Professional Documents

Culture Documents

67697425-Bolt-Design 89

67697425-Bolt-Design 89

Uploaded by

pawkom0 ratings0% found this document useful (0 votes)

44 views1 pageThe document summarizes corrosion resistance test results for various zinc and zinc alloy coatings on steel samples exposed to salt spray conditions. It provides the coating material, thickness, any surface sealing, and the time until white and red rust is observed according to DIN EN ISO 9227 standards. Coatings with thicker films, passivation, surface sealing, or additional topcoats demonstrated better corrosion resistance with longer times until rust observation.

Original Description:

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document summarizes corrosion resistance test results for various zinc and zinc alloy coatings on steel samples exposed to salt spray conditions. It provides the coating material, thickness, any surface sealing, and the time until white and red rust is observed according to DIN EN ISO 9227 standards. Coatings with thicker films, passivation, surface sealing, or additional topcoats demonstrated better corrosion resistance with longer times until rust observation.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

44 views1 page67697425-Bolt-Design 89

67697425-Bolt-Design 89

Uploaded by

pawkomThe document summarizes corrosion resistance test results for various zinc and zinc alloy coatings on steel samples exposed to salt spray conditions. It provides the coating material, thickness, any surface sealing, and the time until white and red rust is observed according to DIN EN ISO 9227 standards. Coatings with thicker films, passivation, surface sealing, or additional topcoats demonstrated better corrosion resistance with longer times until rust observation.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

Corrosion protection

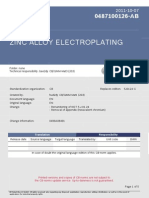

Corrosion resistance of Cr(VI)-free surfaces in salt spray tests

Coating Zn (thin film) passivated, no surface sealing Zn (thin film) passivated, with surface sealing Zn (thick film) passivated, no surface sealing Zn (thick film) passivated, with surface sealing ZnFe black, with surface sealing ZnFe transparent, no surface sealing ZnFe transparent, with surface sealing ZnNi transparent, no surface sealing ZnNi transparent, with surface sealing ZnNi black passivated, no surface sealing ZnNi black, with surface sealing Zn, black passivated, with surface sealing Zinc flake coating, e.g. DIN EN ISO 10683 flZnnc-480 h Zinc flake coating DIN EN ISO 10683 flZnnc-720 h-L Zinc flake coating DIN EN ISO 10683 flZnncL-480 h Zinc flake coating DIN EN ISO 10683 flZnnc-480 h black Coating thickness [m] 5 8 5 8 5 8 5 8 5 8 5 8 5 8 5 8 5 8 8* 5 8 8* ~8 DIN EN ISO 9227 SS white rust [h] 12 24 72 72 48 72 96 96 120 120 72 72 120 120 120 120 144 144 24 120 120 12 DIN EN ISO 9227 SS red rust [h] 36 72 96 120 72 120 168 240 168 360 168 360 240 360 360 600 480 720 360 480 720 72 480 Bllhoff surface C1 C2 V1 V2 C5 C6 V5 V6 E8 E9 E1 E2 E3 E4 N0 N1 N3 N4 N7 N8 N9 C9 Examples: G1 = Geomet 321 A, L0 = Delta Protekt KL 100, L8=Magni Flake Examples: G7 = Geomet 321 B + VL, L1 = Delta Protekt KL 100 + VH 301 GZ Example: G9 = Geomet 500 A Examples: L4 = Delta-Protekt KL 100 B + Delta Seal, L9 = Zintek 300 + Techseal SL

~ 10

720

~ 10

480

~8

120

480

The values given are guideline values for barrel plated products tested immediately after coating. * Recommended minimum coating thickness.

89

You might also like

- The Essential Guide To FramingDocument121 pagesThe Essential Guide To Framingpawkom100% (9)

- TL - 260 - en 2015Document11 pagesTL - 260 - en 2015hand42100% (2)

- DatasheetDocument2 pagesDatasheetnirmalNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Wood Joints in Classical Japanese Architecture PDFDocument69 pagesWood Joints in Classical Japanese Architecture PDFDavid Freire CuevaNo ratings yet

- Timber Frame ShedDocument5 pagesTimber Frame Shedpawkom100% (5)

- Framing With RoofsDocument5 pagesFraming With Roofsgreenelephant150No ratings yet

- Principles of Timber Framed ConstructionDocument76 pagesPrinciples of Timber Framed Constructionpawkom67% (6)

- Fixing Bracing Guidelines - Timber Roof TrussesDocument20 pagesFixing Bracing Guidelines - Timber Roof Trussesjaffna100% (1)

