Professional Documents

Culture Documents

Bulk Head: 7500 Series Self Adjusting Solid Installation Guide

Bulk Head: 7500 Series Self Adjusting Solid Installation Guide

Uploaded by

gornjakOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bulk Head: 7500 Series Self Adjusting Solid Installation Guide

Bulk Head: 7500 Series Self Adjusting Solid Installation Guide

Uploaded by

gornjakCopyright:

Available Formats

7500 Series Self Adjusting Solid Installation Guide

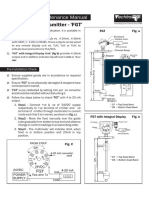

Any questions please call 1-800-257-1243 Installation Instructions Be sure O-ring is seated properly on inboard of seal. Orient seal with O-ring f acing the bulkhead and then caref ully slip housing ov er the shaf t and seat it f lush agains t the bulkhead of equipm ent. Use soapy water or P-80 Rubber Lubricant as needed. (Note: Loosen seal hardware only if required to seat it) * Housing must be perpendic ular/normal to the shaf t. * Mis-alignm ent of housing to shaf t not to exceed 2. Check f or equal spacing around the shaf t and the ID of the seal. Adjust as needed and then tighten mounting hardware to recommended torque setting of 18 f t. lbs WARNING!!! Purge seal prior to operating. Purge options Option 1: Air Purge using a Regulator. Option 2: Sy nthetic Greas e, pref erably Dow Corning G-4500 Option 1: Using Air Purge with regulator Mount Regulator to Seal using appropriat e f ittings. 2 ports f or gauge are prov ided f or conv enienc e. Assembly gauge as desired & plug the unused port.

Bulk Head Shaft O�ring Housing Outboard

NPT Port

Purge Access

Regulator Pull to adjust IN NPT Purge Port Access

Length as req'd Gauge

Note: Pull knob and adjust airflow until air leaks from seal. Reduce airflow until leaking stops. Press knob to lock regulator

Option 2: Using Synthetic Grease

NPT Purge Port Access Purge seal w ith grease until excess seeps out. Plug w ith appropriate fitting. *Check w eekly.

* Operat ing temperature range: - 50F / 45.55C to 500F / 260C Rev ised 03/06/09 Note: Abov e 200F must use air purge

You might also like

- Yoshan YS-6kg 12kg 15kg Installation Guide & Manual BookDocument30 pagesYoshan YS-6kg 12kg 15kg Installation Guide & Manual BookAgMyat KyawNo ratings yet

- 99 AX Booster Assembly ManualDocument34 pages99 AX Booster Assembly ManualFernando Nunez100% (1)

- Roots Blower Operating ManualDocument15 pagesRoots Blower Operating Manualanup_nairNo ratings yet

- CFDmentorDocument7 pagesCFDmentorgornjakNo ratings yet

- Air Blower ManualDocument16 pagesAir Blower ManualshaiknayeemabbasNo ratings yet

- Drager Air BreathingDocument26 pagesDrager Air BreathingMYO WINNo ratings yet

- Cam-Tite Ball Valve Operating Instructions: WarningDocument3 pagesCam-Tite Ball Valve Operating Instructions: WarningSubbarayan SaravanakumarNo ratings yet

- 1800CMANUS01Document4 pages1800CMANUS01chrisocamNo ratings yet

- IP010 Clamp Sleeve 2016Document8 pagesIP010 Clamp Sleeve 2016Sami KahtaniNo ratings yet

- Standard Gate Valves ManualDocument8 pagesStandard Gate Valves ManualmechanikyNo ratings yet

- Section Iv Main Landing GearDocument51 pagesSection Iv Main Landing GearLeonardo Alfonso Carcamo CarreñoNo ratings yet

- A 084 BDocument12 pagesA 084 BDenis JimenezNo ratings yet

- Plidco Split+Sleeve Installation InstructionsDocument6 pagesPlidco Split+Sleeve Installation Instructionsdhani projectoNo ratings yet

