Professional Documents

Culture Documents

MBX Bristle Blaster

MBX Bristle Blaster

Uploaded by

Juan Novillo RamosCopyright:

Available Formats

You might also like

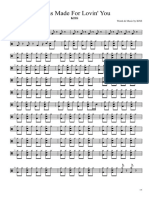

- KISS - I Was Made For Lovin You - pdf-BASS PDFDocument7 pagesKISS - I Was Made For Lovin You - pdf-BASS PDFJuan Novillo RamosNo ratings yet

- Deep Nitrided 32crmov13 Steel For Aerospace Bearings ApplicationsDocument8 pagesDeep Nitrided 32crmov13 Steel For Aerospace Bearings ApplicationsmvanzijpNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- KISS - I Was Made For Lovin You - pdf-BASS PDFDocument7 pagesKISS - I Was Made For Lovin You - pdf-BASS PDFJuan Novillo RamosNo ratings yet

- MBX - Amoladora Quita OxidoDocument6 pagesMBX - Amoladora Quita OxidoomarNo ratings yet

- Bristle - Blaster - Brochure SSPC SP 11Document6 pagesBristle - Blaster - Brochure SSPC SP 11yanuar iskhakNo ratings yet

- Bristle Blaster Brochure PDFDocument6 pagesBristle Blaster Brochure PDFPedro Diaz UzcateguiNo ratings yet

- Bristle Blaster BrochureDocument6 pagesBristle Blaster BrochureDom BergeronNo ratings yet

- Bristle Blaster: ... Introducing TheDocument6 pagesBristle Blaster: ... Introducing Thenktiah1207No ratings yet

- Baniqued FinalrequirementDocument9 pagesBaniqued FinalrequirementDASH BANIQUEDNo ratings yet

- VSL SlabDocument12 pagesVSL SlabhazemNo ratings yet

- Nit Project Mould EnbrDocument10 pagesNit Project Mould EnbrdonsieNo ratings yet

- THEORY of METAL CUTTING-Cutting Tool, Cutting Fluid & Machining EconomicsDocument17 pagesTHEORY of METAL CUTTING-Cutting Tool, Cutting Fluid & Machining EconomicsIzi75% (4)

- Friction Stir Welding of Aluminum MMC: Tracy W. Nelson, Dick LederichDocument22 pagesFriction Stir Welding of Aluminum MMC: Tracy W. Nelson, Dick LederichSanthosh Kumar KodhandapaniNo ratings yet

- Baniqued FinalrequirementDocument9 pagesBaniqued FinalrequirementDASH BANIQUEDNo ratings yet

- M6 Surface TreatmentDocument20 pagesM6 Surface TreatmentFrans PasaribuNo ratings yet

- Shot BlastingDocument2 pagesShot BlastingDinesh DhaipulleNo ratings yet

- Fatigue Life Improvement of The High Strength Steel Welded Joints by Ultrasonic Impact PeeningDocument15 pagesFatigue Life Improvement of The High Strength Steel Welded Joints by Ultrasonic Impact PeeningThong LeNo ratings yet

- Non-Traditional Machining: Mechanical Processes (USM, WJM, AWJM, IJM, MAF)Document61 pagesNon-Traditional Machining: Mechanical Processes (USM, WJM, AWJM, IJM, MAF)Yahya Abdelhameed AamerNo ratings yet

- InsertDocument48 pagesInsertJagdish RanaNo ratings yet

- Fact Sheet: METAL REMOVAL/CUTTINGDocument4 pagesFact Sheet: METAL REMOVAL/CUTTINGAl EnggNo ratings yet

- Unit I 4 Types of ChipsDocument6 pagesUnit I 4 Types of ChipsvelladuraiNo ratings yet

- C E P S I: Joël RECHDocument12 pagesC E P S I: Joël RECHwitiabNo ratings yet

- Elite Extrusion BrochureDocument13 pagesElite Extrusion BrochureSultana Khanum0% (1)

