Professional Documents

Culture Documents

Design of A Wormgear Set With A Steel Worm and A Bronze Gear

Design of A Wormgear Set With A Steel Worm and A Bronze Gear

Uploaded by

Evelin MamaniCopyright:

Available Formats

You might also like

- Base Plate Design - BS CodeDocument3 pagesBase Plate Design - BS Codemicheleling669667% (3)

- Anchor Bolt CalculationDocument17 pagesAnchor Bolt CalculationSrinivasa Rao Venkumahanthi100% (6)

- FIN PLATE - Beam To BeamDocument71 pagesFIN PLATE - Beam To BeamHemant Ramesh Narkar100% (3)

- Belt Selection CalculationDocument29 pagesBelt Selection CalculationElwathig BakhietNo ratings yet

- Lifting Lug CalculationDocument5 pagesLifting Lug CalculationEm Mar100% (2)

- PSC Design (EC2) Tutorial PDFDocument49 pagesPSC Design (EC2) Tutorial PDFGeorge LazarNo ratings yet

- Estrella, Tria A. BSME 5-1 ME 511a Machine Design 1 Exercise #1: Nature of Mechanical DesignDocument12 pagesEstrella, Tria A. BSME 5-1 ME 511a Machine Design 1 Exercise #1: Nature of Mechanical DesignHannahNo ratings yet

- Operatin G Pulse Feed Per Unit 360 465 4 360 0.72 58125Document7 pagesOperatin G Pulse Feed Per Unit 360 465 4 360 0.72 58125aef agus sapariNo ratings yet

- Input Data: Bevel GearingDocument2 pagesInput Data: Bevel GearingHarol Wladimir Mamani TotoraNo ratings yet

- Embodyment Design: Sambungan (Pengelasan)Document7 pagesEmbodyment Design: Sambungan (Pengelasan)naschuy2No ratings yet

- Design CalculationsDocument18 pagesDesign CalculationsPat SulaimanNo ratings yet

- Input Data: Helical GearingDocument2 pagesInput Data: Helical GearingHarol Wladimir Mamani TotoraNo ratings yet

- Uplift With Moment CalculationDocument4 pagesUplift With Moment CalculationdennykvgNo ratings yet

- SolutionsofGears PDFDocument4 pagesSolutionsofGears PDFGautam AdhikariNo ratings yet

- Design of Transmission Systems: Unit IDocument29 pagesDesign of Transmission Systems: Unit Ipsunmoorthy100% (1)

- Connection Weld Bolt (06!06!2016)Document21 pagesConnection Weld Bolt (06!06!2016)raymond100% (1)

- V-Belt DriveDocument9 pagesV-Belt DriveCHANDRASEKARANNo ratings yet

- Muthu Cad 2Document8 pagesMuthu Cad 2Sagarias AlbusNo ratings yet

- Design of AgitatorDocument3 pagesDesign of AgitatorManish PatelNo ratings yet

- Chain Drive Calculation - 31-May-2017: Chain: ANSI 60 (ISO 606) Duplex Renold Synergy Serial Number: GY60A2Document1 pageChain Drive Calculation - 31-May-2017: Chain: ANSI 60 (ISO 606) Duplex Renold Synergy Serial Number: GY60A2Principe Reyes JuniorNo ratings yet

- Exp. 5. Application of Information Technology in Calculating The Machine ElementsDocument25 pagesExp. 5. Application of Information Technology in Calculating The Machine ElementsBah NahNo ratings yet

- Topic BeltsDocument20 pagesTopic BeltsAstri Ngent100% (1)

- Chain Drive CalculationsDocument42 pagesChain Drive CalculationsAchin67% (3)

- Belt Drives and Chain DrivesDocument39 pagesBelt Drives and Chain DrivesSeparatorNo ratings yet

- Design Calculation HandlingDocument51 pagesDesign Calculation HandlingArshad KhanNo ratings yet

- Drive DesignDocument1 pageDrive DesignnarupvNo ratings yet

- CONNECTIONDESIGNMANUALDocument34 pagesCONNECTIONDESIGNMANUALanon_97209652No ratings yet

- Design Methodology of Garlic Peeling MachineDocument11 pagesDesign Methodology of Garlic Peeling MachineIJSTENo ratings yet

