Professional Documents

Culture Documents

3 01 Att.5 R1 PDF

3 01 Att.5 R1 PDF

Uploaded by

Hadi BarakOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3 01 Att.5 R1 PDF

3 01 Att.5 R1 PDF

Uploaded by

Hadi BarakCopyright:

Available Formats

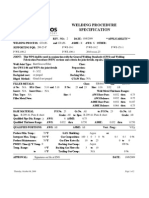

LANL Engineering Standards Manual ISD 341-2

WPS 3-01 Application of Welding Procedure Specifications

Attachment 5: API Welding Procedure Specification Form

Chapter 13, Welding & Joining Rev. 1, 10/27/06

API WELDING PROCEDURE SPECIFICATION

WPS: REV. NO.: PROCESS: DATE:

API-1104 QUALIFIED PRANGES Diameter: Thickness: Material: Positions: WELD JOINT: Joint Description: Sketch Number: FILLER MATERIALS: SFA Class: Number of Beads: BASE MATERIALS: Thickness Welded: Pipe Diameter: ASME P No.: Fixed: Group: Rolled: Spec: API Group No.: F No.: Fixed: Type: Rolled:

Filler Metal Group: Joint Type:

Progression: Class:

NOTE: This WPS shall be used in conjunction with the applicable sections of the LANL General Welding Standard (GWS).

AWS Class: Sizes (s):

to to to

Spec:

Pipe Diameter to P No.: Time at F.: Group:

POSITIONS: Progression: PREHEAT:

PWHT:

Temperature Range F: Minimum Temp F: GAS: Flow Rate: Shielding: Backing: CFH

Composition:

ELECTRICAL CHARACTERISTICS: Current: Transfer Mode: Electrode size and Type MAX. TIME BETWEEN PASSES: Polarity: WFS/IPM: Travel/IPM RANGES Amps: Volts:

Page 1 of 2

LANL Engineering Standards Manual ISD 341-2

WPS 3-01 Application of Welding Procedure Specifications

Attachment 5: API Welding Procedure Specification Form

Chapter 13, Welding & Joining Rev. 1, 10/27/06 Date:

WPS No.:

Rev. No.: WELDING TECHNIQUE

Line-Up Clamp:

Stringer (S) or Weave (W) Bead: Cleaning and/or Grinding: PROCEDURE QUALIFIED FOR: Maximum K/J Heat Input:

Single Pass

Multi Pass

Charpy V Notch

NDTT

D.T.

JOINT SKETCH AND BEAD NUMBER AND SEQUENCE

NOTE: Weld layers are representative only actual number of passes and layer sequence may vary due to variation in joint design, thickness and fit-up.

Pass Number 1 2 3 4 5 6 7 8

Filler/ Electrode

Size

TYPICAL WELDING PARAMETERS Travel AMPS VOLTS Speed

Other

PREPARED BY: APPROVED BY:

DATE: DATE:

Page 2 of 2

You might also like

- ISO 9606 Revised 4 SeptDocument34 pagesISO 9606 Revised 4 Septaravindan100% (5)

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerFrom EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerRating: 5 out of 5 stars5/5 (1)

- PQR Wps WPQ FormatDocument12 pagesPQR Wps WPQ FormatessnelsonNo ratings yet

- Welding Procedure Specification (WPS) FormDocument2 pagesWelding Procedure Specification (WPS) FormEarl Harbert0% (2)

- Flame Arrestor DatasheetDocument2 pagesFlame Arrestor DatasheetAmit Pandey67% (6)

- WPS 03Document2 pagesWPS 03mansoor_an100% (1)

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Engineering Standards Manual - Welding Standards M Anual - Volume 3 Welding Procedure SpecificationsDocument3 pagesEngineering Standards Manual - Welding Standards M Anual - Volume 3 Welding Procedure Specificationslaz_k50% (2)

- API-1000-11 Rev 0Document3 pagesAPI-1000-11 Rev 0Mahesh MishraNo ratings yet

- Daily Welding Visual Inspection Report: Title: ITP For Piping InstallationDocument10 pagesDaily Welding Visual Inspection Report: Title: ITP For Piping Installationtranvando1986No ratings yet

- WPSPQRDocument11 pagesWPSPQR0502raviNo ratings yet

- Welding Procedure Specification (WPS) : (Section IX ASME Boiler and Pressure Vessel Code)Document2 pagesWelding Procedure Specification (WPS) : (Section IX ASME Boiler and Pressure Vessel Code)Hiren PanchalNo ratings yet

- Essar Constructions Ltd. Hazira.: List of FormatsDocument68 pagesEssar Constructions Ltd. Hazira.: List of Formatsravi00098No ratings yet

