Professional Documents

Culture Documents

Buckling of Thin Metal Shells 234

Buckling of Thin Metal Shells 234

Uploaded by

pawkomOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Buckling of Thin Metal Shells 234

Buckling of Thin Metal Shells 234

Uploaded by

pawkomCopyright:

Available Formats

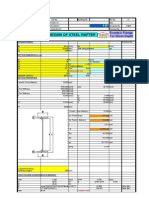

Cylindrical shells under shear stresses

209

7 6 E(t/r)1.25 (r/I)0.5 5 4 3 2 1 0 1 2 5 l ( r / t r 10 0.5 1 l) 5 10

8.7

2 ki = 4.82E(t/l )

Long tube

1.5 ki = 0.25E(t /r)

Plate strip (1+42/l 3)0.5

ki/0.75

m=

2

50

l r t /r

Figure 8.3 Critical torsional buckling stresses Rc (called ki in the diagram) for classical boundary conditions S3 (Lindner et al. 1998; reproduced by kind permission of Beuth Verlag).

Buckling of a medium-length cylinder: Rc = 0.85 2 t E r 12(1 2 )5/8

5/4

r l

1/2

= 0.75E

t r

5/4

r l

1/2

for = 0.3 (3)

The transition to the buckling of a plate strip can be expressed by adding a factor C to Eq. (3), where: C = 1 + 42 r l

3

t r

1.5

(4)

Buckling of a long tubular cylinder with (l/r) 8.7(r/t)0.5 : Rc = 3 E 2(1 2 )3/4 t r

3/2

= 0.25E

t r

3/2

for = 0.3.

(5)

An even greater challenge than the calculation of the linear elastic buckling eigenvalues was the determination of the complete load-deection path and the behaviour in the postbuckling range (Hutchinson and Koiter 1970; Budiansky 1974). Approximate solutions for cylinders under torsion were obtained, for example, by Batdorf (1947) and Nash (1957). A detailed overview can be found once again in Yamaki (1984). Experimental investigations First research was done mainly on behalf of the aerospace industry to determine experimental elastic buckling loads of thin-walled cylindrical shells and to check

You might also like

- The Essential Guide To FramingDocument121 pagesThe Essential Guide To Framingpawkom100% (9)

- Calculation of Earthing Sys.Document12 pagesCalculation of Earthing Sys.Rania Fathy Mohammed100% (6)

- Riser Span Verification Analysis - HydrotestDocument9 pagesRiser Span Verification Analysis - HydrotestfirmansyahperdanaNo ratings yet

- Cable Design Calculations (Air)Document8 pagesCable Design Calculations (Air)Inayat HathiariNo ratings yet

- Sol Ch6 Part2Document9 pagesSol Ch6 Part2mazharNo ratings yet

- Wood Joints in Classical Japanese Architecture PDFDocument69 pagesWood Joints in Classical Japanese Architecture PDFDavid Freire CuevaNo ratings yet

- Timber Frame ShedDocument5 pagesTimber Frame Shedpawkom100% (5)

- Framing With RoofsDocument5 pagesFraming With Roofsgreenelephant150No ratings yet

- Principles of Timber Framed ConstructionDocument76 pagesPrinciples of Timber Framed Constructionpawkom67% (6)

- Fixing Bracing Guidelines - Timber Roof TrussesDocument20 pagesFixing Bracing Guidelines - Timber Roof Trussesjaffna100% (1)

- Asme Viii Uhx Tubesheet CalcsDocument3 pagesAsme Viii Uhx Tubesheet CalcsjdfdfererNo ratings yet

- Drag Coefficients of Circular Cylinders v1.1 - CalculationDocument2 pagesDrag Coefficients of Circular Cylinders v1.1 - CalculationLuan TochettoNo ratings yet

- Buckling of Thin Metal Shells 240Document1 pageBuckling of Thin Metal Shells 240pawkomNo ratings yet

