Professional Documents

Culture Documents

Bar Reinforcement Schedule

Bar Reinforcement Schedule

Uploaded by

Dan AI0 ratings0% found this document useful (0 votes)

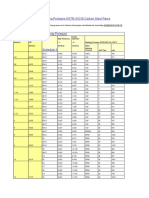

42 views5 pagesThis document provides a bar reinforcement schedule and guidelines for dimensions. It includes a table with bar size information for calculating hook and bend allowances for mild steel and high tensile/yield bars. The schedule then lists the reference, bar type and size, number of bars, and automatically calculates the total length of main bars and binders/links/stirrups using provided formulas. Remarks can also be included.

Original Description:

BAR REINFORCEMENT SCHEDULE

Original Title

BAR REINFORCEMENT SCHEDULE

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides a bar reinforcement schedule and guidelines for dimensions. It includes a table with bar size information for calculating hook and bend allowances for mild steel and high tensile/yield bars. The schedule then lists the reference, bar type and size, number of bars, and automatically calculates the total length of main bars and binders/links/stirrups using provided formulas. Remarks can also be included.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

42 views5 pagesBar Reinforcement Schedule

Bar Reinforcement Schedule

Uploaded by

Dan AIThis document provides a bar reinforcement schedule and guidelines for dimensions. It includes a table with bar size information for calculating hook and bend allowances for mild steel and high tensile/yield bars. The schedule then lists the reference, bar type and size, number of bars, and automatically calculates the total length of main bars and binders/links/stirrups using provided formulas. Remarks can also be included.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 5

BAR REINFORCEMENT SCHEDULE

User guides (to be read together with the schedule below)

A. Dimensions to be keyed in - white columns

1. Reference Refer to grid line/ types/items 2. Reinforcement Bar Ref Size Reference of bar (top/bot/by coding/links/stirrups/ etc.) Size/Diameter and type of bar Choose by clicking arrow down key T = High tensile bar R = Mild steel bar (for this schedule, only T & R bar provided. If there is Y bar (high yield) take it as T bar. No Each Number of bars in each item Nos. Off Number of items Length Total length of bar together with bends/hooks/etc. For minimum bend and hook allowances refer to BS4466:1989 (as table below) MILD STEEL BARS Bar size Hook Bend Allowance Allowance 6 8 10 12 16 20 25 32 40 100 100 100 110 150 180 230 290 360 100 100 100 100 100 100 130 160 200 HIGH TENSILE/HIGH YIELD BAR Bar size Hook Bend Allowance Allowance 6 8 10 12 16 20 25 32 40 100 100 110 140 180 220 350 450 560 100 100 100 100 100 110 180 230 280

B. Dimensions automatically calculated - blue columns

1. Main bar Formula: Length x No. Each x Nos. off

2. Binders/links/stirrups Formula: Length x No. Each x Nos. off Formula for No. Each = length / centers + 1

Or For Mild Steel Bar - Hook 9D, Bend 5D For High Tensile - Hook 11D, Bend 5.5D 3. Remarks

BAR REINFORCEMENT SCHEDULE

REFERENCE REF REINFORCEMENT BAR NO OFF SIZE NO EA MAIN BARS T16 T20 1.579 2.467 BINDER R9 0.499 REMARKS R10 0.617 R12 0.888 -

LENGTH

T6 0.222 -

T10 0.616 -

T12 -

T22 2.985 -

T25 3.855 -

T32 6.313 -

R6 0.222 -

R8 0.395 -

LENGHT : MULTIPLY BY : TOTAL :

0.888 -

You might also like

- ASME B31 4 Calculator V1 1Document11 pagesASME B31 4 Calculator V1 1vazzoleralex6884100% (1)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Flat Oval Tube (Oval - Hotchkiss)Document9 pagesFlat Oval Tube (Oval - Hotchkiss)Blanca LopezNo ratings yet

- Threaded Weld-In Socket Weld and Limited Space ThermowellsDocument2 pagesThreaded Weld-In Socket Weld and Limited Space ThermowellsRajadurai SinghNo ratings yet

- EN6114Document17 pagesEN6114Andrei Cozma67% (3)

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Bar Reinforcement ScheduleDocument5 pagesBar Reinforcement ScheduleAsenNo ratings yet

- RCC41 Continuous Beams (A & D)Document17 pagesRCC41 Continuous Beams (A & D)Zayyan RomjonNo ratings yet

- D&D Main Beam Grids C To HDocument17 pagesD&D Main Beam Grids C To Hdicktracy11No ratings yet

- ASME-B31-4 CalcDocument9 pagesASME-B31-4 Calcshafeeqm3086100% (1)

- Calculator ASME B31 4Document9 pagesCalculator ASME B31 4jleonos100% (3)

- RCC41 Continuous Beams (A & D)Document18 pagesRCC41 Continuous Beams (A & D)Anonymous lEmizZaJ100% (1)

- Hydraulic Cylinders CH: - Big Bore Sizes To Iso 6020-3 - Nominal Pressure 16 Mpa (160 Bar) - Max 25 Mpa (250 Bar)Document6 pagesHydraulic Cylinders CH: - Big Bore Sizes To Iso 6020-3 - Nominal Pressure 16 Mpa (160 Bar) - Max 25 Mpa (250 Bar)Stoianovici CristianNo ratings yet