- Joint Design Process (Es) : Applicable To Off Plot Piping Per ASME B31.8Document2 pagesJoint Design Process (Es) : Applicable To Off Plot Piping Per ASME B31.8hekayat71No ratings yet

- NSH-DALM-JERP-WPS-11-P2 Rev.00Document10 pagesNSH-DALM-JERP-WPS-11-P2 Rev.00Alam MD SazidNo ratings yet

- Wps Pip Gtaw - ArabianDocument1 pageWps Pip Gtaw - ArabianIshack MohammedNo ratings yet

- WPS PQRDocument51 pagesWPS PQRLuis Muñoz100% (1)

- Welder Cirt TotalDocument78 pagesWelder Cirt TotalNguyễn ChâuNo ratings yet

- Sample API 1104 WpsDocument6 pagesSample API 1104 Wpsjacquesmayol100% (3)

- Standards in Welding and ApprovalDocument1 pageStandards in Welding and Approvalkiki270977No ratings yet

- Procedure Qualification Records (PQR) : in Accordance With ASME SECTION IX For Power PippingDocument6 pagesProcedure Qualification Records (PQR) : in Accordance With ASME SECTION IX For Power PippingNovita Dwi IsnaeniNo ratings yet

- WPS D9.1Document1 pageWPS D9.1pjbedelNo ratings yet

- QC Interview Questions IMPDocument10 pagesQC Interview Questions IMPAnonymous bIe9JSMphsNo ratings yet

- Welding Procedure SpecificationDocument30 pagesWelding Procedure Specificationrahman196011100% (1)

- 094135-PE-SPC-001 Piping Material Specification-REV 4Document76 pages094135-PE-SPC-001 Piping Material Specification-REV 4thongpvgas100% (1)

- Wps 15614 TemplateDocument2 pagesWps 15614 Template0502raviNo ratings yet

- Piping Material Specifications (Part 4 of 10) FlangesDocument2 pagesPiping Material Specifications (Part 4 of 10) Flangesfarshid KarpasandNo ratings yet

- BK TNG 001 TS PI SP 001 - Piping Specification - Rev 2Document45 pagesBK TNG 001 TS PI SP 001 - Piping Specification - Rev 2Kev TraNo ratings yet

- Wps - 09 Mt-Imecol Asme304 Gtaw Sheet-Tubesheet Rev 0Document5 pagesWps - 09 Mt-Imecol Asme304 Gtaw Sheet-Tubesheet Rev 0Oscar Iván Duque DíazNo ratings yet

- 5026-PS-001 - 0 Supply of Piping MaterialsDocument17 pages5026-PS-001 - 0 Supply of Piping MaterialsCARLOS OLIVEROSNo ratings yet

- WPS & PQR - 2021Document82 pagesWPS & PQR - 2021Subramanian R100% (1)

- Training Session On Api Specification 5L 46 EditionDocument32 pagesTraining Session On Api Specification 5L 46 EditionVenkatesh Naidu100% (1)

- WPS - PQR As Per IsDocument3 pagesWPS - PQR As Per IsNiladri Sekhar Maiti50% (4)

- GSDocument58 pagesGSSalimNo ratings yet

- BK - TNG 001 TS PI SP 001 Piping Material Specification Rev.1Document45 pagesBK - TNG 001 TS PI SP 001 Piping Material Specification Rev.1Kev Tra100% (1)

- Applicable To Off Plot Piping Per ASME B31.8: Joint DesignDocument1 pageApplicable To Off Plot Piping Per ASME B31.8: Joint Designhekayat71No ratings yet

- Engineering Standards Manual - Welding Standards Manual - Volume 3 Welding Procedure SpecificationsDocument3 pagesEngineering Standards Manual - Welding Standards Manual - Volume 3 Welding Procedure SpecificationsjacquesmayolNo ratings yet

- Wps 01-07 - 15Document2 pagesWps 01-07 - 15Majdi JerbiNo ratings yet

- Prpposed Welding Procedure Specification (WPS) : Code: Asme Ix API 1104 AWS D1.1Document1 pagePrpposed Welding Procedure Specification (WPS) : Code: Asme Ix API 1104 AWS D1.1MohamedNo ratings yet

- GEN-L-XXX-SP-0001 - 5 - Specification For Piping and Valve MaterialsDocument107 pagesGEN-L-XXX-SP-0001 - 5 - Specification For Piping and Valve MaterialsWilliam Smith100% (3)

- Sample Forms AWS, ASME and APIDocument14 pagesSample Forms AWS, ASME and APIaamirtec301No ratings yet