- Earthing CalculationDocument20 pagesEarthing CalculationIwanTiaraMotorNo ratings yet

- Section 5.4 Shell-And-tube Heat Exchanger - CorrectedDocument17 pagesSection 5.4 Shell-And-tube Heat Exchanger - CorrectedPerumalSamyNo ratings yet

- Buckling of Thin Metal Shells 233Document1 pageBuckling of Thin Metal Shells 233pawkomNo ratings yet

- Visco MeterDocument5 pagesVisco MeterYasin KaradaşNo ratings yet

- Correlation of Power Consumption of Several Kinds of Mixing ImpellersDocument7 pagesCorrelation of Power Consumption of Several Kinds of Mixing Impellersjuanita_hidalgoNo ratings yet

- RC Crack Width CalculatorDocument23 pagesRC Crack Width CalculatorSuraj De Silva100% (3)

- sm3 023Document2 pagessm3 023Sadie HnatowNo ratings yet

- Unit 3 Tension Members: StructureDocument28 pagesUnit 3 Tension Members: StructureRaj BakhtaniNo ratings yet

- Sif Factors Sec III NDDocument4 pagesSif Factors Sec III NDVicky GautamNo ratings yet

- Design of Steel Rafter: Econmic Flange For Given DepthDocument31 pagesDesign of Steel Rafter: Econmic Flange For Given DepthYusuf KardelenNo ratings yet

- EC3EXT200102 Steel Reference in EC3Document6 pagesEC3EXT200102 Steel Reference in EC3mileNo ratings yet

- New - Reinforcement of NozzleDocument31 pagesNew - Reinforcement of NozzleChagar HarshpalNo ratings yet

- EC2 Creep and Shrinkage LossesDocument9 pagesEC2 Creep and Shrinkage LossesSorin SavescuNo ratings yet

- Chord Length and DeviationDocument2 pagesChord Length and DeviationLcm TnlNo ratings yet

- 5 EarthingDocument4 pages5 EarthingPrabhash Verma0% (1)

- 250 HP Engine For Unmanned HelicopterDocument52 pages250 HP Engine For Unmanned HelicopteryanfengzhangNo ratings yet

- CRTH R' (C) L / ' (5)Document5 pagesCRTH R' (C) L / ' (5)january1969No ratings yet

- Reference Example For Lecture 7 Example 2 of IITK-GSDMA GuidelineDocument9 pagesReference Example For Lecture 7 Example 2 of IITK-GSDMA Guidelinemanoj_structureNo ratings yet

- Model Based Optimization of Drilling Fluid Density and ViscosityDocument34 pagesModel Based Optimization of Drilling Fluid Density and ViscositySai KumarNo ratings yet

- Heat Transfer in Jacketed VesselDocument2 pagesHeat Transfer in Jacketed VesselMuthuKumar Arunachalam0% (1)

- PA HE - Shell and TubeDocument60 pagesPA HE - Shell and Tubeniaaparamita100% (1)

- ستيل 2Document6 pagesستيل 2عقيل باسم عبد فرحانNo ratings yet

- W14x43 To HSS6x6x1 - 2 Moment ConnDocument21 pagesW14x43 To HSS6x6x1 - 2 Moment ConnrajedmaglinteNo ratings yet

- 33KV Earthmat 1designDocument176 pages33KV Earthmat 1designVelavan AnnamalaiNo ratings yet

- Local Thin Areas in ASME Code Pressure VesselsDocument5 pagesLocal Thin Areas in ASME Code Pressure VesselsMOHAMED ASHRAFXINo ratings yet

- TorsionDocument41 pagesTorsionАбдельнасир АбдельрахманNo ratings yet

- Two-Way Slabs (Tables)Document1 pageTwo-Way Slabs (Tables)NAM296No ratings yet

- Tabla C1Document59 pagesTabla C1Armin Fernández GerardoNo ratings yet

- Design of TransformerDocument65 pagesDesign of TransformerYaqoob Ahmad75% (4)

