 Red SecundariaDocument1 pageDescripcion Red Primaria Total S/. Obras Civiles 86,372.47 Red SecundariaPedro BartolomeNo ratings yet

- 21UEEE9002Document1 page21UEEE9002tanish gehlotNo ratings yet

- Cost Allocation ApportionmentDocument2 pagesCost Allocation ApportionmentYougal MalikNo ratings yet

- 450 Appendix: Other CostsDocument1 page450 Appendix: Other CostssivavalaiNo ratings yet

- CFT Connection L62 at Grid TC (West) : Built Up 2) Plates of Different Grade 355 355 355 0Document1 pageCFT Connection L62 at Grid TC (West) : Built Up 2) Plates of Different Grade 355 355 355 0Muhammad MohsinNo ratings yet

- Lot W3Document3 pagesLot W3ebubeogbukeNo ratings yet

- Lista Cantitati 3.6 Rev1Document56 pagesLista Cantitati 3.6 Rev1Anonymous kqcev0No ratings yet

- Compass_2024PipelinesMiningOffshoreCostDatabase_Watermark_01-24Document16 pagesCompass_2024PipelinesMiningOffshoreCostDatabase_Watermark_01-24Tunji AminuNo ratings yet

- Continuous Concrete Beam Design To Bs 81101997 Table 3.5Document8 pagesContinuous Concrete Beam Design To Bs 81101997 Table 3.5sarv_kishoreNo ratings yet

- 0 CANDY Vista Geral 1Document1 page0 CANDY Vista Geral 1Tiago PereiraNo ratings yet

- 20UCIV3071Document1 page20UCIV3071yomax687No ratings yet

- Crane Gantry Girder Design: Default Example: Input DataDocument13 pagesCrane Gantry Girder Design: Default Example: Input DataVishnu SamyNo ratings yet

- Benzene Tk-311 EPC Cost EstimateDocument13 pagesBenzene Tk-311 EPC Cost EstimaterodantetorresNo ratings yet

- A440 Detail Design Estimate (Final Rev 6)Document14 pagesA440 Detail Design Estimate (Final Rev 6)GP100% (1)

- Proposed Training SchoolDocument3 pagesProposed Training SchoolrokiahhassanNo ratings yet

- B.Tech 2019 SE Rev2020 FinalDocument135 pagesB.Tech 2019 SE Rev2020 FinalprismNo ratings yet

- G+7 Watersupply, Septic AnkDocument633 pagesG+7 Watersupply, Septic AnkSantosh ChowdaryNo ratings yet

- Final Bill - ClaimedDocument1 pageFinal Bill - Claimedshamal royNo ratings yet

- Quiz#1Document5 pagesQuiz#1abdullahzaki249No ratings yet

- Cost Control Spreadsheet BLK ADocument17 pagesCost Control Spreadsheet BLK AØwięs MØhãmmed100% (1)

- Sagip Chapter 8Document7 pagesSagip Chapter 8Christopherchan ChanNo ratings yet

- Report FinalDocument15 pagesReport Finalmhd shakirNo ratings yet

- 19UPIE1321 4rtDocument1 page19UPIE1321 4rtNarpat Singh ChouhanNo ratings yet

- World Energy DemandDocument5 pagesWorld Energy DemandKenzyNo ratings yet

- 100 - Waterpower Dam Bill of QuantitiesDocument4 pages100 - Waterpower Dam Bill of QuantitiesLimgeeGideonzNo ratings yet

- Gauri Parbati/ Mrit Sanjiwoni J/V: Detail Cost Break DownDocument2 pagesGauri Parbati/ Mrit Sanjiwoni J/V: Detail Cost Break DownDoodhpokhari ChepeNo ratings yet

- Laporan Fa Detail (16 Segmen)Document8 pagesLaporan Fa Detail (16 Segmen)wangbadistraNo ratings yet

- SVC SNS 270913 (Renovation) Issue R5Document5 pagesSVC SNS 270913 (Renovation) Issue R5Thaiminh VoNo ratings yet

- JyjyyiyiioDocument1 pageJyjyyiyiioThe LakshyaNo ratings yet

- Lot W12Document4 pagesLot W12ebubeogbukeNo ratings yet

- External Static Pressure Calculation: AHU-B6 - 05 Hvac 7/27 M.M 4 June 2014 MA/CAL/7Document3 pagesExternal Static Pressure Calculation: AHU-B6 - 05 Hvac 7/27 M.M 4 June 2014 MA/CAL/7Engr.MmosaadNo ratings yet