- Gouveia 2015Document15 pagesGouveia 2015Alexandre MartinsNo ratings yet

- Fatigue Performance of Thermally Cut Bolt Holes in Structural Steel S460MDocument13 pagesFatigue Performance of Thermally Cut Bolt Holes in Structural Steel S460Mcarlos aquinoNo ratings yet

- InTech-Mechanical Micromachining by Drilling Milling and SlottingDocument25 pagesInTech-Mechanical Micromachining by Drilling Milling and Slottingbalabmk9228No ratings yet

- Preloaded Bolting: (Image Courtesy of Mabey Bridge LTD.)Document9 pagesPreloaded Bolting: (Image Courtesy of Mabey Bridge LTD.)Benjamin IndrawanNo ratings yet

- TBN QMS-000495 Corrosion and Scratches On Torque Tubes - Rev ADocument3 pagesTBN QMS-000495 Corrosion and Scratches On Torque Tubes - Rev Asamwel kariukiNo ratings yet

- Lecture 10 (B) - DR S K Garg On Ductile Detailing of Steel BridgesDocument20 pagesLecture 10 (B) - DR S K Garg On Ductile Detailing of Steel BridgesSulabh GuptaNo ratings yet

- Failure Analysis of A Helical GearDocument7 pagesFailure Analysis of A Helical Geartheerapat patkaewNo ratings yet

- Lecture 2 - 4 - Fundametals of MachiningDocument58 pagesLecture 2 - 4 - Fundametals of MachiningAINAMANI AMOSNo ratings yet

- Production Technology AssignmentDocument10 pagesProduction Technology AssignmentJatin Pandey100% (2)

- Boiler Pressure Parts - Tube Weld OverlayDocument1 pageBoiler Pressure Parts - Tube Weld OverlayLTE002No ratings yet

- Bentuk, Dimensi Dan Cara Pemasangan Sheet PileDocument12 pagesBentuk, Dimensi Dan Cara Pemasangan Sheet PileTeuku Rizki Muda KeulanaNo ratings yet

- Steel SpecificationsDocument18 pagesSteel SpecificationssurenderbuddhaNo ratings yet

- Cracks in A Powder VibratingDocument12 pagesCracks in A Powder Vibratinglrodriguez_892566No ratings yet

- PaM Compact Blow-Bars enDocument48 pagesPaM Compact Blow-Bars enDaniel Alejandro Navarro Jara100% (1)

- Welded Panel Replacement: Group 3Document58 pagesWelded Panel Replacement: Group 3george georgeNo ratings yet

- Wet Drum Separator Rebuilds IMTDocument1 pageWet Drum Separator Rebuilds IMTduc trongNo ratings yet

- Analysis of RC Beam Project Report CoverDocument21 pagesAnalysis of RC Beam Project Report CoverYashvanth KadurNo ratings yet

- Mechanical Engineering Issues Sushil Sharma, NSLS-II ProjectDocument23 pagesMechanical Engineering Issues Sushil Sharma, NSLS-II ProjectfirmjunkNo ratings yet

- Acri 2019Document28 pagesAcri 2019Ilter KilerciNo ratings yet

- Tool WearDocument12 pagesTool WearSharath Kumar Bm100% (1)

- FEM Modelling of Weld Damage in Continuous Cold RoDocument11 pagesFEM Modelling of Weld Damage in Continuous Cold RoAimen AouniNo ratings yet

- Partie 3Document34 pagesPartie 3vincent.guilbault7894No ratings yet

- Insocoat: - Electrically Insulated Rolling BearingsDocument12 pagesInsocoat: - Electrically Insulated Rolling Bearingsmsb42No ratings yet

- Piston RingsDocument1 pagePiston RingsdensrxNo ratings yet

- Magnetic Pulse Welding, Crimping and Forming: Cold - Clean - Strong - Cost-EffectiveDocument12 pagesMagnetic Pulse Welding, Crimping and Forming: Cold - Clean - Strong - Cost-EffectiveAli MoghiNo ratings yet

- Design and Modeling of High Mast Solar Light PDFDocument5 pagesDesign and Modeling of High Mast Solar Light PDFGeEs AnggaNo ratings yet

