Professional Documents

Culture Documents

Design of Plan Bracing

Design of Plan Bracing

Uploaded by

dsanandaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design of Plan Bracing

Design of Plan Bracing

Uploaded by

dsanandaCopyright:

Available Formats

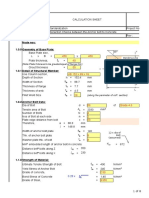

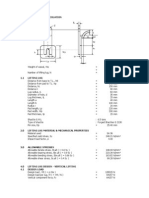

Design of Plan Bracing Connections

Node No. = 1557 L/C = Member No = ( Maximum ) 109 3182

Plan Bracing Axial Force, P = 113.092 kN Memb = Load Data Fy = 250 N/mm2 Sectional Area A =13.8 cm2 L90x90x8

Axial Capacity, T 155.25 = kN > 113.092 KN, OK Design for 75 % Axial capacity = 116.4375 kN A) Connection Type-1 ( Bolted Conn.) Alternative Grade of Bolts = 8.8 Dia of Bolts, db = 24 mm Total Nos of bolts (n)= 2 Tensile Stress, Ft =286 N/mm2 Shear Stress, Fv = 191 N/mm2 Shear Check V= Max ( P or 75 % T ) / n

( Tc = 0.45 x Fy x A )

Root Area of 366.5829 Bolt = mm2 Capacity of Bolt Tension, Tc = 104.8427 kN Shear, Vc = 70.01733 kN

Shear per bolt, 58.21875 V= kN < Shear Capacity, OK Weld length Calculations Weld Thkness, tw = 6 mm Length Reqd, P/ lw ( sw = x 0.707 x t ) lw Req.= 275 mm Weld Prov. 2 =x(90+25+50+50) Weld Prov. = 420 mm A) Profile Welded Connection Weld length Calculations sw = 100 N/mm2

Weld Provide is OK

Weld Thkness, tw = 6 mm Length Reqd, P/ lw ( sw = x 0.707 x t ) lw Req.= 275 mm Lw = 2x(90+74) Weld Prov.Lw = 328 mm

sw =

100 N/mm2

Weld Provide is OK

You might also like

- Bolted or Riveted Tension MembersDocument39 pagesBolted or Riveted Tension MembersKristin Brienne Leander-Renomeron88% (8)

- Base Plate Design - BS CodeDocument3 pagesBase Plate Design - BS Codemicheleling669667% (3)

- Design of Anchor Bolt - Rev.ADocument8 pagesDesign of Anchor Bolt - Rev.AcivilaskarNo ratings yet

- Cap Plate Trial CalculationDocument18 pagesCap Plate Trial CalculationStar100% (1)

- Lifting LugDocument8 pagesLifting LugAzwan ShahNo ratings yet

- Base Plate Design Is 800-2007Document6 pagesBase Plate Design Is 800-2007Suneesh P91% (11)

- Truss Design NS NegiDocument23 pagesTruss Design NS NegiSushmit Sharma100% (1)

- API 650 Design TanksDocument34 pagesAPI 650 Design TanksSyedZainAli100% (13)

- FIN PLATE - Beam To BeamDocument71 pagesFIN PLATE - Beam To BeamHemant Ramesh Narkar100% (3)

- Design of Horizontal BracingDocument1 pageDesign of Horizontal BracingdsanandaNo ratings yet

- Composite Steel GirderDocument10 pagesComposite Steel GirdersorowareNo ratings yet

- Project: Matrade Exhibition Center-Main Roof: Calculation For Steel Column Base PlateDocument10 pagesProject: Matrade Exhibition Center-Main Roof: Calculation For Steel Column Base PlateYANIshaNo ratings yet

- Section Size: W200X36: Refer Appendix D For Support ReactionsDocument10 pagesSection Size: W200X36: Refer Appendix D For Support Reactionsramuce04No ratings yet

- Base Plate DesignDocument32 pagesBase Plate DesignGautam Sharma50% (2)

- FootingDocument84 pagesFootingUma MaheshNo ratings yet

- End Plate ConnectionDocument10 pagesEnd Plate ConnectionMohamed Tahar Allagui100% (1)

- Combined Gusset Plate DesignDocument3 pagesCombined Gusset Plate Designkalpanaadhi100% (3)

- 6.1 Design of Main Chs Member: Calculation of Compressive Capacity According To Clause E3Document8 pages6.1 Design of Main Chs Member: Calculation of Compressive Capacity According To Clause E3abdulNo ratings yet

- Composite Bridge Design Calculation: General InformationDocument16 pagesComposite Bridge Design Calculation: General Informationbakti20No ratings yet

- 2 Way Slab Design-Roof SlabDocument120 pages2 Way Slab Design-Roof SlabSambhav PoddarNo ratings yet

- Corbel DesignDocument3 pagesCorbel DesignManoj JaiswalNo ratings yet

- Line Stop Welded To Shoe CalculationDocument4 pagesLine Stop Welded To Shoe CalculationpipestressNo ratings yet

- Canal DesignDocument34 pagesCanal Designniranjan100% (2)

- Design Input:: Design Sheet Title: Design of Anchor Bolts & Base Plate For A Fixed Base Column Ameya STDDocument4 pagesDesign Input:: Design Sheet Title: Design of Anchor Bolts & Base Plate For A Fixed Base Column Ameya STDSuryaSinghNo ratings yet

- Base PlateDocument32 pagesBase PlateSunil SinghNo ratings yet

- DG Consulting Engineers: Job NoDocument52 pagesDG Consulting Engineers: Job NosthakshyNo ratings yet