- Corrosion Protection: General Information: Industry AirDocument1 pageCorrosion Protection: General Information: Industry AirMAI_QualityNo ratings yet

- 3.2 S-MS, S-MD Z en - AutoperforantesDocument52 pages3.2 S-MS, S-MD Z en - AutoperforantescanocarloNo ratings yet

- 16 StaticgasketsDocument10 pages16 StaticgasketsRobinReyndersNo ratings yet

- DC54D ZDocument4 pagesDC54D ZGustavoNo ratings yet

- Izolatii Termice Saltea STDocument2 pagesIzolatii Termice Saltea STIonut IgnatNo ratings yet

- Brochure Cathelain GBDocument28 pagesBrochure Cathelain GBFg FgNo ratings yet

- Gate ValvesDocument8 pagesGate ValvesPaul BarahonaNo ratings yet

- Basics 13 14Document71 pagesBasics 13 14DekorNo ratings yet

- Katalog Proizvoda - Sendvic PaneliDocument20 pagesKatalog Proizvoda - Sendvic PaneliHermes Sturla Erobregen ThorvaldenNo ratings yet

- Swing Check Valve Rubber DiscDocument2 pagesSwing Check Valve Rubber DiscsathishNo ratings yet

- Diaval ST Type Rubber Lined Flanged EndsDocument3 pagesDiaval ST Type Rubber Lined Flanged EndsMarketing RNSNo ratings yet

- Profile SurveyDocument10 pagesProfile Surveygalici2002No ratings yet

- Q915525-00-4 - en - To Hop Thep Hinh LoescheDocument5 pagesQ915525-00-4 - en - To Hop Thep Hinh LoescheHai lm5No ratings yet

- Cooper Medc Datasheet Xb9 6ds098 Issue KDocument2 pagesCooper Medc Datasheet Xb9 6ds098 Issue KKaoka Kaoka KaokaoNo ratings yet

- Rinox Exports Catalogue3.0Document116 pagesRinox Exports Catalogue3.0Giovanny VelasquezNo ratings yet

- Type 320 Tank Sight Glass Round DIN 28120Document2 pagesType 320 Tank Sight Glass Round DIN 28120Stefano SalicchiNo ratings yet

- Analysis Flange: Design ConditionsDocument35 pagesAnalysis Flange: Design ConditionsahmadNo ratings yet

- Next Generation: Ultragrip Reducing CouplingsDocument1 pageNext Generation: Ultragrip Reducing CouplingsblindjaxxNo ratings yet

- Anochrome Coating Data Sheet 15-10-14Document3 pagesAnochrome Coating Data Sheet 15-10-14ellisforheroesNo ratings yet

- Ca 3241Document1 pageCa 3241Tien LamNo ratings yet

- HRD Frame Anchor Redundant FasteningDocument18 pagesHRD Frame Anchor Redundant FasteningFarrukh KhanNo ratings yet

- Weidmuller JBDocument134 pagesWeidmuller JBMuhammad MaskurNo ratings yet

- Black PassivationDocument12 pagesBlack PassivationZineb100% (1)

- Type Zlic Brand SihiDocument8 pagesType Zlic Brand SihiArdi 4791No ratings yet

- Plating Standard - NOR - 0487100126 - 00 - 20111212 - 0AB - Dy - DMDocument5 pagesPlating Standard - NOR - 0487100126 - 00 - 20111212 - 0AB - Dy - DMParag AdwankarNo ratings yet

- Volute Casing Pumps: SupernovaDocument9 pagesVolute Casing Pumps: SupernovaP. Ernesto C. GutierrezNo ratings yet

- Catalog ChiavetteDocument96 pagesCatalog Chiavettevalentinp3No ratings yet

- 6677 MeguinGleitoelCGLP68 16.0 en (Hidraulika)Document1 page6677 MeguinGleitoelCGLP68 16.0 en (Hidraulika)Marko VitakovićNo ratings yet

- Jed-739 008 GDocument5 pagesJed-739 008 GPaulo Henrique NascimentoNo ratings yet

- Spare Parts ListDocument188 pagesSpare Parts ListhanhccidNo ratings yet

- ZLKDocument10 pagesZLKHunter NoVaNo ratings yet

- Knauf D12 SystemDocument28 pagesKnauf D12 SystemAmin ChhipaNo ratings yet

- Hydraulic Tubes and PipesDocument18 pagesHydraulic Tubes and Pipeshp_vijaykNo ratings yet