- Insocoat: - Electrically Insulated Rolling BearingsDocument12 pagesInsocoat: - Electrically Insulated Rolling Bearingsiyilmaz1No ratings yet

- Electropolishing PDFDocument30 pagesElectropolishing PDFAnonymous uL3JlWfh100% (2)

- Unconventional Machining ProcessDocument27 pagesUnconventional Machining ProcessNandam HarshithNo ratings yet

- Tab 5000 V 6000 White Paper Final 03.08.10Document5 pagesTab 5000 V 6000 White Paper Final 03.08.10TaberExtrusionsNo ratings yet

- Production Engineering I (Meng 3191) : Lecture On: Chip FormationDocument52 pagesProduction Engineering I (Meng 3191) : Lecture On: Chip FormationFasil Getachew100% (1)

- Failure_Analysis_of_a_Helical_GearDocument7 pagesFailure_Analysis_of_a_Helical_GearGuilherme BandeiraNo ratings yet

- Stainless Steel ReinforcementDocument8 pagesStainless Steel Reinforcementsattar12345No ratings yet

- Mecamax Dok EsDocument4 pagesMecamax Dok EsValdir Anderson SilverioNo ratings yet

- Advanced Materials for Emerging Applications Innovations, Improvements, Inclusion and ImpactFrom EverandAdvanced Materials for Emerging Applications Innovations, Improvements, Inclusion and ImpactNo ratings yet

- WPS VR1Document1 pageWPS VR1Juan Novillo RamosNo ratings yet

- 6.1 MTC of Coil-Lot2Document100 pages6.1 MTC of Coil-Lot2Juan Novillo RamosNo ratings yet

- Carbon and Alloy Steel Forgings For Pipe Flanges, Fittings, Valves, and Parts For High-Pressure Transmission ServiceDocument3 pagesCarbon and Alloy Steel Forgings For Pipe Flanges, Fittings, Valves, and Parts For High-Pressure Transmission ServiceJuan Novillo RamosNo ratings yet

- DD B66Document7 pagesDD B66Juan Novillo RamosNo ratings yet

- Common VerbsDocument2 pagesCommon VerbsJuan Novillo RamosNo ratings yet

- Repair of Damaged and Uncoated Areas of Hot-Dip Galvanized CoatingsDocument3 pagesRepair of Damaged and Uncoated Areas of Hot-Dip Galvanized CoatingsJuan Novillo RamosNo ratings yet

- KISS - I Was Made For Lovin You PDFDocument4 pagesKISS - I Was Made For Lovin You PDFJuan Novillo RamosNo ratings yet

- Guía de SoldaduraDocument44 pagesGuía de SoldaduraJuan Novillo RamosNo ratings yet

- Lincoln6011 AS ES-MX PDFDocument2 pagesLincoln6011 AS ES-MX PDFJuan Novillo RamosNo ratings yet

- Lista de Verbos Irregulares en InglésDocument5 pagesLista de Verbos Irregulares en InglésJuan Novillo RamosNo ratings yet

- Goulds Model CV 3171: Vertical Sump and Process Pumps Designed For The Total Range of Industry ServicesDocument1 pageGoulds Model CV 3171: Vertical Sump and Process Pumps Designed For The Total Range of Industry ServicesJuan Novillo RamosNo ratings yet

- Verbos RegularesDocument21 pagesVerbos RegularesJuan Novillo RamosNo ratings yet

MBX Bristle Blaster

MBX Bristle Blaster

Uploaded by

Juan Novillo RamosOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MBX Bristle Blaster

MBX Bristle Blaster

Uploaded by

Juan Novillo RamosCopyright:

Available Formats

MBX Bristle Blaster

by Monti Part Number Electric: MT-USSE-06-02 Part Number Pneumatic: MT-USSP-06-02 Click to Buy MBX Bristle Brush Belts Online

The bristle blasting process is a new innovation that both removes corrosion and generates an anchor profile (also known as "anchor pattern") by using a specially designed rotary bristle tool. This tool consists of hardened wire bristle tips that are bent forward and dynamically tuned to a hand-held power tool which operates at approximately 3,500 rpm. The bristle tips are designed to strike the corroded surface with kinetic energy. Immediately after the bristle tips strike the corroded steel surface, they retract from the surface, which results in both corrosion removal and a microindentation that exposes fresh metal surface.