- Buckling of Thin Metal Shells 75Document1 pageBuckling of Thin Metal Shells 75pawkomNo ratings yet

- BTB 24 TriacDocument10 pagesBTB 24 Triacagus2kNo ratings yet

- Torsion MEDocument24 pagesTorsion MEmohamed.hassan031No ratings yet

- Pipeline Design Calculations PDFDocument21 pagesPipeline Design Calculations PDFjimallen21281% (21)

- Nust June 08 2011Document20 pagesNust June 08 2011Jeff_mambaNo ratings yet

- Heat Chap07 035Document16 pagesHeat Chap07 035Kerem GönceNo ratings yet

- Ageing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityFrom EverandAgeing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityNo ratings yet

- Characteristic Modes: Theory and Applications in Antenna EngineeringFrom EverandCharacteristic Modes: Theory and Applications in Antenna EngineeringNo ratings yet

- The Mediterranean Sea: Temporal Variability and Spatial PatternsFrom EverandThe Mediterranean Sea: Temporal Variability and Spatial PatternsNo ratings yet

- Gas Hydrates 1: Fundamentals, Characterization and ModelingFrom EverandGas Hydrates 1: Fundamentals, Characterization and ModelingDaniel BrosetaNo ratings yet

- Physics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to DisplaysFrom EverandPhysics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to DisplaysNo ratings yet

- Mathematical and Computational Modeling: With Applications in Natural and Social Sciences, Engineering, and the ArtsFrom EverandMathematical and Computational Modeling: With Applications in Natural and Social Sciences, Engineering, and the ArtsRoderick MelnikNo ratings yet

- 3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesFrom Everand3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesNo ratings yet

- Analytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportFrom EverandAnalytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportNo ratings yet

- Hybrid Systems Based on Solid Oxide Fuel Cells: Modelling and DesignFrom EverandHybrid Systems Based on Solid Oxide Fuel Cells: Modelling and DesignNo ratings yet

- Thermodynamic Degradation Science: Physics of Failure, Accelerated Testing, Fatigue, and Reliability ApplicationsFrom EverandThermodynamic Degradation Science: Physics of Failure, Accelerated Testing, Fatigue, and Reliability ApplicationsNo ratings yet

- Simpson Strong Tie Catalog 09Document196 pagesSimpson Strong Tie Catalog 09Jeff Strickland100% (1)

- Bracing ManualDocument101 pagesBracing ManualErrol HobdenNo ratings yet

- Structural Glued-Laminated Timber (40pag)Document40 pagesStructural Glued-Laminated Timber (40pag)pawkom100% (1)

- Buckling of Thin Metal Shells 299Document1 pageBuckling of Thin Metal Shells 299pawkomNo ratings yet

- Buckling of Thin Metal Shells 292Document1 pageBuckling of Thin Metal Shells 292pawkomNo ratings yet

- Bolted Joints in Glulam and Structural Timber Composites (Davis+Claisse)Document11 pagesBolted Joints in Glulam and Structural Timber Composites (Davis+Claisse)pawkomNo ratings yet

- Buckling of Thin Metal Shells 287Document1 pageBuckling of Thin Metal Shells 287pawkomNo ratings yet

- Buckling of Thin Metal Shells 298Document1 pageBuckling of Thin Metal Shells 298pawkomNo ratings yet

- Buckling of Thin Metal Shells 296Document1 pageBuckling of Thin Metal Shells 296pawkomNo ratings yet

- Buckling of Thin Metal Shells 293Document1 pageBuckling of Thin Metal Shells 293pawkomNo ratings yet

- Buckling of Thin Metal Shells 285Document1 pageBuckling of Thin Metal Shells 285pawkomNo ratings yet

- Buckling of Thin Metal Shells 291Document1 pageBuckling of Thin Metal Shells 291pawkomNo ratings yet