- KSB Globe ValvesDocument2 pagesKSB Globe ValvesvttneverloseNo ratings yet

- 4133 - GV Sub Fig7012Document6 pages4133 - GV Sub Fig7012Bryan STNo ratings yet

- Comparison of Steel Standards - VoestalpineDocument14 pagesComparison of Steel Standards - VoestalpineAnonymous 6aGAvbN100% (1)

- Pressure Vessel Inspection ReportDocument34 pagesPressure Vessel Inspection ReportJinlong SuNo ratings yet

- Pub099 001 00 - 1117Document4 pagesPub099 001 00 - 1117Rizky KusumahNo ratings yet

- Visilume Standard Sightglass: (Also Available Complete With Wiper Assembly)Document2 pagesVisilume Standard Sightglass: (Also Available Complete With Wiper Assembly)Dương HoàngNo ratings yet

- Electrodeposited Coatings of Zinc With Passivation On SteelDocument4 pagesElectrodeposited Coatings of Zinc With Passivation On Steelradule021No ratings yet

- Scame Doze AntiexDocument6 pagesScame Doze AntiextotovasiNo ratings yet

- Design Information Sheet (Dis) : EnglishDocument4 pagesDesign Information Sheet (Dis) : EnglishMinh Tâm TrầnNo ratings yet

- Sandwich Panels TechnicalDocument8 pagesSandwich Panels TechnicaltmssorinNo ratings yet

- HD 25 C L1 10,00m VC 25-1 NPT Ms SnAl VC 25-1 NPT Ms SnAlDocument3 pagesHD 25 C L1 10,00m VC 25-1 NPT Ms SnAl VC 25-1 NPT Ms SnAldouglas diasNo ratings yet

- Technical Data of Powder CoatingDocument1 pageTechnical Data of Powder CoatingLahore 4C2No ratings yet

- Hilti Hit Hy 150 Max Con Barra CorrugadaDocument20 pagesHilti Hit Hy 150 Max Con Barra Corrugadalandsv01No ratings yet

- Trimo Introduces Itself: DetailsDocument290 pagesTrimo Introduces Itself: DetailsinstorkNo ratings yet

- Gear Oil CLP 220-11-En - GBDocument1 pageGear Oil CLP 220-11-En - GBputel_ajaNo ratings yet

- Glass Block TechnicalDocument18 pagesGlass Block TechnicalPrunici IonNo ratings yet

- Bs en 14399 Parts 1 To 8Document7 pagesBs en 14399 Parts 1 To 8ramonyk_003558100% (1)

- Advances in Ceramic Armor XIFrom EverandAdvances in Ceramic Armor XIJerry C. LaSalviaNo ratings yet

- Ceramic Materials for Energy Applications VIFrom EverandCeramic Materials for Energy Applications VIHua-Tay LinNo ratings yet

- Metal Tanks (Heavy Gauge) World Summary: Market Values & Financials by CountryFrom EverandMetal Tanks (Heavy Gauge) World Summary: Market Values & Financials by CountryNo ratings yet

- Bracing ManualDocument101 pagesBracing ManualErrol HobdenNo ratings yet

- Structural Glued-Laminated Timber (40pag)Document40 pagesStructural Glued-Laminated Timber (40pag)pawkom100% (1)

- Simpson Strong Tie Catalog 09Document196 pagesSimpson Strong Tie Catalog 09Jeff Strickland100% (1)

- Buckling of Thin Metal Shells 299Document1 pageBuckling of Thin Metal Shells 299pawkomNo ratings yet

- Bolted Joints in Glulam and Structural Timber Composites (Davis+Claisse)Document11 pagesBolted Joints in Glulam and Structural Timber Composites (Davis+Claisse)pawkomNo ratings yet

- Buckling of Thin Metal Shells 296Document1 pageBuckling of Thin Metal Shells 296pawkomNo ratings yet

- Buckling of Thin Metal Shells 298Document1 pageBuckling of Thin Metal Shells 298pawkomNo ratings yet

- Buckling of Thin Metal Shells 292Document1 pageBuckling of Thin Metal Shells 292pawkomNo ratings yet

- Buckling of Thin Metal Shells 293Document1 pageBuckling of Thin Metal Shells 293pawkomNo ratings yet

- Buckling of Thin Metal Shells 291Document1 pageBuckling of Thin Metal Shells 291pawkomNo ratings yet

- Buckling of Thin Metal Shells 287Document1 pageBuckling of Thin Metal Shells 287pawkomNo ratings yet

- Buckling of Thin Metal Shells 285Document1 pageBuckling of Thin Metal Shells 285pawkomNo ratings yet