Common Applications

removal of corrosion, mill scale, protective coatings post-weld cleaning well-drilling and bridge refurbishment fabrication and repair of naval / marine vessels

industrial maintenance

Key Features of the Bristle Blasting Process...

Corrosion/Coating Removal meets SSPC "white metal" visual standards Improved fatigue resistance due to compressive residual stress generated at the surface Surface texture/profile anchor pattern 2.5 to 3.5 mils Increased surface hardness for improved wear resistance Simplicity eliminates the need for complex abrasive blast equipment

Note: The MBX Bristle Blaster Set includes a carry case. Always wear protective equipment such as gloves and face/eye protection. Additional protective measures may be required, dependent upon your specific situation, laws, and policies.

You might also like

- KISS - I Was Made For Lovin You - pdf-BASS PDFDocument7 pagesKISS - I Was Made For Lovin You - pdf-BASS PDFJuan Novillo RamosNo ratings yet

- Deep Nitrided 32crmov13 Steel For Aerospace Bearings ApplicationsDocument8 pagesDeep Nitrided 32crmov13 Steel For Aerospace Bearings ApplicationsmvanzijpNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- KISS - I Was Made For Lovin You - pdf-BASS PDFDocument7 pagesKISS - I Was Made For Lovin You - pdf-BASS PDFJuan Novillo RamosNo ratings yet

- MBX - Amoladora Quita OxidoDocument6 pagesMBX - Amoladora Quita OxidoomarNo ratings yet

- Bristle - Blaster - Brochure SSPC SP 11Document6 pagesBristle - Blaster - Brochure SSPC SP 11yanuar iskhakNo ratings yet

- Bristle Blaster Brochure PDFDocument6 pagesBristle Blaster Brochure PDFPedro Diaz UzcateguiNo ratings yet

- Bristle Blaster BrochureDocument6 pagesBristle Blaster BrochureDom BergeronNo ratings yet

- Bristle Blaster: ... Introducing TheDocument6 pagesBristle Blaster: ... Introducing Thenktiah1207No ratings yet

- Baniqued FinalrequirementDocument9 pagesBaniqued FinalrequirementDASH BANIQUEDNo ratings yet

- VSL SlabDocument12 pagesVSL SlabhazemNo ratings yet

- Nit Project Mould EnbrDocument10 pagesNit Project Mould EnbrdonsieNo ratings yet

- THEORY of METAL CUTTING-Cutting Tool, Cutting Fluid & Machining EconomicsDocument17 pagesTHEORY of METAL CUTTING-Cutting Tool, Cutting Fluid & Machining EconomicsIzi75% (4)

- Friction Stir Welding of Aluminum MMC: Tracy W. Nelson, Dick LederichDocument22 pagesFriction Stir Welding of Aluminum MMC: Tracy W. Nelson, Dick LederichSanthosh Kumar KodhandapaniNo ratings yet

- Baniqued FinalrequirementDocument9 pagesBaniqued FinalrequirementDASH BANIQUEDNo ratings yet

- M6 Surface TreatmentDocument20 pagesM6 Surface TreatmentFrans PasaribuNo ratings yet

- Shot BlastingDocument2 pagesShot BlastingDinesh DhaipulleNo ratings yet

- Fatigue Life Improvement of The High Strength Steel Welded Joints by Ultrasonic Impact PeeningDocument15 pagesFatigue Life Improvement of The High Strength Steel Welded Joints by Ultrasonic Impact PeeningThong LeNo ratings yet

- Non-Traditional Machining: Mechanical Processes (USM, WJM, AWJM, IJM, MAF)Document61 pagesNon-Traditional Machining: Mechanical Processes (USM, WJM, AWJM, IJM, MAF)Yahya Abdelhameed AamerNo ratings yet