- Computation For Floor JoistsDocument7 pagesComputation For Floor JoistsTalen Marzan-LelisNo ratings yet

- Bell Method Example 7 5Document9 pagesBell Method Example 7 5jnmanivannanNo ratings yet

- Moment ConnectionsDocument15 pagesMoment ConnectionsHector Aguana100% (1)

- Premium TankDocument26 pagesPremium TankAnonymous p0iwBo50% (2)

- Base PlateDocument7 pagesBase Plateabdul karee100% (6)

- Wid Stiffener Welding CalculationDocument2 pagesWid Stiffener Welding CalculationrichardchiamNo ratings yet

- UB254 To UB457Document7 pagesUB254 To UB457ihpeterNo ratings yet

- Design of Pier: Type of Pier: Limit State Method Confirming To IS: 456-2000Document8 pagesDesign of Pier: Type of Pier: Limit State Method Confirming To IS: 456-2000iplogu100% (1)

- 33 KV E Pole DesignDocument40 pages33 KV E Pole DesignSri Gaja Govind BabuNo ratings yet

- Rean'S Building 5/24/2002 Angle Plate Design: Framed Beam ConnectionDocument11 pagesRean'S Building 5/24/2002 Angle Plate Design: Framed Beam ConnectionrbalmodalNo ratings yet

- Combine Footing by IS 456:2000Document18 pagesCombine Footing by IS 456:2000Huzaifa NakhwaNo ratings yet

- Moment Connection - Flush End Plate-19.01.06Document48 pagesMoment Connection - Flush End Plate-19.01.06kalpanaadhi83% (6)

- 6-Bracing Connection - TDocument2 pages6-Bracing Connection - TMUTHUKKUMARAMNo ratings yet

- Att-5 - End-Plate Shear ConnectionDocument7 pagesAtt-5 - End-Plate Shear Connectioncravikumar1971100% (3)

- 20 M SpanDocument20 pages20 M SpanEr KanwarPal SinghNo ratings yet

- Design Calc Sheet - Septic Tank Rev1 15-03-09 - 200Document12 pagesDesign Calc Sheet - Septic Tank Rev1 15-03-09 - 200Bok MortegaNo ratings yet

- Hamt K: 1 Basic ParameterDocument7 pagesHamt K: 1 Basic ParameterVenkatesha HebbarNo ratings yet

- Analytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportFrom EverandAnalytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportNo ratings yet

- Southern Marine Engineering Desk Reference: Second Edition Volume IFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume INo ratings yet

- Hyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationFrom EverandHyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationNo ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- Electricity in Fish Research and Management: Theory and PracticeFrom EverandElectricity in Fish Research and Management: Theory and PracticeNo ratings yet

- 3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesFrom Everand3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesNo ratings yet

- Nof - To Staad Stability AnalysisDocument3 pagesNof - To Staad Stability AnalysisdsanandaNo ratings yet

- Stability of Stack: Node L/C Force-X KNDocument4 pagesStability of Stack: Node L/C Force-X KNdsanandaNo ratings yet

- Computation of Idc PDFDocument1 pageComputation of Idc PDFdsanandaNo ratings yet

- Properties of Star Built Up Section: X-Dir y - Dir A KG/MDocument3 pagesProperties of Star Built Up Section: X-Dir y - Dir A KG/Mdsananda100% (1)

- Lattice Girder DesignDocument3 pagesLattice Girder DesigndsanandaNo ratings yet

- Volume Calculatorv 2Document2 pagesVolume Calculatorv 2dsanandaNo ratings yet

- Flood Hydrology FrequencyDocument3 pagesFlood Hydrology FrequencydsanandaNo ratings yet

- View Flow-Duration Curve Go To Inputs: Log Log Chart For Data AnalysysDocument2 pagesView Flow-Duration Curve Go To Inputs: Log Log Chart For Data AnalysysdsanandaNo ratings yet

- Broad Vrested WeirDocument5 pagesBroad Vrested WeirdsanandaNo ratings yet

- Back Water Profile Computations: at WeirDocument4 pagesBack Water Profile Computations: at WeirdsanandaNo ratings yet

- Pitching 3Document4 pagesPitching 3dsanandaNo ratings yet

- 2way Wall Table53 ReynoldsDocument2 pages2way Wall Table53 Reynoldsdsananda100% (1)

- Staad Listing: Analysis of Aquaduct Portal by Staad ModelDocument3 pagesStaad Listing: Analysis of Aquaduct Portal by Staad ModeldsanandaNo ratings yet

- Filter - Text File AaDocument4 pagesFilter - Text File AadsanandaNo ratings yet

- Oh - Tank - Foundation As Per Indian Standard CodeDocument7 pagesOh - Tank - Foundation As Per Indian Standard Codedsananda100% (1)

- Design of Ogee SpillwayDocument4 pagesDesign of Ogee Spillwaydsananda100% (3)

- Design of Embankment DamDocument5 pagesDesign of Embankment DamdsanandaNo ratings yet

- Design of Builtup SectionDocument4 pagesDesign of Builtup SectiondsanandaNo ratings yet

- Types - Elstomeric BearingsDocument4 pagesTypes - Elstomeric BearingsdsanandaNo ratings yet

- Design of Aquaduct Portal by Staad ModelDocument8 pagesDesign of Aquaduct Portal by Staad ModeldsanandaNo ratings yet

- Steel BracketDocument3 pagesSteel Bracketdsananda100% (2)

- Optimisation of EmbankmentDocument5 pagesOptimisation of EmbankmentdsanandaNo ratings yet

- Base Plate DesignMS601aDocument3 pagesBase Plate DesignMS601aduazo2009No ratings yet