Professional Documents

Culture Documents

Air / Air / Air / Air / Air / V V V V VA A A A Acuum Cuum Cuum Cuum Cuum V V V V VAL AL AL AL Alve VE VE VE VE

Air / Air / Air / Air / Air / V V V V VA A A A Acuum Cuum Cuum Cuum Cuum V V V V VAL AL AL AL Alve VE VE VE VE

Uploaded by

nazar7500 ratings0% found this document useful (0 votes)

18 views2 pagesThe document describes specifications for APCO Series 140 Air/Vacuum Valves. The valves allow air to escape when a pump starts and enter when it stops to prevent vacuum. The valve consists of a body, cover, baffle, float, and seat made of materials like cast iron, Delrin, and stainless steel. The float and seat must withstand 1000 psi and provide a tight shut-off.

Original Description:

air valve-apco

Original Title

s-140

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document describes specifications for APCO Series 140 Air/Vacuum Valves. The valves allow air to escape when a pump starts and enter when it stops to prevent vacuum. The valve consists of a body, cover, baffle, float, and seat made of materials like cast iron, Delrin, and stainless steel. The float and seat must withstand 1000 psi and provide a tight shut-off.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

18 views2 pagesAir / Air / Air / Air / Air / V V V V VA A A A Acuum Cuum Cuum Cuum Cuum V V V V VAL AL AL AL Alve VE VE VE VE

Air / Air / Air / Air / Air / V V V V VA A A A Acuum Cuum Cuum Cuum Cuum V V V V VAL AL AL AL Alve VE VE VE VE

Uploaded by

nazar750The document describes specifications for APCO Series 140 Air/Vacuum Valves. The valves allow air to escape when a pump starts and enter when it stops to prevent vacuum. The valve consists of a body, cover, baffle, float, and seat made of materials like cast iron, Delrin, and stainless steel. The float and seat must withstand 1000 psi and provide a tight shut-off.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

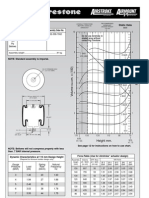

AIR / VACUUM VAL VE ALVE

DELRIN ASTM D4181

DATE

09-01-03

DRWG. NO.

S-140

SPECIFICATIONS OTHER SIDE

September 1, 2003

SPECIFICA TIONS SPECIFICATIONS

SERIES 140 AIR / VACUUM VALVES

Air / Vacuum Valves shall be designed to allow large quantities of air to escape out the orifice when the vertical turbine pump starts and to close water tight when the liquid enters the valve. The Air / Vacuum Valves shall also permit large quantities of air to enter thru the orifice when the pump stops to break the vacuum. The discharge orifice area shall be equal or greater than the inlet of the valve. The valve shall consist of a body, cover, baffle, float and seat. The seat shall be compression molded BunaN, fastened to the valve cover without distortion for tight shut-off and easy removal or replacement if necessary. The float shall be stainless steel designed to withstand a minimum of 1000 psi (static). The float shall be center guided for positive shut-off into the seat. All materials of construction shall be certified in writing to conform to A.S.T.M. specifications as follows: Body, cover Baffle [,1 & 2"] Baffle [3"] Float* Seat Exterior paint Cast iron Delrin Cast iron Stainless steel Buna-N Universal Primer ASTM A126 Gr.B ASTM D4181 ASTM A48 CL-30 ASTM A240 T304 FDA Approved for Potable Water Contact

*Float design may vary on certain sizes. Note: Other materials available. Valve to be APCO Series 140 Air / Vacuum Valves per Bulletin 601, as manufactured by Valve & Primer Corporation, Schaumburg, Illinois, U.S.A.

1420 S. Wright BLVD. Schaumburg, IL 60193-4599 847-524-9000 FAX 847-524-9007 800-323-6969 WEBSITE: www.apcovalves.com EMAIL: factory@apcovalves.com

You might also like

- ASV 10 20 BrochureDocument8 pagesASV 10 20 BrochureThomas Duane DavidsonNo ratings yet

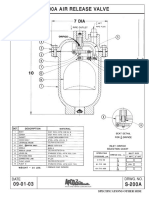

- APCO. S-200a Air Release ValveDocument2 pagesAPCO. S-200a Air Release ValveAlberto Diaz100% (2)

- Air Release Valve - APCODocument2 pagesAir Release Valve - APCOBaraa' KahlawiNo ratings yet

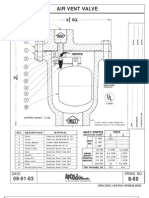

- AIR AIR AIR AIR Air Vent Vent Vent Vent Vent V V V V VAL AL AL AL Alve VE VE VE VEDocument2 pagesAIR AIR AIR AIR Air Vent Vent Vent Vent Vent V V V V VAL AL AL AL Alve VE VE VE VEAhmad MarthaNo ratings yet