- Title of The Project: Design of Automatic Paper: Punching Machine by Using Geneva MechaniasmDocument10 pagesTitle of The Project: Design of Automatic Paper: Punching Machine by Using Geneva MechaniasmBaldev SinghNo ratings yet

- Chapter11 Prob01Document13 pagesChapter11 Prob01imranakhtarNo ratings yet

- N N D D: Bab Ii Perencanaan Roda GigiDocument24 pagesN N D D: Bab Ii Perencanaan Roda GigiShabrina Meitha Nadhila RamadhanNo ratings yet

- Mathcad - Baseplate Design - 8Document6 pagesMathcad - Baseplate Design - 8Monotobo X MakinaNo ratings yet

- Perhitungan Tension, Type Dan Size BeltDocument12 pagesPerhitungan Tension, Type Dan Size BeltHarry EP SitumorangNo ratings yet

- DTS - Unit - 2 PDFDocument14 pagesDTS - Unit - 2 PDFmani100% (1)

- Bolted Cover Plate Splice Connection B1Document4 pagesBolted Cover Plate Splice Connection B1ikanyu79No ratings yet

- Spur Gear PDFDocument8 pagesSpur Gear PDFLovely BalajiNo ratings yet

- Input Power (P) 22 KW Input RPM 1400 RPM Reduction Ratio 31.5:1Document6 pagesInput Power (P) 22 KW Input RPM 1400 RPM Reduction Ratio 31.5:1Shree JadhavNo ratings yet

- Project: Matrade Exhibition Center-Main Roof: Calculation For Steel Column Base PlateDocument10 pagesProject: Matrade Exhibition Center-Main Roof: Calculation For Steel Column Base PlateYANIshaNo ratings yet

- Problems s8Document4 pagesProblems s8zangue billy jamesNo ratings yet

- Design of Gear: The Standard Values and Equations Taken From Text Book of Machine Design byDocument4 pagesDesign of Gear: The Standard Values and Equations Taken From Text Book of Machine Design byLemi Chala BeyeneNo ratings yet

- Machine ElementsDocument30 pagesMachine ElementsNhat Vinh DoanNo ratings yet

- Design of AgitatorDocument3 pagesDesign of Agitatorkaps12No ratings yet

- Analisis de Los DatosDocument15 pagesAnalisis de Los DatosManuel A. Samaniego LaoNo ratings yet

- Design of Multi-Axis Welding Positioner WithDocument7 pagesDesign of Multi-Axis Welding Positioner Withsuraj dhulannavarNo ratings yet

- (Epm) B5-60Document80 pages(Epm) B5-60RinNo ratings yet

- Advanced Electric Drives: Analysis, Control, and Modeling Using MATLAB / SimulinkFrom EverandAdvanced Electric Drives: Analysis, Control, and Modeling Using MATLAB / SimulinkNo ratings yet

- Analog Dialogue, Volume 48, Number 1: Analog Dialogue, #13From EverandAnalog Dialogue, Volume 48, Number 1: Analog Dialogue, #13Rating: 4 out of 5 stars4/5 (1)

- Physics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to DisplaysFrom EverandPhysics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to DisplaysNo ratings yet

- Discrete Wavelet Transform: A Signal Processing ApproachFrom EverandDiscrete Wavelet Transform: A Signal Processing ApproachRating: 5 out of 5 stars5/5 (2)

- Modern Borehole Analytics: Annular Flow, Hole Cleaning, and Pressure ControlFrom EverandModern Borehole Analytics: Annular Flow, Hole Cleaning, and Pressure ControlNo ratings yet

- Mathematical and Computational Modeling: With Applications in Natural and Social Sciences, Engineering, and the ArtsFrom EverandMathematical and Computational Modeling: With Applications in Natural and Social Sciences, Engineering, and the ArtsRoderick MelnikNo ratings yet

- Advanced Chipless RFID: MIMO-Based Imaging at 60 GHz - ML DetectionFrom EverandAdvanced Chipless RFID: MIMO-Based Imaging at 60 GHz - ML DetectionNo ratings yet

- Programmable Logic Controllers: A Practical Approach to IEC 61131-3 using CoDeSysFrom EverandProgrammable Logic Controllers: A Practical Approach to IEC 61131-3 using CoDeSysNo ratings yet

- High Performance Loudspeakers: Optimising High Fidelity Loudspeaker SystemsFrom EverandHigh Performance Loudspeakers: Optimising High Fidelity Loudspeaker SystemsRating: 4 out of 5 stars4/5 (1)