- InsertDocument48 pagesInsertJagdish RanaNo ratings yet

- Fact Sheet: METAL REMOVAL/CUTTINGDocument4 pagesFact Sheet: METAL REMOVAL/CUTTINGAl EnggNo ratings yet

- Unit I 4 Types of ChipsDocument6 pagesUnit I 4 Types of ChipsvelladuraiNo ratings yet

- C E P S I: Joël RECHDocument12 pagesC E P S I: Joël RECHwitiabNo ratings yet

- Elite Extrusion BrochureDocument13 pagesElite Extrusion BrochureSultana Khanum0% (1)

- Gouveia 2015Document15 pagesGouveia 2015Alexandre MartinsNo ratings yet

- Fatigue Performance of Thermally Cut Bolt Holes in Structural Steel S460MDocument13 pagesFatigue Performance of Thermally Cut Bolt Holes in Structural Steel S460Mcarlos aquinoNo ratings yet

- InTech-Mechanical Micromachining by Drilling Milling and SlottingDocument25 pagesInTech-Mechanical Micromachining by Drilling Milling and Slottingbalabmk9228No ratings yet

- Preloaded Bolting: (Image Courtesy of Mabey Bridge LTD.)Document9 pagesPreloaded Bolting: (Image Courtesy of Mabey Bridge LTD.)Benjamin IndrawanNo ratings yet

- TBN QMS-000495 Corrosion and Scratches On Torque Tubes - Rev ADocument3 pagesTBN QMS-000495 Corrosion and Scratches On Torque Tubes - Rev Asamwel kariukiNo ratings yet

- Lecture 10 (B) - DR S K Garg On Ductile Detailing of Steel BridgesDocument20 pagesLecture 10 (B) - DR S K Garg On Ductile Detailing of Steel BridgesSulabh GuptaNo ratings yet

- Failure Analysis of A Helical GearDocument7 pagesFailure Analysis of A Helical Geartheerapat patkaewNo ratings yet

- Lecture 2 - 4 - Fundametals of MachiningDocument58 pagesLecture 2 - 4 - Fundametals of MachiningAINAMANI AMOSNo ratings yet

- Production Technology AssignmentDocument10 pagesProduction Technology AssignmentJatin Pandey100% (2)

- Boiler Pressure Parts - Tube Weld OverlayDocument1 pageBoiler Pressure Parts - Tube Weld OverlayLTE002No ratings yet

- Bentuk, Dimensi Dan Cara Pemasangan Sheet PileDocument12 pagesBentuk, Dimensi Dan Cara Pemasangan Sheet PileTeuku Rizki Muda KeulanaNo ratings yet

- Steel SpecificationsDocument18 pagesSteel SpecificationssurenderbuddhaNo ratings yet

- Cracks in A Powder VibratingDocument12 pagesCracks in A Powder Vibratinglrodriguez_892566No ratings yet

- PaM Compact Blow-Bars enDocument48 pagesPaM Compact Blow-Bars enDaniel Alejandro Navarro Jara100% (1)

- Welded Panel Replacement: Group 3Document58 pagesWelded Panel Replacement: Group 3george georgeNo ratings yet

- Wet Drum Separator Rebuilds IMTDocument1 pageWet Drum Separator Rebuilds IMTduc trongNo ratings yet

- Analysis of RC Beam Project Report CoverDocument21 pagesAnalysis of RC Beam Project Report CoverYashvanth KadurNo ratings yet

- Mechanical Engineering Issues Sushil Sharma, NSLS-II ProjectDocument23 pagesMechanical Engineering Issues Sushil Sharma, NSLS-II ProjectfirmjunkNo ratings yet

- Acri 2019Document28 pagesAcri 2019Ilter KilerciNo ratings yet

- Tool WearDocument12 pagesTool WearSharath Kumar Bm100% (1)

- FEM Modelling of Weld Damage in Continuous Cold RoDocument11 pagesFEM Modelling of Weld Damage in Continuous Cold RoAimen AouniNo ratings yet