- Airpro Max™ Air Valves Specifications: Air Release Valve SpecificationDocument2 pagesAirpro Max™ Air Valves Specifications: Air Release Valve SpecificationAstri NgentNo ratings yet

- Apco Vacuum Reliefair Inlet Valves Avr 1500 PDFDocument8 pagesApco Vacuum Reliefair Inlet Valves Avr 1500 PDFTanmoy Dutta100% (1)

- CatalogueDocument429 pagesCatalogueHarkamal SinghNo ratings yet

- Sewage Air ValveDocument10 pagesSewage Air ValveAhmed TalaatNo ratings yet

- 07 ValvesDocument33 pages07 Valvesshiva_ssk17No ratings yet

- Astam Super CheckDocument5 pagesAstam Super Checkmusaismail8863No ratings yet

- Airline AccesoriesDocument137 pagesAirline AccesoriesmaciasrobNo ratings yet

- Standard Technical Specification-Bfv (SS) PDFDocument5 pagesStandard Technical Specification-Bfv (SS) PDFpl_arunachalam79No ratings yet

- Standard Technical Specification-Bfv (SS) PDFDocument5 pagesStandard Technical Specification-Bfv (SS) PDFpl_arunachalam79No ratings yet

- Av 813 W (1-Av)Document1 pageAv 813 W (1-Av)SrStrikeNo ratings yet

- 2854164 - Air Release Valve Data Sheet and DimensionalDocument4 pages2854164 - Air Release Valve Data Sheet and DimensionalAdriana GonzálezNo ratings yet

- Combination Air ValvesDocument4 pagesCombination Air ValvesFelipe OliverosNo ratings yet

- Air Release 2014Document4 pagesAir Release 2014Aly AnisNo ratings yet

- Metraflex Valves SpecDocument2 pagesMetraflex Valves SpecCARLOSNo ratings yet

- Bolted Bonet ValveDocument32 pagesBolted Bonet ValveRiza Ahmad Sofikul IrfanNo ratings yet

- Broady 3500 BrochureDocument12 pagesBroady 3500 Brochureahmedm2020No ratings yet

- AV2000 ThermostaticAirVentDocument1 pageAV2000 ThermostaticAirVentauxiliar.termicaNo ratings yet

- Amcot Cooling Tower Corporation: Operating Instructions and Service Manual For Model ST 3 1500Document13 pagesAmcot Cooling Tower Corporation: Operating Instructions and Service Manual For Model ST 3 1500HECTOR IBARRANo ratings yet

- Check Horizontal PDFDocument2 pagesCheck Horizontal PDFJorge CarionNo ratings yet

- Клапан Регулирующий Поворотный Finetrol Fc Fg 5ft20 EnDocument12 pagesКлапан Регулирующий Поворотный Finetrol Fc Fg 5ft20 EnAli KianersiNo ratings yet

- Section 05110 - Butterfly ValvesDocument6 pagesSection 05110 - Butterfly Valvesse781No ratings yet

- Curvas Simple EntradaDocument56 pagesCurvas Simple EntradaDania AlarcónNo ratings yet

- Informacion Valvula DesaireadoraDocument4 pagesInformacion Valvula DesaireadoraCesar GraterolNo ratings yet

- Safety Valve Srv1-2 BrochureDocument4 pagesSafety Valve Srv1-2 BrochurePoojan ThakoreNo ratings yet

- Pressure Relief ValveDocument2 pagesPressure Relief ValvembloexNo ratings yet

- ValvesDocument6 pagesValvesstevegazeleyNo ratings yet

- Spring LoadedDocument6 pagesSpring Loadedsamar ramzyNo ratings yet

- Cooling Coil Spec ###Document2 pagesCooling Coil Spec ###PeterWangNo ratings yet

- Silent Check Silent Check Silent Check Silent Check Silent Check V V V V VAL AL AL AL Alve - VE-VE - VE - Ve - W W W W Wafer Style Afer Style Afer Style Afer Style Afer StyleDocument2 pagesSilent Check Silent Check Silent Check Silent Check Silent Check V V V V VAL AL AL AL Alve - VE-VE - VE - Ve - W W W W Wafer Style Afer Style Afer Style Afer Style Afer Styletanvir04169No ratings yet

- KVC 01Document35 pagesKVC 01hamidreza_m85No ratings yet

- Raasm HoseDocument40 pagesRaasm HoseEsteban Fernando Meza IbacetaNo ratings yet

- Stack Economizer Specification For Section VIII-Model CREDocument1 pageStack Economizer Specification For Section VIII-Model CRELinggar Setiawan NNo ratings yet

- Valves Reference PDFDocument35 pagesValves Reference PDFJulio RodriguezNo ratings yet