- Maintenance Instruction Manual: Severe Service Control ValvesDocument9 pagesMaintenance Instruction Manual: Severe Service Control Valvesابزار دقیقNo ratings yet

- Air Springs Cab - ConvolutedDocument98 pagesAir Springs Cab - ConvolutedСергей ЕгоровNo ratings yet

- Safety Valve (1700 SERIES) : Bharat Heavy Electricals Limited TiruchirapalliDocument39 pagesSafety Valve (1700 SERIES) : Bharat Heavy Electricals Limited TiruchirapalliUJJAL KUMAR BHATTACHARYAYNo ratings yet

- Jatco O9a TransmissionDocument2 pagesJatco O9a TransmissionDusko IvanNo ratings yet

- Installer's Guide For Condensing Units: 2TTB0 & 2TTB2Document8 pagesInstaller's Guide For Condensing Units: 2TTB0 & 2TTB2jimbodunkyNo ratings yet

- SD-425 SEHI InstallationDocument4 pagesSD-425 SEHI InstallationSampoerna MildNo ratings yet

- CP360 Manual - 120v, HaskelDocument16 pagesCP360 Manual - 120v, HaskelbradygbutlerNo ratings yet

- Nordson EFD 736HPA NV Installation Guide PDFDocument4 pagesNordson EFD 736HPA NV Installation Guide PDFFelipePerezNo ratings yet

- Safety Valve O&MDocument39 pagesSafety Valve O&MaravindharajanNo ratings yet

- 2TWR2 Install GuideDocument8 pages2TWR2 Install GuideedwcsdNo ratings yet

- Valtek MK1 IOMDocument12 pagesValtek MK1 IOMJuan HernandezNo ratings yet

- 50BYBL ManualDocument24 pages50BYBL ManualNguyễn HùngNo ratings yet

- Needle Valve Maintenance Instructions - Alco Valves PM-221Document5 pagesNeedle Valve Maintenance Instructions - Alco Valves PM-221AzaelNo ratings yet

- JC 2648 Seal IOM Manual PDFDocument4 pagesJC 2648 Seal IOM Manual PDFRené Mora-CasalNo ratings yet

- Elster-American-1800-2000-IOMDocument28 pagesElster-American-1800-2000-IOMSergio Gaete CovarrubiasNo ratings yet

- Choke Maintnance PDFDocument42 pagesChoke Maintnance PDFbtrasla9023No ratings yet

- Sno 450 XRDocument20 pagesSno 450 XRMelvin HrsNo ratings yet

- IOMDocument11 pagesIOMDaniel JacobsNo ratings yet

- Cylinder Change PurgingDocument16 pagesCylinder Change Purgingengg_mech77No ratings yet

- Parker Lucifer Valves 321h35 ManualDocument4 pagesParker Lucifer Valves 321h35 ManualFerney Martinez Romero Martinez RomeroNo ratings yet

- 200TG Installation and Maintenance InstructionsDocument2 pages200TG Installation and Maintenance InstructionsMiguel MedinaNo ratings yet

- XB 13 InstallDocument8 pagesXB 13 InstalljbozakNo ratings yet

- IOM Manual For Air Cylinder Operated ValvesDocument21 pagesIOM Manual For Air Cylinder Operated Valvesjhon riosNo ratings yet

- Maintenance and Operation Manual Hydraulic Choke and Control ConsoleDocument42 pagesMaintenance and Operation Manual Hydraulic Choke and Control ConsoleMehdi Hajd KacemNo ratings yet

- Ev2 MK4 2010Document18 pagesEv2 MK4 2010YorkshireTeaNo ratings yet

- Circuit Setter Plus Model MC: Instruction ManualDocument4 pagesCircuit Setter Plus Model MC: Instruction Manualmacanipharoldf6220No ratings yet

- IBHCVDocument71 pagesIBHCVdvmahiidaNo ratings yet

- Lava Heat Italia - Ember Mini Patio Heater - Owners ManualDocument18 pagesLava Heat Italia - Ember Mini Patio Heater - Owners ManuallavaheatitaliaNo ratings yet