- Partie 3Document34 pagesPartie 3vincent.guilbault7894No ratings yet

- Insocoat: - Electrically Insulated Rolling BearingsDocument12 pagesInsocoat: - Electrically Insulated Rolling Bearingsmsb42No ratings yet

- Piston RingsDocument1 pagePiston RingsdensrxNo ratings yet

- Magnetic Pulse Welding, Crimping and Forming: Cold - Clean - Strong - Cost-EffectiveDocument12 pagesMagnetic Pulse Welding, Crimping and Forming: Cold - Clean - Strong - Cost-EffectiveAli MoghiNo ratings yet

- Design and Modeling of High Mast Solar Light PDFDocument5 pagesDesign and Modeling of High Mast Solar Light PDFGeEs AnggaNo ratings yet

- Insocoat: - Electrically Insulated Rolling BearingsDocument12 pagesInsocoat: - Electrically Insulated Rolling Bearingsiyilmaz1No ratings yet

- Electropolishing PDFDocument30 pagesElectropolishing PDFAnonymous uL3JlWfh100% (2)

- Unconventional Machining ProcessDocument27 pagesUnconventional Machining ProcessNandam HarshithNo ratings yet

- Tab 5000 V 6000 White Paper Final 03.08.10Document5 pagesTab 5000 V 6000 White Paper Final 03.08.10TaberExtrusionsNo ratings yet

- Production Engineering I (Meng 3191) : Lecture On: Chip FormationDocument52 pagesProduction Engineering I (Meng 3191) : Lecture On: Chip FormationFasil Getachew100% (1)

- Failure_Analysis_of_a_Helical_GearDocument7 pagesFailure_Analysis_of_a_Helical_GearGuilherme BandeiraNo ratings yet

- Stainless Steel ReinforcementDocument8 pagesStainless Steel Reinforcementsattar12345No ratings yet

- Mecamax Dok EsDocument4 pagesMecamax Dok EsValdir Anderson SilverioNo ratings yet

- Advanced Materials for Emerging Applications Innovations, Improvements, Inclusion and ImpactFrom EverandAdvanced Materials for Emerging Applications Innovations, Improvements, Inclusion and ImpactNo ratings yet

- WPS VR1Document1 pageWPS VR1Juan Novillo RamosNo ratings yet

- 6.1 MTC of Coil-Lot2Document100 pages6.1 MTC of Coil-Lot2Juan Novillo RamosNo ratings yet

- Carbon and Alloy Steel Forgings For Pipe Flanges, Fittings, Valves, and Parts For High-Pressure Transmission ServiceDocument3 pagesCarbon and Alloy Steel Forgings For Pipe Flanges, Fittings, Valves, and Parts For High-Pressure Transmission ServiceJuan Novillo RamosNo ratings yet

- DD B66Document7 pagesDD B66Juan Novillo RamosNo ratings yet

- Common VerbsDocument2 pagesCommon VerbsJuan Novillo RamosNo ratings yet

- Repair of Damaged and Uncoated Areas of Hot-Dip Galvanized CoatingsDocument3 pagesRepair of Damaged and Uncoated Areas of Hot-Dip Galvanized CoatingsJuan Novillo RamosNo ratings yet

- KISS - I Was Made For Lovin You PDFDocument4 pagesKISS - I Was Made For Lovin You PDFJuan Novillo RamosNo ratings yet

- Guía de SoldaduraDocument44 pagesGuía de SoldaduraJuan Novillo RamosNo ratings yet

- Lincoln6011 AS ES-MX PDFDocument2 pagesLincoln6011 AS ES-MX PDFJuan Novillo RamosNo ratings yet

- Lista de Verbos Irregulares en InglésDocument5 pagesLista de Verbos Irregulares en InglésJuan Novillo RamosNo ratings yet

- Goulds Model CV 3171: Vertical Sump and Process Pumps Designed For The Total Range of Industry ServicesDocument1 pageGoulds Model CV 3171: Vertical Sump and Process Pumps Designed For The Total Range of Industry ServicesJuan Novillo RamosNo ratings yet

- Verbos RegularesDocument21 pagesVerbos RegularesJuan Novillo RamosNo ratings yet