- Rate AnalysisDocument5 pagesRate AnalysisPradeep Kannamangalath100% (1)

- Jahafar Price EsculationDocument1 pageJahafar Price EsculationArse AbiNo ratings yet

- Group B - Teaneck CompanyDocument10 pagesGroup B - Teaneck Companyfdsfsfsfdf100% (1)

- Find Attached QuotationDocument2 pagesFind Attached Quotationfeezy11No ratings yet

- 21UEEE9002Document1 page21UEEE9002tanish gehlotNo ratings yet

- Geotechnical Review of Low Wall Pit Xy - Case StudyDocument8 pagesGeotechnical Review of Low Wall Pit Xy - Case Study09devilNo ratings yet

- Laporan Fa Detail (16 Segmen)Document8 pagesLaporan Fa Detail (16 Segmen)Fahri AryadinNo ratings yet

- Mechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandMechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesDileep SinghNo ratings yet

- Advanced Processing and Manufacturing Technologies for Nanostructured and Multifunctional Materials IIFrom EverandAdvanced Processing and Manufacturing Technologies for Nanostructured and Multifunctional Materials IITatsuki OhjiNo ratings yet

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášNo ratings yet

- Ceramic Materials for Energy Applications VIFrom EverandCeramic Materials for Energy Applications VIHua-Tay LinNo ratings yet

- Reducing Business Jet Carbon Footprint: Using the Power of the Aircraft Electric Taxi SystemFrom EverandReducing Business Jet Carbon Footprint: Using the Power of the Aircraft Electric Taxi SystemNo ratings yet

- Processing, Properties, and Design of Advanced Ceramics and CompositesFrom EverandProcessing, Properties, and Design of Advanced Ceramics and CompositesGurpreet SinghNo ratings yet

- Model Predictive Control of High Power Converters and Industrial DrivesFrom EverandModel Predictive Control of High Power Converters and Industrial DrivesNo ratings yet

- Hours: Table 19.25 Engineering Estimating System PerformanceDocument1 pageHours: Table 19.25 Engineering Estimating System PerformancesivavalaiNo ratings yet

- Cost Estimate Summary Case: Estimating 119Document1 pageCost Estimate Summary Case: Estimating 119sivavalaiNo ratings yet

- Semi-Detailed Estimating System: M LabDocument1 pageSemi-Detailed Estimating System: M LabsivavalaiNo ratings yet

- 3 - Shakedown Areas.: Construction ManagementDocument1 page3 - Shakedown Areas.: Construction ManagementsivavalaiNo ratings yet

- Communications 241: 17.2 Documentation ChecklistDocument1 pageCommunications 241: 17.2 Documentation ChecklistsivavalaiNo ratings yet

- Phases The Startup: of An For ofDocument1 pagePhases The Startup: of An For ofsivavalaiNo ratings yet

- 15.5 Control During Construction: 80% of Bulk Materials Normally SuppliedDocument1 page15.5 Control During Construction: 80% of Bulk Materials Normally SuppliedsivavalaiNo ratings yet

- This Page Intentionally Left BlankDocument1 pageThis Page Intentionally Left BlanksivavalaiNo ratings yet

- Project Control: Plant LayoutDocument1 pageProject Control: Plant LayoutsivavalaiNo ratings yet

- Process Design Phaseolphasel: Phase 1 SpecificationsDocument1 pageProcess Design Phaseolphasel: Phase 1 SpecificationssivavalaiNo ratings yet

- Speclfic To Project: 2 - Depth and BreadthDocument1 pageSpeclfic To Project: 2 - Depth and BreadthsivavalaiNo ratings yet

- Agreement: ContractingDocument1 pageAgreement: ContractingsivavalaiNo ratings yet

- Project Control Problem Correction: During ConstructionDocument1 pageProject Control Problem Correction: During ConstructionsivavalaiNo ratings yet

- 14.3 Construction Management ActivitiesDocument1 page14.3 Construction Management ActivitiessivavalaiNo ratings yet

- Estimating Methods: Engineering EstimatesDocument1 pageEstimating Methods: Engineering EstimatessivavalaiNo ratings yet

- 2 - Drawings.: 3 - SpecificationsDocument1 page2 - Drawings.: 3 - SpecificationssivavalaiNo ratings yet

- All Equipment Should Be Accessible by Either Crane or Lift TruckDocument1 pageAll Equipment Should Be Accessible by Either Crane or Lift TrucksivavalaiNo ratings yet