- Stress Concentration Factor For A Notched Flat Bar in Axial TensionDocument1 pageStress Concentration Factor For A Notched Flat Bar in Axial TensionEvelin MamaniNo ratings yet

- Mod12 1Document1 pageMod12 1Evelin MamaniNo ratings yet

- Module 1-2c - Data Conversion Formulas For Stress, Pressure, and Force Stress or Pressure Conversions English Units To SIDocument1 pageModule 1-2c - Data Conversion Formulas For Stress, Pressure, and Force Stress or Pressure Conversions English Units To SIEvelin MamaniNo ratings yet

- Module 1-2d - Data Conversion Formulas For Mass and Density Mass Conversions English Units To SIDocument1 pageModule 1-2d - Data Conversion Formulas For Mass and Density Mass Conversions English Units To SIEvelin MamaniNo ratings yet

- Abamectin: Codex Alimentarius Maximum Residue Limits For Veterinary Drugs in FoodsDocument26 pagesAbamectin: Codex Alimentarius Maximum Residue Limits For Veterinary Drugs in FoodsEvelin MamaniNo ratings yet

Design of A Wormgear Set With A Steel Worm and A Bronze Gear

Design of A Wormgear Set With A Steel Worm and A Bronze Gear

Uploaded by

Evelin MamaniOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design of A Wormgear Set With A Steel Worm and A Bronze Gear

Design of A Wormgear Set With A Steel Worm and A Bronze Gear

Uploaded by

Evelin MamaniCopyright:

Available Formats

MOD3_3.

XLS

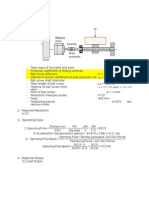

Module 11-7 Design of a Wormgear Set with a Steel Worm and a Bronze Gear

Worm (pinion)

Wormgear (gear)

Insert the required information:

C= N1 = N2 = 13.945 1 70 20 1400 1 in Center-to-center distance Worm teeth number Gear teeth number degrees RPM integer

Worm normal press angle

jn =

n=

Cast method

Paso diametral

Pinion speed

1=sand, 2=chill, 3=centrifugal

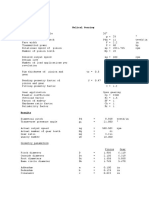

The computed output values are as follows:

mG = dp = dg = Fe = l = vt = Cm = Cv = Cs = m = Wt = Wf = Po = Pl = Pi = h= 70 Speed ratio 4.560 in Worm diameter 23.330 in Gear diameter 3.055 in Gear face width 4.181 degrees Lead angle 1675.704 ft/min Tangential velocity 0.691 Ratio correction factor 0.192 Velocity factor 537.761 Material factor 0.017 Coefficient of friction 2705.799 lbf Tangential load 47.954 lbf Friction force 10.020 horsepower Output power 2.435 horsepower Power lost in friction 12.455 horsepower Input power 80.4% Power efficiency

Note: This module has embedded Visual Basic functions to compute intermediate values. These were developed using Microsoft Excel and may not work with other spreadsheet programs. Source: AGMA Standard 6034-B92, Practice for Enclosed Cylindrical Wormgear Speed Reducers and Gearmotors

MOD3_3.XLS

with the permission of the publisher, American Gear Manufacturers Association, 1500 King Street, Suite 201, Alexandria, VA 22314.

MOD3_3.XLS

3.0004 23.33333 11.83333

You might also like

- Base Plate Design - BS CodeDocument3 pagesBase Plate Design - BS Codemicheleling669667% (3)

- Anchor Bolt CalculationDocument17 pagesAnchor Bolt CalculationSrinivasa Rao Venkumahanthi100% (6)

- FIN PLATE - Beam To BeamDocument71 pagesFIN PLATE - Beam To BeamHemant Ramesh Narkar100% (3)

- Belt Selection CalculationDocument29 pagesBelt Selection CalculationElwathig BakhietNo ratings yet

- Lifting Lug CalculationDocument5 pagesLifting Lug CalculationEm Mar100% (2)

- PSC Design (EC2) Tutorial PDFDocument49 pagesPSC Design (EC2) Tutorial PDFGeorge LazarNo ratings yet