- Agilent 6850 Gas Chromatograph Maintenance PDFDocument9 pagesAgilent 6850 Gas Chromatograph Maintenance PDFFrancesco MoriscoNo ratings yet

- Labconco-1063400 Rev A Freeze Dryer Installation GuideDocument5 pagesLabconco-1063400 Rev A Freeze Dryer Installation GuidewandopgNo ratings yet

- 330C-IG COMPRESSOR KIT 24V ManualDocument8 pages330C-IG COMPRESSOR KIT 24V ManualDavid B.No ratings yet

- Aeroquip InbstructionsDocument2 pagesAeroquip Inbstructionsmattyman2No ratings yet

- Float Guided Transmitter - 'FGT': Instruction & Maintenance ManualDocument4 pagesFloat Guided Transmitter - 'FGT': Instruction & Maintenance ManualNILESHNo ratings yet

- Manual - Air Arms - EV2Document18 pagesManual - Air Arms - EV2Ron MasisNo ratings yet

- Dive Scubapro BPI Maintenance ProcedureDocument4 pagesDive Scubapro BPI Maintenance ProceduremanonpomNo ratings yet

- Worcester Large 3-Piece Cryogenic Valves: Installation, Operating & Maintenance InstructionsDocument14 pagesWorcester Large 3-Piece Cryogenic Valves: Installation, Operating & Maintenance Instructionsافضح الكوارثNo ratings yet

- RWRG0051 - Splitter Complaint - Fault Code 42: Pre-Authorized Warranty Repair Guideline RWRG0051Document2 pagesRWRG0051 - Splitter Complaint - Fault Code 42: Pre-Authorized Warranty Repair Guideline RWRG0051Z MuvingiNo ratings yet

- Do Not Discard Instructions. This Manual Must Remain With The Unit For Future Reference. This Emergency Information Must Be Prominently DisplayedDocument24 pagesDo Not Discard Instructions. This Manual Must Remain With The Unit For Future Reference. This Emergency Information Must Be Prominently DisplayedIcemaster RefrigeraciónNo ratings yet

- Instruction Manual Temperature SwitchesDocument4 pagesInstruction Manual Temperature Switchesdel110001No ratings yet

- Greenheck (471558GGB Iom)Document12 pagesGreenheck (471558GGB Iom)Joey BrillNo ratings yet

- Manual 1956 PN 09-1013 VF-61Document3 pagesManual 1956 PN 09-1013 VF-61fabiosparkNo ratings yet

- Circuit Setter ManualDocument4 pagesCircuit Setter ManualAnonymous 7xHNgoKE6eNo ratings yet

- Installation and Start-Up InstructionsDocument12 pagesInstallation and Start-Up InstructionstkarsonovichNo ratings yet

- 755Document19 pages755JOHNNo ratings yet

- Coil Tubing Deployment - 5756337 - 01Document3 pagesCoil Tubing Deployment - 5756337 - 01KHALEDFEKAIRNo ratings yet

- Engine Tune-Up: Ii. Tools and MaterialsDocument6 pagesEngine Tune-Up: Ii. Tools and MaterialsdrakuleeNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Technical Data Features, Benefits & Applications: Measurement Condition ValueDocument1 pageTechnical Data Features, Benefits & Applications: Measurement Condition ValuegornjakNo ratings yet

- How To Select Rotor ClearancesDocument1 pageHow To Select Rotor ClearancesgornjakNo ratings yet

- 3ds Catia Natural Sketch Final 221111Document2 pages3ds Catia Natural Sketch Final 221111gornjakNo ratings yet

- Technical Data: Measurement Condition ValueDocument1 pageTechnical Data: Measurement Condition ValuegornjakNo ratings yet

- Calculate AccelerationDocument2 pagesCalculate AccelerationgornjakNo ratings yet

- NPT Thread ChartDocument2 pagesNPT Thread Chartprabu_v50% (2)

- Standard QAP For Wave WashersDocument2 pagesStandard QAP For Wave WashersgornjakNo ratings yet