- Welding Procedure SpecificationDocument5 pagesWelding Procedure SpecificationFranklin londono0% (1)

- WPS 03 GtawDocument3 pagesWPS 03 GtawBiswajit DeyNo ratings yet

- WPS ExampleDocument2 pagesWPS ExampleMarcio Jr.No ratings yet

- MPCC 20 WPS12Document3 pagesMPCC 20 WPS12hekayat71No ratings yet

- Wps 316L Gtaw R00Document3 pagesWps 316L Gtaw R00Richard Periyanayagam75% (4)

- WPS-PQR For Split TeeDocument9 pagesWPS-PQR For Split TeemaheshmalaichamyNo ratings yet

- WPS AMC-0195 Rev 01Document3 pagesWPS AMC-0195 Rev 01umer.shariff87No ratings yet

- Aluminim WPSDocument2 pagesAluminim WPSKarthikeyan ShanmugavelNo ratings yet

- GWAW Welding SpecificationDocument2 pagesGWAW Welding SpecificationSaurabh GuptaNo ratings yet

- A Comparison of ISO 15614 Part 1 and ASME IXDocument2 pagesA Comparison of ISO 15614 Part 1 and ASME IXtuanNo ratings yet

- WPS PQR As Per IsDocument3 pagesWPS PQR As Per Istarun kaushalNo ratings yet

- Sample WPS Form (GTAW & SMAW) Welding Procedure Specification (WPS)Document1 pageSample WPS Form (GTAW & SMAW) Welding Procedure Specification (WPS)Ehab HarbNo ratings yet

- Sa00 Epxxxx Sdpi Bsds 0101 b03 A Piping Design Basis PPD NocDocument11 pagesSa00 Epxxxx Sdpi Bsds 0101 b03 A Piping Design Basis PPD Nocamini_mohiNo ratings yet

- WPS - How To CreateDocument10 pagesWPS - How To CreateMohammed SibghatullaNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- MT II Course Outline PDFDocument3 pagesMT II Course Outline PDFHadi BarakNo ratings yet

- GWS 1-02-Att.3R1 PDFDocument2 pagesGWS 1-02-Att.3R1 PDFHadi BarakNo ratings yet

- 6013Document2 pages6013Hadi BarakNo ratings yet

- 02 Guidance On The Documentation Requirements of Iso 9001 2008.Document7 pages02 Guidance On The Documentation Requirements of Iso 9001 2008.Hadi BarakNo ratings yet

- Matris Co. - Power Pricelist - Litepower Date: 1392/10/26: No. Model Price (Rials) Watt PFC Fan Size StockDocument3 pagesMatris Co. - Power Pricelist - Litepower Date: 1392/10/26: No. Model Price (Rials) Watt PFC Fan Size StockHadi BarakNo ratings yet

- Isiri 871:: e .: !"# $% e - &: ' Uts '+, - ./0 !1 21-34Document2 pagesIsiri 871:: e .: !"# $% e - &: ' Uts '+, - ./0 !1 21-34Hadi BarakNo ratings yet

- W02MDocument2 pagesW02MHadi BarakNo ratings yet

- Design and Simulation of Induction HeatingDocument3 pagesDesign and Simulation of Induction HeatingHadi BarakNo ratings yet

- Clincher™ Flat Cable Connectors: ReceptaclesDocument1 pageClincher™ Flat Cable Connectors: ReceptaclesHadi BarakNo ratings yet

- .100" Single Row Headers .100" Double Row Headers (Cont.)Document1 page.100" Single Row Headers .100" Double Row Headers (Cont.)Hadi BarakNo ratings yet

- GWS 1-02-Att.3R1 PDFDocument2 pagesGWS 1-02-Att.3R1 PDFHadi BarakNo ratings yet

- Selecting The Best Serial EEPROM Interface Protocol For Your ApplicationDocument6 pagesSelecting The Best Serial EEPROM Interface Protocol For Your ApplicationHadi BarakNo ratings yet

- Recalcol PDFDocument1 pageRecalcol PDFHadi BarakNo ratings yet

- Engineering Standards Manual ISD 341-2: Chapter 13, Welding & Joining Volume 3, Welding Procedure SpecificationDocument5 pagesEngineering Standards Manual ISD 341-2: Chapter 13, Welding & Joining Volume 3, Welding Procedure SpecificationHadi BarakNo ratings yet

- Advantech - USB Installation GuideDocument1 pageAdvantech - USB Installation GuideHadi BarakNo ratings yet

- Enter 400 Bad Request Nginx/1.2.9Document9 pagesEnter 400 Bad Request Nginx/1.2.9Hadi BarakNo ratings yet