- Estrella, Tria A. BSME 5-1 ME 511a Machine Design 1 Exercise #1: Nature of Mechanical DesignDocument12 pagesEstrella, Tria A. BSME 5-1 ME 511a Machine Design 1 Exercise #1: Nature of Mechanical DesignHannahNo ratings yet

- Operatin G Pulse Feed Per Unit 360 465 4 360 0.72 58125Document7 pagesOperatin G Pulse Feed Per Unit 360 465 4 360 0.72 58125aef agus sapariNo ratings yet

- Input Data: Bevel GearingDocument2 pagesInput Data: Bevel GearingHarol Wladimir Mamani TotoraNo ratings yet

- Embodyment Design: Sambungan (Pengelasan)Document7 pagesEmbodyment Design: Sambungan (Pengelasan)naschuy2No ratings yet

- Design CalculationsDocument18 pagesDesign CalculationsPat SulaimanNo ratings yet

- Input Data: Helical GearingDocument2 pagesInput Data: Helical GearingHarol Wladimir Mamani TotoraNo ratings yet

- Uplift With Moment CalculationDocument4 pagesUplift With Moment CalculationdennykvgNo ratings yet

- SolutionsofGears PDFDocument4 pagesSolutionsofGears PDFGautam AdhikariNo ratings yet

- Design of Transmission Systems: Unit IDocument29 pagesDesign of Transmission Systems: Unit Ipsunmoorthy100% (1)

- Connection Weld Bolt (06!06!2016)Document21 pagesConnection Weld Bolt (06!06!2016)raymond100% (1)

- V-Belt DriveDocument9 pagesV-Belt DriveCHANDRASEKARANNo ratings yet

- Muthu Cad 2Document8 pagesMuthu Cad 2Sagarias AlbusNo ratings yet

- Design of AgitatorDocument3 pagesDesign of AgitatorManish PatelNo ratings yet

- Chain Drive Calculation - 31-May-2017: Chain: ANSI 60 (ISO 606) Duplex Renold Synergy Serial Number: GY60A2Document1 pageChain Drive Calculation - 31-May-2017: Chain: ANSI 60 (ISO 606) Duplex Renold Synergy Serial Number: GY60A2Principe Reyes JuniorNo ratings yet

- Exp. 5. Application of Information Technology in Calculating The Machine ElementsDocument25 pagesExp. 5. Application of Information Technology in Calculating The Machine ElementsBah NahNo ratings yet

- Topic BeltsDocument20 pagesTopic BeltsAstri Ngent100% (1)

- Chain Drive CalculationsDocument42 pagesChain Drive CalculationsAchin67% (3)

- Belt Drives and Chain DrivesDocument39 pagesBelt Drives and Chain DrivesSeparatorNo ratings yet

- Design Calculation HandlingDocument51 pagesDesign Calculation HandlingArshad KhanNo ratings yet

- Drive DesignDocument1 pageDrive DesignnarupvNo ratings yet

- CONNECTIONDESIGNMANUALDocument34 pagesCONNECTIONDESIGNMANUALanon_97209652No ratings yet

- Design Methodology of Garlic Peeling MachineDocument11 pagesDesign Methodology of Garlic Peeling MachineIJSTENo ratings yet

- Title of The Project: Design of Automatic Paper: Punching Machine by Using Geneva MechaniasmDocument10 pagesTitle of The Project: Design of Automatic Paper: Punching Machine by Using Geneva MechaniasmBaldev SinghNo ratings yet

- Chapter11 Prob01Document13 pagesChapter11 Prob01imranakhtarNo ratings yet

- N N D D: Bab Ii Perencanaan Roda GigiDocument24 pagesN N D D: Bab Ii Perencanaan Roda GigiShabrina Meitha Nadhila RamadhanNo ratings yet

- Mathcad - Baseplate Design - 8Document6 pagesMathcad - Baseplate Design - 8Monotobo X MakinaNo ratings yet

- Perhitungan Tension, Type Dan Size BeltDocument12 pagesPerhitungan Tension, Type Dan Size BeltHarry EP SitumorangNo ratings yet

- DTS - Unit - 2 PDFDocument14 pagesDTS - Unit - 2 PDFmani100% (1)

- Bolted Cover Plate Splice Connection B1Document4 pagesBolted Cover Plate Splice Connection B1ikanyu79No ratings yet