- SIMpull Cable Pull Calculator 3 6Document21 pagesSIMpull Cable Pull Calculator 3 6zabiruddin786No ratings yet

- SRTDocument3 pagesSRTDaniel SamokovliaNo ratings yet

- RTDDocument68 pagesRTDMaria DenetNo ratings yet

- Att 2 - EdsDocument30 pagesAtt 2 - Eds정동현No ratings yet

- RCC41 Continuous Beams (A & D)Document17 pagesRCC41 Continuous Beams (A & D)aksNo ratings yet

- RCC41 Continuous Beams (A & D)Document28 pagesRCC41 Continuous Beams (A & D)aminjoles100% (1)

- RCC43 Wide Beams (A & D)Document31 pagesRCC43 Wide Beams (A & D)HambugerLơ.tơ.mơhaynằm.mơăn.tráibơNo ratings yet

- AppuisDocument10 pagesAppuisSopheaNo ratings yet

- Calculator ASME B31 4Document11 pagesCalculator ASME B31 4Denstar Ricardo Silalahi50% (2)

- RCC 43 Wide Beam SadDocument25 pagesRCC 43 Wide Beam Sadttlong230487No ratings yet

- Heat HXerDocument2 pagesHeat HXerGade JyNo ratings yet

- Air Cylinder TPCDocument9 pagesAir Cylinder TPCDwi AbdullahNo ratings yet

- RCC41Document23 pagesRCC41kibzeamNo ratings yet

- Lifting Eye Blind: NotesDocument1 pageLifting Eye Blind: Notesnarutothunderjet216No ratings yet

- Dimensionare Bare CupruDocument5 pagesDimensionare Bare CupruAnne KelleyNo ratings yet

- Maximum Working Pressure-ASTM A53 B Carbon Steel PipesDocument2 pagesMaximum Working Pressure-ASTM A53 B Carbon Steel PipesBFEVietnamNo ratings yet

- Bolt Length CalculationDocument7 pagesBolt Length CalculationYusrie EzalNo ratings yet

- Norgren 31000Document0 pagesNorgren 31000sheth_bhNo ratings yet

- Bolt Length TableDocument16 pagesBolt Length TablePrasanta Kumar BeheraNo ratings yet

- Rectangular Tank SizingDocument66 pagesRectangular Tank SizinglavascudoNo ratings yet

- 081201X V3533 PDFDocument59 pages081201X V3533 PDFClemente Rafael Marval Escalona50% (2)

- Required Thicknesses of Pipe or Tube Per Asme B31.3-2010 Process Piping CodeDocument1 pageRequired Thicknesses of Pipe or Tube Per Asme B31.3-2010 Process Piping CodeZoebairNo ratings yet

- Nippon Pulse: Your Partner in Motion ControlDocument2 pagesNippon Pulse: Your Partner in Motion ControlElectromateNo ratings yet

- Trelleborg Piping SPEC. REV CDocument1 pageTrelleborg Piping SPEC. REV CSIVANo ratings yet

- Spirax BSA TDocument4 pagesSpirax BSA TNang DapiNo ratings yet

- Sae and Din HosesDocument5 pagesSae and Din Hosesapi-247972389No ratings yet

- Ss 01059 eDocument8 pagesSs 01059 eDavid LapacaNo ratings yet

- Dimensions of Steel Pipes ASME B36.10 and B36.19 Suffix (S) : NPS 2 3 3 4 5 OD 73 88.9 101.6 114.3 141.3Document2 pagesDimensions of Steel Pipes ASME B36.10 and B36.19 Suffix (S) : NPS 2 3 3 4 5 OD 73 88.9 101.6 114.3 141.3MaysaraNo ratings yet

- Line Stop Welded To Shoe CalculationDocument4 pagesLine Stop Welded To Shoe CalculationpipestressNo ratings yet

- Welding SignDocument20 pagesWelding SignNopparutNo ratings yet

- Guidelines For Collect DesignDocument24 pagesGuidelines For Collect DesignArun LeleNo ratings yet

- Tube Trading CoDocument3 pagesTube Trading CoChenthil KumarNo ratings yet

- BS 970 SteelsDocument8 pagesBS 970 SteelsTamal Guha100% (2)

- Tube SupportsDocument8 pagesTube SupportsSyahirul AlimNo ratings yet

- SP 12 314Document23 pagesSP 12 314Quantudogon DangNo ratings yet

- TML Flat CableDocument2 pagesTML Flat CableMahmoud Al-SherbinyNo ratings yet

- Asna 2531 2006-09 K 2Document7 pagesAsna 2531 2006-09 K 2Speeder JohnNo ratings yet

- Thread o Ring - Fittings (T O R)Document2 pagesThread o Ring - Fittings (T O R)Jimmy ChanNo ratings yet

- 044 RSHDocument6 pages044 RSHsandi_oilNo ratings yet

- Technical Info (1) - Hose and FittingDocument24 pagesTechnical Info (1) - Hose and FittingJohn MaNo ratings yet

- Nippon Pulse: Your Partner in Motion ControlDocument2 pagesNippon Pulse: Your Partner in Motion ControlElectromateNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)

- A Guide to Vintage Audio Equipment for the Hobbyist and AudiophileFrom EverandA Guide to Vintage Audio Equipment for the Hobbyist and AudiophileNo ratings yet