- Sapag-8100-ENDocument11 pagesSapag-8100-ENHamza AliNo ratings yet

- Dartmouth College Design January 3, 2012 & Construction GuidelinesDocument6 pagesDartmouth College Design January 3, 2012 & Construction GuidelinesSalman AkramNo ratings yet

- Central Blower Laboratory Fan CatalogDocument16 pagesCentral Blower Laboratory Fan Catalogrogel_ganaNo ratings yet

- AL-BL Rotary Valve PDFDocument6 pagesAL-BL Rotary Valve PDFIvanNo ratings yet

- Williams - Válvulas Tipo Bola API 608 API 6dDocument15 pagesWilliams - Válvulas Tipo Bola API 608 API 6despanolasaNo ratings yet

- VELMATIC Well Service Air ValveDocument2 pagesVELMATIC Well Service Air Valvecarlos37No ratings yet

- W01 358 7751Document29 pagesW01 358 7751MROstop.comNo ratings yet

- W01 358 7304Document29 pagesW01 358 7304MROstop.comNo ratings yet

- W02 358 7002Document30 pagesW02 358 7002MROstop.comNo ratings yet

- 501SHDocument2 pages501SHbhaskarbabaiNo ratings yet

- VNotchDocument3 pagesVNotchThiruThirunavukkarasuNo ratings yet

- AMERICAN Pipe Manual Flanged Pipe 1 19 21Document16 pagesAMERICAN Pipe Manual Flanged Pipe 1 19 21Christian ChiodoNo ratings yet

- Manual Spirax SarcoDocument2 pagesManual Spirax SarcoAlex CarreraNo ratings yet

- Bimetallic Steam TrapsDocument2 pagesBimetallic Steam Trapsasad_naqviNo ratings yet

- W01 358 9048Document29 pagesW01 358 9048MROstop.comNo ratings yet

- 830 SpecDocument2 pages830 Specmonarchy1103No ratings yet

- NFPA 22 (2003) Special RequirementsDocument4 pagesNFPA 22 (2003) Special RequirementsLeslie Scott67% (3)

- W01 358 8118Document29 pagesW01 358 8118MROstop.comNo ratings yet

- AV-C Butterfly ValveDocument20 pagesAV-C Butterfly ValveSopon SrirattanapiboonNo ratings yet

- W01 358 7561Document29 pagesW01 358 7561MROstop.comNo ratings yet

- Static Mixer Designing QuestionnairesDocument1 pageStatic Mixer Designing Questionnairesnazar750No ratings yet

- String: "String".title "String".upper : "String".lower F" Sring (String) (String) String"Document16 pagesString: "String".title "String".upper : "String".lower F" Sring (String) (String) String"nazar750No ratings yet

- Helical Static Mixer Data SheetDocument5 pagesHelical Static Mixer Data Sheetnazar750No ratings yet

- The Mathematics of Pumping Water PDFDocument9 pagesThe Mathematics of Pumping Water PDFOualid LamraouiNo ratings yet

- Static Mixer User ManualDocument9 pagesStatic Mixer User Manualnazar750No ratings yet

- SolidWorks Motion Tutorial 2013Document32 pagesSolidWorks Motion Tutorial 2013bhumijayaNo ratings yet

- Jonshon ScreenDocument25 pagesJonshon Screennazar750No ratings yet

- Sewer AppDocument27 pagesSewer AppEr Harsh MahajanNo ratings yet

- ElectricalDocument46 pagesElectricalRobert Columbine100% (2)

- Horizontal ScrubberDocument8 pagesHorizontal Scrubbernazar750No ratings yet

- 01-203 RW Mechanical DrawingsDocument6 pages01-203 RW Mechanical Drawingsnazar750No ratings yet

- List of AbbreviationsDocument3 pagesList of Abbreviationsnazar750No ratings yet

- Blower DenizDocument1 pageBlower Deniznazar750No ratings yet

- 01-203 RW Mechanical DrawingsDocument6 pages01-203 RW Mechanical Drawingsnazar750No ratings yet

- Chlorine SiemensDocument3 pagesChlorine Siemensnazar750No ratings yet

- 01-243 TW Mechanical DrawingsDocument4 pages01-243 TW Mechanical Drawingsnazar750No ratings yet

- Sluice Gate DenizDocument1 pageSluice Gate Deniznazar750No ratings yet

- Toggle Clamp DrawingsDocument5 pagesToggle Clamp Drawingsnazar750No ratings yet

- Wire Length Calculator: Quick OverviewDocument2 pagesWire Length Calculator: Quick Overviewnazar750No ratings yet

- How To Model A Citrus Squeezer in SolidWorksDocument40 pagesHow To Model A Citrus Squeezer in SolidWorksnazar750No ratings yet

- Basics of Control ComponentsDocument100 pagesBasics of Control ComponentsImma DamalerioNo ratings yet