- Spur Gear PDFDocument8 pagesSpur Gear PDFLovely BalajiNo ratings yet

- Input Power (P) 22 KW Input RPM 1400 RPM Reduction Ratio 31.5:1Document6 pagesInput Power (P) 22 KW Input RPM 1400 RPM Reduction Ratio 31.5:1Shree JadhavNo ratings yet

- Project: Matrade Exhibition Center-Main Roof: Calculation For Steel Column Base PlateDocument10 pagesProject: Matrade Exhibition Center-Main Roof: Calculation For Steel Column Base PlateYANIshaNo ratings yet

- Problems s8Document4 pagesProblems s8zangue billy jamesNo ratings yet

- Design of Gear: The Standard Values and Equations Taken From Text Book of Machine Design byDocument4 pagesDesign of Gear: The Standard Values and Equations Taken From Text Book of Machine Design byLemi Chala BeyeneNo ratings yet

- Machine ElementsDocument30 pagesMachine ElementsNhat Vinh DoanNo ratings yet

- Design of AgitatorDocument3 pagesDesign of Agitatorkaps12No ratings yet

- Analisis de Los DatosDocument15 pagesAnalisis de Los DatosManuel A. Samaniego LaoNo ratings yet

- Design of Multi-Axis Welding Positioner WithDocument7 pagesDesign of Multi-Axis Welding Positioner Withsuraj dhulannavarNo ratings yet

- (Epm) B5-60Document80 pages(Epm) B5-60RinNo ratings yet

- Advanced Electric Drives: Analysis, Control, and Modeling Using MATLAB / SimulinkFrom EverandAdvanced Electric Drives: Analysis, Control, and Modeling Using MATLAB / SimulinkNo ratings yet

- Analog Dialogue, Volume 48, Number 1: Analog Dialogue, #13From EverandAnalog Dialogue, Volume 48, Number 1: Analog Dialogue, #13Rating: 4 out of 5 stars4/5 (1)

- Physics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to DisplaysFrom EverandPhysics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to DisplaysNo ratings yet

- Discrete Wavelet Transform: A Signal Processing ApproachFrom EverandDiscrete Wavelet Transform: A Signal Processing ApproachRating: 5 out of 5 stars5/5 (2)

- Modern Borehole Analytics: Annular Flow, Hole Cleaning, and Pressure ControlFrom EverandModern Borehole Analytics: Annular Flow, Hole Cleaning, and Pressure ControlNo ratings yet

- Mathematical and Computational Modeling: With Applications in Natural and Social Sciences, Engineering, and the ArtsFrom EverandMathematical and Computational Modeling: With Applications in Natural and Social Sciences, Engineering, and the ArtsRoderick MelnikNo ratings yet

- Advanced Chipless RFID: MIMO-Based Imaging at 60 GHz - ML DetectionFrom EverandAdvanced Chipless RFID: MIMO-Based Imaging at 60 GHz - ML DetectionNo ratings yet

- Programmable Logic Controllers: A Practical Approach to IEC 61131-3 using CoDeSysFrom EverandProgrammable Logic Controllers: A Practical Approach to IEC 61131-3 using CoDeSysNo ratings yet

- High Performance Loudspeakers: Optimising High Fidelity Loudspeaker SystemsFrom EverandHigh Performance Loudspeakers: Optimising High Fidelity Loudspeaker SystemsRating: 4 out of 5 stars4/5 (1)

- Stress Concentration Factor For A Notched Flat Bar in Axial TensionDocument1 pageStress Concentration Factor For A Notched Flat Bar in Axial TensionEvelin MamaniNo ratings yet

- Mod12 1Document1 pageMod12 1Evelin MamaniNo ratings yet

- Module 1-2c - Data Conversion Formulas For Stress, Pressure, and Force Stress or Pressure Conversions English Units To SIDocument1 pageModule 1-2c - Data Conversion Formulas For Stress, Pressure, and Force Stress or Pressure Conversions English Units To SIEvelin MamaniNo ratings yet

- Module 1-2d - Data Conversion Formulas For Mass and Density Mass Conversions English Units To SIDocument1 pageModule 1-2d - Data Conversion Formulas For Mass and Density Mass Conversions English Units To SIEvelin MamaniNo ratings yet

- Abamectin: Codex Alimentarius Maximum Residue Limits For Veterinary Drugs in FoodsDocument26 pagesAbamectin: Codex Alimentarius Maximum Residue Limits For Veterinary Drugs in FoodsEvelin MamaniNo ratings yet